Abstract

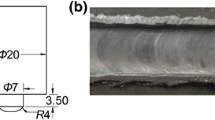

The primary objective of this research work is to analyse the effect of double pass on grain refinement during friction stir processing (FSP). The impact of double pass was also assessed on the microstructure, micro-hardness, and tensile strength of the hybrid reinforced aluminum alloy. Field emission scanning microscopy with energy dispersive spectroscopic analysis was used to analyze the grain size distribution as well as the percentage of elements present across the stir zone (SZ) and mode of fracture during the tensile testing. Results show a notable increase in mechanical properties and a huge reduction in grain size when compared to base material (BM). The grain size of SZ in single pass FSP (FSPed-SP) and double pass FSP (FSPed-DP) was reduced to 76.71% and 91.8% in comparison to the BM because repetitive stirring action causes huge dynamic recrystallization. However, peak micro-hardness in FSPed-DP and FSPed-SP was achieved as 30.58% and 22.79% of the BM due to the hall–petch effect. FSPed-DP demonstrated superior ultimate tensile strength and percentage of elongation in contrast to FSPed-SP, which exhibited values of 29.03% and 25% respectively.

Graphical Abstract

Similar content being viewed by others

References

N. Merah, M. Abdul Azeem, H.M. Abubaker, F. Al-Badour, J. Albinmousa, A.A. Sorour, Friction Stir processing influence on microstructure, mechanical, and corrosion behavior of steels: a review. Materials 14(17), 5023 (2021)

A.P. Zykova, S.Y. Tarasov, A.V. Chumaevskiy, E.A. Kolubaev, A review of friction stir processing of structural metallic materials: process, properties, and methods. Metals 10(6), 772 (2020)

P. Dwivedi, A.N. Siddiquee, S. Maheshwari, Issues and requirements for aluminum alloys used in aircraft components: state of the art. Russ. J. Non-Ferrous Met. 62(2), 212–225 (2021)

C. Zhang, G. Huang, Y. Cao, Y. Zhu, X. Huang, Y. Zhou, Q. Li, Q. Zeng, Q. Liu, Microstructure evolution of thermo-mechanically affected zone in dissimilar AA2024/7075 joint produced by friction stir welding. Vacuum 179, 109515 (2020)

C.F. Chen, P.W. Kao, L.W. Chang, N.J. Ho, Effect of processing parameters on microstructure and mechanical properties of an Al-Al11 Ce3-Al2O3 in-situ composite produced by friction stir processing. Metall. Mater. Trans. A 41, 513–522 (2010)

N. Gangil, A. Noor-Siddiquee, S. Maheshwari, A.M. Al-Ahmari, M.H. Abidi, State of the art of ex-situ aluminium matrix composite fabrication through friction stir processing, Arch. Metall. Mater. 63(2), 719–738 (2018)

N.F. Lone, D. Bajaj, N. Gangil, T. Khan, M.H. Abidi, A. Al-Ahmari, A.N. Siddiquee, Multi principal element alloy particle reinforced metal matrix composites: synthesis, microstructure, and mechanical aspects. Manuf. Lett. 36, 46–51 (2023)

N. Yuvaraja, S. Aravindanb, Vipin, Effect of process parameters on the microhardness and wear behavior of Friction stir processing (FSP)ed Al5083/B4C surface composite, in Proceedings of the 17th ISME Conference (ISME17). New Delhi, 3-4 (2015)

Z.Y. Ma, Friction stir processing technology: a review. Metall. Mater. Trans. A 39, 642–658 (2008)

S. Meenia, F. Khan, S. Babu, R.J. Immanuel, S.K. Panigrahi, G.D.J. Ram, Particle refinement and fine-grain formation leading to enhanced mechanical behaviour in a hypo-eutectic Al–Si alloy subjected to multi-pass friction stir processing. Mater. Charact. 113, 134–143 (2016)

H. Mehdi, R.S. Mishra, Effect of multi-pass friction stir processing and SiC nanoparticles on microstructure and mechanical properties of AA6082-T6. Adv. Ind. Manuf. Eng. 3, 100062 (2021)

S. Arulvel, Development of multi-pass processed AA6082/SiCp surface composite using friction stir processing and its mechanical and tribology characterization. Surf. Coatings Technol. 394, 125900 (2020)

V. Bikkina, S.R. Talasila, K. Adepu, Characterization of aluminum based functionally graded composites developed via friction stir processing. Trans. Nonferrous Met. Soc. China 30(7), 1743–1755 (2020)

M. Zhang et al., Impact of multiple FSP passes on structure, mechanical, tribological and corrosion behaviors of AA6061/316 stainless-steel reinforced Al matrix composites. Surf. Coatings Technol. 447, 128801 (2022)

Z.Y. Liu, B.L. Xiao, W.G. Wang, Z.Y. Ma, Analysis of carbon nanotube shortening and composite strengthening in carbon nanotube/aluminum composites fabricated by multi-pass friction stir processing. Carbon 69, 264–274 (2014)

M. Barmouz, M.K.B. Givi, Fabrication of in situ Cu/SiC composites using multi-pass friction stir processing: Evaluation of microstructural, porosity, mechanical and electrical behavior. Compos. Part A Appl. Sci. Manuf. 42(10), 1445–1453 (2011)

A. Shafiei-Zarghani, S.F. Kashani-Bozorg, A. Zarei-Hanzaki, Microstructures and mechanical properties of Al/Al2O3 surface nano-composite layer produced by friction stir processing. Mater. Sci. Eng. A 500(1–2), 84–91 (2009)

N. Yuvaraj, S. Aravindan, Fabrication of Al5083/B4C surface composite by friction stir processing and its tribological characterization. J. Mater. Res. Technol. 4(4), 398–410 (2015)

Y.F. Sun, H. Fujii, The effect of SiC particles on the microstructure and mechanical properties of friction stir welded pure copper joints. Mater. Sci. Eng. A 528(16–17), 5470–5475 (2011)

Y. Li et al., Fabrication of the novel hybridized AZ31B Mg/CeO2+ ZrO2 composites via multiple pass friction stir processing. J. Mater. Res. Technol. 24, 9984–10004 (2023)

M. Sivanesh Prabhu, A. Elaya Perumal, S. Arulvel, Development of multi-pass processed AA6082/SiCp surface composite using friction stir processing and its mechanical and tribology characterization. Surf. Coatings Technol. 394, 125900 (2020)

N. Gangil, S. Maheshwari, E.A. Nasr, A.M. El-Tamimi, M.A. El-Meligy, A.N. Siddiquee, Another approach to characterize particle distribution during surface composite fabrication using friction stir processing. Metals 8(8), 568 (2018)

P. Asadi, M.K.B. Givi, K. Abrinia, M. Taherishargh, R. Salekrostam, Effects of SiC particle size and process parameters on the microstructure and hardness of AZ91/SiC composite layer fabricated by FSP. J. Mater. Eng. Perform. 20, 1554–1562 (2011)

M. Song, B. Huang, Effects of particle size on the fracture toughness of SiCp/Al alloy metal matrix composites. Mater. Sci. Eng. A 488(1–2), 601–607 (2008)

N. Gangil, S. Maheshwari, A.N. Siddiquee, Novel use of distribution facilitators and time-temperature range for strengthening in surface composites on AA7050-T7451. Metallogr. Microstruct. Anal. 7(5), 561–577 (2018).

C. Confalonieri, A.T. Grimaldi, E. Gariboldi, Ball-milled Al–Sn alloy as composite phase change material. Mater. Today Energy 17, 100456 (2020)

T. Saito, Magnetic properties of Mn–Al system alloys produced by mechanical alloying. J. Appl. Phys. 93(10), 8686–8688 (2003)

M.V.N.V. Satyanarayana, K. Adepu, K. Chauhan, Effect of overlapping friction stir processing on microstructure, mechanical properties and corrosion behavior of AA6061 alloy. Met. Mater. Int. 27, 3563–3573 (2021)

P. Su, A. Gerlich, T.H. North, G.J. Bendzsak, Material flow during friction stir spot welding. Sci. Technol. Weld. Join. 11(1), 61–71 (2006)

P. Dwivedi, S. Maheshwari, A.N. Siddiquee, Fe-SiC-Sn-Mn reinforced surface composite via FSP: a comprehensive analysis. Mater. Today Commun. 35, 105783 (2023)

A. Maqbool, N.F. Lone, T. Ahmad, N.Z. Khan, A.N. Siddiquee, Effect of hybrid reinforcement and number of passes on microstructure, mechanical and corrosion behavior of WE43 Mg alloy based metal matrix composite. J. Manuf. Process. 89, 170–181 (2023)

T. Khan, D. Bajaj, A.N. Siddiquee, Friction stir engineering for fabrication of ultra-refined cunimgzn alloys. Mater. Lett. 291, 129596 (2021)

P. Dwivedi, S. Maheshwari, M.H. Abidi, A.N. Siddiquee, J. Haider, H. Alkhalefah, Toward devising pilot experiments to establish parameter window for FSP of aluminum alloys. Adv. Mech. Eng. 14(6), 16878132221108268 (2022)

L.X. Bach, D.L. Son, M.T. Phong, L.V. Thang, M.Z. Bian, N.D. Nam, A study on Mg and AlN composite in microstructural and electrochemical characterizations of extruded aluminum alloy. Compos. Part B Eng. 156, 332–343 (2019)

H. Mehdi, R.S. Mishra, Modification of microstructure and mechanical properties of AA6082/ZrB2 processed by multipass friction stir processing. J. Mater. Eng. Perform. 32(1), 285–295 (2023)

N.F. Lone, D. Bajaj, N. Gangil, S.M.A.K. Mohammed, D. Chen, A.N. Siddiquee, A novel study on the effect of tool offset in friction stir processing for Mg-NiTi Composite. Crystals 12(11), 1651 (2022)

M. Paidar, O.O. Ojo, H.R. Ezatpour, A. Heidarzadeh, Influence of multi-pass FSP on the microstructure, mechanical properties and tribological characterization of Al/B4C composite fabricated by accumulative roll bonding (ARB). Surf. Coatings Technol. 361, 159–169 (2019)

S.R. Nathan, K. Suganeswaran, S. Kumar, P. Thangavel, V.K. Gobinath, Investigations on microstructure, thermo-mechanical and tribological behavior of graphene oxide reinforced AA7075 surface composites developed via friction stir processing. J. Manuf. Process. 90, 139–150 (2023)

G. Girish. Effect of tool pin geometry and multi-pass intermittent friction stir processing on the surface properties of aerospace grade aluminium 7075 alloy. Proc. Inst. Mech. Eng. E (2023) https://doi.org/10.1177/0954408923115894

A. Sharma, V.M. Sharma, B. Sahoo, S.K. Pal, J. Paul, Effect of multiple micro channel reinforcement filling strategy on Al6061-graphene nanocomposite fabricated through friction stir processing. J. Manuf. Process. 37, 53–70 (2019)

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The author(s) declared no conflicts of interest with respect to the research, authorship, and/or publication of this article.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Dwivedi, P., Maheshwari, S. & Siddiquee, A.N. Microstructure and Mechanical Properties of SiC + Fe + Mn + Sn Hybrid Reinforced Surface Composites Fabricated by Friction Stir Processing: Effect of Double Pass. Met. Mater. Int. (2024). https://doi.org/10.1007/s12540-024-01697-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12540-024-01697-7