Abstract

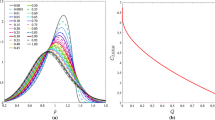

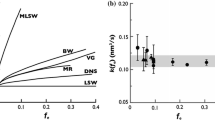

According to Lifshitz, Slyozov, and Wagner (LSW) and Trans-Interface Diffusion-Controlled (TICD) theoretical models, this paper reports the microstructure and its coarsening behavior of γ′ metastable-coherent precipitates in concentration gradient of Ni-13.75Ti (at%)/Ni generated by diffusion couple. The coarsening of precipitates was evaluated in two different Ti contents (R1-11.4Ti (at%) and R2-13Ti (at%)) generated along the concentration gradient and includes average size, size distributions and growth rate. The solvus and metastable-coherent bimodal lines as determined at 850 °C of 9.16 (at%) and 9.92Ti (at%) respectively by scanning electron microscopy. This paper suggests that elastic strains produced by the matrix/precipitate lattice mismatch caused significant deviations between the experimental results and those predicted by the LSW or TIDC theories. Activation energies for TIDC (Q i ) and LSW (Q r ) are Q r : 219.69 and 172.61 kJ mol-1 for R1 and R2 regions, respectively, and Q i : 218.46 and 164.56 kJmol-1 for R1 and R2 regions, respectively. A concentration gradient allows the study of various alloys with different concentration and volume-fraction in a single sample.

Similar content being viewed by others

References

T. M. Pollock and S. Tin, J. Propul. Power. 22, 361 (2006).

S. Zhao, X. Xie, G. D. Smith, and S. J. Patel, Mater. Lett. 58, 1784 (2004).

L. Hongyu, Z. Lingli, S. Xiping, W. Yanli, and C. Guoliang, Rare Metals 28, 197 (2009).

R. C. Reed, The Superalloys Fundamentals and Applications, pp.33–114, Cambridge University Press, UK (2008).

A. Baldan, J. Mater. Sci. 37, 2171 (2002).

L. Ratke and P. W. Voorhees, Growth and Coarsening: Ostwald Ripening in Material Processing, pp.117–150, Springer Science & Business Media, Germany (2002).

G. Kostorz, Phase Transformations in Materials, pp.309–407, WILEY-VCH Verlag GmbH, Weinheim, Germany (2001).

C. Wagner, Z. Elektrochem. 65, 581 (1961).

I. M. Lifshitz and V. V. Slyozov, J. Phys. Chem. Solids. 19, 35 (1961).

A. J. Ardell, Acta Metall. 20, 61 (1972).

A. D. Brailsford and P. Wynblatt, Acta Metall. 27, 489 (1979).

C. K. L. Davies, P. Nash, and R. N. Stevens, Acta Metall. 28, 179 (1980).

K. Tsumaraya and Y. Miyata, Acta Metall. 31, 437 (1983).

J. A. Marqusee and J. Rose, J. Chem. Phys. 80, 536 (1984).

M. Tokuyama and K. Kawasaki, Physica A. 123, 386 (1984).

P. W. Voorhees and M. E. Glicksman, Acta Metall. 32, 2001 (1984).

D. M. Kim and A. J. Ardell, Scripta Mater. 43, 381 (2000).

A. Maheshwari and A. J. Ardell, Acta Metall. Mater. 40, 2661 (1992).

D. M. Kim and A. J. Ardell, Metall. Mater. Trans. A 35, 3063 (2004).

D. M. Kim and A. J. Ardell, Acta Mater. 51, 4073 (2003).

J. H. Cho and A. J. Ardell, Acta Mater. 46, 5907 (1998).

A. J. Ardell, Scripta Metall. Mater. 24, 343 (1990).

A. J. Ardell and V. Ozolins, Nature Mater. 4, 309 (2005).

A. J. Ardell, Acta Mater. 58, 4325 (2010).

A. J. Ardell, Metall. Trans. B 1, 525 (1970).

R. Grune, Acta Metall. 36, 2797 (1988).

R. Sinclair, J. A. Leake, and B. Ralph, Phys. Status Solidi A 26, 285 (1974).

P. Vyskocil, J.S. Pedersen, G. Kostorz, and B. Schönfeld, Acta Mater. 45, 3311 (1997).

A. J. Ardell, D. M. Kim, and V. Ozolins, Z. Metallkde. 97, 295 (2006).

A. J. Ardell, J. Mater. Sci. 46, 4832 (2011).

C. G. Garay-Reyes, F. Hernández-Santiago, N. Cayetano-Castro, V. M. López-Hirata, J. García-Rocha, J. L. Hernández-Rivera, et al. Mater. Charact. 83, 35 (2013).

C. G. Garay-Reyes, F. Hernández-Santiago, N. Cayetano-Castro, R. Martínez-Sánchez, J. L. Hernández-Rivera, H. J. Dorantes-Rosales, et al. B. Mater. Sci. 37, 823 (2014).

A. D. Sequeira, H. A. Calderon, G. Kostorz, and J. S. Pedersen, Acta Metall. Mater. 43, 3441 (1995).

S. Hinotani and Y. Ohmori, T. Jpn. I. Met. 29, 116 (1988).

B. Wierzba, Physica A 392, 2860 (2013).

C. A. C. Sequeira and L. Amaral, T. Nonferr. Metal. Soc. 24, 1 (2014).

M. H. de Sá, I. Isomäki, J. A. Ferreira, M. Hämäläinen, and M. H. Braga, Mater. Sci. Forum. 730-732, 775 (2013).

C. Y. Cui, Y. F. Gu, D. H. Ping, H. Harada, and T. Fukuda, Mat. Sci. Eng. A 485, 651 (2008).

M. J. Donachie and S. J. Donachie, Superalloys: A Technical Guide, 2nd Ed., pp.25–39, ASM International, Ohio, USA (2002).

K. Hashimoto and T. Tsujimoto, T. Jpn. I. Met. 19, 77 (1978).

A. Taylor and R. W. Floyd, J. I. Met. 81, 25 (1952-53).

Y. A. Bagariatskii and Y. D. Tiapkin, Sov. Phys. Crystallogr. 2, 414 (1957).

Y. A. Bagariatskii and Y. D. Tiapkin, Sov. Phys. Crystallogr. 5, 841 (1961).

C. Bücle, B. Genty, and J. Manenc, Rev. Metall. 56, 247 (1959).

D. H. Ben Israel and M. E. Fine, Acta metall. 11, 1051 (1963).

S. L. Sass, T. Mur, and J. B. Cohen, Philos. Mag. 16, 680 (1967).

K. Saito and R. Watanabe, Jpn. J. Appl. Phys. 8, 14 (1969).

R. Sinclair, J. A. Leake, and B. Ralph, Phys. Status Solidi A 26, 285 (1974).

D. E. Laughlin, Acta Metall. 24, 53 (1976).

R. Grune, Acta Metall. 36, 2797 (1988).

A. Cerri, B. Schönfeld, and G. Kostorz, Phys. Rev. B 42, 958 (1990).

R. Bucher, B. Demè, H. Heinrich, J. Kohlbrecher, M. Kompatscher, G. Kostorz, et al. Mat. Sci. Eng. A 324, 77 (2002).

M. Kompatscher, B. Schönfeld, H. Heinrich, and G. Kostorz, Acta Mater. 51, 165 (2003).

A. C. Lund, P. W. Voorhees, Philos. Mag. 83, 1719 (2003).

A. J. Ardell and R. B. Nicholson, Acta Metall. 14, 1295 (1966).

T. Miyazaki, H. Imamura, and T. Kozaki, Mater. Sci. Eng. 54, 9 (1982).

R. A. Mackay and L. J. Ebert, Metall. Mater. Trans. A 16, 1969 (1985).

J. D. Eshelby, P. R. Soc. A 241, 376 (1957).

H. Yamauchi and D. De Fontaine, Acta Metall. 27, 763 (1979).

W. C. Johnson and J. K. Lee, Metall. Mater. Trans. A 10, 1141 (1979).

E. H. Yoffe, Philos. Mag. 30, 923 (1974).

A. G. Khachaturyan, Sov. Phys. Sol. State. 8, 2163 (1967).

W. C. Johnson, Metall. Mater. Trans. A 14, 2219 (1983).

T. Miyazaki, H. Imamura, H. Mori, and T. Kozaki, J. Mater. Sci. 16, 1197 (1981).

M. Doi, T. Miyazaki, and T. Wakatsuki, Mater. Sci. Eng. 67, 247 (1984).

M. Doi, T. Miyazaki, and T. Wakatsuki, Mater. Sci. Eng. 74, 139 (1985).

M. Doi and T. Wakatsuki, Mater. Sci. Eng. 78, 87 (1986).

A. G. Khachaturyan, S. V. Semenovskaya, and J. W. Morris Jr, Acta Metall. 36, 1563 (1988).

P. W. Voorhees, J. Stat. Phys. 38, 231 (1985).

P. Fratzl, O. Penrose, and J. L. Lebowitz, J. Stat. Phys. 95, 1429 (1999).

A. Maheshwari and A. J. Ardell, Acta Metall. Mater. 40, 2661 (1992).

J. H. Cho and A. J. Ardell, Acta Mater. 46, 5907 (1998).

D. M. Kim and A. J. Ardell, Scripta Mater. 43, 381 (2000).

D. M. Kim and A. J. Ardell, Acta Mater. 51, 4073 (2003).

D. M. Kim and A. J. Ardell, Metall. Mater. Trans. A. 35, 3063 (2004).

P. K. Footner and B. P. Richards, J. Mater. Sci. 17, 2141 (1982).

M. Jahazi and A. R. Mashreghi, Mater. Sci. Tech. 18, 458 (2002).

D. Hadjiapostolidou and B. A. Shollock, Superalloys 2008: Proc. Eleventh International Symposium on Superalloys (eds. R. C. Reed, K. A. Green, P. Caron, T. P. Gabb, M. G. Fahrmann, E. S. Huron, and S. A. Woodard), pp.733–739, TMS, PA, USA (2008).

J. Safari, S. Nategh, and M. McLean, Mater. Sci. Tech. 22, 888 (2006).

B. G. Choi, I. S. Kim, D. H. Kim, S. M. Seo, and C. Y. Jo, Superalloys 2004: Proc. Tenth International Symposium on Superalloys (eds. K. A. Green, T. M. Pollock, H. Harada, T. E. Howson, R. C. Reed, J. J. Schirra, and S, Walston), pp.163–171, TMS, PA, USA (2004).

Z. Guo and W. Sha, Mater. Trans. 43, 1273 (2002).

A. J. Ardell, Metall. Mater. Trans. A 16, 2131 (1985).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Garay-Reyes, C.G., Hernández-Martínez, S.E., Hernández-Rivera, J.L. et al. Comparative study of Oswald ripening and trans-interface diffusion-controlled theory models: Coarsening of γ′ precipitates affected by elastic strain along a concentration gradient. Met. Mater. Int. 23, 298–307 (2017). https://doi.org/10.1007/s12540-017-6388-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-017-6388-3