Abstract

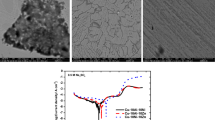

In this study, manufacturing of Ti–5Al and Ti–5Al–5Cu alloys were accomplished employing mechanical alloying technique. The corrosion resistance in 3.5 wt% NaCl solution of Ti–5Al and Ti–5Al–5Cu alloys was investigated using cyclic polarization (CPP), electrochemical impedance spectroscopy (EIS) and chronoamperometric current–time measurements. The corroded surfaces of Ti–5Al and Ti–5Al–5Cu were examined by the use of a scanning electron microscopy and energy dispersive X-ray spectroscopy. It is found that Ti–5Al suffers both uniform and pitting corrosion, particularly with prolonging the time of exposure period in the chloride solution. While, the addition of Cu, Ti–5Al–5Cu alloy, increases the intensity of uniform corrosion and decreases the probability of pitting attack. Prolonging the immersion time to 48 h before measurement decreases the corrosion of Ti–5Al alloy, while increases the corrosion of Ti–5Al–5Cu.

Similar content being viewed by others

References

C. Suryanarayana, Recent developments in mechanical alloying. Rev. Adv. Mater. Sci. 18, 203–211 (2008)

J.S. Benjamin, Mechanical alloying-A prospective. Met. Powder Rep. 45, 122–127 (1990)

C.C. Koch, Intermetallic matrix composites prepared by mechanical alloying—a review. Mater. Sci. Eng. A 244, 39–48 (1998)

H.D.K.H. Bhadeshia, Mechanically alloyed metals. Mater. Sci. Technol. 1, 1404–1411 (2000)

M.A. Shaikh et al., Alloying of immiscible Ge with Al by ball milling. Mater. Lett. 57, 3681–3685 (2003)

E. Ma, M. Atzmon, Phase transformations induced by mechanical alloying in a binary system. Mater. Chem. Phys. 39, 249–267 (1995)

C.C. Koch, J.D. Whittenberger, Review: mechanical milling/alloying of Intermetallic. Intermetallics 4, 339–355 (1996)

Yuhua Li, Chao Yang, Haidong Zhao, Qu Shengguan, Xiaoqiang Li, Yuanyuan Li, New developments of Ti-based alloys for biomedical applications. Materials 7(3), 1709–1800 (2014)

S. Gorsse, D.B. Miracle, Mechanical properties of Ti–6Al–4V/TiB composites with randomly oriented and aligned TiB reinforcements. Acta Mater. 51, 2427–2442 (2003)

R.W. Hayes, G.B. Viswanathan, M.J. Mills, Creep behavior of Ti–6Al–2Sn–4Zr–2Mo: the effect of nickel on creep deformation and microstructure. Acta Mater. 50, 4953–4963 (2002)

H. Zhang, H. Kou, J. Yang, D. Huang, H. Nan, J. Li, Microstructure evolution and tensile properties of Ti–6.5Al–2Zr–Mo–V alloy processed with thermo hydrogen treatment. Mater. Sci. Eng. A 619, 274–280 (2014)

H.J. Rack, J.I. Qazi, Titanium alloys for biomedical applications. Mater. Sci. Eng. C 26, 1269–1277 (2006)

L.C. Zhang, H. Attar, Selective laser melting of titanium alloys and titanium matrix composites for biomedical applications: a review. Adv. Eng. Mater. 18, 463–475 (2016)

J. Pang, D.J. Blackwood, Corrosion of titanium alloys in high temperature near anaerobic seawater. Corros. Sci. 105, 17–24 (2016)

I.V. Gorynin, Titanium alloys for marine application. Mater. Sci. Eng. A 263, 112–116 (1999)

M.F. Erinosho, E.T. Akinlabi, S. Pityana, Microstructure and corrosion behaviour of laser metal deposited Ti6Al4V/Cu composites in 3.5% sea water. Mater. Today Proc. 2, 1166–1174 (2015)

L.L.G. da Silva, M. Ueda, M.M. Silva et al., Corrosion behavior of Ti–6Al–4V alloy treated by plasma immersion ion implantation process. Surf. Coat. Technol. 201, 8136–8139 (2007)

H. Ahn, D. Lee, K.-M. Lee et al., Oxidation behavior and corrosion resistance of Ti–10Ta–10Nb alloy. Surf. Coat. Technol. 202, 5784–5789 (2008)

R. Narayanan, S.K. Seshadri, Point defect model and corrosion of anodic oxide coatings on Ti–6Al–4V. Corros. Sci. 50, 1521–1529 (2008)

Y. Li, L. Qu, F. Wang, The electrochemical corrosion behavior of TiN and (Ti, Al)N coatings in acid and salt solution. Corros. Sci. 45, 1367–1381 (2003)

L.T. Duarte, S.R. Biaggio, R.C. Rocha-Filho et al., Surface characterization of oxides grown on the Ti–13Nb–13Zr alloy and their corrosion protection. Corros. Sci. 72, 35–40 (2013)

E.S.M. Sherif, A.A. Almajid, F.H. Latif, H. Junaedi, Effects of graphite on the corrosion behavior of aluminum-graphite composite in sodium chloride solutions. Int. J. Electrochem. Sci. 6, 1085–1099 (2011)

E.S.M. Sherif, Effects of exposure time on the anodic dissolution of Monel-400 in aerated stagnant sodium chloride solutions. J. Solid State Electrochem. 16, 891–899 (2012)

F.H. Latief, E.S.M. Sherif, A.A. Almajid, H. Junaedi, Fabrication of exfoliated graphite nanoplatelets-reinforced aluminum composites and evaluating their mechanical properties and corrosion behavior. J. Anal. Appl. Pyrolysis 92, 485–492 (2011)

E.S.M. Sherif, J.H. Potgieter, J.D. Comins, L. Cornish, P.A. Olubambi, C.N. Machio, The beneficial effect of ruthenium additions on the passivation of duplex stainless steel corrosion in sodium chloride solutions. Corros. Sci. 51, 1364–1371 (2009)

El-Sayed M. Sherif, Abdulhakim A. Almajid, Corrosion of magnesium/manganese alloy in chloride solutions and its inhibition by 5-(3-aminophenyl)-tetrazole. Int. J. Electrochem. Sci. 6, 2131–2148 (2011)

K.A. Khalil, E.S.M. Sherif, A.A. Almajid, Corrosion passivation in simulated body fluid of magnesium/hydroxyapatite nanocomposites sintered by high frequency induction heating. Int. J. Electrochem. Sci. 6, 6184–6199 (2011)

W.A. Badawy, F.M. Al-Kharafi, A.A. El-Azab, Electrochemical behaviour and corrosion inhibition of Al, Al-6061 and Al–Cu in neutral aqueous solutions. Corros. Sci. 41, 709–727 (1999)

J.W. Diggle, T.C. Downie, C. Goulding, The dissolution of porous oxide films on aluminium. Electrochim. Acta 15, 1079–1093 (1970)

W.A. Badawy, M.S. El-Basiouny, M.M. Ibrahim, Kinetics of the dissolution of phosphoric acid anodized aluminium as revealed from impedance measurements in phosphate media. Indian J. Technol. 24, 1–6 (1986)

F.D. Wall, M.A. Martinez, J.J. Vandenavyle, Relationship between induction time for pitting and pitting potential for high-purity aluminum. J. Electrochem. Soc. 151, B354–B358 (2004)

C.M.A. Brett, I.A.R. Gomes, J.P.S. Martins, The electrochemical behaviour and corrosion of aluminium in chloride media. The effect of inhibitor anions. Corros. Sci. 36, 915–923 (1994)

F.M. Al-Kharafi, W.A. Badawy, Corrosion and passivation of Al and Al-Si alloys in nitric acid solutions II—Effect of chloride ions. Electrochim. Acta 40, 1811–1817 (1995)

F. Hunkeler, G.S. Frankel, H. Bohni, Technical note: on the mechanism of localized corrosion. Corrosion (Houston) 43, 189–191 (1987)

N. Sato, The stability of localized corrosion. Corros. Sci. 37, 1947–1967 (1995)

M.M. Mazhar, W.A. Badawy, M.M. Abou-Romia, Impedance studies of corrosion resistance of aluminium in chloride media. Surf. Coat. Technol. 29, 337–345 (1987)

R.T. Foley, T.H. Nguyen, The chemical nature of aluminum corrosion-V. Energy transfer in aluminum dissolution. J. Electrochem. Soc. 129, 464–467 (1982)

L. Tomcsanyi, K. Varga, I. Bartik, G. Horanyi, E. Maleczki, Electrochemical study of the pitting corrosion of aluminium and its alloys—II. Study of the interaction of chloride ions with a passive film on aluminium and initiation of pitting corrosion. Electrochim. Acta 34, 855–859 (1989)

N. Alharthi, E.S.M. Sherif, H.S. Abdo, S. Zein El Abedin, Effect of nickel content on the corrosion resistance of iron-nickel alloys in concentrated hydrochloric acid pickling solutions. Adv. Mater. Sci. Eng. 2017, 1–8 (2017)

Acknowledgements

The authors would like to extend their sincere appreciation to the Deanship of Scientific Research at King Saud University for its funding of this research through the Research Group Project No. RGP-160.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sherif, ES.M., Latief, F.H., Abdo, H.S. et al. Electrochemical and Spectroscopic Study on the Corrosion of Ti–5Al and Ti–5Al–5Cu in Chloride Solutions. Met. Mater. Int. 25, 1511–1520 (2019). https://doi.org/10.1007/s12540-019-00306-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-019-00306-2