Abstract

Intrinsic wetting behaviors of Ag, AgCu and AgCuTi on TC4 were studied by ISD and MSD method. A linear spreading was found in Ag/TC4 system with a rate of ~ 0.14 mm/s. No significant difference in wetting behavior between AgCu/TC4 and AgCuTi/TC4, which can be divided into three stages. The first stage is controlled by the dissolution process at the solid/liquid interface, and the second and third stages are characterized by near linear and linear spreading. The corresponding spreading rates are ~ 0.017 mm/s and ~ 0.004 mm/s, which may be controlled by the solid solution reactions of Cu and TC4 and Ag and TC4, respectively.

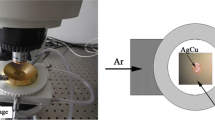

Graphical Abstract

Similar content being viewed by others

Data Availability

The raw/processed data required to reproduce these findings cannot be shared at this time due to technical limitations.

References

S. Zhu, K. Xie, Q. Lin, R. Cao, F. Qiu, Experimental determination of surface energy for high-energy surface: a review. Adv. Colloid Interface Sci. 315, 102905 (2023)

Q. Qin, Z. Zhang, L. Yang, J. Li, Non-reciprocal heterogeneous nucleation in solidification of Ag–Cu alloys. Met. Mater. Int. 30, 1270–1281 (2024)

P. Protsenko, A. Terlain, V. Traskine, N. Eustathopoulos, The role of intermetallics in wetting in metallic systems. Scr. Mater. 45(12), 1439–1445 (2001)

A. Koochaki-Abkenar, A. Malekan, M. Bozorg, K. Nematipour, Hot corrosion and oxidation behavior of Pt–aluminide and Pt–Rh–aluminide coatings applied on nickle-base and cobalt-base substrates. Met. Mater. Int. (2024). https://doi.org/10.1007/s12540-024-01653-5

R. Sui, F. Li, W. Ci, Q. Lin, Wetting of Cu and Cu–Sn IMCs by Sn–Bi alloys over wide composition at 350 °C. J. Electron. Mater. 48(7), 4660–4668 (2019)

A. Be’er, Y. Lereah, H. Taitelbaum, Reactive wetting of Hg–Ag system at room temperature. Mater. Sci. Eng. A 495(1–2), 102–107 (2008)

N. Eustathopoulos, R. Voytovych, The role of reactivity in wetting by liquid metals: a review. J. Mater. Sci. 51(1), 425–437 (2015)

N. Eustathopoulos, M.G. Nicholas, B. Drevet, Wettability at High Temperatures (Elsevier, Oxford, 1999)

Z. Ma, Q. Lin, Comment on “Wetting of liquid copper on TC4 titanium alloy and 304 stainless-steel at 1273–1433K” Materials & Design 169 (2019) 107667. Mater. Des. 235, 112404 (2023)

X. Yu, J. Yang, M. Yan, X.-W. Hu, Y.L. Li, Kinetics of wetting and spreading of AgCu filler metal over Ti–6Al–4V substrates. J. Mater. Sci. 51, 10960–10969 (2016)

G. Liu, Y. Li, W. Long, X. Hu, J. Cao, M. Yan, Wetting kinetics and spreading phenomena of the precursor film and bulk liquid in the AgCuTi/TC4 system. J. Alloys Compd. 802, 345–354 (2019)

L. Hao, J. Liu, Y. Li, Wetting and spreading of AgCuTi on selective laser-melted Ti–6Al–4V. Materials 14(17), 4804 (2021)

N. Sobczak, J. Sobczak, R. Asthana, R. Purgert, The mystery of molten metal. China Foundry 7(4), 425–437 (2010)

P. Shen, H. Fujii, T. Matsumoto, K. Nogi, Critical factors affecting the wettability of a-alumina by molten aluminum. J. Am. Ceram. Soc. 87(11), 2151 (2004)

T.B. Massalski, Binary Phase Diagram (CD-ROM). ASM International (1996)

A.P. Xian, Precursor film of tin-based active solder wetting on ceramics. J. Mater. Sci. 28(4), 1019–1030 (1993)

J.A. Warren, W.J. Boettinger, A.R. Roosen, Modeling reactive wetting. Acta Mater. 46(9), 3247–3264 (1998)

L. Yin, B.T. Murray, T.J. Singler, Dissolutive wetting in the Bi-Sn system. Acta Mater. 54(13), 3561–3574 (2006)

P. Protsenko, O. Kozlova, R. Voytovych, N. Eustathopoulos, Dissolutive wetting of Si by molten Cu. J. Mater. Sci. 43(16), 5669–5671 (2008)

W.F. Gale, T.C. Totemeier, Smithells Metals Reference Book (Elsevier, Amsterdam, 2003)

P.R. Sharps, A.P. Tomsia, J.A. Pask, Wetting and spreading in the Cu–Ag system. Acta Metall. 29(5), 855–865 (1981)

I. Barin, Thermochemical Data of Pure Substances, 3rd edn. (Wiley, Weinheim, 1995)

O. Yong-Taeg, S. Fujino, K. Morinaga, Fabrication of transparent silica glass by powder sintering. Sci. Technol. Adv. Mater. 3(4), 297–301 (2002)

H. Zhuang, E. Lugscheider, High Temperature Brazing (National Defense Industry Press, Beijing, 1989)

N.A. Gokcen, Statistical Thermodynamics of Alloys (Springer, New York, 2012)

A.R. Miedema, F.R. de Boer, R. Boom, Model predictions for the enthalpy of formation of transition metal alloys. Calphad – Comput. Coupling Phase Diagr. Thermochem. 1(4), 341–359 (1977)

L. Yin, A. Chauhan, T.J. Singler, Reactive wetting in metal/metal systems: dissolutive versus compound-forming systems. Mater. Sci. Eng. A 495(1–2), 80–89 (2008)

J. Wolfenstine, U. Lee, B. Poese, J.L. Allen, Effect of oxygen partial pressure on the discharge capacity of LiCoPO4. J. Power. Sources 144(1), 226–230 (2005)

Q. Lin, L. Liu, W. Zhu, Formation mechanism of precursor films at high temperatures: a review. Chin. J. Mech. Eng. 35(1), 21 (2022)

W.D. Bascom, R.L. Cottington, C.R. Singleterry, Dynamic Surface Phenomena in the Spontaneous Spreading of Oils on Solids (ACS Publications, Washington, D.C., 1964)

B.W. Cherry, Kinetics of wetting of surfaces by polymers. J. Colloid Interface Sci. 29, 174–176 (1969)

T.D. Blake, J.M. Haynes, Kinetics of liquidliquid displacement. J. Colloid Interface Sci. 30(3), 421–423 (1969)

E. Ruckenstein, C.S. Dunn, Slip velocity during wetting of solids. J. Colloid Interface Sci. 59(1), 135–138 (1977)

W.B. Hardy III., The spreading of fluids on glass. Lond. Edinb. Dublin Philos. Mag. J. Sci. 38(223), 49–55 (1919)

S.I. Tanaka, C. Iwamoto, Nanoscale dynamic wetting and spreading of molten Ti alloy on 6H–SiC. Mater. Sci. Eng. A 495(1–2), 168–173 (2008)

C. Iwamoto, S.I. Tanaka, Atomic morphology and chemical reactions of the reactive wetting front. Acta Mater. 50(4), 749–755 (2002)

Acknowledgements

This work is supported by National Natural Science Foundation of China (No. 52165044).

Author information

Authors and Affiliations

Contributions

Kaibin Xie: Methodology, Writing, Ran Sui: Writing—review and editing, Zixu Zuo: Methodology, Qiaoli Lin: Writing—review and editing, Resources, Funding acquisitions.

Corresponding authors

Ethics declarations

Conflict of interests

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Xie, K., Sui, R., Zuo, Z. et al. Intrinsic Wetting of TC4 by Ag, AgCu and AgCuTi Alloys. Met. Mater. Int. (2024). https://doi.org/10.1007/s12540-024-01685-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12540-024-01685-x