Abstract

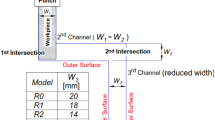

The Twist Multi Channel Angular Pressing (TMCAP) process is presented for the first time to investigate the mechanical properties of AL1050 numerically and experimentally. TMCAP that can be categorized as a SPD method is a process based on combining the Equal Channel Angular Pressing and Twist Extrusion processes. The process was simulated entirely using dynamic explicit solution of ABAQUS/software. Based on the simulation results as well as considering the hydrostatic pressure effect on die filling and strain distribution, the TMCAP die was designed in which the horizontal channel creates a required hydrostatic pressure during the process. This process can effectively impose large strains to a bulk material to enhance the mechanical properties. Upon on a single pass of routes, a value of nearly 2.4 total strain was obtained without having significant changes in the billet cross section. In addition, the load obtained from simulation of TMCAP process at the first pass was about 22 tons which has a good conformity with the value obtained from experimental study. The process was also repeated up to four passes to evaluate the subsequent mechanical properties such as the flow stress and the Vickers micro-hardness as well as microstructure after each pass.

Graphic Abstract

Similar content being viewed by others

References

R.Z. Valiev, Y. Estrin, Z. Horita, T.G. Langdon, M.J. Zechetbauer, Y.T. Zhu, Producing bulk ultrafine-grained materials by severe plastic deformation. JOM 58, 33–39 (2006)

R.Z. Valiev, R.K. Islamgaliev, I.V. Alexandrov, Bulk nanostructured materials from severe plastic deformation. Prog. Mater. Sci. 45, 103–189 (2000)

V.M. Segal, V.I. Reznikov, A.E. Dobryshevshiy, V.I. Kopylov, Plastic working of metals by simple shear. Russ. Met. 1, 99–105 (1981)

H.S. Kim, Finite element analysis of deformation behaviour of metals during equal channel multi-angular pressing. Mater. Sci. Eng. A 328, 317–323 (2002)

Y. Beygelzimer, D. Orlov, V. Varyukhin, A new severe plastic deformation method: twist extrusion, in Ultrafine Grained Materials II (2002), pp. 297–304

S.A. Asghar, A. Mousavi, S.R. Bahador, Investigation and numerical analysis of strain distribution in the twist extrusion of pure aluminum. JOM 63, 69–76 (2011)

S.A. Mousavi, S.R. Bahadori, The effects of post annealing on the mechanical properties, microstructure and texture evolutions of pure copper deformed by twist extrusion process. Mater. Sci. Eng. A 528, 1242–1246 (2011)

H. Zendehdel, A. Hassani, Influence of twist extrusion process on microstructure and mechanical properties of 6063 aluminum alloy. Mater. Des. 37, 13–18 (2012)

S.R. Bahadori, S.A. Mousavi, Examination of an aluminum alloy behavior under different routes of twist extrusion processing. Mater. Sci. Eng. A 528, 6527–6534 (2011)

Y. Beygelzimer, V. Varyukhin, S. Synkov, D. Orlov, Useful properties of twist extrusion. Mater. Sci. Eng. A 503, 14–17 (2009)

Y. Beygelzimer, D. Orlov, A. Korshunov, S. Synkov, V. Varyukhin, I. Vedernikova et al., Features of twist extrusion: method, structures and material properties, in Solid State Phenomena, vol. 114 (Trans Tech Publications, Zürich, 2006), pp. 69–78

V. Segal, Severe plastic deformation: simple shear versus pure shear. Mater. Sci. Eng. A 338, 331–344 (2002)

A. Vinogradov, S. Yasuoka, S. Hashimoto, On the effect of deformation mode on fatigue: simple shear vs. pure shear, in Materials Science Forum, vol. 584 (Trans Tech Publications, 2008), pp. 797–802

H. Bisadi, M.R. Mohamadi, H. Miyanaji, M. Abdoli, A modification on ECAP process by incorporating twist channel. J. Mater. Eng. Perform. 22, 875–881 (2013)

V. Varyukhin, Y. Beygelzimer, S. Synkov, D. Orlov, Application of twist extrusion, in Materials Science Forum, vol. 503 (Trans Tech Publications, 2006), pp. 335–340

X.-X. Wang, H. Min, Z. Zhen, K.-M. Xue, L. Ping, Influence of twist extrusion process on consolidation of pure aluminum powder in tubes by equal channel angular pressing and torsion. Trans. Nonferrous Met. Soc. China 25, 2122–2129 (2015)

S.-H. Joo, H.S. Kim, Comparison of deformation and microstructural evolution between equal channel angular pressing and forward extrusion using the dislocation cell mechanism-based finite element method. J. Mater. Sci. 45, 4705–4710 (2010)

M. Furukawa, Y. Iwahashi, Z. Horita, M. Nemoto, T.G. Langdon, The shearing characteristics associated with equal-channel angular pressing. Mater. Sci. Eng. A 257, 328–332 (1998)

V. Segal, Equal channel angular extrusion: from macromechanics to structure formation. Mater. Sci. Eng. A 271, 322–333 (1999)

H.S. Kim, Finite element analysis of equal channel angular pressing using a round corner die. Mater. Sci. Eng., A 315, 122–128 (2001)

H. Zendehdel, A. Hassani, Influence of twist extrusion process on microstructure and mechanical properties of 6063 aluminum alloy. Mater. Des. 37, 13–18 (2012)

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Alavizadeh, S.M., Abrinia, K. & Parvizi, A. Twisted Multi Channel Angular Pressing (TMCAP) as a Novel Severe Plastic Deformation Method. Met. Mater. Int. 26, 260–271 (2020). https://doi.org/10.1007/s12540-019-00319-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-019-00319-x