Abstract

Titanium alloys are well known with their superior properties such as corrosion resistance, specific strength; however, machining and shaping of this material are quite tricky and costly. In the present study, an attempt was made to improve the machinability of Ti–6Al–4V alloy by conducting deep and shallow cryogenic treatment. For this purpose grade, 5 in ASTM B348 titanium alloy was supplied as bar material. Cryogenic treatment was conducted to both annealed and aged state Ti–6Al–4V alloy. Machinability of different heat-treated materials was tested by using a CNC wire electro discharge machining machine. The test results were evaluated by material removal rate, surface roughness and surface hardness of the machined surface. Additionally, the electrical conductivity of different heat-treated specimens was measured. An XRD test was conducted to understand the internal changes happened with the effect of heat treatment. The results of the study show that the application of cryogenic treatment to both annealed and aged samples improved the machinability and electrical conductivity and provides better surface roughness of machined surfaces. This study suggests an alternative approach to improve the machinability of Ti–6Al–4V alloy and presents a characterization study about the effect of cryogenic treatment on Ti–6Al–4V alloy.

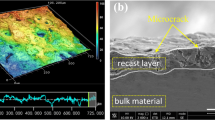

Graphic Abstract

Similar content being viewed by others

References

C. Veiga, J.P. Davim, A.J.R. Loureiro, Review on machinability of titanium alloys: the process perspective. Rev. Adv. Mater. Sci. 34(2), 148–164 (2013)

A. Pramanik, Problems and solutions in machining of titanium alloys. Int. J. Adv. Manuf. Technol. 70(5–8), 919–928 (2014). https://doi.org/10.1007/s00170-013-5326-x

N. Khanna, A. Garay, L.M. Iriarte, D. Soler, K.S. Sangwan, P.J. Arrazola, Effect of heat treatment conditions on the machinability of Ti64 and Ti54M alloys. Procedia CIRP 1, 477–482 (2012). https://doi.org/10.1016/j.procir.2012.04.085

S. Gürgen, F.H. Çakır, M.A. Sofuoğlu, S. Orak, M.C. Kuşhan, H. Li, Multi-criteria decision-making analysis of different non-traditional machining operations of Ti6Al4V. Soft Comput. 23(13), 5259–5272 (2019). https://doi.org/10.1007/s00500-019-03959-8

R.A. Rahman Rashid, S. Sun, G. Wang, M.S. Dargusch, Machinability of a near beta titanium alloy. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 225(12), 2151–2162 (2011). https://doi.org/10.1177/2041297511406649

M.K. Gupta et al., Machining characteristics based life cycle assessment in eco-benign turning of pure titanium alloy. J. Clean. Prod. 251, 119598 (2020). https://doi.org/10.1016/j.jclepro.2019.119598

S.Y. Hong, Y. Ding, Cooling approaches and cutting temperatures in cryogenic machining of Ti–6Al–4V. Int. J. Mach. Tools Manuf. 41(10), 1417–1437 (2001). https://doi.org/10.1016/S0890-6955(01)00026-8

S. Sun, M. Brandt, M.S. Dargusch, Machining Ti–6Al–4V alloy with cryogenic compressed air cooling. Int. J. Mach. Tools Manuf. 50(11), 933–942 (2010). https://doi.org/10.1016/j.ijmachtools.2010.08.003

M. Mia et al., Multi-objective optimization and life cycle assessment of eco-friendly cryogenic N2 assisted turning of Ti–6Al–4V. J. Clean. Prod. 210, 121–133 (2019). https://doi.org/10.1016/j.jclepro.2018.10.334

A.K. Parida, K. Maity, Hot machining of Ti–6Al–4V: FE analysis and experimental validation. Sādhanā (2019). https://doi.org/10.1007/s12046-019-1127-8

T.L. Ginta, A.K.M.N. Amin, Surface integrity in end milling titanium alloy Ti–6Al–4V under heat assisted machining. Asian J. Sci. Res. 6(3), 609–614 (2013). https://doi.org/10.3923/ajsr.2013.609.614

M.A. Sofuoğlu, F.H. Çakır, S. Gürgen, S. Orak, M.C. Kuşhan, Numerical investigation of hot ultrasonic assisted turning of aviation alloys. J. Braz. Soc. Mech. Sci. Eng. (2018). https://doi.org/10.1007/s40430-018-1037-4

M. Lotfi, S.A. Sajjady, S. Amini, Wettability analysis of titanium alloy in 3D elliptical ultrasonic assisted turning. Int. J. Lightweight Mater. Manuf. (2019). https://doi.org/10.1016/j.ijlmm.2019.05.001

S. Lei, W. Liu, High-speed machining of titanium alloys using the driven rotary tool. Int. J. Mach. Tools Manuf. 42(6), 653–661 (2002). https://doi.org/10.1016/S0890-6955(02)00012-3

R. Singh, B. Singh, Comparison of cryo-treatment effect on machining characteristics of titanium in electric discharge machining. Int. J. Automot. Mech. Eng. 3, 239–248 (2011). https://doi.org/10.15282/ijame.3.2011.1.0020

S.S. Gill, J. Singh, Effect of deep cryogenic treatment on machinability of titanium alloy (Ti-6246) in electric discharge drilling. Mater. Manuf. Process. 25(6), 378–385 (2010). https://doi.org/10.1080/10426910903179914

V.S. Jatti, T.P. Singh, Effect of deep cryogenic treatment on machinability of Niti shape memory alloys in electro discharge machining. Appl. Mech. Mater. 592–594, 197–201 (2014). https://doi.org/10.4028/www.scientific.net/AMM.592-594.197

J.W. Kim, J.A. Griggs, J.D. Regan, R.A. Ellis, Z. Cai, Effect of cryogenic treatment on nickel–titanium endodontic instruments. Int. Endod. J. 38(6), 364–371 (2005). https://doi.org/10.1111/j.1365-2591.2005.00945.x

S. Kumar, A. Batish, R. Singh, T. Singh, Machining performance of cryogenically treated Ti–5Al–2.5Sn titanium alloy in electric discharge machining: a comparative study. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. (2016). https://doi.org/10.1177/0954406215628030

‘ASM Material Data Sheet’. https://asm.matweb.com/search/SpecificMaterial.asp?bassnum=MTP641. Accessed 01 July 2019.

K.-X. Gu, K.-K. Wang, J.-P. Zheng, L.-B. Chen, J.-J. Wang, Electrochemical behavior of Ti–6Al–4V alloy in Hank’s solution subjected to deep cryogenic treatment. Rare Met. (2018). https://doi.org/10.1007/s12598-018-1163-2

Acknowledgement

This work was supported by a research program supported by the Eskisehir Osmangazi University, Project Number 2017/15A210.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Çakir, F.H., Çelik, O.N. Improvement of the Machinability of Ti–6Al–4V Alloy Wire Electro Discharge Machining with Cryogenic Treatment. Met. Mater. Int. 27, 3529–3537 (2021). https://doi.org/10.1007/s12540-020-00667-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-020-00667-z