Abstract

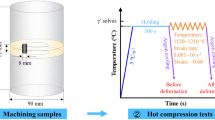

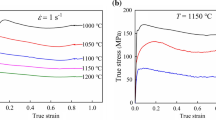

GH3536 nickel-based superalloy was prepared using selective laser melting (SLM) to study its hot deformation behavior, microstructure evolution, and recrystallization mechanism during hot compression. GH3536 superalloy was hot compressed by a Gleeble-3800 hot simulation testing machine. The compression temperature was 900℃~1050℃, and the strain rate was 0.01s− 1~10s− 1. The results show that the deformation conditions will significantly affect the flow stress, dislocation density, and the development of grain boundary and subgrains boundary. The dynamic recrystallization (DRX) mechanism is also easily affected by the deformation conditions and different deformation regions. The alloy has experienced work hardening (WH), dynamic recovery (DRV), and DRX in hot deformation and finally entered the steady-state rheological stage. The dynamic softening effect is more evident at a low strain rate. The temperature will strongly affect the migration of dislocations and limit the transformation from LAGB to HAGB, thus affecting the formation of grain boundaries and finally affecting the DRX mechanism. It is found that DRX is not a single process, and discontinuous dynamic recrystallization (DDRX) and continuous dynamic recrystallization (CDRX) exist at the same time. DDRX is the primary nucleation mechanism characterized by grain boundary expansion. CDRX is an auxiliary nucleation mechanism characterized by gradual rotation of subgrains, and CDRX is easier to activate at low temperatures.

Graphical Abstract

Similar content being viewed by others

References

D. Tomus, P.A. Rometsch, M. Heilmaier, X. Wu, Addit. Manuf. 16, 65–72 (2017)

D. Tomus, T. Jarvis, X. Wu, J. Mei, P. Rometsch, E. Herny, J.F. Rideau, S. Vaillant, Phys. Procedia 41, 823–827 (2013)

E.J. Pickering, H. Mathur, A. Bhowmik, O.M.D.M. Messe, J.S. Barnard, M.C. Hardy, R. Krakow, K. Loehnert, H.J. Stone, C.M.F. Rae, Acta Mater. 60, 2757–2769 (2012)

D. Tomus, Y. Tian, P.A. Rometsch, M. Heilmaier, X. Wu, Mater. Sci. Eng. A 667, 42–53 (2016)

S.V.S. Murty, S. Torizuka, K. Nagai, T. Kitai, Y. Kogo, Scripta Mater. 53, 763–768 (2005)

H.U. Hong, I.S. Kim, B.G. Choi, H.W. Jeong, C.Y. Jo, Mater. Lett. 62, 4351–4353 (2008)

J. Kundin, L. Mushongera, H. Emmerich, Acta Mater. 95, 343–356 (2015)

J. He, J. Dong, M. Zhang, Z. Yao, Mater. Sci. Eng. A 649, 369–381 (2016)

H. Zhang, K. Zhang, H. Zhou, Z. Lu, C. Zhou, X. Yang, Mater. Des. 80, 51–62 (2015)

C.Y. Lin, X.Y. Wu, X.M. Chen, J. Chen, D.X. Wen, Alloys Compd. 640, 101–113 (2015)

S.C. Medeiros, Y.V.R.K. Prasad, W.G. Frazier, R. Srinivasan, Mater. Sci. Eng. A 293, 198–207 (2000)

T. Etter, K. Kunze, F. Geiger, H. Meidani, IOP Conf. Ser. Mater. Sci. Eng. 82, 012097 (2015)

T. Yang, D. Tomus, P. Rometsch, X. Wu, Addit. Manuf. 13, 103–112 (2017)

F. Wang, Int. J. Adv. Manuf. Technol. 58, 545–551 (2012)

B.C. Xie, B.Y. Zhang, H. Yu, H. Yang, Q. Liu, Y.Q. Ning, Mater. Sci. Eng. A 784, 139334 (2020)

P.J. Hurley, F.J. Humphreys, Acta Mater. 51, 1087–1102 (2003)

A.M. Wusatowska-Sarnek, H. Miura, T. Sakai, Mater. Sci. Eng. A 323, 177–186 (2002)

D. Li, Q. Guo, S. Guo, H. Peng, Z. Wu, Mater. Des. 32, 696–705 (2011)

X.M. Chen, Y.C. Lin, D.X. Wen, J.L. Zhang, M. He, Mater. Des. 57, 568–577 (2014)

B.C. Xie, H. Yu, T. Sheng, Y. Xiong, Y.Q. Ning, M.W. Fu, J. Alloys Compd. 803, 16–29 (2019)

M. Haël, Acta Mater. 81, 21–29 (2014)

Y. Wang, W.Z. Shao, L. Zhen, L. Yang, X.M. Zhang, Mater. Sci. Eng. A 497, 479–486 (2008)

O. Sanchez-Mata, J.A. Muiz-Lerma, X. Wang, S.E. Atabay, M. Attarian Shandiz, M. Brochu, Mater. Sci. Eng. A 780, 139177 (2020)

A. Momeni, K. Dehghani, H. Keshmiri, G.R. Ebrahimi, Mater. Sci. Eng. A 527, 1605–1611 (2010)

D. Zhang, N. Wen, X. Cao, Z. Liu, Mater. Sci. Eng. A 644, 32–40 (2015)

D. Jia, W. Sun, D. Xu, F. Liu, J. Mater. Sci. Technol. 35, 1851–1859 (2019)

J.-C. Zhao, M. Larsen, V. Ravikumar, Mater. Sci. Eng. A 293, 112–119 (2000)

C. Zhang, L. Zhang, W. Shen, Q. Xu, Y. Cui, J. Alloys Compd. 728, 1269–1278 (2017)

K. Chen, J. Wu, H. Shi, X. Chen, Z. Shen, M. Zhang, L. Zhang, A. Shan, Mater. Charact. 106, 175–184 (2015)

M.R. Ghandehari Ferdowsi, M. Mazinani, G.R. Ebrahimi, Mater. Sci. Eng. A 606, 214–227 (2014)

N.N. Guo, L. Wang, L.S. Luo, X.Z. Li, R.R. Chen, Y.Q. Su, J.J. Guo, H.Z. Fu, Mater. Sci. Eng. A 651, 698–707 (2016)

Z. Wan, Y. Sun, L. Hu, H. Yu, Mater. Des. 122, 11–20 (2017)

Acknowledgements

The authors are very grateful for the support received from the Nature Science Foundation of Shaanxi (NO. 2021JQ-286), Key Research and Development Plan in Shaanxi Province of China (NO. 2021GY-211) and Fundamental Research Funds for the Central Universities, CHD (No. 300102311403).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Yuan, Z., Wang, S., Zhang, H. et al. Microstructure Evolution and Dynamic Recrystallization Behavior of SLM GH3536 Superalloy During hot Deformation. Met. Mater. Int. 29, 3356–3370 (2023). https://doi.org/10.1007/s12540-023-01446-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-023-01446-2