Abstract

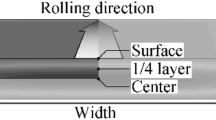

To investigate the quenching sensitivity of the 2195 Al–Li alloy rolled sheet and guide the design of the quenching process, the time–temperature-property (TTP) curves of this material were researched through interrupted quenching experiments. The differential scanning calorimetry (DSC) and transmission electron microscope (TEM) were used to characterize the evolution of precipitates during isothermal treatment. The results of this essay demonstrated that the nose temperature of 2195 Al–Li alloy is around 370 °C and the temperature range of quenching sensitivity is 340 °C to 400 °C. The microstructure observation revealed that the T1 particles precipitate and grow rapidly at the temperature from 340 to 400 °C, which is due to the high nucleation rate of phase and fast solute diffusion kinetics, especially at the nose temperature. The needle-shaped θ′/θ″ and T1 particles grow up quickly as the isothermal preservation time prolonged, leading to the decrease of the supersaturated solid solution of the matrix. This will reduce the number of the age-induced precipitate and weaken the subsequent age hardening effect. Therefore, the rate of cooling should be increased in the quenching sensitivity range (340–400 °C) to inhibit the precipitation of the second phase and obtain excellent mechanical properties. While in other temperature ranges, the cooling rate should be decreased appropriately to reduce residual stress. The appropriate average cooling rate is recommended to be around 13 °C s−1 at the temperature from 340 to 400 °C.

Graphic Abstract

Similar content being viewed by others

References

S.Y. Betsofen, V.V. Antipov, M.I. Knyazev, Russ. Metall. 2016, 326 (2016)

S. Nouri, S. Sahmani, M. Hadavi, S. Mirdamadi, Met. Mater. Int. 26, 1134 (2020)

M. Ubaid, D. Bajaj, A.K. Mukhopadhyay, A.N. Siddiquee, Met. Mater. Int. 26, 1841 (2020)

S.V.S.N. Murty, A. Sarkar, P.R. Narayanan, P.V. Venkitakrishnan, J. Mukhopadhyay, Mater. Sci. Eng. A 677, 41 (2016)

R.J. Rioja, Mater. Sci. Eng. A 257, 100 (1998)

T. Dursun, C. Soutis, Mater. Design 56, 862 (2014)

G. Kakauridze, B. Kilosanidze, in Proceedings of SPIE, ed. by H.I. Bjelkhagen. SPIE OPTO 2011, San Francisco, 23, 24, 26 January 2011. Vol. 7957, Practical Holography XXV: Materials and Applications (SPIE, Washington, 2011), p. 79570T

H. Wang, Y. Yi, S. Huang, J. Alloy. Compd. 690, 446 (2017)

A. Deschamps, Y. Bréchet, Scripta Mater. 39, 1517 (1998)

B. Milkereit, M.J. Starink, Mater. Design 76, 117 (2015)

J.S. Robinson, R.L. Cudd, D.A. Tanner, G.P. Dolan, J. Mater. Process. Tech. 119, 261 (2001)

B. Yang, B. Milkereit, Y. Zhang, P.A. Rometsch, O. Kessler, C. Schick, Mater. Charact. 120, 30 (2016)

B. Milkereit, N. Wanderka, C. Schick, O. Kessler, Mater. Sci. Eng. A 550, 87 (2012)

Y. Zhang, B. Milkereit, O. Kessler, C. Schick, P.A. Rometsch, J. Alloy. Compd. 584, 581 (2014)

D.A. Tanner, J.S. Robinson, Mater. Design 29, 1489 (2008)

E.Y. Kaputkin, Mater. Sci. Eng. A 280, 76 (2000)

P. Archambault, D. Godard, Scripta Mater. 42, 675 (2000)

X. Dai, C. Xiong, N. Li, Y. Luo, Rare Metal Mat. Eng. 48, 721 (2019)

J.W. Evancho, J.T. Staley, Metall. Mater. Trans. B 5, 43 (1974)

J.T. Staley, Mater. Sci. Tech.-Lond. 3, 923 (1987)

M. Tiryakioĝlu, R.T. Shuey, Mater. Sci. Eng. A 527, 5033 (2010)

H. Li, M. Han, C. Zeng,, Mater. Sci. Technol. 22, 6 (2014)

M.J. Starink, B. Milkereit, Y. Zhang, P.A. Rometsch, Mater. Design 88, 958 (2015)

B. Nie, P. Liu, T. Zhou, Mater. Sci. Eng. A 667, 106 (2016)

C. Zhang, M. Liu, Z. Meng, Q. Zhang, G. Zhao, L. Chen, H. Zhang, J. Wang, J. Mater. Process. Tech. 283, 116718 (2020)

R.J. Rioja, J. Liu, Metall. Mater. Trans. A 43, 3325 (2012)

Y. Li, Z. Shi, J. Lin, Y.L. Yang, Q. Rong, B.M. Huang, T.F. Chung, C.S. Tsao, J.R. Yang, D.S. Balint, Int. J. Plasticity 89, 130 (2017)

P. Ma, L. Zhan, C. Liu, Q. Wang, H. Li, D. Liu, Z. Hu, J. Alloy. Compd. 790, 8 (2019)

H.H. Jo, K.-I. Hirano, Mater. Sci. Forum 13–14, 377 (1987)

B. Cai, Z.Q. Zheng, D.Q. He, S.C. Li, H.P. Li, J. Alloy. Compd. 649, 19 (2015)

B. Decreus, A. Deschamps, F. De Geuser, P. Donnadieu, C. Sigli, M. Weyland, Acta Mater. 61, 2207 (2013)

A. Deschamps, M. Garcia, J. Chevy, B. Davo, F. De Geuser, Acta Mater. 122, 32 (2017)

H. Sidhar, N.Y. Martinez, R.S. Mishra, J. Silvanus, Mater. Design 106, 146 (2016)

Q. Chu, W.Y. Li, X.W. Yang, J.J. Shen, A. Vairis, W.Y. Feng, W.B. Wang, J. Mater. Sci. Technol. 34, 1739 (2018)

H. Sidhar, R.S. Mishra, Mater. Design 110, 60 (2016)

T. Dorin, A. Deschamps, F. De Geuser, W. Lefebvre, C. Sigli, Philos. Mag. 94, 1012 (2014)

M.H. Tosten, A.K. VasudÉvan, P.R. Howell, Metall. Trans. A 19, 51 (1988)

P. Donnadieu, Y. Shao, F. De Geuser, G.A. Botton, S. Lazar, M. Cheynet, M. De Boissieu, A. Deschamps, Acta Mater. 59, 462 (2011)

O. Sitdikov, E. Avtokratova, M. Markushev, Met. Mater. Int. (2020). https://doi.org/10.1007/s12540-020-00842-2

W.B. Chen, D.H. Xiao, M.D. Wu, J. Huang, L.P. Huang, W.S. Liu, J. Mater. Res. Technol. 9, 9675 (2020)

L. Wu, X. Li, H. Wang, Mater. Charact. 171, 110800 (2021)

E. Balducci, L. Ceschini, S. Messieri, S. Wenner, R. Holmestad, Mater. Design 119, 54 (2017)

T. Dorin, A. Deschamps, F. De Geuser, M. Weyland, in ICAA13 Pittsburgh, ed. by H. Weiland, A.D. Rollett, W.A. Cassada, 13th International Conference on Aluminum Alloys, Pittsburgh, 3-7 June 2012 (Springer, Cham, 2012), p. 1155

R.N. Lumley (ed.), Fundamentals of Aluminium Metallurgy (Woodhead Publishing, Cambridge, 2018)

H. Li, L. Zhan, M. Huang, X. Zhao, C. Zhou, and Z. Qiang, J. Alloy. Compd. 851, 156829 (2021)

D. Shin, A. Shyam, S. Lee, Y. Yamamoto, J.A. Haynes, Acta Mater. 141, 327 (2017)

J. Silcock, T. Heal, H. Hardy, J. I. Met. 82, 239 (1954)

A.K. Gupta, P. Gaunt, M.C. Chaturvedi, Philos. Mag. A 55, 375 (1987)

E. Balducci, L. Ceschini, S. Messieri, S. Wenner, R. Holmestad, Mater. Sci. Eng. A 707, 221 (2017)

Q. Liu, R.H. Zhu, J.F. Li, Y.L. Chen, X.H. Zhang, L. Zhang, Z.Q. Zheng, T. Nonferr. Metal. Soc. 26, 607 (2016)

N. Jiang, X. Gao, Z.Q. Zheng, T. Nonferr. Metal. Soc. 20, 740 (2010)

B.C. Shang, Z.M. Yin, G. Wang, B. Liu, Z.Q. Huang, Mater. Design 32, 3818 (2011)

Acknowledgements

This work was accomplished through the cooperation with Southwest Aluminum Group Company and supported by the National Natural Science Foundation of China [Grant number 51875583]. We would like to thank Fei Dong, Jingjing Zhang, Wanfu Guo, and Shan Guo for English language editing and Ke Huang, Jiaguo Tang, Chenguang Wang, and Jingting Yang for their help and fruitful discussions.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhang, Z., Yi, Y., You, W. et al. Investigation of Quench Sensitivity and Microstructure Evolution During Isothermal Treatment in 2195 Al–Li Alloy. Met. Mater. Int. 28, 1423–1432 (2022). https://doi.org/10.1007/s12540-021-01000-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-021-01000-y