Abstract

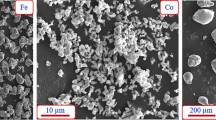

The objective of this study was to examine and compare the structural, and magnetic properties of two alloys, namely Ni80Fe20 and (Ni80Fe20)90Cu10, which were fabricated using mechanical alloying. The milled samples were analyzed using x-ray diffraction, scanning electron microscopy, energy dispersive x-ray spectroscopy, and vibrating sample magnetometer. These techniques were employed to assess and characterize the alloys regarding their structural composition, morphology, and magnetic properties. In both composition alloys, the coercivity values displayed an increasing trend. However, the rate of increase was comparatively lower for the (Ni80Fe20)90Cu10 alloy than that the other alloy. In the annealed last stage sample of the (Ni80Fe20)90Cu10 alloy at 650 °C, a significant increase in magnetic saturation and a drastic decrease in coercivity value to as low as 6 Oe were observed. These findings indicated that the (Ni80Fe20)90Cu10 alloy can be considered a promising candidate for a soft magnetic alloy, as it demonstrates improved magnetic properties with enhanced saturation and reduced coercivity.

Graphical Abstract

Similar content being viewed by others

Data Availability

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

R.M. Bozorth, Ferromagnetism (Van Nostrand, New York, 1951)

C.W.T. McLyman, High Reliability Magnetic Devices: Design & Fabrication (CRC Press, Boca Raton, 2002)

I. Chicinas, O. Geoffroy, O. Isnard, V. Pop, J. Magn. Magn. Mater. 290, 1531–1534 (2005)

C. Kuhrt, L. Schultz, J. Appl. Phys. 71, 1896–1900 (1992)

M.E. McHenry, M.A. Willard, D.E. Laughlin, Prog. Mater. Sci. 44, 291–433 (1999)

M. Pękała, D. Oleszak, E. Jartych, J. Żurawicz, J. Non-cryst. Solids. 250, 757–761 (1999)

A. Guittoum, A. Layadi, A. Bourzami, H. Tafat, N. Souami, S. Boutarfaia, D. Lacour, J. Magn. Magn. Mater. 320, 1385–1392 (2008)

Suprianto, C.-L. Chen, Met. Mater. Int. 29, 420–428 (2023)

J. Parida, S.C. Mishra, A. Behera, Met. Mater. Int. 29, 1145–1164 (2023)

C. Capdevila, U. Miller, H. Jelenak, H. Bhadeshia, Mater. Sci. Engineering: A 316, 161–165 (2001)

M. Hajipour, H. Raanaei, S. Zarei, J. Magn. Magn. Mater. 548, 168992 (2021)

B. Avar, A.K. Chattopadhyay, T. Simsek, T. Simsek, S. Ozcan, B. Kalkan, Appl. Phys. A 128, 537 (2022)

E. Özer, M. Ayvaz, M. Übeyli, İ. Sarpkaya, Met. Mater. Int. 29, 402–419 (2023)

T. Gu, L.-M. Wang, Q. Hu, X.-B. Liang, D.-X. Fu, Y.-X. Chen, X.-M. Zhao, Y.-W. Sheng, Met. Mater. Int. 28, 2571–2582 (2022)

B. Zhang, N.-E. Fenineche, H. Liao, C. Coddet, J. Magn. Magn. Mater. 336, 49–54 (2013)

K. Gheisari, S. Shahriari, S. Javadpour, J. Alloys Compd. 574, 71–82 (2013)

R. Koohkan, S. Sharafi, H. Shokrollahi, K. Janghorban, J. Magn. Magn. Mater. 320, 1089–1094 (2008)

D. Olekšáková, P. Kollar, J. Füzer, M. Kusý, S. Roth, K. Polanski, J. Magn. Magn. Mater. 316, e838–e841 (2007)

A. Mazeeva, M. Staritsyn, V. Bobyr, S. Manninen, P. Kuznetsov, V. Klimov, J. Alloys Compd. 814, 152315 (2020)

V. Chaudhary, N.M.S.K.K. Yadav, S.A. Mantri, S. Dasari, A. Jagetia, R. Ramanujan, R. Banerjee, J. Alloys Compd. 823, 153817 (2020)

Y. Yoshizawa, S. Oguma, K. Yamauchi, J. Appl. Phys. 64, 6044–6046 (1988)

D. Ping, K. Hono, H. Kanekiyo, S. Hirosawa, IEEE Trans. Magn. 35, 3262–3264 (1999)

A. Sharifati, S. Sharafi, Mater. Design. 41, 8–15 (2012)

L. Lutterotti, S. Matthies, H. Wenk, Newsletter of the CPD. 21, 14–15 (1999)

S. Louidi, F. Bentayeb, W. Tebib, J. Suñol, A. Mercier, J. Grenèche, J. Non-cryst. Solids. 356, 1052–1056 (2010)

C. Suryanarayana, Prog. Mater. Sci. 46, 1–184 (2001)

B. Neamţu, T. Marinca, I. Chicinaş, O. Isnard, F. Popa, Adv. Powder Technol. 26, 323–328 (2015)

B. Bhoi, V. Srinivas, V. Singh, J. Alloys Compd. 496, 423–428 (2010)

M.S. El-Eskandarany, Mechanical Alloying: For Fabrication of Advanced Engineering Materials (William Andrew, Norwich, 2001)

M. Vaidya, A. Karati, A. Marshal, K. Pradeep, B. Murty, J. Alloys Compd. 770, 1004–1015 (2019)

I. Moravcik, A. Kubicek, L. Moravcikova-Gouvea, O. Adam, V. Kana, V. Pouchly, A. Zadera, I. Dlouhy, Metals 10, 1186 (2020)

C.-W. Chen, Magnetism and Metallurgy of Soft Magnetic Materials (Courier Corporation, North Chelmsford, 1986)

M. Pekała, D. Oleszak, E. Jartych, J. Żurawicz, Nanostruct. Mater. 11, 789–796 (1999)

M. Kalita, A. Perumal, A. Srinivasan, J. Magn. Magn. Mater. 320, 2780–2783 (2008)

H. Raanaei, M. Fakhraee, J. Magn. Magn. Mater. 438, 144–151 (2017)

A.H. Taghvaei, M. Stoica, M.S. Khoshkhoo, J. Thomas, G. Vaughan, K. Janghorban, J. Eckert, Mater. Chem. Phys. 134, 1214–1224 (2012)

M. Nowroozi, H. Shokrollahi, J. Magn. Magn. Mater. 335, 53–58 (2013)

H. Raanaei, M. Rahimi, V. Mohammad-Hosseini, J. Magn. Magn. Mater. 508, 166870 (2020)

R.L. Comstock, Introduction to Magnetism and Magnetic Recording (Wiley, Hoboken, 1999)

G. Herzer, Scr. Metall. Mater. 33, 1741–1756 (1995)

B.D. Cullity, C.D. Graham, Introduction to Magnetic Materials, 2nd edn. (Wiley, Hoboken, 2011)

Acknowledgements

The authors would like to thank gratefully the research council of Persian Gulf University for the generous support with grant no. 1129177.

Author information

Authors and Affiliations

Contributions

Elham Ahmadi-Gheidari: performed the experiments, data analysis, writing. Hossein Raanaei: writing the first draft of manuscript, reviewing, data analysis, editing, supervision.

Corresponding author

Ethics declarations

Competing Interests

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ahmadi-Gheidari, E., Raanaei, H. Influence of Copper Additive on Structural and Magnetic Behavior of Ne80Fe20 Alloyed Powder. Met. Mater. Int. (2024). https://doi.org/10.1007/s12540-024-01663-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12540-024-01663-3