Abstract

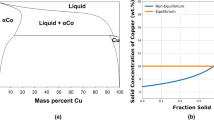

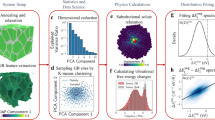

Instrumental errors in microsegregation measurements in multicomponent alloys complicate the treatment of randomly sampled data. In this article, two new alloy-independent data treatment algorithms are presented that are capable of separating the effects of scatter in the data from the underlying segregation trends, assigning each measurement location a unique fraction solid. These new methods are physically reasonable and result in improved estimates of segregation parameters, particularly the solute partitioning at the dendrite tip. This is demonstrated by determining the microsegregation in four successive generations of single-crystal (SX) nickel-based superalloys. Artificial, noise-induced, tails commonly seen in the microsegregation profiles are also minimized. A methodology for evaluating sorting schemes is introduced that does not depend upon a priori knowledge of the partitioning direction. Comparison is made to both other sorting methods and CALPHAD predicted partition coefficients. Implications for alloy design are reported, illustrating the interaction between solute species such as Ru, Re, Co, and W.

Similar content being viewed by others

References

D.J. Frasier, J.R. Whetstone, K. Harris, G.L. Erickson, and R.E. Schwer: in High Temperature Materials for Power Engineering 1990, E. Bachelet, R. Brunetaud, D. Coutsouradis, P. Esslinger, J. Ewald, I. Kvernes, Y. Lindblom, D.B. Meadowcroft, V. Regis, R.B. Scarlin, K. Schneider, and R. Singer, eds., Kluwer Academic Publishers, Liege, 1990, pp. 1281–1300.

M. McLean, P.D. Lee, and B.A. Shollock: in Advanced Materials and Processes for Gas Turbines, G.E. Fuchs, A. James, T.P. Gabb, M. McLean, and H. Harada, eds., TMS, Warrendale, PA, 2002, pp. 83–90.

T.M. Pollock and W.H. Murphy: Metall. Mater. Trans. A, 1996, vol. 27A, pp. 1081–94.

M. Durand-Charre: The Microstructure of Superalloys, Gordon and Breach Science Publishers, Amsterdam, The Netherlands, 1997.

N. D’Souza, B.A. Shollock, and M. McLean: in Solidification Processing 1997, J. Beech, and H. Jones, eds., University of Sheffield, Sheffield, United Kingdom, 1997, pp. 316–20.

G.E. Fuchs: Mater. Sci. Eng. A, 2001, vol. 300A, pp. 52–60.

M.S.A. Karunaratne, D.C. Cox, P. Carter, and R.C. Reed: in Superalloys 2000, T.M. Pollock, R.D. Kissinger, R.R. Bowman, K.A. Green, M. McLean, S. Olson, and J.J. Schirra, eds., TMS, Warrendale, PA, 2000, pp. 263–72.

A. Wagner, N.D. Souza, B.A. Shollock, and M. McLean: 2001 Int. Symp. on Liquid Metal Processing and Casting, A. Mitchell, and J. Van Den Avyle, eds., AVS, Santa Fe, NM, 2001, pp. 310–13.

S. Tin, T.M. Pollock, and W.T. King: in Superalloys 2000, T.M. Pollock, R.D. Kissinger, R.R. Bowman, K.A. Green, M. McLean, S. Olson, and J.J. Schirra, eds., TMS, Warrendale, PA, 2000, pp. 201–10.

S. Tin and T.M. Pollock: in Advanced Materials and Processes for Gas Turbines, G.E. Fuchs, A. James, T.P. Gabb, M. McLean, and H. Harada, eds., TMS, Warrendale, PA, 2002, pp. 91–100.

D. Dye, O. Hunziker, and R.C. Reed: Acta Mater., 2001, vol. 49, pp. 683–97.

M.S.A. Karunaratne, C.M.E. Rae, and R.C. Reed: Metall. Mater. Trans. A, 2001, vol. 32A, pp. 2409–21.

M.L. Clemens, A. Price, and R.S. Bellows: J. Met., 2003, vol. 55, pp. 27–31.

A.J. Elliott, T.M. Pollock, S. Tin, W.T. King, S.C. Huang, and M.F.X. Gigliotti: in Parsons 2003, A. Strang, R.D. Conroy, W.M. Banks, M. Blacker, J. Leggett, G.M. McGolvin, S. Simpson, M. Smith, F. Starr, and R.W. Vanstone, eds., Maney Publishing, Institute of Materials, Dublin, 2003, pp. 649–61.

Q. Feng, T.K. Nandy, S. Tin, and T.M. Pollock: Acta Mater., 2003, vol. 51, pp. 269–84.

S. Tin and T.M. Pollock: Mater. Sci. Eng. A, 2003, vol. 348A, pp. 111–21.

J.-C. Zhao and M.F. Henry: Adv. Eng. Mater., 2002, vol. 4, pp. 501–08.

W. Wang, P.D. Lee, and M. McLean: Acta Mater., 2003, vol. 51, pp. 2971–87.

W. Wang, A. Kermanpur, P.D. Lee, and M. McLean: J. Mater. Sci., 2003, vol. 38, pp. 4385–91.

J. Lacaze and G.R.J. Lesoult: in Nature and Properties of Semi-Solid Materials, J.A. Sekhar, and J.A. Dantzig, eds., TMS, Warrendale, PA, 1991, pp. 105–42.

A. Howe, J. Lacaze, and P. Benigni: Adv. Eng. Mater., 2003, vol. 5, pp. 37–46.

M.C. Flemings, D.R. Poirier, R.V. Barone, and H.D. Brody: J. Iron Steel Int., 1970, vol. 208, pp. 371–81.

S.C. Huang, L. Peluso, and D. Backman: in Solidification 1999, W.H. Hofmeister, J.R. Rogers, N.B. Singh, S.P. Marsh, and P.W. Vorhees, eds., TMS, Warrendale, PA, 1999, pp. 163–72.

F.-Y. Xie, T. Kraft, Y. Zuo, C.-H. Moon, and Y.A. Chang: Acta Mater., 1999, vol. 47, pp. 489–500.

F. Xie, X. Yan, L. Ding, F. Zhang, S. Chen, M.G. Chu, and Y.A. Chang: Mater. Sci. Eng. A, 2003, vol. 355A, pp. 144–53.

J. Lacaze and G.R.J. Lesoult: Mater. Sci. Eng. A, 1993, vol. 173A, pp. 119–22.

J. Lacaze and G. Lesoult: Iron Steel Inst. Jpn., 1995, vol. 35, pp. 658–64.

M.N. Gungor: Metall. Trans. A, 1989, vol. 20A, pp. 2529–33.

S.N. Tewari, M. Vijayakumar, J.E. Lee, and P.A. Curreri: NASA TM-103518, NASA, Washington, DC, 1990.

N. Siredey, and J. Lacaze: 11th Int. Conf. on Vacuum Metallurgy, Societe Francaise Du Vide, Antibes-Juan-les-Pins, 1992, pp. 149–51.

X. Yan, S. Chen, F. Xie, and Y.A. Chang: Acta Mater., 2002, vol. 50, pp. 2199–2207.

E.A. Feest: Solidification Technology in the Foundry and Cast House, The Metals Society, Coventry, 1980, pp. 188–94.

W. Yang, W. Chen, K.M. Chang, S. Manna, and J. DeBarbadillo: in Superalloys 2000, T.M. Pollock, R.D. Kissinger, R.R. Bowman, K.A. Green, M. McLean, S. Olson, and J.J. Schirra, eds., TMS, Seven Springs, PA, 2000, pp. 75–84.

W. Yang, K.M. Chang, W. Chen, S. Mannan, and J. DeBarbadillo: Metall. Mater. Trans. A, 2000, vol. 31A, pp. 2569–74.

T.M. Pollock, W.H. Murphy, E.H. Goldman, D.L. Uram, and J.S. Tu: in Superalloys 1992, S.D. Antolovich, R.W. Stusrud, R.A. MacKay, D.L. Anton, T. Khan, R.D. Kissinger, and D.L. Klarstrom, eds., TMS, Champion, PA, 1992, pp. 125–34.

D.G. McCartney and J.D. Hunt: Acta Mater., 1981, vol. 29, pp. 1851–63.

T. Grosdidier, A. Hazotte, and A. Simon: in High Temperature Materials for Power Engineering 1990, E. Bachelet, R. Brunetaud, D. Coutsouradis, P. Esslinger, J. Ewald, I. Kvernes, Y. Lindblom, D.B. Meadowcroft, V. Regis, R.B. Scarlin, K. Schneider, and R. Singer, eds., Kluwer Academic Publishers, Liege, 1990, pp. 1271–80.

B.C. Wilson, J.A. Hickman, and G.E. Fuchs: J. Met., 2003, vol. 55, pp. 35–40.

S. Tin, T.M. Pollock, and W. Murphy: Metall. Mater. Trans. A, 2001, vol. 32A, pp. 1743–53.

C. Selig and J. Lacaze: Metall. Mater. Trans. B, 2000, vol. 31B, pp. 827–36.

A. Wagner: Ph.D. Thesis, Imperial College of Science, Technology and Medicine, London, United Kingdom, 2002.

R. Elliott and J. Liu: Int. J. Cast Met. Res., 1999, vol. 12, pp. 75–82.

M. Charpentier, D. Daloz, A. Hazotte, E. Gautier, G. Lesoult, and M. Grange: Metall. Mater. Trans. A, 2003, vol. 34A, pp. 2139–48.

T. Grosdidier, A. Hazotte, and A. Simon: Mater. Sci. Eng. A, 1998, vol. 256A, pp. 183–96.

W. Hermann, J. Lacaze, and D. Oquab: Adv. Eng. Mater., 2003, vol. 5, pp. 32–37.

N. Saunders, X. Li, A.P. Miodownik, and J.-P. Schille: in Modeling of Casting, Welding and Advanced Solidification Processes X, D.M. Stefanescu, J.A. Warren, M.R. Jolly, and M.J.M. Krane, eds., TMS, Warrendale, PA, 2003, pp. 1–8.

K.A. Al-Jarba, and G.E. Fuchs: Mater. Sci. Eng. A, 2004, vol. 373A, pp. 255–67.

K.L. Zeisler-Mashl and B.J. Pletka: in Superalloys 1992, S.D. Antolovich, R.W. Stusrud, R.A. MacKay, D.L. Anton, T. Khan, R.D. Kissinger, and D.L. Klarstrom, eds., TMS, Warrendale, PA, 1992, pp. 175–84.

A.C. Yeh and S. Tin: in Parsons 2003, A. Strang, R.D. Conroy, W.M. Banks, M. Blacker, J. Leggett, G.M. McGolvin, S. Simpson, M. Smith, F. Starr, and R.W. Vanstone, eds., Maney Publishing, Institute of Materials, Dublin, 2003, pp. 673–86.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Ganesan, M., Dye, D. & Lee, P.D. A technique for characterizing microsegregation in multicomponent alloys and its application to single-crystal superalloy castings. Metall Mater Trans A 36, 2191–2204 (2005). https://doi.org/10.1007/s11661-005-0338-2

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11661-005-0338-2