Abstract

An experimental investigation has been conducted with respect to the element segregation and microstructure evolution of a Mn–Cr–Mo alloyed oil casing steel from different solidification cooling rates (0.5 °C/s, 3 °C/s and 10 °C/s) and subsequent defined homogenization treatment using the confocal scanning laser microscope (CSLM). A quantitative relation between the secondary dendrite arm spacing and cooling rates is achieved through regression analysis. The experimental results shown that the micro-segregation area of Mn, Cr and Mo elements decreased significantly, but its concentration increased in the finer inter-dendritic region with the increase of solidification cooling rate. The distribution of the experimental elements determined by the grid point measurements (obtained with EPMA-WDS) processed by the weighted interval rank sort method is consistent with the modified V–B segregation model considering the proper partition coefficient by the mass balance analysis method. Moreover, the residual element segregation index apparently decreased and the element micro-segregation was effectively eliminated during the subsequent homogenization treatment especially for the sample prepared by a higher cooling rate in the as-cast period.

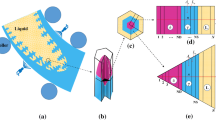

Graphical Abstract

Similar content being viewed by others

References

H. Li, Y. Li, D. Wei, J. Liu, X. Wang, Mater. Sci. Eng. A 530, 367–372 (2011)

Y. Ji, P. Lan, H. Geng, Q. He, C. Shang, J. Zhang, Steel Res. Int. 89, 1700331 (2018)

W. Liang, Q. Yuan, S. Liu, G. Xu, J. Xie, Metals Mater. Int. 27, 1587–1598 (2021)

B. Li, M. Luo, Z. Yang, F. Yang, H. Liu, H. Tang, Z. Zhang, J. Zhang, Materials 12, 3310 (2019)

L. Li, Z. Zhang, M. Luo, B. Li, P. Lan, J. Zhang, Metals 11, 9 (2021)

G. Krauss, Metall. Mater. Trans. B 34, 781–792 (2003)

J.D. Verhoeven, J. Mater. Eng. Perform. 9, 286–296 (2000)

M.H. Trejo, E.A. Lopez, J. Mondragon, M. Roman, H. Tovar, Metals Mater. Int. 16, 731–737 (2010)

S. Dépinoy, M. Sennour, L. Ferhat, C. Colin, Scr. Mater. 194, 113663 (2021)

H. Lee, H. Jeong, S. Seo, D. Yun, K. Park, K. Yim, Y. Yoo, Metals Mater. Int. 27, 691–704 (2021)

Z. Huang, X. He, K. Chen, X. Wang, J. Alloys Compd. 912, 165107 (2022)

Y. Li, D. Zou, W. Chen, Y. Zhang, W. Zhang, F. Xu, Metals Mater. Int. 28, 1907–1918 (2022)

M. Mao, H. Guo, F. Wang, X. Sun, ISIJ Int. 59, 848–857 (2019)

M.N. Khan, M. Aljarrah, J.T. Wood, M. Medraj, J. Mater. Res. 26, 974–982 (2011)

M. Bleckmann, J. Gleinig, J. Hufenbach, H. Wendrock, L. Giebeler, J. Zeisig, U. Diekmann, J. Alloys Compd. 634, 200–207 (2015)

J.N. Dupont, S.W. Banovic, A. Marder, Weld. J. 82, 125–135 (2003)

S. Ganesan, D.R. Poirier, J. Cryst. Growth 97, 851–859 (1989)

T.W. Clyne, W. Kurz, Metall. Trans. A 12, 965–971 (1981)

T.W. Clyne, M. Wolf, W. Kurz, Metall. Mater. Trans. B 13, 259–266 (1982)

V.R. Voller, C. Beckermann, Metall. Mater. Trans. A 30, 2183–2189 (1999)

C.J. Farnin, S. Orzolek, J.N. DuPont, Metall. Mater. Trans. A 51, 5771–5780 (2020)

Z.J. Miao, A.D. Shan, Y.B. Wu, J. Lu, W.L. Xu, H.W. Song, Trans. Nonferrous Metals Soc. China 21, 1009–1017 (2011)

W. Mu, P. Hedström, H. Shibata, P.G. Jönsson, K. Nakajima, JOM 70, 2283–2295 (2018)

R. Bharadwaj, A. Sarkar, B. Rakshe, Metallogr. Microstruct. Anal. 11, 661–672 (2022)

C. Liang, W. Wang, H. He, J. Zeng, J. Mater. Res. Technol. 23, 6090–6100 (2023)

T. Liu, M. Long, D. Chen, Y. Huang, J. Yang, H. Duan, L. Gui, P. Xu, Metall. Mater. Trans. B 51, 338–352 (2020)

R. Chen, Z. Zheng, N. Li, J. Li, F. Feng, Mater. Charact. 144, 400–410 (2018)

Y. Hao, J. Li, X. Li, W. Liu, G. Cao, C. Li, Z. Liu, J. Mater. Process. Technol. 275, 116326 (2020)

Z. Huang, X. He, K. Chen, X. Wang, J. Mater. Sci. 58, 3307–3322 (2023)

M. Reid, D. Phelan, R. Dippenaar, ISIJ Int. 44, 565–572 (2004)

D. Zhang, H. Terasaki, Y. Komizo, Acta Mater. 58, 1369–1378 (2010)

H. Jacobi, K. Wünnenberg, Steel Res. 70, 362–367 (1999)

J.M.C. Marrero, V.C. Galindo, R.D. Morales, F.C. Alcalá, ISIJ Int. 38, 812–821 (1998)

R. Pierer, C. Bernhard, J. Mater. Sci. 43, 6938–6943 (2008)

M.E. Bealy, B.G. Thomas, Metall. Mater. Trans. B 27, 689–693 (1996)

Y. Shen, J. Liu, H.A.O. Xu, H. Liu, Metall. Mater. Trans. B 51, 2963–2975 (2020)

M. Ganesan, D. Dye, P.D. Lee, Metall. Mater. Trans. A 36, 2191–2204 (2005)

Y. Meng, B.G. Thomas, Metall. Mater. Trans. B 34, 685–705 (2003)

S. Uhm, J. Moon, C. Lee, J. Yoon, B. Lee, ISIJ Int. 44, 1230–1237 (2004)

Y. Xu, D. Tang, Y. Song, X. Pan, Mater. Des. 36, 275–278 (2012)

L.Y. Lan, C.L. Qiu, D.W. Zhao, X.H. Gao, L.X. Du, Mater. Sci. Technol. 27, 1657–1663 (2011)

Acknowledgements

The financial support for this work from the National Natural Science Foundation of China (52274342, 52130408) are gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interests

The authors declare that they have no conflict of interest in this paper. All the authors listed have approved the manuscript.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Liang, C., Song, G., Liang, L. et al. Effect of Solidification Cooling Rates and Subsequent Homogenization Treatment on Mn–Cr–Mo Element Segregation in Oil Casing Steels. Met. Mater. Int. (2024). https://doi.org/10.1007/s12540-024-01633-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12540-024-01633-9