Abstract

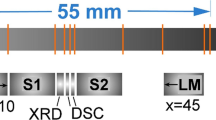

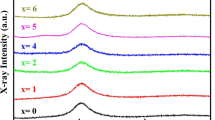

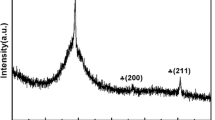

The effect of the type of the crystalline phase and its volume fraction on the mechanical property of Cu50Zr50-xTix alloys (x = 0-10) bulk metallic glass composites has been investigated in this study. Up to 6 at% of Ti, B19’ phase particles distributed in the glassy matrix, while at 8 and 10% of Ti, B2 phase particles are retained in the glass matrix due to suppression of the eutectoid transformation of B2 phase and by avoidance of martensitic transformation of B2 into B19’. The volume fraction of crystalline phase is strongly dependent on the cooling rate. The larger volume fraction of the crystalline phases results in the lower yield stress, the higher plastic strain, and the more pronounced work hardening behavior. At the crystalline volume fraction below ~30%, the variation of the yield strength can be described by the rule of mixture model (ROM), while at the crystalline volume fraction higher than ~50% by the load-bearing model (LBM). At the crystal fractions between 30 and 50%, there is a yield strength drop and a transition from the ROM to the LBM. This transition is due to the formation of the crystalline structural framework at higher crystal fraction.

Similar content being viewed by others

References

A. L. Greer, Science 267, 1947 (1995).

M. F. Ashby and A. L. Greer, Scripta Mater. 54, 321 (2006).

B.-T. Jang, Y.-I. Kim, and S.-H. Yi, Korean J. Met. Mater. 53, 519 (2015).

A. Inoue and A. Takeuchi, Acta Mater. 59, 2243 (2011).

X. H. Du, J. C. Huang, H. M. Chen, H. S. Chou, Y. H. Lai, P. K. Liaw, et al., Intermetallics 17, 607 (2009).

C. P. P. Chou and F. Spaepen, Acta Metall. 23, 609 (1975).

G. He, W. Löser, J. Eckert, and L. Schultz, Mat. Sci. Eng. A 352, 179 (2003).

R. Li, S. Pang, H. Men, C. Ma, and T. Zhang, Scripta Mater. 54, 1123 (2006).

H. Choi-Yim and W. L. Johnson, Appl. Phys. Lett. 71, 3808 (1997).

R. D. Conner, R. B. Dandliker, and W. L. Johnson, Acta Mater. 46, 6089 (1998).

Y. S. Oh, C. P. Kim, S. Lee, and N. J. Kim, Acta Mater. 59, 7277 (2011).

E. S. Park and D. H. Kim, Acta Mater. 54, 2597 (2006).

M. Chen, Annu. Rev. Mater. Res. 38, 445 (2008).

M. L. Lee, Y. Li and C. A. Schuh, Acta Mater. 52, 4121 (2004).

S. H. Hong, J. T. Kim, M. W. Lee, J. M. Park, M. H. Lee, K. B. Kim, et al., Metall. Mater. Trans. A 45, 2376 (2014).

S. H. Hong, J. T. Kim, H. J. Park, Y. S. Kim, J. M. Park, K. B. Kim, et al., Appl. Microsc. 45, 37 (2015).

D. C. Hofmann, J. Y. Suh, A. Wiest, G. Duan, M. L. Lind, M. D. Demetriou, and W. L. Johnson, Nature 451, 1085 (2008).

S. H. Hong, J. T. Kim, H. J. Park, J. Y. Suh, K. R. Lim, Y. S. Na, J. M. Park, and K. B. Kim, Intermetallics 62, 36 (2015).

E. S. Park and D. H. Kim, Met. Mater. Int. 11, 19 (2005).

Y. H. Liu, G. Wang, R. J. Wang, D. Q. Zhao, M. X. Pan, and W. H. Wang, Science 315, 1385 (2007).

S. Pauly, J. Das, J. Bednarcik, N. Mattern, K. B. Kim, D. H. Kim, and J. Eckert, Scripta Mater. 60, 431 (2009).

K. K. Song, S. Pauly, Y. Zhang, P. Gargarella, R. Li, J. Eckert, et al., Acta Mater. 59, 6620 (2011).

Y. Wu, Y. Xiao, G. Chen, C. T. Liu, and Z. Lu, Adv. Mater. 22, 2770 (2010).

P. Yu, H. Y. Bai, and W. H. Wang, J. Mater. Res. 21, 1674 (2006).

H. Men, S. J. Pang, and T. Zhang, Mat. Sci. Eng. A 408, 326 (2005).

W. Zhang and A. Inoue, J. Mater. Res. 21, 234 (2006).

H.-J. Jun, K. S. Lee, C. P. Kim, and Y. W. Chang, Met. Mater. Int. 14, 297 (2008).

T.-H. Nam, J.-Y. Jang, and E.-S. Kim, Korean J. Met. Mater. 53, 451 (2015).

Y. N. Koval, G. S. Firstov, L. Delaey, and J. V. Humbeeck, Scripta Metall. Mater. 31, 799 (1994).

A. Castellero, T. A. Baser, J. Das, P. Matteis, J. Eckert, L. Battezzati, and M. Baricco, J. Alloy. Compd. 509, S99 (2011).

S. Pauly, G. Liu, G. Wang, U. Kühn, N. Mattern, and J. Eckert, Acta Mater. 57, 5445 (2009).

P. Gargarella, S. Pauly, M. Samadi Khoshkhoo, U. Kühn, and J. Eckert, Acta Mater. 65, 259 (2014).

M. Matsuda, K. Hayashi, and M. Nishida, Mater. Trans. 50, 2335 (2009).

M. Matsuda, T. Nishimoto, Y. Morizono, S. Tsurekawa, and M. Nishida, Intermetallics 19, 894 (2011).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kim, B.J., Yun, Y.S., Kim, W.T. et al. Phase formation and mechanical properties of Cu-Zr-Ti bulk metallic glass composites. Met. Mater. Int. 22, 1026–1032 (2016). https://doi.org/10.1007/s12540-016-6386-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-016-6386-x