Abstract

In this research, AA6061-T6 aluminum alloy sheets were successfully lap-joined to St14 low-carbon steel sheets through the friction stir spot welding-brazing method with a pinless tool in the presence of a zinc interlayer. The effects of rotating speed and dwell time on the metallurgical structure and mechanical properties were investigated. It was observed that placing the pinless tool on the steel side melts the zinc interlayer and aluminum base metal and leads to forming different microstructures on both sides of the joint. The achievements demonstrated that the joints had a sound shape, and the maximum tensile-shear failure load (TSFL) obtained for all the joints was more than 4.2 kN. The specimen produced at the rotating speed of 1200 rpm and dwell time of 15 s represented a maximum TSFL and fracture energy of 7.4 kN and 35 J, respectively. Moreover, increasing the intermetallic layer thickness to almost 25 μm improved the TSFL. However, any further thickness growth caused an intense drop in the TSFL. The intermetallic layer, composed of brittle FeAl3 and Fe2Al5 phases, was formed near the Al-Zn alloy interface with a great amount of Al, and this culminated in an expansion of the joint surface. Furthermore, fracture surface analysis indicated the occurrence of a fracture at the interface. Some porosities with an average diameter of 50 to 255 μm were observed for the sample having the maximum heat input at the fracture surface of the aluminum side, which was probably due to the zinc volatilization causing a decrease in the mechanical properties.

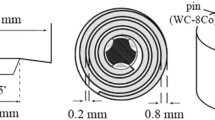

Graphical Abstract

Similar content being viewed by others

Data availability

The raw data required to reproduce these findings cannot be shared at this time as the data also forms part of an ongoing study.

Change history

29 August 2022

A Correction to this paper has been published: https://doi.org/10.1007/s12540-022-01288-4

References

P. Li, S. Chen, H. Dong, H. Ji, Y. Li, X. Guo, G. Yang, X. Zhang, X. Han, J. Manuf. Process. 49, 385 (2020). https://doi.org/10.1016/j.jmapro.2019.09.047

G. Filliard, M. Elmansori, L. Tirado, S. Mezghani, C. Bremont, M. de Metz-Noblat, J. Manuf. Process. 25, 104 (2017). https://doi.org/10.1016/j.jmapro.2016.12.002

R.P. Mahto, S. Anishetty, A. Sarkar, O. Mypati, S.K. Pal, J.D. Majumdar, Met. Mater. Int. 25, 752 (2019). https://doi.org/10.1007/s12540-018-00222-x

N. Kumar, W. Yuan, R.S. Mishra, Friction Stir Welding of Dissimilar Alloys and Materials: A volume in Friction Stir Welding and Processing (Butterworth-Heinemann, Oxford, 2015)

A. Heidarzadeh, S. Mironov, R. Kaibyshev, G. Çam, A. Simar, A. Gerlich, F. Khodabakhshi, A. Mostafaei, D.P. Field, J.D. Robson, A. Deschamps, P.J. Withers, Prog. Mater. Sci. 117, 100752 (2021). https://doi.org/10.1016/j.pmatsci.2020.100752

K.P. Mehta, J. Mater. Res. 34, 78 (2019). https://doi.org/10.1557/jmr.2018.332

R.P. Mahto, R. Kumar, S.K. Pal, Mater. Charact. 160, 110115 (2020). https://doi.org/10.1016/j.matchar.2019.110115

G. Çam, M. Koçak, J. Mater. Sci. 42, 7154 (2007). https://doi.org/10.1007/s10853-007-1604-z

G. Çam, V. Ventzke, J.F. Dos Santos, M. Koçak, G. Jennequin, P. Gonthier-Maurin, Sci. Technol. Weld. Join. 4, 317 (1999). https://doi.org/10.1179/136217199101537941

M.R. Arghavani, M. Movahedi, A.H. Kokabi, Mater. Design 102, 106 (2016). https://doi.org/10.1016/j.matdes.2016.04.033

S. Alaeibehmand, S.E. Mirsalehi, E. Ranjbarnodeh, J. Mater. Res. Technol. 15, 996 (2021). https://doi.org/10.1016/j.jmrt.2021.08.071

B. Rahmatian, K. Dehghani, S.E. Mirsalehi, J. Manuf. Process. 52, 152 (2020). https://doi.org/10.1016/j.jmapro.2020.01.046

G. İpekoğlu, G. Çam, Metall. Mater. Trans. A 45, 3074 (2014). https://doi.org/10.1007/s11661-014-2248-7

G. Çam, G. İpekoğlu, H. Tarık Serindağ, Sci. Technol. Weld. Join. 19, 715 (2014). https://doi.org/10.1179/1362171814Y.0000000247

Y. Bozkurt, S Salman, G. Çam, Sci. Technol. Weld. Join. 18, 337 (2013). https://doi.org/10.1179/1362171813Y.0000000111

N. Kashaev, V. Ventzke, G. Çam, J. Manuf. Process. 36, 571 (2018). https://doi.org/10.1016/j.jmapro.2018.10.005

G. İpekoğlu, S. Erim, B.G. Kıral, G. Çam, Kovove Mater. 51, 155 (2013). https://doi.org/10.4149/km_2013_3_155

B. Bagheri, M. Abbasi, A. Abdollahzadeh, H. Omidvar, Met. Mater. Int. 26, 1562 (2020). https://doi.org/10.1007/s12540-019-00416-x

G. Zhang, L. Zhang, C. Kang, J. Zhang, Mater. Design 94, 502 (2016). https://doi.org/10.1016/j.matdes.2016.01.057

P. Chai, Y. Wang, Met. Mater. Int. 25, 1574 (2019). https://doi.org/10.1007/s12540-019-00291-6

M.R. Akbarpour, A. Mashhuriazar, M. Daryani, Met. Mater. Int. 27, 4074 (2021). https://doi.org/10.1007/s12540-020-00840-4

A.N. Ashong, M. Lee, S.-T. Hong, Y.S. Lee, J.H. Kim, Met. Mater. Int. 27, 639 (2021). https://doi.org/10.1007/s12540-020-00788-5

J.Y. Cao, M. Wang, L. Kong, H.X. Zhao, P. Chai, Mater. Charact. 128, 54 (2017). https://doi.org/10.1016/j.matchar.2017.03.023

H. Moghanni, K. Dehghani, A. Shafiei, J. Mater. Res. Technol. 16, 1069 (2022). https://doi.org/10.1016/j.jmrt.2021.12.050

R.Z. Xu, D.R. Ni, Q. Yang, B.L. Xiao, C.Z. Liu, Z.Y. Ma, Mater. Charact. 140, 197 (2018). https://doi.org/10.1016/j.matchar.2018.04.011

M. Sarkari Khorrami, A.H. Kokabi, M. Movahedi, J. Mater. Eng. Perform. 24, 2158 (2015). https://doi.org/10.1007/s11665-015-1489-y

P. Gao, Y. Zhang, K.P. Mehta, Met. Mater. Int. 27, 3085 (2021). https://doi.org/10.1007/s12540-020-00759-w

B. Kuang, Y. Shen, W. Chen, X. Yao, H. Xu, J. Gao, J. Zhang, Mater. Design 68, 54 (2015). https://doi.org/10.1016/j.matdes.2014.12.008

A. Ebrahimian, A.H. Kokabi, Mater. Design 116, 599 (2017). https://doi.org/10.1016/j.matdes.2016.12.057

J. Yang, Y.L. Li, H. Zhang, W. Guo, Y. Zhou, Mater. Sci. Eng. A 645, 323 (2015). https://doi.org/10.1016/j.msea.2015.08.036

Q. Zheng, X. Feng, Y. Shen, G. Huang, P. Zhao, J. Alloy. Compd. 686, 693 (2016). https://doi.org/10.1016/j.jallcom.2016.06.092

G. Zhang, W. Su, J. Zhang, Z. Wei, Metall. Mater. Trans. A 42, 2850 (2011). https://doi.org/10.1007/s11661-011-0677-0

C. Leitao, E. Arruti, E. Aldanondo, D.M. Rodrigues, Mater. Design 106, 153 (2016). https://doi.org/10.1016/j.matdes.2016.05.101

Z. Zhang, Y. Yu, H. Zhao, X. Wang, Metals 9, 691 (2019). https://doi.org/10.3390/met9060691

H. Zhang, J. Liu, Mater. Sci. Eng. A 528, 6179 (2011). https://doi.org/10.1016/j.msea.2011.04.039

S. Deng, R. Yuan, X. Tang, F. Lu, Mater. Design 188, 108489 (2020). https://doi.org/10.1016/j.msea.2011.04.039

M.-J. Hsieh, R.-T. Lee, Y.-C. Chiou, J. Mater. Process. Tech. 240, 118 (2017). https://doi.org/10.1016/j.jmatprotec.2016.08.034

X. Zhou, Y. Chen, S. Li, Y. Huang, K. Hao, P. Peng, Metals 8, 922 (2018). https://doi.org/10.3390/met8110922

P. Jedrasiak, H.R. Shercliff, A. Reilly, G.J. McShane, Y.C. Chen, L. Wang, J. Robson, P. Prangnell, J. Mater. Eng. Perform. 25, 4089 (2016). https://doi.org/10.1007/s11665-016-2225-y

T. Küçükömeroğlu, S.M. Aktarer, G. İpekoğlu, G. Çam, Mater. Test. 60, 1163 (2018). https://doi.org/10.3139/120.111266

T. Küçükömeroğlu, S.M. Aktarer, G. İpekoğlu, G. Çam, Int. J. Miner. Metall. Mater. 25, 1457 (2018). https://doi.org/10.1007/s12613-018-1700-x

Y. Su, W. Li, X. Wang, T. Ma, L. Ma, X. Dou, Mater. Sci. Eng. A 764, 138251 (2019). https://doi.org/10.1016/j.msea.2019.138251

G. Çam, S. Mistikoglu, M. Pakdil, Weld. J. 88, 225S (2009). https://app.aws.org/wj/supplement/WJ_2009_11_s225.pdf

A. Kapil, T. Lee, A. Vivek, J. Bockbrader, T. Abke, G. Daehn, J. Mater. Process. Tech. 255, 219 (2018). https://doi.org/10.1016/j.jmatprotec.2017.12.012

Y. Liang, J. Shen, S. Hu, H. Wang, J. Pang, J. Mater. Process. Tech. 255, 161 (2018). https://doi.org/10.1016/j.jmatprotec.2017.12.006

Z. Ling, Y. Li, Z. Luo, S. Ao, Z. Yin, Y. Gu, Q. Chen, Int. J. Adv. Manuf. Tech. 92, 1923 (2017). https://doi.org/10.1007/s00170-017-0310-5

K. Prasad Rao, N. Ramanaiah, N. Viswanathan, Mater. Design 29, 179 (2008). https://doi.org/10.1016/j.matdes.2006.10.022

J. Singh, K.S. Arora, D.K. Shukla, J. Mater. Process. Tech. 283, 116728 (2020). https://doi.org/10.1016/j.jmatprotec.2020.116728

G. Huang, X. Feng, Y. Shen, Q. Zheng, P. Zhao, Mater. Design 99, 403 (2016). https://doi.org/10.1016/j.matdes.2016.03.094

R. Cao, J.H. Chang, Q. Huang, X.B. Zhang, Y.J. Yan, J.H. Chen, J. Manuf. Process. 31, 674 (2018). https://doi.org/10.1016/j.jmapro.2018.01.001

L. Shao, Y. Shi, J.K. Huang, S.J. Wu, Mater. Design 66, 453 (2015). https://doi.org/10.1016/j.matdes.2014.06.026

Z. Ding, Q. Hu, W. Lu, X. Ge, S. Cao, S. Sun, T. Yang, M. Xia, J. Li, Mater. Charact. 136, 157 (2018). https://doi.org/10.1016/j.matchar.2017.12.024

S. Bozzi, A.L. Helbert-Etter, T. Baudin, B. Criqui, J.G. Kerbiguet, Mater. Sci. Eng. A 527, 4505 (2010). https://doi.org/10.1016/j.msea.2010.03.097

H. Ma, G. Qin, Z. Ao, L. Wang, J. Mater. Process. Tech. 252, 595 (2018). https://doi.org/10.1016/j.jmatprotec.2017.10.015

G. Qin, Z. Ao, Y. Chen, C. Zhang, P. Geng, J. Mater. Process. Tech. 273, 116255 (2019). https://doi.org/10.1016/j.jmatprotec.2019.116255

I. Hejazi, S.E. Mirsalehi, T. Nonferr. Metal. Soc. China 26, 2313 (2016). https://doi.org/10.1016/S1003-6326(16)64351-0

V. Zohoori-Shoar, A. Eslami, F. Karimzadeh, M. Abbasi-Baharanchi, J. Manuf. Process. 26, 84 (2017). https://doi.org/10.1016/j.jmapro.2017.02.003

F. Hayat, Mater. Sci. Eng. A 556, 834 (2012). https://doi.org/10.1016/j.msea.2012.07.077

G. Mathers, The Welding of Aluminium and Its Alloys (Woodhead Publishing, Sawston, 2002)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

The original online version of this article was revised due to the graphic abstract was appeared in PDF, it should be ignored from the PDF, and the graphic abstract will be available only in XML version.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Moradi, K., Mirsalehi, S.E. Dissimilar Joining of Low-Carbon Steel to 6061-T6 Aluminum Alloy by Novel Method of Pinless Friction Stir Spot Welding-Brazing. Met. Mater. Int. 29, 174–190 (2023). https://doi.org/10.1007/s12540-022-01204-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-022-01204-w