Abstract

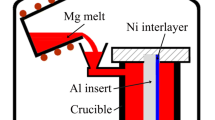

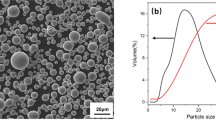

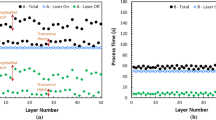

This study innovatively joins magnesium and titanium alloys by incorporating a 3D-printed lattice structure into a magnesium alloy melt via compound casting. Simulation results highlight the significant effect of the length-to-diameter ratio (l/ds) and node-to-strut diameter ratio (dn/ds) on joint strength, with the inclination angle (ω) deemed negligible. X-ray microcomputed tomography reveals a minimal 0.048% porosity in the bimetal joint with a cell dimension of 9 mm, prepared at a casting temperature of 730 °C. Experimental validation affirms the optimized lattice structure yielding impressive Mg/Ti composite joining strength (95.4 MPa) and fracture energy (8987 J). This optimal structure with l/ds, dn/ds, and ω of 5.8, 2.4, and 56° respectively, leverages rough surface texture from selective laser melting, promoting a serrated interface for enhanced Mg/Ti bimetallic bonding.

Graphical Abstract

Similar content being viewed by others

Data Availability

The data that support the findings of this study are available from the corresponding author, [author initials], upon reasonable request.

References

L. Raimondi, L. Tomesani, L. Donati, A. Zucchelli, Lattice material infiltration for hybrid metal-composite joints: manufacturing and static strength. Compos. Struct. 269, 114069 (2021). https://doi.org/10.1016/j.compstruct.2021.114069

F. Hua, H. Song, T. Sun, J. Li, Inter-diffusion based analytical model for growth kinetics of IMC layers at roll bonded Cu/Al interface during annealing process. Met. Mater. Int. 26, 333–345 (2020). https://doi.org/10.1007/s12540-019-00333-z

X. Cheng, Y. Gao, H. Fu, J. Xing, B. Bai, Microstructural characterization and properties of Al/Cu/steel diffusion bonded joints. Met. Mater. Int. 16, 649–655 (2010). https://doi.org/10.1007/s12540-010-0820-2

J.L. Song, S.B. Lin, C.L. Yang, C.L. Fan, Effects of Si additions on intermetallic compound layer of aluminum–steel TIG welding–brazing joint. J. Alloys Compd. 488, 217–222 (2009). https://doi.org/10.1016/j.jallcom.2009.08.084

G. Chen, G. Xu, Interfacial reaction in twin-roll cast AA1100/409L clad sheet during different sequence of cold rolling and annealing. Met. Mater. Int. 27, 3013–3025 (2021). https://doi.org/10.1007/s12540-020-00621-z

G. Li, W. Jiang, F. Guan, Z. Zhang, J. Wang, Y. Yu, Z. Fan, Preparation, interfacial regulation and strengthening of Mg/Al bimetal fabricated by compound casting: a review. J. Magnes. Alloy. 11, 3059–3098 (2023). https://doi.org/10.1016/j.jma.2023.09.001

G. Li, W. Jiang, F. Guan, J. Zhu, Y. Yu, Z. Fan, Microstructure evolution, mechanical properties and fracture behavior of Al-xSi/AZ91D bimetallic composites prepared by a compound casting. J. Magnes. Alloy. (2022). https://doi.org/10.1016/j.jma.2022.08.010

S. Fan, W. Jiang, G. Li, J. Mo, Z. Fan, Fabrication and microstructure evolution of Al/Mg bimetal using a near-net forming process. Mater. Manuf. Processes 32, 1391–1397 (2017). https://doi.org/10.1080/10426914.2017.1328118

F.J. Yao, G.Q. You, L. Wang, Q. Li, S. Zeng, Y. Ming, Design, fabrication, microstructure, and mechanical properties of interlayer-free vacuum diffusion bonding Mg/Ti composites. Vacuum 199, 110947 (2022). https://doi.org/10.1016/j.vacuum.2022.110947

C.W. Tan, X.G. Song, B. Chen, L.Q. Li, J.C. Feng, Enhanced interfacial reaction and mechanical properties of laser welded-brazed Mg/Ti joints with Al element from filler. Mater. Lett. 167, 38–42 (2016). https://doi.org/10.1016/j.matlet.2015.12.119

C.W. Tan, B. Chen, S.H. Meng, K.P. Zhang, X.G. Song, L. Zhou, J.C. Feng, Microstructure and mechanical properties of laser welded-brazed Mg/Ti joints with AZ91 Mg based filler. Mater. Des. 99, 127–134 (2016). https://doi.org/10.1016/j.matdes.2016.03.073

J.J. Shangguan, J.H. Zhao, Y. Shi, C. Gu, B.Y. Jin, J. Cheng, Y. Guo, Effects of Zn interlayer on microstructures and mechanical properties of TC4/AZ91D bimetal via solid-liquid compound casting process. Int. J. Metalcast. 16, 419–434 (2022). https://doi.org/10.1007/s40962-021-00612-9

F.L. Wen, J.H. Zhao, M.W. Yuan, J.F. Wang, D.Z. Zheng, J.Y. Zhang, K. He, J.J. Shangguan, Y. Guo, Influence of Ni interlayer on interfacial microstructure and mechanical properties of Ti-6Al-4V/AZ91D bimetals fabricated by a solid–liquid compound casting process. J. Magnesium Alloys 9, 1382–1395 (2021). https://doi.org/10.1016/j.jma.2020.05.021

F. Wen, J. Zhao, K. Feng, M. Yuan, D. Zheng, C. Gu, B. Xu, Investigation of Cu interlayer on joint formation of Ti/Mg bimetal fabricated by liquid-solid compound casting process. Met. Mater. Int. 28, 1711–1724 (2022). https://doi.org/10.1007/s12540-021-01027-1

W. Jiang, H. Jiang, G. Li, F. Guan, J. Zhu, Z. Fan, Microstructure, mechanical properties and fracture behavior of magnesium/steel bimetal using compound casting assisted with hot-dip aluminizing. Met. Mater. Int. 27, 2977–2988 (2021). https://doi.org/10.1007/s12540-019-00606-7

J. Cheng, J. Zhao, D. Zheng, K. He, Y. Guo, Effect of the vacuum heat treatment on the microstructure and mechanical properties of the galvanized-Q235/AZ91D bimetal material produced by solid-liquid compound casting. Met. Mater. Int. 27, 545–555 (2021). https://doi.org/10.1007/s12540-019-00503-z

B. Onuike, A. Bandyopadhyay, Functional bimetallic joints of Ti6Al4V to SS410. Addit. Manuf. 31, 100931 (2020). https://doi.org/10.1016/j.addma.2019.100931

A.M. Atieh, T.I. Khan, TLP bonding of Ti-6Al-4V and Mg-AZ31 alloys using pure Ni electro-deposited coats. J. Mater. Process. Technol. 214, 3158–3168 (2014). https://doi.org/10.1016/j.jmatprotec.2014.07.028

Z.Q. Zhang, C.W. Tan, G. Wang, B. Chen, X.G. Song, H.Y. Zhao, L.Q. Li, J.C. Feng, Laser welding-brazing of immiscible AZ31B Mg and Ti-6Al-4V alloys using an electrodeposited Cu interlayer. J. Mater. Eng. Perform. 27, 1414–1426 (2018). https://doi.org/10.1007/s11665-018-3196-y

J.J. Shangguan, J.H. Zhao, J.X. Zhang, C. Gu, Y. Shi, Y.J. Wang, Improving shear strength of Ti/Mg bimetal composites prepared by hot-dip aluminizing and solid–liquid compound casting. Adv. Eng. Mater. 24, 2200298 (2022). https://doi.org/10.1002/adem.202200298

A. AlHazaa, I. Alhoweml, M.A. Shar, M. Hezam, H.S. Abdo, H. AlBrithen, Transient liquid phase bonding of Ti-6Al-4V and Mg-AZ31 alloys using Zn coatings. Materials 12, 769 (2019). https://doi.org/10.3390/ma12050769

Z. Zhang, W. Jiang, G. Li, J. Wang, F. Guan, G. Jie, Z. Fan, Effect of La on microstructure, mechanical properties and fracture behavior of Al/Mg bimetallic interface manufactured by compound casting. J. Mater. Sci. Technol. 105, 214–225 (2022). https://doi.org/10.1016/j.jmst.2021.08.011

F. Wen, J. Zhao, M. Yuan, J. Wang, D. Zheng, J. Zhang, K. He, J. Shangguan, Y. Guo, Influence of Ni interlayer on interfacial microstructure and mechanical properties of Ti-6Al-4V/AZ91D bimetals fabricated by a solid–liquid compound casting process. J. Magnes. Alloy 9, 1382–1395 (2021). https://doi.org/10.1016/j.jma.2020.05.021

M. Gao, Z.M. Wang, X.Y. Li, X.Y. Zeng, Laser keyhole welding of dissimilar Ti-6Al-4V titanium alloy to AZ31B magnesium alloy. Metall. Mater. Trans. A 43, 163–172 (2012). https://doi.org/10.1007/s11661-011-0825-6

T. Bagnato, A.R. Ravindran, A. Mirabedini, R.B. Ladani, E. Kandare, A.C. Orifici, P. Chang, J. Wang, A.P. Mouritz, Superior interfacial toughening of hybrid metal-composite structural joints using 3D printed pins. Compos. A: Appl. Sci. Manuf. 168, 107479 (2023). https://doi.org/10.1016/j.compositesa.2023.107479

N. Li, P.H. Chen, X.Y. Liu, W. Ma, X.C. Wang, A micro-macro finite element model for failure prediction of ComeldTM joints. Compos. Sci. Technol. 117, 334–341 (2015). https://doi.org/10.1016/j.compscitech.2015.07.001

W. Xiong, B. Blackman, J.P. Dear, X. Wang, The effect of composite orientation on the mechanical properties of hybrid joints strengthened by surfi-sculpt. Compos. Struct. 134, 587–592 (2015). https://doi.org/10.1016/j.compstruct.2015.08.083

S. Ucsnik, M. Scheerer, S. Zaremba, D.H. Pahr, Experimental investigation of a novel hybrid metal–composite joining technology. Compos. A: Appl. Sci. Manuf. 41, 369–374 (2010). https://doi.org/10.1016/j.compositesa.2009.11.003

S. Heimbs, A.C. Nogueira, E. Hombergsmeier, M. May, J. Wolfrum, Failure behaviour of composite T-joints with novel metallic arrow-pin reinforcement. Compos. Struct. 110, 16–28 (2014). https://doi.org/10.1016/j.compstruct.2013.11.022

M. Grasso, B.M. Colosimo, Process defects and in situ monitoring methods in metal powder bed fusion: a review. Meas. Sci. Technol. 28, 044005 (2017). https://doi.org/10.1088/1361-6501/aa5c4f

A.T.T. Nguyen, M. Brandt, S. Feih, A.C. Orifici, Pin pull-out behaviour for hybrid metal-composite joints with integrated reinforcements. Compos. Struct. 155, 160–172 (2016). https://doi.org/10.1016/j.compstruct.2016.07.047

A.T.T. Nguyen, C.K. Amarasinghe, M. Brandt, S. Feih, A.C. Orifici, Loading, support and geometry effects for pin-reinforced hybrid metal-composite joints. Compos. A: Appl. Sci. Manuf. 98, 192–206 (2017). https://doi.org/10.1016/j.compositesa.2017.03.019

A.T.T. Nguyen, N. Pichitdej, M. Brandt, S. Feih, A.C. Orifici, Failure modelling and characterisation for pin-reinforced metal-composite joints. Compos. Struct. 188, 185–196 (2018). https://doi.org/10.1016/j.compstruct.2017.12.043

T. Maconachie, M. Leary, B. Lozanovski, X. Zhang, M. Qian, O. Faruque, M. Brandt, SLM lattice structures: properties, performance, applications and challenges. Mater. Des. 183, 108137 (2019). https://doi.org/10.1016/j.matdes.2019.108137

H. Lei, C. Li, J. Meng, H. Zhou, Y. Liu, X. Zhang, P. Wang, D. Fang, Evaluation of compressive properties of SLM-fabricated multi-layer lattice structures by experimental test and μ-CT-based finite element analysis. Mater. Des. 169, 107685 (2019). https://doi.org/10.1016/j.matdes.2019.107685

S. McKown, Y. Shen, W.K. Brookes, C.J. Sutcliffe, W.J. Cantwell, G.S. Langdon, G.N. Nurick, M.D. Theobald, The quasi-static and blast loading response of lattice structures. Int. J. Impact Eng 35, 795–810 (2008). https://doi.org/10.1016/j.ijimpeng.2007.10.005

M. Mazur, M. Leary, S. Sun, M. Vcelka, D. Shidid, M. Brandt, Deformation and failure behaviour of Ti-6Al-4V lattice structures manufactured by selective laser melting (SLM). Int. J. Adv. Manuf. Technol. 84, 1391–1411 (2016). https://doi.org/10.1007/s00170-015-7655-4

A. Alghamdi, T. Maconachie, D. Downing, M. Brandt, M. Qian, M. Leary, Effect of additive manufactured lattice defects on mechanical properties: an automated method for the enhancement of lattice geometry. Int. J. Adv. Manuf. Technol. 108, 957–971 (2020). https://doi.org/10.1007/s00170-020-05394-8

T. Hasegawa, K. Okazaki, Analysis of strain rate dependence of tensile elongation for a mechanical milling Al–1.1Mg–1.2Cu alloy tested at 748 K from a dislocation dynamics viewpoint. Mater. Sci. Eng. A 260, 294–300 (1999). https://doi.org/10.1016/S0921-5093(98)00961-7

F. Zhao, Y.L. Li, T. Suo, W.D. Huang, J.R. Liu, Compressive deformation behavior of AZ31 magnesium alloy under quasi-static and dynamic loading. Trans. Nonferr. Metal. Soc. China 20, 1316–1320 (2010). https://doi.org/10.1016/S1003-6326(09)60297-1

N. Tahreen, D.L. Chen, M. Nouri, D.Y. Li, Effects of aluminum content and strain rate on strain hardening behavior of cast magnesium alloys during compression. Mater. Sci. Eng. A 594, 235–245 (2014). https://doi.org/10.1016/j.msea.2013.11.078

Y. Liu, J.H. Meng, L. Zhu, H.Y. Chen, Z.G. Li, S.X. Li, D. Wang, Y.G. Wang, K. Kosiba, Dynamic compressive properties and underlying failure mechanisms of selective laser melted Ti-6Al-4V alloy under high temperature and strain rate conditions. Addit. Manuf. 54, 102772 (2022). https://doi.org/10.1016/j.addma.2022.102772

I.R. Ahmad, D.W. Shu, Tensile properties of die-cast magnesium alloy AZ91D at high strain rates in the range between 300 s(-1) and 1500 s(-1). Appl. Mech. Mater. VII 24, 325–330 (2010). https://doi.org/10.4028/www.scientific.net/AMM.24-25.325

Y. Shimizu, S. Miki, T. Soga, I. Itoh, H. Todoroki, T. Hosono, K. Sakaki, T. Hayashi, Y.A. Kim, M. Endo, S. Morimoto, A. Koide, Multi-walled carbon nanotube-reinforced magnesium alloy composites. Scr. Mater. 58, 267–270 (2008). https://doi.org/10.1016/j.scriptamat.2007.10.014

X. Yang, W. Ma, Z. Zhang, S. Liu, H. Tang, Ultra-high specific strength Ti6Al4V alloy lattice material manufactured via selective laser melting. Mater. Sci. Eng. A 840, 142956 (2022). https://doi.org/10.1016/j.msea.2022.142956

Q.X. Feng, Q. Tang, Y. Liu, R. Setchi, S. Soe, S. Ma, L. Bai, Quasi-static analysis of mechanical properties of Ti6Al4V lattice structures manufactured using selective laser melting. Int. J. Adv. Manuf. Technol. 94, 2301–2313 (2018). https://doi.org/10.1007/s00170-017-0932-7

A. Santos, E. Córdoba, Z. Ramírez, C. Sierra, Y. Ortega, Determination of the coefficient of dynamic friction between coatings of alumina and metallic materials. in Journal of Physics: Conference Series 935, 012042 (2017). https://doi.org/10.1088/1742-6596/935/1/012042

SIMULIA, Abaqus/CAE 6.14 User’s Manual, (Dassault Systémes Inc, Provid. RI, USA, 2014), pp. 1–1146. https://www.scopus.com/inward/record.uri?eid=2-s2.0-85089823156&partnerID=40&md5=a05a511616dc358e75723ebf30084b49

T.E.D. Belytschko, The finite element method: linear static and dynamic finite element analysis—Thomas J. R. Hughes. Comput. Aided Civ. Infrastruct. Eng. 4, 245–246 (1989). https://doi.org/10.1111/j.1467-8667.1989.tb00025.x

Y. Huang, Y. Xue, X. Wang, F. Han, Mechanical behavior of three-dimensional pyramidal aluminum lattice materials. Mater. Sci. Eng. A 696, 520–528 (2017). https://doi.org/10.1016/j.msea.2017.04.053

R. Guo, L. Liu, Preparation and experimental study on anti-penetration capability of the interlocking lattice sandwich plate filled with ceramic rods and hybrid fillers. J. Sandwich Struct. Mater. 20, 153–168 (2018). https://doi.org/10.1177/1099636216643426

R. Gümrük, R.A.W. Mines, Compressive behaviour of stainless steel micro-lattice structures. Int. J. Mech. Sci. 68, 125–139 (2013). https://doi.org/10.1016/j.ijmecsci.2013.01.006

K. Ushijima, W.J. Cantwell, R.A.W. Mines, S. Tsopanos, M. Smith, An investigation into the compressive properties of stainless steel micro-lattice structures. J. Sandwich Struct. Mater. 13, 303–329 (2010). https://doi.org/10.1177/1099636210380997

M. Simonelli, Y.Y. Tse, C. Tuck, Effect of the build orientation on the mechanical properties and fracture modes of SLM Ti–6Al–4V. Mater. Sci. Eng. A 616, 1–11 (2014). https://doi.org/10.1016/j.msea.2014.07.086

J. Schukraft, D. Horny, K. Schulz, K.A. Weidenmann, 3D modeling and experimental investigation on the damage behavior of an interpenetrating metal ceramic composite (IMCC) under compression. Mater. Sci. Eng. A 844, 143147 (2022). https://doi.org/10.1016/j.msea.2022.143147

M. Balasubramanian, Application of Box–Behnken design for fabrication of titanium alloy and 304 stainless steel joints with silver interlayer by diffusion bonding. Mater. Des. 77, 161–169 (2015). https://doi.org/10.1016/j.matdes.2015.04.003

K. Yetilmezsoy, A. Saral, Stochastic modeling approaches based on neural network and linear–nonlinear regression techniques for the determination of single droplet collection efficiency of countercurrent spray towers. Environ. Model. Assess. 12, 13–26 (2007). https://doi.org/10.1007/s10666-006-9048-4

Q. Zhao, Z.B. Shao, Q.C. Leng, X.D. Zhang, C.J. Liu, B.K. Li, M.F. Jiang, Preparation of Cu-Cr alloy powder by heat mechanical alloying and Box–Behnken design based optimization. Powder Technol. 321, 326–335 (2017). https://doi.org/10.1016/j.powtec.2017.08.039

R.K. Tayal, S. Kumar, V. Singh, R. Garg, Characterization and microhardness evaluation of A356/Mg joint produced by vacuum-assisted sand mold compound casting process. Int. J. Metalcast. 13, 392–406 (2019). https://doi.org/10.1007/s40962-018-0264-x

A. Balasundaram, A.M. Gokhale, Quantitative characterization of spatial arrangement of shrinkage and gas (air) pores in cast magnesium alloys. Mater Charact 46, 419–426 (2001). https://doi.org/10.1016/S1044-5803(01)00141-3

D.L. Prakash, B. Prasanna, D. Regener, Computational microstructure analyzing technique for quantitative characterization of shrinkage and gas pores in pressure die cast AZ91 magnesium alloys. Comput. Mater. Sci. 32, 480–488 (2005). https://doi.org/10.1016/j.commatsci.2004.09.017

Y. Li, H. Yang, X. Lin, W. Huang, J. Li, Y. Zhou, The influences of processing parameters on forming characterizations during laser rapid forming. Mater. Sci. Eng. A 360, 18–25 (2003). https://doi.org/10.1016/S0921-5093(03)00435-0

J.J. Ding, Q.W. Qin, S.M. Hao, X.T. Wang, G.L. Chen, Partial phase diagram of the Ti-Al binary system. J. Phase Equilib. 17, 117–120 (1996). https://doi.org/10.1007/BF02665786

H. Zhang, Y. Chen, A.A. Luo, A novel aluminum surface treatment for improved bonding in magnesium/aluminum bimetallic castings. Scr. Mater. 86, 52–55 (2014). https://doi.org/10.1016/j.scriptamat.2014.05.007

Acknowledgements

This work was supported by the National Natural Science Foundation of China (51875062 and 52205336), and China Postdoctoral Science Foundation (2021M700567).

Funding

National Natural Science Foundation of China, 51875062, Jian-hua Zhao, 52205336, Cheng Gu, China Postdoctoral Science Foundation, 2021M700567, Cheng Gu

Author information

Authors and Affiliations

Contributions

YW: conceptualization, methodology, writing—original draft. JZ: formal analysis, funding acquisition, supervision. CG: review & editing, data curation. LY: investigation, data curation.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wu, Y., Zhao, J., Yu, L. et al. Enhanced Interfacial Joining Strength of Mg/Ti Bimetal Casting via 3D-Printed Ti-Based Lattice Material. Met. Mater. Int. (2024). https://doi.org/10.1007/s12540-024-01640-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12540-024-01640-w