Abstract

In this study, interactive alternate forward extrusion (AFE) experiments with varying number of extrusion passes of AZ31 magnesium alloy were carried out. The evolution of microstructure, and texture and their effects on the mechanical properties were studied. The results show that with the increase of loading passes, the grains are significantly refined, and the dynamic recrystallisation (DRX) structure is uniformly distributed in the product, which is the main reason for the increase in microhardness, compressive strength and failure strain. Further, slip and twinning induced DRX behaviour are considered to be the main deformation methods in the early stage of deformation. Whereas continuous DRX is considered to be the main deformation methods for the change in grain morphology in the later stage. During the extrusion process, the deflection angle of the base pole decreases. Finally, the fibre texture is formed; the texture strength is significantly reduced because of the effect of recrystallisation. The AZ31 magnesium alloy interactive AFE process is discussed with respect to the technological experiment and the microstructure deformation, thus providing a vital scientific basis for further application.

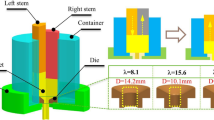

Graphic Abstract

Similar content being viewed by others

References

S.M. Fatemi, A. Zarei-Hanzaki, J.M. Cabrera, Metall. Mater. Trans. A 48, 2563 (2017)

Y. Wang, F. Li, X.W. Li, W.B. Fang, J. Mater. Process. Technol. 275, 116360 (2020)

D. Sarker, D.L. Chen, Mater. Sci. Eng. A 596, 134 (2014)

Y. Chino, M. Mabuchi, R. Kishihara, H. Hosokawa, Y. Yamada, C. Wen, K. Shimojima, H. Iwasaki, Mater. Trans. 43, 2554 (2002)

Y. Wang, S. Zhang, R.Z. Wu, J. Mater. Sci. Technol. 61, 197 (2021)

R. Ma, L. Wang, Y.N. Wang, D.Z. Zhou, Mater. Sci. Eng. A 638, 190 (2015)

F. Pan, Q. Wang, B. Jiang, J. He, Y. Chai, J. Xu, Mater. Sci. Eng. A 655, 339 (2016)

S.Q. Zhu, H.G. Yan, X.Z. Liao, S.J. Moody, G. Sha, Y.Z. Wu, S.P. Ringer, Acta Mater. 82, 344 (2015)

X.P. Lin, T.B. Zhao, Y. Dong, J. Ye, Z.B. Fan, H.B. Xie, L. Wang, Mater. Sci. Eng. A 700, 681 (2017)

P. Minárik, R. Král, J. Čížek, F. Chmelík, Acta Mater. 107, 83 (2016)

S.M. Fatemi-Varzaneh, A. Zarei-Hanzaki, H. Beladi, Mater. Sci. Eng. A 456, 52 (2007)

B.M. Morrow, R.J. Mccabe, E.K. Cerreta, C.N. Tomé, Metall. Mater. Trans. A 45, 36 (2014)

S.M. Fatemi-Varzaneh, A. Zarei-Hanzaki, J.M. Cabrera, P.R. Calvillo, Mater. Chem. Phys. 149-150, 339 (2015)

B.-Y. Liu, F, Liu, N, Yang, X,-B, Zhai, L, Zhang, Y, Yang, B. Li, J. Li, E. Ma, J.-F. Nie, Z.-W. Shan, Science 365, 73 (2019)

X.P. Chen, L.X. Wang, R. Xiao, X.Y. Zhong, G.J. Huang, Q. Liu, J. Alloy. Compd. 604, 112 (2014)

Y.J. Chen, Q.D. Wang, H.J. Roven, M.P. Liu, M. Karlsen, Y.D. Yu, J. Hjelen, Scripta Mater. 58, 311 (2008)

S.-H. Kim, J.H. Lee, C.S. Lee, J. Yoon, S.H. Park, J. Mater. Sci. Technol. 35, 473 (2019)

J. Stráská, M. Janeček, J. Gubicza, T. Krajňák, E.Y. Yoon, H.S. Kim, Mater. Sci. Eng. A 625, 98 (2015)

X.Y. Liu, L.W. Lu, K. Sheng, T. Zhou, Acta Metall. Sin. Engl. 32, 710 (2019)

F. Li, Y. Liu, X.B. Li, Front. Mater. Sci. 11, 296 (2017)

F. Li, Y. Liu, X. Li, Acta Metall. Sin. Engl. 30, 1135 (2017)

L. Lu, X. Liu, D. Shi, M. Ma, Z, Wang, JOM 71, 1566 (2019)

P.B. Berbon, M. Furukawa, Z. Horita, Z. Horita, M. Nemoto, T.G. Langdon, Metall. Mater. Trans. A 30, 1989 (1999)

H. Chen, B. Song, N. Guo, T. Liu, T. Zhou, J. He, Met. Mater. Int. 25, 147 (2019)

X. Zhang, Y. Cheng, J. Alloy. Compd. 622, 1105 (2015)

Y.P. Wang, F. Li, X.W. Li, Int. J. Adv. Manuf. Tech. 108, 289 (2020)

K.D. Molodov, T. Al-Samman, D.A. Molodov, D.A. Molodov, G. Gottstein, Acta Mater. 76, 314 (2014)

H. Chen, T. Liu, H. Yu, B. Song, D. Hou N. Guo, J. He, Adv. Eng. Mater. 18, 1683 (2016)

X. Zhao, S. Li, F. Yan, Z. Zhang, Y. Wu, Materials 12, 4223 (2019)

S.M. Fatemi-Varzaneh, A. Zarei-Hanzaki, H. Beladi, Mater. Sci. Eng. A 456, 52 (2015)

A.G. Beer, M.R. Barnett, Metall. Mater. Trans. A 38, 1856 (2007)

P. Vostrý, I. Stulíková, J. Kiehn, M. Šamatová, K.U. Kainer, F.M. Knoop, Mater. Sci. Forum 210-213, 635 (1996)

Y. Chino, K. Kimura, M. Mabuchi, Mater. Sci. Eng. A 486, 481 (2008)

Acknowledgements

This project is supported by National Natural Science Foundation of China (Grant No. 51975166) and the Fundamental Research Foundation for Universities of Heilongjiang Province (No. LGYC2018JQ011).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wang, Y., Li, F., Wang, Y. et al. Role of Grain Refinement Mechanism on Microstructure and Performance in AZ31B Alloy During Interactive Alternating Forward Extrusion (AFE) Process. Met. Mater. Int. 28, 823–832 (2022). https://doi.org/10.1007/s12540-020-00962-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-020-00962-9