Abstract

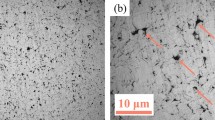

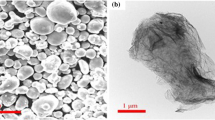

A 0.5 wt% GNP/Al composite was prepared by powder metallurgy and hot pressing. The numerical simulations and experiments of porthole die extrusion were performed at 440 °C, 460 °C, 480 °C and 500 °C. The effect of extrusion temperature on the microstructure and mechanical properties of the composites was studied. The results showed that the composite near the welding zone underwent dynamic recrystallization due to the large strain to form fine grains, some of which grew to coarse grains because of the local high temperature. The extrusion temperature influenced the properties of the 0.5 wt% GNP/Al composite along both the extrusion and transverse directions. This influence is combined with synergistic effects on the recrystallization of the grain, fluidity and plasticity of the matrix, determined by the delamination, distribution and structure of graphene and welding behavior in the welding zone. Therefore, the comprehensive mechanical properties of the composite reached the highest values in the extrusion direction and the transverse direction at 460 °C; the TEM images showed that the graphene and aluminum matrix were in contact with each other via a small wavy transition overlapping zone or that interaction forces caused by welding and shearing allowed the formation of a direct interface with the Al matrix. The deformed graphene formed a good interface with the matrix, ensuring outstanding mechanical properties in the welding zone.

Graphical Abstract

Similar content being viewed by others

References

M. Awad, N.M. Hassan, S. Kannan, Proc. Inst. Mech. Eng. Part B 235, 2093–2107 (2021). https://doi.org/10.1177/09544054211015956

A. Rashid, A. Fahad, Z. Aqib, N.S. Rub, H.T. Naeem, H. Tianbing, S. Muhammad, A. Zahid, S. Attaullah, M. Arshad, B.A. Hasan, J. Alloys Compd. 889, 161531 (2021). https://doi.org/10.1016/j.jallcom.2021.161531

R. Sachin, K. Ratnesh, L. Kunwar, Proc. Inst. Mech. Eng., Part B 235, 1892–1903 (2021). https://doi.org/10.1177/09544054211021341

Y. Mao, J.X. Li, V. Anupam, S.D. Glenn, Mater. Lett. 303, 103549 (2021). https://doi.org/10.1016/j.matlet.2021.130549

W.S. Yang, Q.Q. Zhao, L. Xin, J. Qiao, J.Y. Zou, P.Z. Shao, Z.H. Yu, Q. Zhang, G.H. Wu, J. Alloys Compd. 732, 748–758 (2018). https://doi.org/10.1016/j.jallcom.2017.10.283

X.R. Chen, D.F. Fu, J. Teng, H. Zhang, J. Alloys Compd. 753, 566–575 (2018). https://doi.org/10.1016/j.jallcom.2018.04.223

J.C. Li, X.X. Zhang, L. Geng, Compos. Part A Appl. Sci. Manuf. 121, 487–498 (2019). https://doi.org/10.1016/j.compositesa.2019.04.010

R.V. Kumar, R. Harichandran, U. Vignesh, M. Thangavel, S.B. Chandrasekhar, J. Alloys Compd. 855, 157448 (2021). https://doi.org/10.1016/j.jallcom.2020.157448

M.E. Turan, M. Rashad, H. Zengin, I. Topcu, Y. Sun, M. Asif, J. Mater. Eng. Perform. 29, 5227–5237 (2020). https://doi.org/10.1007/s11665-020-05032-0

Z.H. Yu, W.S. Yang, C. Zhou, N.B. Zhang, Z.L. Chao, H. Liu, Y.F. Cao, Y. Sun, P.Z. Shao, G.H. Wu, Carbon 141, 25–39 (2019). https://doi.org/10.1016/j.carbon.2018.09.041

P.Z. Shao, W.S. Yang, Q. Zhang, Q.Y. Meng, X. Tan, Z.Y. Xiu, J. Qiao, Z.H. Yu, G.H. Wu, Compos. Part A Appl. Sci. Manuf. 109, 151–162 (2018). https://doi.org/10.1016/j.compositesa.2018.03.009

S.M. Lou, A.N. Wang, S. Lu, G.X. Guo, C.D. Qu, C.J. Su, Int. J. Adv. Manuf. Technol. 103, 1309–1323 (2019). https://doi.org/10.1007/s00170-019-03573-w

X. Xu, G.Q. Zhao, Y.X. Wang, X.X. Chen, C.S. Zhang, Vacuum 167, 28–39 (2019). https://doi.org/10.1016/j.vacuum.2019.05.032

W.M. Jiang, J.W. Zhu, G.Y. Li, F. Guan, Y. Yu, Z.T. Fan, J. Mater. Sci. Technol. 88, 119–131 (2021). https://doi.org/10.1016/j.jmst.2021.01.077

J.W. Zhu, W.M. Jiang, G.Y. Li, F. Guan, Z.T. Fan, J. Mater. Process. Technol. 283, 116699 (2020). https://doi.org/10.1016/j.jmatprotec.2020.116699

W.M. Jiang, Z.T. Fan, D.J. Liu, Trans. Nonferr. Met. Soc. China 22, s7–s13 (2012). https://doi.org/10.1016/s1003-6326(12)61676-8

A.J. den Bakker, R.J. Werkhoven, W.H. Sillekens, L. Katgerman, J. Mater. Process. Technol. 214, 2349–2358 (2014). https://doi.org/10.1016/j.jmatprotec.2014.05.001

S.W. Bai, G. Fang, J. Zhou, J. Mater. Process. Technol. 250, 109–120 (2017). https://doi.org/10.1016/j.jmatprotec.2017.07.012

X.H. Fan, D. Tang, W.L. Fang, D.Y. Li, Y.H. Peng, Mater. Charact. 118, 468–480 (2016). https://doi.org/10.1016/j.matchar.2016.06.025

Y. Zhao, B.Y. Song, Z.Y. Yan, X. Zhang, J.Y. Pei, J. Mater. Process. Technol. 235, 149–157 (2016). https://doi.org/10.1016/j.jmatprotec.2016.04.021

J.Q. Yu, G.Q. Zhao, L. Chen, J. Mater. Process. Technol. 230, 153–166 (2016). https://doi.org/10.1016/j.jmatprotec.2015.11.020

J.Q. Yu, G.Q. Zhao, X.T. Zhao, L. Chen, M.M. Chen, J. Mater. Process. Technol. 267, 1–16 (2019). https://doi.org/10.1016/j.jmatprotec.2018.12.006

J.W. Tang, L. Chen, G.Q. Zhao, C.S. Zhang, X.R. Chu, Mater. Sci. Eng. A 773, 138718 (2020). https://doi.org/10.1016/j.msea.2019.138718

S.J. Yan, S.L. Dai, X.Y. Zhang, C. Yang, Q.H. Hong, J.Z. Chen, Z.M. Lin, Mater. Sci. Eng. A 612, 440–444 (2014). https://doi.org/10.1016/j.msea.2014.06.077

P.Z. Shao, G.Q. Chen, B.Y. Ju, W.S. Yang, Q. Zhang, Z.J. Wang, X. Tan, Y.Y. Pei, S.J. Zhong, M. Hussain, G.H. Wu, Carbon 162, 455–464 (2020). https://doi.org/10.1016/j.carbon.2020.02.080

G.H. Wu, Z.H. Yu, L.T. Jiang, C. Zhou, G. Deng, X.B. Deng, Y.Z. Xiao, Carbon 152, 932–945 (2019). https://doi.org/10.1016/j.carbon.2019.06.077

S.M. Lou, B.J. Cheng, Y.Q. Liu, X. Li, X.F. Bai, P. Chen, Y.M. Li, L. Li, J. Mater. Eng. Perform. (2022). https://doi.org/10.1007/s11665-022-07775-4

S.M. Lou, L.W. Ran, Y.Q. Liu, P. Chen, C.J. Su, Q.B. Wang, J. Mater. Eng. Perform. 31, 6533–6544 (2022). https://doi.org/10.1007/s11665-022-06723-6

C.S. Zhang, G.Q. Zhao, Z. Chen, H. Chen, F.J. Kou, Mater. Sci. Eng. B 177, 1691–1697 (2012). https://doi.org/10.1016/j.mseb.2011.09.041

J. Zeng, F.H. Wang, S. Dong, X. Nie, Y. Fan, J. Dong, Metall. Mater. Trans. A 52, 316–331 (2021). https://doi.org/10.1007/s11661-020-06064-w

A.C. Ferrari, D.M. Basko, Nat. Nanotechnol. 8, 235–246 (2013). https://doi.org/10.1038/nnano.2013.46

A.C. Ferrari, Solid State Commun. 143, 47–57 (2007). https://doi.org/10.1016/j.ssc.2007.03.052

A. Gupta, G. Chen, P. Joshi, S. Tadigadapa, P. Eklund, Nano Lett. 6, 2667–2673 (2006). https://doi.org/10.1021/nl061420a

S.E. Shin, Y.J. Ko, D.H. Bae, Compos. Part B Eng. 106, 66–73 (2016). https://doi.org/10.1016/j.compositesb.2016.09.017

T.M.G. Mohiuddin, A. Lombardo, R.R. Nair, A. Bonetti, G. Savini, R. Jalil, N. Bonini, D.M. Basko, C. Galiotis, N. Marzari, K.S. Novoselov, A.K. Geim, A.C. Ferrari, Phys. Rev. B 79(20), 205433 (2009). https://doi.org/10.1103/PhysRevB.79.205433

J. Xu, T. Sun, Y.T. Xu, Q.H. Han, Constr. Build. Mater. 230, 116904 (2020). https://doi.org/10.1016/j.conbuildmat.2019.116904

B.W. Pu, X. Zhang, D.D. Zhao, C.N. He, C.S. Shi, E.Z. Liu, J.W. Sha, N.Q. Zhao, Carbon 183, 530–545 (2021). https://doi.org/10.1016/j.carbon.2021.07.042

R.Q. Han, H.Y. Song, M.R. An, Comput. Mater. Sci. 197, 110604 (2021). https://doi.org/10.1016/j.commatsci.2021.110604

Acknowledgements

This work was financially supported by Key project of the Shandong Provincial Natural Science Foundation, China (ZR2020KE013), National Natural Science Foundation of China (No. 51705295), Shandong Provincial Natural Science Foundation (No. ZR2022ME032), and SDUST Research Fund (No. 2018TDJH101).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Lou, S., Li, Y., Cheng, B. et al. Effects of Extrusion Temperature on the Properties of a 0.5 wt% GNP/Al Composite in Porthole Die Extrusion. Met. Mater. Int. 29, 3607–3617 (2023). https://doi.org/10.1007/s12540-023-01471-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-023-01471-1