Abstract

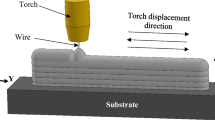

Wire plus arc additive manufacturing (WAAM) technology is utilized to fabricate a 347 stainless steel (SS347) plate using the gas metal arc welding process. The tensile properties of the WAAM plate revealed enhanced strength in comparison with the wrought alloy SS347. The microhardness and the ferrite measurement along the building direction (BD) were in the range of 265–226 HV0.5 and 2.2–5.1 FN (Ferrite number), respectively. The microstructural features were comprehensively examined using electron backscatter diffraction (EBSD) analysis and the Inverse pole figure (IPF) maps revealed a strong <001> texture along the BD. Also, well-aligned equiaxed and columnar dendrites with a lower fraction of niobium carbide (NbC) was noticed in the microstructures of the as-built WAAM plate. A three-dimensional finite element model was developed to simulate the build-up of a WAAM plate. Goldak heat source is used to model heat flux in thermal analysis, and the temperature distributions were predicted. Further, residual stress and plastic strain distributions were examined at various stages of the WAAM process.

Graphic Abstract

source model: a Schematic illustration, and b FE analysis

source comparison between experimental and FE analysis: a during the deposition, and b the cooling phase

Similar content being viewed by others

References

D.S. Choi, S.H. Lee, B.S. Shin, K.H. Whang, Y.A. Song, S.H. Park, H.S. Jee, J. Mater. Process. Tech. 113, 273 (2001)

N. Jeyaprakash, C.H. Yang, K.R. Ramkumar, Met. Mater. Int. (2021). https://doi.org/10.1007/s12540-020-00933-0

E. Karayel, Y. Bozkurt, J. Mater. Res. Technol. 9, 11424 (2020)

Y. Ma, D. Cuiuri, C. Shen, H. Li, Z. Pan, Addit. Manuf. 8, 71 (2015)

K. Benarji, Y.R. Kumar, A.N. Jinoop, C.P. Paul, K.S. Bindra, Met. Mater. Int. 27, 488 (2021)

T.A. Rodrigues, V.R. Duarte, D. Tomás, J.A. Avila, J.D. Escobar, E. Rossinyol, N. Schell, T.G. Santos, J.P. Oliveira, Addit. Manuf. 34, 101200 (2020)

J.G. Lopes, C.M. Machado, V.R. Duarte, T.A. Rodrigues, T.G. Santos, J.P. Oliveira, J. Manuf. Process. 59, 739 (2020)

Z. Zeng, B.Q. Cong, J.P. Oliveira, W.C. Ke, N. Schell, B. Peng, Z.W. Qi, F.G. Ge, W. Zhang, S.S. Ao, Addit. Manuf. 32, 101051 (2020)

X. Bai, P. Colegrove, J. Ding, X. Zhou, C. Diao, P. Bridgeman, J.R. Hönnige, H. Zhang, S. Williams, Int. J. Heat Mass Tran. 124, 504 (2018)

D. Ding, Z. Pan, D. Cuiuri, H. Li, Int. J. Adv. Manuf. Tech. 81, 465 (2015)

J. Xiong, G. Zhang, J. Mater. Process. Tech. 214, 962 (2014)

B. Parvaresh, R. Salehan, R. Miresmaeili, Met. Mater. Int. 27, 92 (2021)

C.V. Haden, G. Zeng, F.M. Carter III., C. Ruhl, B.A. Krick, D.G. Harlow, Addit. Manuf. 16, 115 (2017)

C. Shen, Z. Pan, Y. Ma, D. Cuiuri, H. Li, Addit. Manuf. 7, 20 (2015)

J.P. Oliveira, T.G. Santos, R.M. Miranda, Prog. Mater. Sci. 107, 100590 (2020)

F. Wang, S. Williams, M. Rush, Int. J. Adv. Manuf. Tech. 57, 597 (2011)

L. Ren, H. Gu, W. Wang, S. Wang, C. Li, Z. Wang, Y. Zhai, P. Ma, Met. Mater. Int. 27, 68 (2021)

H.J. Yi, J.W. Kim, Y.L. Kim, S. Shin, Met. Mater. Int. 26, 1235 (2020)

R.B. Song, J.Y. Xiang, D.P. Hou, J. Iron Steel Res. Int. 18, 53 (2011)

B. Senior, Mater. Sci. Eng. 100, 219 (1988)

S. Suryakumar, K.P. Karunakaran, U. Chandrasekhar, M.A. Somashekara, P. I. Mech. Eng. B J. Eng. 227, 1138 (2013)

W. Jin, C. Zhang, S. Jin, Y. Tian, D. Wellmann, W. Liu, Appl. Sci. 10, 1563 (2020)

A.R. Kannan, S.M. Kumar, R. Pramod, N.P. Kumar, N.S. Shanmugam, Y. Palguna, Sci. Technol. Weld. Joi. 26, 47 (2020)

J. Ge, T. Ma, W. Han, T. Yuan, T. Jin, H. Fu, R. Xiao, Y. Lei, J. Lin, Appl. Therm. Eng. 163, 114335 (2019)

H. Zhao, G. Zhang, Z. Yin, L. Wu, J. Mater. Process. Tech. 211, 488 (2011)

M. Saadatmand, R. Talemi, Frat. ed Integrita Strutt. 14, 98 (2020)

S.N. Ahmad, Y.HP. Manurung, M.F. Mat, Z. Minggu, A. Jaffar, S. Pruller, M. Leitner, IOP Conf. Ser. Mat. Sci. 834, 012083 (2020)

M.A. Somashekara, M. Naveenkumar, A. Kumar, C. Viswanath, S. Simhambhatla, Int. J. Adv. Manuf. Tech. 90, 2009 (2017)

R. Pramod, S.M. Kumar, B. Girinath, A.R. Kannan, N.P. Kumar, N.S. Shanmugam, Weld. World. 64, 1905 (2020)

A.H. Nickel, D.M. Barnett, F.B. Prinz, Mater. Sci. Eng. A 317, 59 (2001)

P. Michaleris, Finite Elem. Anal. Des. 86, 51 (2014)

F. Montevecchi, G. Venturini, A. Scippa, G. Campatelli, Procedia CIRP 55, 109 (2016)

J. Goldak, A. Chakravarti, M. Bibby, Metall. Trans. B 15, 299 (1984)

R. Tangestani, G.H. Farrahi, M. Shishegar, B.P. Aghchehkandi, S. Ganguly, A. Mehmanparast, J. Mater. Eng. Perform. 29, 2073 (2020)

J. Ding, P. Colegrove, J. Mehnen, S. Ganguly, P.M. Sequeira Almeida, F. Wang, S. Williams, Comp. Mater. Sci. 50, 3315 (2011)

W. Kim, K.S. Kim, H. Lee, K. Yoo, J. Mech. Sci. Technol. 30, 1773 (2016)

P. Kyvelou, H. Slack, D.D. Mountanou, M.A. Wadee, T.B. Britton, C. Buchanan, L. Gardner, Mater. Design 192, 108675 (2020)

A.V. Jebaraj, L.A. Kumar, C.R. Deepak, Procedia Eng. 173, 883 (2017)

S.M. Kumar, N.S. Shanmugam, Mater. Res. Express 5, 106524 (2018)

ASTM A240 / A240M - 20a, Standard specification for Chromium and Chromium-Nickel stainless steel plate, sheet, and strip for pressure vessels and for general applications (ASTM International, West Conshohocken, 2020)

H.K.D.H. Bhadeshia, in Mathematical Modelling of Weld Phenomena 2, ed. by H. Cerjak, H. Bhadeshia. Possible effects of stress on steel weld microstructures (Institute of Materials, London, 1995), p. 71

Z. Wang, T.A. Palmer, A.M. Beese, Acta Mater. 110, 226 (2016)

B.E. Carroll, T.A. Palmer, A.M. Beese, Acta Mater. 87, 309 (2015)

S.M. Kumar, S. Sankarapandian, N.S. Shanmugam, J. Braz. Soc. Mech. Sci. 42, 292 (2020)

V. Manvatkar, A. De, T. DebRoy, Mater. Sci. Technol. 31, 924 (2015)

K. Zhang, S. Wang, W. Liu, X. Shang, Mater. Design 55, 104 (2014)

X. Wu, Mater. Sci. Technol. 23, 631 (2007)

Z. Sun, X. Tan, S.B. Tor, C.K. Chua, NPG Asia Mater. 10, 127 (2018)

S. Kou, Welding Metallurgy, 3rd edn. (Wiley, Hoboken, 2020), pp. 172–177

J.P. Oliveira, T.M. Curado, Z. Zeng, J.G. Lopes, E. Rossinyol, J.M. Park, N. Schell, F.M. Braz Fernandes, H.S. Kim, Mater. Design 189, 108505 (2020)

M. Gong, Y. Meng, S. Zhang, Y. Zhang, X. Zeng, M. Gao, Addit. Manuf. 33, 101180 (2020)

B. Xie, J. Xue, X. Ren, Metals 10, 1 (2020)

A. Bandyopadhyay, M. Upadhyayula, K.D. Traxel, B. Onuike, Mater. Lett. 255, 126541 (2019)

A.R. Kannan, S.M. Kumar, N.P. Kumar, N.S. Shanmugam, A.S. Vishnu, Y. Palguna, Mater. Lett. 274, 127968 (2020)

L. Carneiro, B. Jalalahmadi, A. Ashtekar, Y. Jiang, Int. J. Fatigue 123, 22 (2019)

L.C. Shen, X.H. Yang, J.R. Ho, P.C. Tung, C.K. Lin, Materials 13, 1 (2020)

A.R. Kannan, N.S. Shanmugam, V. Rajkumar, M. Vishnukumar, Mater. Lett. 270, 127680 (2020)

D. Hull, D.J. Bacon, Introduction to Dislocations, 5th edn. (Butterworth-Heinemann, Oxford, 2011), pp. 85–107

E. Folkhard, Welding Metallurgy of Stainless Steels, 1st edn. (Springer, Wien, New York, 1988), pp. 112–114

A. Hussein, L. Hao, C. Yan, R. Everson, Mater. Design 52, 638 (2013)

H. Zhao, G. Zhang, Z. Yin, L. Wu, J. Mater. Process. Tech. 212, 276 (2012)

J. Gu, J. Ding, S.W. Williams, H. Gu, P. Ma, Y. Zhai, J. Mater. Process. Tech. 230, 26 (2016)

R. Xie, G. Chen, Y. Zhao, S. Zhang, W. Yan, X. Lin, Q. Shi, J. Manuf. Process. 38, 494 (2019)

B. Zheng, Y. Zhou, J.E. Smugeresky, J.M. Schoenung, E.J. Lavernia, Metall. Mater. Trans. A 39, 2228 (2008)

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Pramod, R., Mohan Kumar, S., Rajesh Kannan, A. et al. Fabrication of Gas Metal Arc Welding Based Wire Plus Arc Additive Manufactured 347 Stainless Steel Structure: Behavioral Analysis Through Experimentation and Finite Element Method. Met. Mater. Int. 28, 307–321 (2022). https://doi.org/10.1007/s12540-021-01026-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-021-01026-2