Abstract

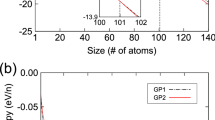

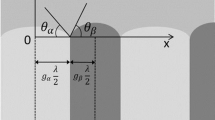

Taking Ag-27 at% Cu hypoeutectic and Ag-67 at% Cu hypereutectic alloys as examples, a theoretical criterion was established based on the classical nucleation theory to predict the non-reciprocal nucleation. For a eutectic alloy composed of α and β solid phases, non-reciprocal nucleation will not occur if the critical nucleation work of one phase on the other phase is approximately equal to that of the latter on the former. Otherwise, one phase can act as the more effective nucleation substrate for the other phase and non-reciprocal nucleation takes place. For Ag–Cu alloys, the wetting angle of β-Cu on α-Ag is larger than that of α-Ag on β-Cu, but the critical nucleation work for β-Cu to heterogeneously nucleate on α-Ag in hypoeutectic alloys is obviously smaller than that for α-Ag on β-Cu in hypereutectic Ag–Cu alloys. Thus, α-Ag phase is a better nucleant for β-Cu phase than vice versa and the Ag–Cu alloys solidify with non-reciprocal nucleation, reflected by only a halo of α-Ag around primary β-Cu phase in the hypereutectic Ag–Cu alloy.

Graphical Abstract

Similar content being viewed by others

References

C. Lemaignan, M.C. Cheynet, N. Eustathopoulos, J. Cryst. Growth. 50, 720–728 (1980). https://doi.org/10.1016/0022-0248(80)90018-4

S.M. Sadrossadat, S. Johansson, R.L. Peng, Met. Mater. Int. 18, 405–411 (2012). https://doi.org/10.1007/s12540-012-3004-4

S.T. Bluni, M.R. Notis, A.R. Marder, Acta Metall. Mater 43, 1775–1782 (1995). https://doi.org/10.1016/0956-7151(94)00397-Z

M.F. Gigliotti, G.A. Colligan, G.L.F. Powell, Metall. Trans. 1, 891–897 (1970). https://doi.org/10.1007/BF02811770

G.L.F. Powell, G.A. Colligan, Metall. Trans. 2, 849–852 (1971). https://doi.org/10.1007/BF02662745

C. Lemaignan, Acta Metall. Mater. 29, 1379–1384 (1981). https://doi.org/10.1016/0001-6160(81)90173-5

R.T. Southin, G.A. Chadwick, Acta Metall. Mater. 26, 223–231 (1978). https://doi.org/10.1016/0001-6160(78)90122-0

B. Cantor, R.D. Doherty, Acta Metall. Mater. 27, 33–46 (1979). https://doi.org/10.1016/0001-6160(79)90054-3

M. Pourgharibshahi, M. Divandari, H. Saghafian, G. Timelli, Metall. Mater. Trans. A 51, 4572–4583 (2020). https://doi.org/10.1007/s11661-020-05876-0

J.H. Hollomon, D. Turnbull, JOM 3, 803–805 (1951). https://doi.org/10.1007/BF03397378

V.V. Podolinsky, J. Cryst. Growth. 98, 838–842 (1989). https://doi.org/10.1016/0022-0248(89)90324-2

B.E. Sundquist, L.F. Mondolfo, Trans. Metall. Soc. AIME 221, 157–164 (1961)

Y.H. Zhao, Npj Comput. Mater. 9, 94 (2023). https://doi.org/10.1038/s41524-023-01038-z

F.J. Bradshaw, M.E. Gasper, S. Pearson, J. Inst. Met. 87, 15–18 (1958)

M.E. Glicksman, W.J. Childs, Acta Metall. Mater. 10, 925–933 (1962). https://doi.org/10.1016/0001-6160(62)90142-6

W.B. Castro, M.L. Maia, C.S. Kiminami, C. Bolfarini, Mater. Sci. Eng. A 304, 255–261 (2001). https://doi.org/10.1016/S0921-5093(00)01519-7

P.R. Subramanian, J.H. Perepezko, J. Phase Equilib. 14, 62–75 (1993). https://doi.org/10.1007/BF02652162

S. Walder, P.L. Ryder, J. Appl. Phys. 73, 1965–1970 (1993). https://doi.org/10.1063/1.353187

S. Zhao, J.F. Li, L. Liu, Y.H. Zhou, Mater. Charact. 60, 519–524 (2009). https://doi.org/10.1016/j.matchar.2008.12.006

H. Dong, Y.Z. Chen, Z.R. Zhang, G.B. Shan, W.X. Zhang, F. Liu, J. Mater. Sci. Technol. 59, 173–179 (2020). https://doi.org/10.1016/j.jmst.2020.05.019

V.V. Podolinsky, Y.N. Taran, V.G. Drykin, J. Cryst. Growth. 74, 57–66 (1986). https://doi.org/10.1016/0022-0248(86)90248-4

M.A. Easton, D.H. Stjohn, Acta Mater. 49, 1867–1878 (2001). https://doi.org/10.1016/S1359-6454(00)00368-2

W.T. Kim, B. Cantor, Acta Metall. Mater. 42, 3115–3127 (1994). https://doi.org/10.1016/0956-7151(94)90409-X

M. Hillert, P. Equilibria, Phase Diagrams and Phase Transformations: Their Thermodynamic Basis, 2nd edn. (Cambridge University Press, New York, 2007), pp.142–143

Y.H. Zhao, B. Zhang, H. Hou, W.P. Chen, M. Wang, J. Mater. Sci. Technol. 35, 1044–1052 (2019). https://doi.org/10.1016/j.jmst.2018.12.009

L.Q. Chen, Y.H. Zhao, Prog. Mater. Sci. 124, 100868 (2022). https://doi.org/10.1016/j.pmatsci.2021.100868

Z. Chvoj, S. Srikanth, P. Ramachandrarao, J. Non-Equilib, Thermodyn 24, 360–371 (1999). https://doi.org/10.1515/JNETDY.1999.021

Z.Y. Jian, K. Kuribayashi, W.Q. Jie, Mater. Trans. 43, 721–726 (2002). https://doi.org/10.2320/matertrans.43.721

Z.Y. Jian, N. Li, M. Zhu, J. Chen, F.G. Chang, W.Q. Jie, Acta Mater. 60, 3590–3603 (2012). https://doi.org/10.1016/j.actamat.2012.02.038

V.T. Witusiewicz, U. Hecht, S.G. Fries, S. Rex, J. Alloys Compd. 385, 133–143 (2004). https://doi.org/10.1016/j.jallcom.2004.04.126

A.T. Dinsdale, Calphad 15, 317–425 (1991). https://doi.org/10.1016/0364-5916(91)90030-N

G. Kaptay, J. Mater. Sci. 50, 678–687 (2015). https://doi.org/10.1007/s10853-014-8627-z

D.N. Lee, Met. Mater. Int. 23, 320–325 (2017). https://doi.org/10.1007/s12540-017-6360-2

M. Enomoto, Met. Mater. Int. 4, 115–123 (1998). https://doi.org/10.1007/BF03026028

J.B. Liu, Y.W. Zeng, L. Meng, J. Alloys Compd. 464, 168–173 (2008). https://doi.org/10.1016/j.jallcom.2007.10.015

B.P. Eftink, N.A. Mara, O.T. Kingstedt, D. Safarik, S. Wang, J. Lambros, I.M. Robertson, Mater. Sci. Eng. A 712, 313–324 (2018). https://doi.org/10.1016/j.msea.2017.11.108

Y.H. Zhao, K.X. Liu, H. Hou, L.Q. Chen, Mater. Des. 216, 110555 (2022). https://doi.org/10.1016/j.matdes.2022.110555

Acknowledgements

This work was supported by the National Natural Science Foundation of China (Grant Nos. 52231002, 51620105012 and 51821001).

Author information

Authors and Affiliations

Contributions

QQ: Conceptsualization, Methodology, Validation, Formal analysis, Investigation, Writing—original draft, Writing—review and editing, Visualization. ZZ Formal analysis, Validation, Writing—review and editing. LY Investigation, Writing—review and editing. JL Methodology, Validation, Writing—review and editing.

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Qin, Q., Zhang, Z., Yang, L. et al. Non-reciprocal Heterogeneous Nucleation in Solidification of Ag–Cu Alloys. Met. Mater. Int. 30, 1270–1281 (2024). https://doi.org/10.1007/s12540-023-01580-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-023-01580-x