Abstract

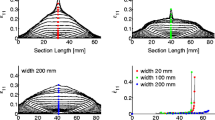

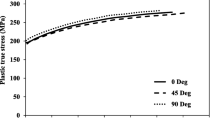

Effects of evolution in anisotropy during plastic deformation under strain path changes on the formability and failure were investigated in the present study. The evolution in anisotropic property of the extra deep drawing steel was considered by implementing the non-quadratic anisotropic yield function Yld2000-2d as a function of effective plastic strain, and the corresponding forming behaviour in two-step forming processes was analysed. For the strain path effect, pre-strain was applied under biaxial mode using Marciniak in-plane stretch forming set-up, followed by the secondary deformation using the out-of-plane stretch forming tool. For failure prediction of the proposed two-step forming, different failure limit approaches were investigated. First, a strain based forming limit diagram (FLD), proposed as the Marciniak–Kuczynski model was modified to include the evolution in anisotropic yield function. The dynamic shift in FLD was also determined by taking strain path change into consideration. In addition, the influence of evolution of yield function on the strain path independent failure limit criteria was also assessed in terms of stress based forming limit diagram. Finally, the prediction accuracy of the failure limit criteria was compared among different models in terms of failure location and limiting dome height (LDH). It was observed that the incorporation of evolution in anisotropic yield surface improved the prediction of formability in terms of the LDH and strain distribution for the investigated material.

Graphic Abstract

Similar content being viewed by others

References

K. Nakazima, T. Kikuma, K. Hasuka, Yawata Technical Report 264, 8517 (1968)

V. Hasek, Blech Rohre Profile 25, 213 (1978)

S.S. Hecker, Met. Eng. Quart. 14, 30 (1974)

R.T. Hill, J. Mech. Phys. Solids 1, 19 (1952)

Z. Marciniak, K. Kuczyński, Int. J. Mech. Sci. 9, 609 (1967)

Z. Marciniak, K. Kuczyński, T. Pokora, Int. J. Mech. Sci. 15, 789 (1973)

V. Tvergaard, A. Needleman, Acta Metall. 32, 157 (1984)

S. Stören, J.R. Rice, J. Mech. Phys. Solids 23, 421 (1975)

R. Sowerby, J.L. Duncan, Int. J. Mech. Sci. 13, 217 (1971)

D. Banabic, E. Dannenmann, J. Mater. Process. Technol. 109, 1 (2001)

S. Panich, F. Barlat, V. Uthaisangsuk, S. Suranuntchai, S. Jirathearanat, Mater. Des. 51, 756 (2013)

A. Graf, W. Hosford, Metall. Trans. A 24, 2503 (1993)

S. Basak, S.K. Panda, J. Mater. Process. Technol. 267, 289 (2019)

A.B. Da Rocha, F. Barlat, J.M. Jalinier, Mater. Sci. Eng. 68, 151 (1985)

M.C. Butuc, F. Barlat, J.J. Gracio, A.B. da Rocha, Int. J. Mater. Form. 3, 191 (2010)

T.B. Stoughton, J. Eng. Mater. Technol. 123, 417 (2001)

P.D. Wu, A. Graf, S.R. MacEwen, D.J. Lioyd, M. Jain, K.W. Neale, Int. J. Solids Struct. 42, 2225 (2005)

K. Yoshida, T. Kuwabara, M. Kuroda, Int. J. Plast. 23, 361 (2007)

K. Bandyopadhyay, M.-G. Lee, S.K. Panda, P. Saha, J. Lee, Int. J. Mech. Sci. 126, 203 (2017)

A. Zamiri, F. Pourboghrat, F. Barlat, Int. J. Plast. 23, 1126 (2007)

H. Wang, M. Wan, X. Wu, Y. Yan, Comp. Mater. Sci. 47, 12 (2009)

J.H. Yoon, O. Cazacu, J. Whan Yoon, R.E. Dick, Int. J. Mech. Sci. 52, 1563 (2010)

M. Safaei, M.G. Lee, S. Zang, W.D. Waele, Comp. Mater. Sci. 81, 15 (2014)

K. Bandyopadhyay, S. Basak, K.S. Prasad, M.G. Lee, S.K. Panda, J. Lee, Int. J. Solids Struct. 156, 263 (2018)

Y. Yang, T. Balan, Int. J. Plast. 119, 331 (2019)

F. Barlat, J.J. Gracio, M.G. Lee, E.F. Rauch, G. Vincze, Int. J. Plast. 27, 1309 (2011)

F. Barlat, J. Ha, J.J. Grácio, M.G. Lee, E.F. Rauch, G. Vincze, Int. J. Plast. 46, 130 (2013)

F. Barlat, G. Vincze, J.J. Grácio, M.G. Lee, E.F. Rauch, C.N. Tomé, Int. J. Plast. 58, 201 (2014)

T.B. Stoughton, Int. J. Mech. Sci. 42, 1 (2000)

M. Merklein, A. Kuppert, Int. J. Mater. Form. 2, 483 (2009)

F. Barlat, J.C. Brem, J.W. Yoon, K. Chung, R.E. Dick, D.J. Lege, F. Pourboghrat, S.-H. Choi, E. Chuet, Int. J. Plast. 19, 1297 (2003)

D.G. Tari, M.J. Worswick, U. Ali, M.A. Gharghouri, Int. J. Plast. 55, 247 (2014)

S. Basak, S.K. Panda, Int. J. Mech. Sci. 151, 356 (2019)

K.S. Raghavan, Mater. Sci. Eng. A 26, 2075 (1995)

S. Basak, S.K. Panda, Thin Wall. Struct. 126, 26 (2018)

F. Barlat, Mater. Sci. Eng. 91, 55 (1987)

J. Lee, H.J. Bong, D. Kim, Y.-S. Lee, Y. Choi, M.-G. Lee, Met. Mater. Int. 26, 682 (2020)

H. Park, S.-J. Kim, J. Lee, J.H. Kim, D. Kim, Met. Mater. Int. 25, 1326 (2019)

K. Hariharan, N.T. Nguyen, F. Barlat, M.G. Lee, J.H. Kim, Mech. Res. Commun. 62, 5 (2014)

S. Kim, J. Lee, F. Barlat, M.G. Lee, J. Mater. Process. Technol. 213, 1929 (2013)

H. Kim, J. Lee, F. Barlat, D. Kim, M.G. Lee, Acta Mater. 97, 435 (2015)

Y. Jeong, T. Manninen, Met. Mater. Int. 25, 1548 (2019)

Acknowledgement

The first author is grateful for KU grant from Korea University during his stay in South Korea. MGL appreciates the partial supports from NRF of Korea (ERC Grant No. 2019R1A5A6099595) and KIAT (Grant No. N0002598).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix: Relevant Equations for MK Models

Appendix: Relevant Equations for MK Models

It is well known that a pre-existing inhomogeneity in the sheet metal is assumed to be the reason of strain accumulation and subsequent failure in MK model. Generally, it is assumed that the principal stress–strain axis is superimposed with material anisotropy axis. A separate local axis system is assigned to the groove region (B), where \(\bar{t}\) denotes the direction parallel to the groove and \(\bar{n}\) indicates the perpendicular direction to the groove length. With this condition both region A (homogeneous) and B (groove) are deformed and the relationship of the strain and stress state in both regions is calculated based on strain compatibility and force equilibrium conditions. In the present study, the equations described by Barlat [36] was utilized and the same are shown below.

The rotation of the groove during deformation is expressed as

The compatibility condition is as follow

The force equilibrium condition at zone “A” and “B” leads to following equation

and

where \(f\) is the inhomogeneity factor and \(H\) is the hardening law.

The above equations can be solved along with this yield criteria \({{\Phi }} = 1\) as a consistency condition. In the above Eqs. (12 to 16), the following terminologies are applied.

Symbols | Terminologies |

|---|---|

\(\eta\) | \(\frac{{\sigma_{xx} }}{{\bar{\sigma }}}\) |

\(\psi\) | Groove angle with respect to principle strain axis, \(\psi_{0}\) is the initial value |

\(\alpha\) | \(\frac{{\sigma_{yy} }}{{\sigma_{xx} }}\) |

\(\beta\) | \(\frac{{\sigma_{xy} }}{{\sigma_{xx} }}\) |

\(\rho\) | \(\frac{{d\varepsilon_{yy} }}{{d\varepsilon_{xx} }}\) |

\(f\) | \(\frac{{t^{B} }}{{t^{A} }}\) |

\(\gamma\) | \(\frac{{d\varepsilon_{xy} }}{{d\varepsilon_{xx} }}\) |

\(k_{1}\) | \(1 + \alpha \rho + 2\beta \gamma\) |

\(k_{2}\) | \(\sin^{2} \psi + \rho \cos^{2} \psi - 2\gamma \sin \psi \cos \psi\) |

\(k_{3}\) | \(\alpha \sin^{2} \psi + \rho \cos^{2} \psi - 2\beta \sin \psi \cos \psi\) |

Rights and permissions

About this article

Cite this article

Bandyopadhyay, K., Basak, S., Choi, H. et al. Influence of Evolution in Anisotropy During Strain Path Change on Failure Limits of Sheet Metals. Met. Mater. Int. 27, 3225–3237 (2021). https://doi.org/10.1007/s12540-020-00896-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-020-00896-2