Abstract

To optimize the hot deformation microstructure of the difficult-to-deform GH4975 superalloy, this study investigates the effect of cooling rate after sup-solvus temperature holding on the initial microstructure before hot deformation, and the effect of initial microstructure difference on the hot deformation microstructure. The results indicate that with decreasing the cooling rate from 1 to 0.1 °C min−1, the γ′ precipitates evolve into big size and irregular shape gradually, and the ratio of volume fraction to size of γ′ precipitates decreases. These changes intensify the bulging of grain boundaries (GBs) and enhance the migration of dislocations and GBs in γ matrix. Therefore, the nucleation and development of dynamic recrystallization (DRX) grains in γ matrix during deformation are promoted, but the refinement effect of DRX grains in γ matrix is weakened. Noteworthily, there is a transition point when the cooling rate is extremely slow so that the fully grown γ′ precipitates can contact each other and separate or seal off the local γ matrix. The DRX grains in γ matrix cannot penetrate the envelope of γ′ precipitates and undergo significant refinement. Moreover, these large and irregular γ′ precipitates are fragmented into chains during deformation, undergo DRX, and eventually become refined. This is to say, sup-solvus temperature holding (1220 °C for 10 h) followed by extremely slow cooling (0.1 °C min−1) can not only ensure high DRX fraction, but also ensure fine grains of deformed microstructure, which is a recommended pretreatment process.

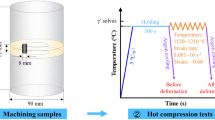

Graphical Abstract

Similar content being viewed by others

References

C. Xu, Z.H. Yao, J.X. Dong, Y.K. Jiang, Rare Met. 38, 642–652 (2019)

M. Ou, Y. Ma, H. Ge, W. Xing, Y. Zhou, S. Zheng, K. Liu, J. Alloys Compd. 735, 193–201 (2018)

L. Tan, Y. Li, F. Liu, Y. Nie, L. Jiang, J. Mater. Sci. Technol. 35, 2591–2599 (2019)

K. Yang, T. An, J. Qu, J. Du, H. Qin, S. Zheng, Z. Bi, Mater. Sci. Eng. A 832, 142459 (2022)

Y. Zhang, X. Li, K. Wei, Z. Wan, C. Jia, T. Wang, Z. Li, Y. Sun, H. Liang, Acta Metall. Sin. 56, 1401–1410 (2020)

X. Xiang, H. Jiang, J. Dong, Z. Yao, Acta Metall. Sin. 56, 988–996 (2020)

Z. Bi, H. Qin, Z. Dong, X. Wang, M. Wang, Y. Liu, J. Du, J. Zhang, Acta Metall. Sin. 55, 1160–1174 (2019)

F. Li, R. Fu, F. Yin, D. Feng, H. Wang, G. Du, Y. Feng, J. Alloys Compd. 693, 1076–1082 (2017)

P.A. Manohar, M. Ferry, T. Chandra, ISIJ Int. 38, 913–924 (1998)

E. Nes, N. Ryum, O. Hunderi, Acta Metall. 33, 11–22 (1985)

Y. Wu, C. Li, X. Xia, H. Liang, Q. Qi, Y. Liu, J. Mater. Sci. Technol. 67, 95–104 (2021)

B. Zhang, G. Zhao, W. Zhang, G. Xu, H. Qin, in Superalloys 2016: Proceedings of the 13th Intenational Symposium of Superalloys, ed. by M. Hardy, E. Huron, U. Glatzel, B. Griffin, B. Lewis, C. Rae, V. Seetharaman, S. Tin (Wiley, Hoboken, 2016), pp. 487–496

X.D. Lu, J.H. Du, Q. Deng, Z.Y. Zhong, J. Alloys Compd. 486, 195–198 (2009)

X.D. Lu, Q. Deng, J.H. Du, J.L. Qu, J.Y. Zhuang, Z.Y. Zhong, J. Alloys Compd. 477, 100–103 (2009)

Z. Liu, W. Liu, H. Zhang, J. Ruan, H. Huang, X. Zhou, F. Meng, S. Zhang, L. Jiang, J. Mater. Res. Technol. 24, 1973–1990 (2023)

C.L. Qiu, P. Andrews, Mater. Charact. 76, 28–34 (2013)

L. Xu, C.Q. Sun, C.Y. Cui, C. Zhang, Mater. Sci. Eng. A 678, 110–115 (2016)

S.L. Semiatin, S.L. Kim, F. Zhang, J.S. Tiley, Metall. Mater. Trans. A 46, 1715–1730 (2015)

H. Wu, Z. Huang, N. Zhou, J. Chen, P. Zhou, L. Jiang, Mater. Sci. Eng. A 739, 473–479 (2019)

S.L. Semiatin, F. Zhang, J.S. Tiley, D.U. Furrer, Mater. High Temp. 33, 301–309 (2016)

V. Randle, B. Ralph, Acta Metall. 34, 891–898 (1986)

A.K. Koul, R. Thamburaj, Metall. Trans. A 16, 17–26 (1985)

A.K. Koul, G.H. Gessinger, Acta Metall. 31, 1061–1069 (1983)

B. Xie, H. Yu, T. Sheng, Y. Xiong, Y. Ning, M.W. Fu, J. Alloys Compd. 803, 16–29 (2019)

M. Winning, G. Gottstein, L.S. Shvindlerman, Mater. Sci. Eng. A 317, 17–20 (2001)

H. Miura, H. Aoyama, T. Sakai, J. Jpn. Inst. Met. 58, 267–275 (1994)

H. Miura, T. Sakai, R. Mogawa, J.J. Jonas, Philos. Mag. 87, 4197–4209 (2007)

Y. Guan, Y. Liu, Z. Ma, H. Li, H. Yu, Met. Mater. Int. 28, 1488–1498 (2022)

P. Liu, R. Zhang, Y. Yuan, C. Cui, F. Liang, X. Liu, Y. Gu, Y. Zhou, X. Sun, J. Mater. Sci. Technol. 77, 66–81 (2021)

D. Feng, X.M. Zhang, S.D. Liu, Y.L. Deng, Mater. Sci. Eng. A 608, 63–72 (2014)

S. Lv, C. Jia, X. He, Z. Wan, Y. Li, X. Qu, Adv. Eng. Mater. 22, 2000622 (2020)

J. Chen, J. Dong, M. Zhang, Z. Yao, Mater. Sci. Eng. A 673, 122–134 (2016)

Y. Wu, Y. Liu, C. Li, X. Xia, J. Wu, H. Li, J. Alloys Compd. 771, 526–533 (2019)

Acknowledgements

Authors acknowledge the financial support by National Natural Science Foundation of China with Grant N.52174303, National Natural Science Foundation of China with Grant N.51874084, Fundamental Research Funds for the Central Universities with Grant N.2125026 and Program of Introducing Talents of Discipline to Universities with Grant N. B21001.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Li, Y., Dong, Y., Jiang, Z. et al. Optimizing the Hot Deformation Microstructure of GH4975 Superalloy by Sup-solvus Temperature Holding Followed by Extremely Slow Cooling. Met. Mater. Int. 30, 1356–1369 (2024). https://doi.org/10.1007/s12540-023-01570-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-023-01570-z