Abstract

The hole expansion formability of W-tempered aluminum 7075 sheet, which is prepared by solution heat treatment and rapid cooling, is investigated comparatively with the peak aged T6 tempered alloy. The W temper heat treatment has been known to be a potential application to cold forming of high strength aluminum including 7075 alloy as an alternative to the warm or hot forming process. The hole expansion tests are designed with a conical punch and the holes are fabricated using wire-cut and punching. Basic mechanical properties and microstructure analyses are performed to study the effect of the strength and ductility in tension on the hole expansion ratios of specimens with different tempers and hole conditions. From the experimental study, the following conclusions are mainly reached. (1) The W-tempered sheets show much improved HER than T6 tempered sheets; i.e., 31 (T6) vs. 58% (W) for wire-cut hole and 19 (T6) vs. 57% (W) for punched hole. (2) The HER of W-tempered sheets show very similar HER values between wire-cut and punched hole specimens, which has not been commonly reported. (3) The initiation of cracks at hole edges is different depending on hole preparation; i.e., RD or TD (wire-cut T6 and wire-cut and punched W) vs. RD, DD, and TD (punched T6). (4) The KAM map validates the cause of lower HER of punched specimen attributes to earlier crack initiation by prior plastic deformation during punching, but the strengthening of shear affected zone has limited effect on HER. (5) The HERs of T6 and W tempered sheets are well correlated to the yield strength, ultimate tensile strength, and total elongation. However, the effect of post uniform elongation on HER is not correlated to the existing report.

Graphical Abstract

Similar content being viewed by others

Change history

18 March 2023

A Correction to this paper has been published: https://doi.org/10.1007/s12540-023-01412-y

References

A. Smeyers, B. Schepers, W. Braunschweig, A. Burger, K. Vieregge, S. Khosla, A. Wise, 7xxx Grades for Automotive Applications. Alum. Int. Today 23, 37 (2011)

T. Dursun, C. Soutis, Recent developments in advanced aircraft aluminium alloys. Mater. Design 56, 862 (2014)

E.A. Starke, J.T. Staley, Application of modern aluminum alloys to aircraft. Prog Aerosp. Sci. 32, 131 (1996)

W. Gan, H.J. Bong, H. Lim, R.K. Boger, F. Barlat, R.H. Wagoner, Mechanism of the Bauschinger effect in Al-Ge-Si alloys. Mater. Sci. Eng. A 684, 353 (2017)

N. Lutsey, Cost-Effectiveness Assessment of Low-Carbon Vehicle and Fuel Technologies. Transport. Res. Rec. 2191, 90 (2010)

M. Kumar, G. Kirov, F. Grabner, E. Mukeli, Sheet forming processes for AW-7xxx alloys: Relevant process parameters. Mater. Sci. Forum 879, 1036 (2016)

H. Wang, Y.B. Luo, P. Friedman, M.H. Chen, L. Gao, Warm forming behavior of high strength aluminum alloy AA7075. T. Nonferr. Metal. Soc. China 22, 1 (2012)

H. Karbasian, A.E. Tekkaya, A review on hot stamping. J. Mater. Process. Tech. 210, 2103 (2010)

N.R. Harrison, S.G. Luckey, Hot Stamping of a B-Pillar Outer from High Strength Aluminum Sheet AA7075. SAE. Int. J. Mater. Manf. 7, 567 (2014)

M.R. Rokni, A. Zarei-Hanzaki, A.A. Roostaei, H.R. Abedi, An investigation into the hot deformation characteristics of 7075 aluminum alloy. Mater. Design 32, 2339 (2011)

E. Romhanji, M. Popović, D. Glišić, M. Stefanović, M. Milovanović, On the {Al-Mg} alloy sheets for automotive application: problems and solutions. Metalurgija 10, 205 (2004)

K. Zheng, D.J. Politis, L. Wang, J. Lin, A review on forming techniques for manufacturing lightweight complex?shaped aluminium panel components. Int. J. Lightweight Mater. Manuf. 1, 55 (2018)

O.N. Senkov, M.R. Shagiev, S.V. Senkova, D.B. Miracle, Precipitation of Al3(Sc,Zr) particles in an Al-Zn-Mg-Cu-Sc-Zr alloy during conventional solution heat treatment and its effect on tensile properties. Acta Mater. 56, 3723 (2008)

M. Kumar, N.G. Ross, Influence of temper on the performance of a high-trength Al-Zn-Mg alloy sheet in the warm forming processing chain. J. Mater. Process. Tech. 231, 189 (2016)

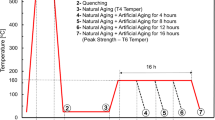

Y. Choi, J. Lee, S.S. Panicker, H.-K. Jin, S.K. Panda, M.-G. Lee, Mechanical properties, springback, and formability of W-temper and peak aged 7075 aluminum alloy sheets: Experiments and modeling. Int. J. Mech. Sci. 170, 105344 (2020)

C. Moon, S. Thuillier, J. Lee, M.-G. Lee, Mechanical properties of solution heat treated Al-Zn-Mg-Cu (7075) alloy under different cooling conditions: Analysis with full field measurement and finite element modeling. J. Alloy. Compd. 856, 158180 (2021)

A. Portevin, F. Le Chatelier, C. R. Hebd. Acad. Sci. 176, 507 (1923)

F. Savart, Ann. Chim. Phys. 65, 337 (1837)

A.P. Masson, Ann. Chim. Phys. (Troisième Série) 3, 451 (1841)

P.G. McCormick, The {Portevin-Le Chatelier} effect in a pressurized low carbon steel. Acta Metall. 21, 873 (1973)

S.H. van den Brink, A. van den Beukel, P.G. McCormick, Strain rate sensitivity and the {Portevin-Le Chatelier} effect in {Au-Cu} alloys. Phys. Status Solidi A 30, 469 (1975)

A.H. Cottrell, B.A. Bilby, Proc. Phys. Soc. A 62, 49 (1949)

H. Halim, D.S. Wilkinson, M. Niewczas, The Portevin?Le Chatelier (PLC) effect and shear band formation in an AA5754 alloy. Acta Mater. 55, 4151 (2007)

J. Kang, D.S. Wilkinson, M. Jain, J.D. Embury, A.J. Beaudoin, S. Kim, R. Mishira, A.K. Sachdev, On the sequence of inhomogeneous deformation processes occurring during tensile deformation of strip cast AA5754. Acta Mater. 54, 209 (2006)

G.I. Taylor, The formation and enlargement of a circular hole in a thin plastic sheet. Q. J. Mech. Appl. Math. 1, 103 (1948)

Z. Cui, L. Gao, Studies on hole-flanging process using multistage incremental forming. CIRP J. Manuf. Sci. Technol. 2, 124 (2010)

G. Centeno, M.B. Silva, V.A.M. Cristino, C. Vallellano, P.A.F. Martins, Hole-flanging by incremental sheet forming. Int. J. Mach. Tools Manuf. 59, 46 (2012)

S.K. Paul, A critical review on hole expansion ratio. Materialia 9, 100566 (2020)

K. Prasad, B. Venkatesh, H. Krishnaswamy, D.K. Banerjee, U. Chakkingal, On the interplay of friction and stress relaxation to improve stretch-flangeability of dual phase (DP600) steel. CIRP J. Manuf. Sci. Technol. 32, 154 (2021)

Y. Yamada, M. Koide, Analysis of the bore-expanding test by the incremental theory of plasticity. Int. J. Mech. Sci. 10, 1 (1968)

S. Sadagopan, D. Urban, C. Wong, M. Huang, B. Yan, Technical Report, DE-FC07-97ID13554 (U.S. Department of Energy, Washington, 2003)

S.K. Paul, J. Mater. Non-linear correlation between uniaxial tensile properties and shear-edge hole expansion ratio. Eng. Perform. 23, 3610 (2014)

X. Chen, H. Jiang, Z. Cui, C. Lian, C. Lu, Procedia Engineer. 81, 718 (2014)

N.M. Wang, M.L. Wenner, An analytical and experimental study of stretch flanging. Int. J. Mech. Sci. 16, 135 (1974)

L. Chen, J.-K. Kim, S.-K. Kim, G.-S. Kim, K.-G. Chin, B.C. De Cooman, Stretch-flangeability of high Mn TWIP steel. Steel Res. Int. 81, 552 (2010)

J.H. Kim, E.J. Seo, M.-H. Kwon, S. Kang, B.C. De Cooman, Effect of quenching temperature on stretch flangeability of a medium Mn steel processed by quenching and partitioning. Mater. Sci. Eng. A 729, 276 (2018)

N. Pathak, C. Butcher, M. Worswick, Assessment of the critical parameters influencing the edge stretchability of advanced high-strength steel sheet. J. Mater. Eng. Perform. 25, 4919 (2016)

P. Larour, J. Freudenthaler, M. Kerschbaum, D. Dolzer, Edge crack sensitivity versus tensile local ductility of AHSS sheet steels. IOP Conf. Ser. Mater. Sci. Eng. 967, 012080 (2020)

J.I. Yoon, J. Jung, H.H. Lee, G.-S. Kim, H.S. Kim, Factors governing hole expansion ratio of steel sheets with smooth sheared edge. Met. Mater. Int. 22, 1009 (2016)

J. Lee, S.-J. Lee, B.C. De Cooman, Effect of micro-alloying elements on the stretch-flangeability of dual phase steel. Mater. Sci. Eng. A 536, 231 (2012)

S.K. Paul, P. I. Mech. Eng. B J. Eng. Manuf. 234, 671 (2020)

J.I. Yoon, J. Jung, J.G. Kim, S.S. Sohn, S. Lee, H.S. Kim, Fracture Toughness to Understand Stretch-Flangeability and Edge Cracking Resistance in AHSS. J. Mater. Sci. 52, 7808 (2017)

D. Casellas, A. Lara, D. Frómeta, D. Gutiérrez, S. Molas, L. Pérez, J. Rehrl, C. Suppan, Key factors of stretch-flangeability of sheet materials. Metall. Mater. Trans. A 48, 86 (2017)

S.K. Paul, M. Mukherjee, S. Kundu, S. Chandra, Prediction of hole expansion ratio for automotive grade steels. Comp. Mater. Sci. 89, 189 (2014)

Y. Choi, J. Ha, M.-G. Lee, Y.P. Korkolis, Effect of plastic anisotropy and Portevin-Le Chatelier bands on hole-expansion in AA7075 sheets in -T6 and -W tempers. J. Mater. Process. Tech. 296, 117211 (2021)

A. Karelova, C. Krempaszky, E. Werner, P. Tsipouridis, T. Hebesberger, A. Pichler, Hole expansion of dual-phase and complex-phase AHS steels - Effect of edge conditions. Steel Res. Int. 80, 71 (2009)

Y.K. Ko, J.S. Lee, H. Huh, H.K. Kim, S.H. Park, Prediction of fracture in hubhole expanding process using a new ductile fracture criterion. J. Mater. Process. Tech. 187-188, 358 (2007)

A. Konieczny, T. Henderson, On formability limitations in stamping involving sheared edge stretching. SAE Transactions 116, 20 (2007)

K. Wang, L. Greve, T. Wierzbicki, FE simulation of edge fracture considering pre-damage from blanking process. Int. J. Solids Struct. 71, 206 (2015)

Y. Choi, C. Moon, M.-G. Lee, Experimental study on the mechanical properties of 7xxx aluminium alloy sheet under different heat treatment conditions. IOP. Conf. Ser. Mater. Sci. Eng. 651, 012080 (2019)

J. Lee, H.J. Bong, D. Kim, Y.-S. Lee, Y. Choi, M.-G. Lee, Mechanical properties and formability of heat-treated 7000-series high-strength aluminum alloy: experiments and finite element modeling. Met. Mater. Int. 26, 682 (2020)

G. Peng, K. Chen, S. Chen, H. Fang, Evolution of the second phase particles during the heating-up process of solution treatment of Al?Zn?Mg?Cu alloy. Mater. Sci. Eng. A 641, 237 (2015)

Y.-W. Kim, Y.-H. Jo, Y.-S. Lee, H.-W. Kim, J.-I. Lee, Effect of dissolution of η’ precipitates on mechanical properties of A7075-T6 Alloy. Korean J. Met. Mater. 60, 83 (2022)

O.R. Terrazas, Correlation of microstructure, tensile properties and hole expansion ratio in cold rolled advanced high strength steels, M.S. Thesis, Colorado School of Mines (2016)

J. Lee, H.J. Bong, D. Kim, Y.-S. Lee, Y. Choi, M.-G. Lee, Application of Combined W-Temper and Cold Forming Technology to High-Strength Aluminum Alloy Automotive Parts. JOM 71, 4393 (2019)

K. Mori, Y. Abe, Y. Suzui, Improvement of stretch flangeability of ultra high strength steel sheet by smoothing of sheared edge. J. Mater. Process. Tech. 210, 653 (2010)

M. Madrid, C.J. Van Tyne, S. Sadagopan, E.J. Pavlina, J. Hu, K.D. Clarke, Effects of testing method on stretch-flangeability of dual-phase 980/1180 steel grades. JOM 70, 918 (2018)

V. Kumar Barnwal, S.-Y. Lee, S.-Y. Yoon, J.-H. Kim, F. Barlat, Fracture characteristics of advanced high strength steels during hole expansion test. Int. J. Fracture 224, 217 (2020)

J.W. Hutchinson, K.W. Neale, Influence of strain-rate sensitivity on necking under uniaxial tensio. Acta Metall. 25, 839 (1977)

A.K. Ghosh, Strain localization in the diffuse neck in sheet metal. Metall. Mater. Tran. B 5, 1607 (1974)

T.K. Eller, L. Greve, M. Andres, M. Medricky, V.T. Meinders, A.H. van den Boogaard, Determination of strain hardening parameters of tailor hardened boron steel up to high strains using inverse FEM optimization and strain field matching. J. Mater. Process. Tech. 228, 43 (2016)

K. Ishikawa, Fractals in dimple patterns of ductile fracture. J. Mater. Sci. Lett. 9, 400 (1990)

Acknowledgements

The authors sincerely acknowledge the assistance of Siwook Park, Woojin Cho, and Jongbeom Kim for experiments at SNU. MGL appreciates the partial support by KEIT (No. 20010717) and the Institute of Engineering Research at Seoul National University. JWL and HJB appreciate the partial support by the Fundamental Research Program of the Korea Institute of Materials Science (KIMS, PNK8440).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

The original online version of this article was revised due to the graphic abstract was missing and it has been updated.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Choi, Y., Lee, J., Bong, H. et al. Hole Expansion Characteristics of W-Tempered 7075 Aluminum Alloy Sheet in Comparison with Peak Aged T6 Tempered Alloy Sheet. Met. Mater. Int. 29, 157–167 (2023). https://doi.org/10.1007/s12540-022-01201-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-022-01201-z