Abstract

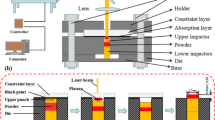

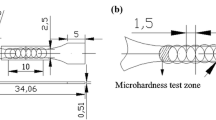

In shock compaction with a single gas gun system, a target fixture is used to safely recover a powder compact processed by shock-wave dynamic impact. However, no standard fixture geometry exists, and its effect on the processed compact is not well studied. In this study, two types of fixture are used for the dynamic compaction of hydrogen-reduced copper powders, and the mechanical properties and microstructures are investigated using the Vickers microhardness test and electron backscatter diffraction, respectively. With the assistance of finite element method simulations, we analyze several shock parameters that are experimentally hard to control. The results of the simulations indicate that the target geometry clearly affects the characteristics of incident and reflected shock waves. The hardness distribution and the microstructure of the compacts also show their dependence on the geometry. With the results of the simulations and the experiment, it is concluded that the target geometry affects the shock wave propagation and wave interaction in the specimen.

Similar content being viewed by others

References

M. A. Meyers, A. Mishra, and D. J. Benson, Prog. Mater. Sci. 51, 427 (2006).

Y. Song, M. Chen, B. Xu, D. Gao, J. Guo, H. S. Kim, et al. Korean J. Met. Mater. 51, 831 (2016).

Y. Song, M. Chen, W. Wang, B. Xu, D. Gao, H. S. Kim, et al. Korean J. Met. Mater. 55, 710 (2017).

G. W. Nieman, J. R. Weertman, and R.W. Siegel, Scripta. Metall. Mater. 23, 2013 (1989).

A. M. El-Sherik and U. Erb, J. Mater. Sci. 30, 5743 (1995).

L. G. Austin, R. R. Klimpel, and P. T. Luckie, Process Engineering of Size Reduction: Ball Milling, AIME, SME, New York, USA (1984).

Z. A. Munir, U. Anselmi-Tamburini, and M. Ohyanagi, J. Mater. Sci. 41, 763 (2006).

D. E. Eakins and N. N. Thadhani, Appl. Phys. Lett. 92, 111903 (2008).

T. Akashi and A. B. Sawaoka, J. Mater. Sci. 22, 3276 (1987).

M. A. Meyers, D. J. Benson, and E. A. Olevsky, Acta Mater. 47, 2089 (1999).

W. H. Gourdin, Prog. Mater. Sci. 30, 39 (1986).

Z. Zhao, X.-J. Li, H.-H. Yan, and D.-H. Liu, Combust. Explos. Shock Waves 44, 119 (2008).

G. A. Emelchenko, I. G. Naumenko, V. A. Veretennikov, and Y. A. Gordopolov, Mat. Sci. Eng. A 503, 55 (2009).

C. Dai and N. N. Thadhani, Acta Mater. 59, 785 (2011).

P. Molian, R. Molian, and R. Nair, Appl. Surf. Sci. 255, 3859 (2009).

L. Davison, D. M. Webb, and R. A. Graham, Shock Waves Condens. Matter-1981 (eds. W. J. Nellis, L. Seaman, and R. A. Graham), pp.67–71, American Institute of Physics, New York, USA (1982).

R. A. Graham and D. M. Webb, Shock Waves Condens. Matter (eds. J. R. Asay, R. A. Graham, and J. K. Straub), pp.211–214, North Holland, Amsterdam, Netherlands (1984).

R. A. Graham and D. M. Webb, Shock Waves Condens. Matter (eds. Y. M. Gupta), pp.831–836, Springer US, Boston, USA (1986).

A. B. Sawaoka, Shock Waves in Materials Science, Springer Science & Business Media, pp.5–7, Germany (2012).

N. N. Thadhani, Ptrog. Mater. Sci. 37, 117 (1993).

D.-H. Ahn, W. Kim, M. Kang, L. J. Park, S. Lee, and H. S. Kim, Mat. Sci. Eng. A 625, 230 (2015).

W. Kim, D.-H. Ahn, L. J. Park, and H. S. Kim, Procedia Eng. 81, 1180 (2014).

Y. Seong, Y. Kim, I. D. Jung, S. Kim, S. J. Kim, S. J. Park, et al. Korean J. Met. Mater. 55, 760 (2017).

J. R. Brown, P. J. C. Chappell, G. T. Egglestone, and E. P. Gellert, J. Phys. E 22, 771 (1989).

C. Poizat, L. Campagne, L. Daridon, S. Ahzi, C. Husson, and L. Merle, Int. J. Form. Process. 8, 29 (2005).

G. R. Johnson and W. H. Cook, Eng. Fract. Mech. 21, 31 (1985).

K. Kim, S. Kuroda, and M. Watanabe, J. Therm. Spray Technol. 19, 1244 (2010).

M. A. Meyers, Dynamic Behavior of Materials, p.133, John wiley & sons, New York, USA (1994).

W. Herrmann, J. Appl. Phys. 40, 2490 (1969).

D.-H. Ahn, W. Kim, E. Y. Yoon, and H. S. Kim, J. Mater. Sci. 51, 82 (2016).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kim, W., Ahn, DH., Yoon, J.I. et al. Effect of target-fixture geometry on shock-wave compacted copper powders. Met. Mater. Int. 24, 84–94 (2018). https://doi.org/10.1007/s12540-017-7344-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-017-7344-y