Abstract

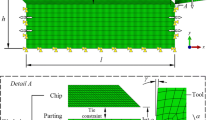

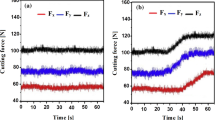

Machining process is a nonlinear process where high stress, temperature and strain are generated in the primary and secondary shear zone. It is difficult to determine these parameters experimentally and also consumes time. In this study, finite-element method (FEM) is applied to hot machining of Ti–6Al–4V alloy using DEFORM software. The simulations are used to investigate the effect of heating temperature on cutting force, cutting temperature, stress, strain and chip morphology for various machining conditions. The predicted results are compared to results obtained in room temperature and hot machining conditions. From this analysis, it is observed that hot machining reduces the cutting force, and changes the chip morphology. To validate the simulation results, an experimental trial is performed and positive coherence is achieved.

Similar content being viewed by others

References

Upadhyay V, Jain P K and Mehta N K 2012 Machinability studies in hot machining of Ti–6Al–4V alloy. Adv. Mater. Res. 622–623: 361–365, https://doi.org/10.4028/www.scientific.net/amr.622-623.361

Rahman Rashid R A, Bermingham M J, Sun S, Wang G and Dargusch M S 2013 The response of the high strength Ti–10V–2Fe-3Al beta titanium alloy to laser assisted cutting. Precis. Eng. 37: 461–472, https://doi.org/10.1016/j.precisioneng.2012.12.002.

Sun S, Brandt M, Barnes J E and Dargusch M S 2011 Experimental investigation of cutting forces and tool wear during laser-assisted milling of Ti–6Al–4V alloy. Proc. Inst. Mech. Eng. Part B: J. Eng. Manuf. 225: 1512–1527, https://doi.org/10.1177/0954405411411608

Ginta T L and Amin A K M N 2013 Thermally-assisted end milling of titanium alloy Ti–6Al–4V using induction heating. Int. J. Mach. Mach. Mater.14: 194–212, https://doi.org/10.1504/ijmmm.2013.055737

Fnides B, Yallese M A, Mabrouki T and Rigal J F 2011 Application of response surface methodology for determining cutting force model in turning hardened AISI H11 hot work tool steel. Sadhana – Acad. Proc. Eng. Sci. 36: 109–123, https://doi.org/10.1007/s12046-011-0007-7

Akasawa T, Takeshita H and Uehara K 1987 Hot machining with cooled cutting tools. CIRP Ann. – Manuf. Technol. 36: 37–40, https://doi.org/10.1016/s0007-8506(07)62548-7

Leshock C E, Kim J N and Shin Y C 2001 Plasma enhanced machining of Inconel 718: modeling of workpiece temperature with plasma heating and experimental results. Int. J. Mach. Tools Manuf. 41: 877–897, https://doi.org/10.1016/s0890-6955(00)00106-1

Tosun N and Ozler L 2004 Optimisation for hot turning operations with multiple performance characteristics. Int. J. Adv. Manuf. Technol. 23: 777–782, https://doi.org/10.1007/s00170-003-1672-4

Maity K P and Swain P K 2008 An experimental investigation of hot-machining to predict tool life. J. Mater. Process. Technol. 198: 344–349, https://doi.org/10.1016/j.jmatprotec.2007.07.018

Baili M, Wagner V, Dessein G, Sallaberry J and Lallement D 2011 An experimental investigation of hot machining with induction to improve Ti-5553 machinability. Appl. Mech. Mater. 62: 67–76, https://doi.org/10.4028/www.scientific.net/amm.62.67

Liu X, Xu W J, Sun J and Zhang L 2012 Research on heating resistance in electric hot machining. Adv. Mater. Res. 430–432: 209–212, https://doi.org/10.4028/www.scientific.net/amr.430-432.209

Muhammad R, Ahmed N, Shariff Y M and Silberschmidt V V 2012 Finite element analysis of forces in drilling of Ti-alloys at elevated temperature. Solid State Phenom. 188: 250–255, https://doi.org/10.4028/www.scientific.net/ssp.188.250

Muhammad R, Maurotto A, Roy A and Silberschmidt V V 2012 Hot ultrasonically assisted turning of β -Ti alloy. Procedia CIRP 1: 336–341, https://doi.org/10.1016/j.procir.2012.04.060

Xiang H, Fu J and Chen Z 2006 3D Finite element modeling of laser machining PMMA. In: Proceedings of the IEEE Conference, vol. 1, pp. 942–946

Singh G, Teli M, Samanta A and Singh R 2013 Finite element modeling of laser-assisted machining of AISI D2 tool steel. Mater. Manuf. Process. 28: 443–448, https://doi.org/10.1080/10426914.2012.700160

Zamani H, Hermani J P, Sonderegger B and Sommitsch C 2013 3D simulation and process optimization of laser assisted milling of Ti6Al4V. Procedia CIRP 8: 75–80, https://doi.org/10.1016/j.procir.2013.06.068.

Shi B, Attia H, Vargas R and Tavakoli S 2008 Numerical and experimental investigation of laser-assisted machining of Inconel 718. Mach. Sci. Technol. 12: 498–513, https://doi.org/10.1080/10910340802523314

Parida A K and Maity K 2018 Analysis of some critical aspects in hot machining of Ti-5553 superalloy: experimental and FE analysis. Def. Technol., https://doi.org/10.1016/j.dt.2018.10.005

DEFORM 3D Version 11.0 2016 User manual. SFTC, Columbus, Ohio State

Joshi S, Tewari A and Joshi S 2014 Influence of preheating on chip segmentation and microstructure in orthogonal machining of Ti6Al4V. J. Manuf. Sci. Eng. 135: 1–11, https://doi.org/10.1115/1.4025741

Umbrello D 2008 Finite element simulation of conventional and high speed machining of Ti6Al4V alloy. J. Mater. Process. Technol. 196: 79–87, https://doi.org/10.1016/j.jmatprotec.2007.05.007

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

PARIDA, A.K., MAITY, K. Hot machining of Ti–6Al–4V: FE analysis and experimental validation. Sādhanā 44, 142 (2019). https://doi.org/10.1007/s12046-019-1127-8

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12046-019-1127-8