Abstract

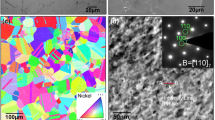

A new Ni-Fe-based superalloy, HT-X, has been developed for applications in 700 °C advanced ultra-supercritical (A-USC) boilers. The HT-X alloy is subjected to various heat treatments. Tensile tests are conducted at room temperature (RT), 700 °C and 750 °C. Creep tests are carried out under conditions of 700 °C/300 MPa and 750 °C/150 MPa. After aging treatment, the yield strength of the HT-X alloy at RT and 750 °C is 787 MPa and 624 MPa, respectively. When additional thermal exposure at 750 °C for 5400 h is applied, the yield strength is decreased to 656 MPa at RT and 480 MPa at 700 °C. For an aged specimen, the a/2<110>dislocation shearing process occurs when tensile testing is conducted at RT and 750 °C. As the γ’ precipitate size increases in the specimen that is thermally exposed at 750 °C for 5400 h, Orowan bowing is the dominant dislocation process, and stacking faults develop in the γ’ precipitates at both RT and 700 °C. Dislocation slip combined with climb is the dominant mechanism under the creep testing conditions. The factors that affect the mechanical properties and deformation mechanisms are discussed.

Similar content being viewed by others

References

C. G. Stolzenberger, Energy Mater. 2, 141 (2007).

S. Z. Li, Z. Eliniyaz, L. T. Zhang, F. Sun, Y. Z. Shen, and A. D. Shan, Mater. Charact. 73, 144 (2012).

D. B. Park, S. M. Hong, K. H. Lee, M. Y. Huh, J. Y. Suh, S. C. Lee, and W. S. Jung, Mater. Charact. 93, 52 (2014).

G. S. Shin, J. Y. Yun, M. C. Park, and S. J. Kim, Mater. Charact. 95, 180 (2014).

R. Viswanathan, K. Coleman, and U. Rao, Int. J. Press. Vessel. Pip. 83, 778 (2006).

N. D. Evans, P. J. Maziasz, R. W. Swindeman, and G. D. Smith, Scr. Mater. 51, 503 (2004).

Y. Chong, Z. D. Liu, G. Andy, W. Liu, and Y. Q. Weng, Mater. Sci. Eng. A 589, 153 (2014).

Q. Y. Wu, H. J. Song, R. W. Swindeman, J. P. Shingledecker, and V. K. Vasudevan, Metall. Mater. Trans. A 39, 2569 (2008).

R. Krishna, S. V. Hainsworth, H. V. Atkinson, and A. Strang, Mater. Sci. Technol. 26, 797 (2010).

M. Akbari-Garakani and M. Mehdizadeh, Mater. Des. 32, 2695 (2011).

P. S. Weitzel, J. M. Tanzosh, B. Boring, N. Okita, T. Takahashi, and N. Ishikawa, Advanced Ultra-supercritical Power Plant (700 to 760C) Design for Indian Coal, http://www.babcock. com/library/documents/br-1884.pdf (accessed December 5, 2014).

L. G. Klingensmith, Proceedings of the 4th Symposium on Heat Resistant Steels and Alloys for High Efficiency USC Power Plants, pp.307–321, China (2011).

J. P. Shingledecker and N. D. Evans, Intl. J. Press. Vessel Pip. 87, 345 (2010).

H. Semba, H. Okada, T. Hamagushi, S. Ishikawa, and M. Yoshizawa, Technical Report of Nippon Steel & Sumitomo Metal 397, 71 (2013).

T. T. Wang, C. S. Wang, J. T. Guo, and L. Z. Zhou, Mater. Sci. Forum 747–748, 647 (2013).

Y. Yuan, Z. H. Zhong, Z. S. Yu, H. F. Yin, Y. Y. Dang, X. B. Zhao, Z. Yang, J. T. Lu, J. B. Yan, and Y. Gu, Mater. Sci. Eng. A 619, 364 (2014).

Y. F. Gu, Y. Yuan, X. B. Zhao, J. T. Lu, J. B. Yan, Y. Y. Dang, Z. Yang, H. Y. Yin, and C. X. Fan, Proc. of APEC Expert Workshop on Innovative Systemic Approaches to Enhancing Coal-Fired Power Generation Efficiency (eds. Z. X. Wang, F. Wang), p.175, China Energy Research Society, China (2015).

J. T. Guo and X. K. Du, Acta Metall. Sinica 41, 1221 (2005).

M. Lifshitz and V. V. Slyozov, J. Phys. Chem. Solids 19, 35 (1961).

C. Wagner, Z. Elektrochem. 65, 581 (1961).

B. Reppich, Acta Metall. 30, 87 (1982).

B. Reppich, P. Schepp, and G. Wehner, Acta Metall. 30, 95 (1982).

K. Gopinath, A. K. Gogia, S. V. Kamat, R. Balamuralikrishnan, and U. Ramamurty, Metall. Mater. Trans. A 39, 2340 (2008).

Y. Yuan, Y. F. Gu, T. Osada, Z. H. Zhong, T. Yokokawa, and H. Harada, Scr. Mater. 67, 137 (2012).

R. R. Unocic, G. B. Viswanathan, P. M. Sarosi, S. Karthikeyan, J. Li, and M. J. Mills, Mater. Sci. Eng. A 483–484, 25 (2008).

G. B. Viswanathan, P. M. Sarosi, M. F. Henry, D. D. Whitis, W. W. Milligan, and M. J. Mills, Acta Mater. 53, 3041 (2005).

S. Raujol, M. Benyoucef, D. Locq, P. Caron, F. Pettinari, N. Clement, and A. Coujou, Philos. Mag. 86, 1189 (2006).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Yuan, Y., Zhong, Z.H., Yu, Z.S. et al. Tensile and creep deformation of a newly developed Ni-Fe-based superalloy for 700 °C advanced ultra-supercritical boiler applications. Met. Mater. Int. 21, 659–665 (2015). https://doi.org/10.1007/s12540-015-4627-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-015-4627-z