Abstract

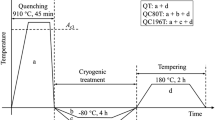

In the present paper, microstructural evolutions and its effect on the mechanical properties of IN617 were investigated in as-received and worked conditions. Worked samples had been operated at 800 °C, under average working stress for operating times of 65,000 and 98,000 h. The different phases were extracted by phase extraction methods. The OM, SEM, TEM, XRD, hardness, impact, stress rupture and tensile tests are used to investigate the microstructure and mechanical properties of operated alloys. The main phases in the specimens are M23C6 and M6C carbides and Ti(C,N) compounds. In addition to these three compounds, γ' phase was also observed in both samples, despite the long operating time; although its volume fraction in the second sample (98,000 h) was less than the first sample (65,000 h). A very small amount of δ phase, topologically closed packed phase, was also detected in the samples. With increasing operating time, the area fraction of carbides increased from 0.5% in the as-received plate to 5.5% in the 98,000 h specimen. Unlike M23C6 carbide, which has an increasing trend with operating time, M6C carbide decreased from 25.7% in the 65,000 h sample to 18.7% in the 98,000 h sample. This decrease is attributed to the M6C + M′ → M23C6 + M′′ reaction. The observed phases are in the form of plate shape, quasi-spherical and irregular and their dimensions increase with increasing operating time. The hardness and strength values are higher in the 65,000 h sample than both the 98,000 h sample and the as-received plate. However these values in the 98,000 h are higher than as-received plate.

Graphical abstract

Similar content being viewed by others

References

S. Chomette, J.M. Gentzbittel, B. Viguier, J. Nucl. Mater. 399, 266 (2010)

T.S. Jo, S.-H. Kim, D.-G. Kim, J.Y. Park, Y.D. Kim, Met. Mater. Int. 14, 739 (2008)

S.F. Di Martino, R.G. Faulkner, S.C. Hogg, S. Vujic, O. Tassa, Mater. Sci. Eng. A 619, 77 (2014)

X. Xiang, Z. Yao, J. Dong, L. Sun, J. Alloy. Compd. 787, 216 (2019)

Y. Yuan, Z.H. Zhong, Z.S. Yu, H.F. Yin, Y.Y. Dang, X.B. Zhao, Z. Yang, J.T. Lu, J.B. Yan, Y. Gu, Met. Mater. Int. 21, 659 (2015)

D. Tytko, P.-P. Choi, J. Klower, A. Kostka, G. Inden, D. Raabe, Acta Mater. 60, 1731 (2012)

Y. Zhao, H. Yao, X. Song, J. Jia, Z. Xiang, Met. Mater. Int. 24, 51 (2018)

M. Speicher, F. Kauffmann, J.-H. Shim, M. Chandran, Mater. Sci. Eng. A 711, 165 (2018)

F. Abe, Engineering 1, 211 (2015)

M. Akbari-Garakani, M. Mehdizadeh, Mater. Design 32, 2695 (2011)

W.L. Mankins, J.C. Hosier, T.H. Bassford, Metall. Mater. Trans. B 5, 2579 (1974)

R. Krishna, S.V. Hainsworth, S.P.A. Gill, A. Strang, H.V. Atkinson, Metall. Mater. Trans. A 44, 1419 (2013)

Q. Wu, H. Song, R.W. Swindeman, J.P. Shingledecker, V.K. Vasudevan, Metall. Mater. Trans. A 39, 2569 (2008)

M. Cabibbo, E. Gariboldi, S. Spigarelli, D. Ripamonti, J. Mater. Sci. 43, 2912 (2008)

S. Kihara, J.B. Newkirk, A. Ohtomo, Y. Saiga, Metall. Trans. A 11, 1019 (1980)

H.W. Jeong, S.M. Seo, B.G. Choi, Y.S. Yoo, Y.K. Ahn, J.H. Lee, Met. Mater. Int. 19, 917 (2013)

R. Krishna, S.V. Hainsworth, H.V. Atkinson, A. Strang, Mater. Sci. Technol. 26, 797 (2010)

Jill K. Wright and Thomas M. Lillo, Idaho National Laboratory (2015). http://www.inl.gov

J. Benz, T. Lillo and R. Wright, Idaho National Laboratory, Materials Science and Engineering (2013). http://www.inl.gov

P.J. Ennis, A. Strang, S.P. Gill, G.M. McColvin, H.V. Atkinson, Energy Mater. 4, 184 (2009)

J.D. Whittenberge, J. Mater. Eng. Perform. 2, 745 (1993)

R. Krishna, H.V. Atkison, S.V. Hainsworth, S.P. Gill, Metall. Mater. Trans. A 47, 178 (2016)

W.-G. Kim, I.M.W. Ekaputra, J.-Y. Park, M.-H. Kim, Y.-W. Kim, Nucl. Eng. Des. 306, 177 (2016)

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors have no conflicts of interest to declare. All co-authors have seen and agree with the contents of the manuscript and there is no financial interest to report.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Mehdizadeh, M., Farhangi, H. Investigation of Microstructural Evolution and Mechanical Properties of IN617 Superalloy During Long-Term Operating at High Temperature. Met. Mater. Int. 28, 2719–2734 (2022). https://doi.org/10.1007/s12540-022-01174-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-022-01174-z