Abstract

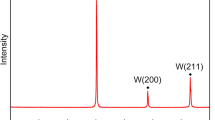

The reduction of sintering temperatures in industrial processes is advantageous for both energy efficiency and material properties in powder metallurgy. Based on the well-known size effects of nano-particles on sintering processes, nano-particles were intentionally used as a homogeneous sintering activator for micro-particles in this study. Two kinds of tungsten bimodal feedstocks which consisted of nano-particles and microparticles were prepared and sintered by spark plasma sintering processed. Even at the low sintering temperature of 1,250 °C and the short sintering time of 300 sec, relatively high densities could be achieved. Depending on the content of the nano-particles in the charged feedstock, the sintered body exhibited different morphological features. Density, field emission scanning electron microscopy, transmission electron microscope was used for analysis.

Similar content being viewed by others

References

R. M. German, Powder Metallurgy and Particulate Materials Processing 38, 522 (2005).

M. Dewidar, Mater. Design 31, 3964 (2010).

A. Bose, B. R. Klotz, F. R. Kellogg, K. C. Cho, and R. J. Dowding, Proc. Int. Conf. on W, Refract & Hardmetals VII, pp. 5-35–5-48, MPIF (2008).

R. Malewar, K. S. Kumar, B. S. Murty, B. Sarma, and S. K. Pabi, J. Mater. Res. 22, 1200 (2007).

J. R. Groza, Int. J. Powder Metall. 35, 59 (1999).

S. Arcidiacono, N. R. Bieri, D. Poulikakos, and C. P. Grigoropoulos, Int. J. Multiphas. Flow 30, 979 (2004).

P. Zeng, S. Zajac, P. C. Clapp, and J. A. Rifkin, Mater. Sci. Eng. A 252, 301 (1998).

R. M. German, Sintering Theory and Practice, pp.271–279, John Wiley and Sons, New York (1996).

S. V. Dresvin and J. Amouroux, Advances in Heat Transfer 40, 451 (2007).

R. C. Flagan and M. M. Lunden, Mater. Sci. Eng. A 204, 113 (1995).

T. Karabacak, P. I. Wang, G. C. Wang, and T. M. Lu, Thin Solid Films 493, 293 (2005).

S. M. Rossnagel, I. C. Noyan, and C. Cabral, J. Vac. Sci. Technol. A 20, 2047 (2002).

A. Mondal, A. Upadhyaya, and D. Agrawal, Int. J. Refract Met. H. 28, 597 (2010).

R. Orru, R. Licheri, A. M. Locci, A. Cincotti, and G. Cao, Mater. Sci. Mater. R 63, 127 (2009).

R. E. Hummel, Int. Mater. Rev. 39, 97 (1994).

R. Chaim, Mater. Sci. Eng. A 443, 25 (2007).

R. M. German, Sintering Theory and Practice, pp. 280–292, John Wiley and Sons, New York (1996).

W. Zhang and I. Gladwell, Comp. Mater. Sci. 12, 84 (1998).

R. M. German, Sintering Theory and Practice, pp. 184–200, John Wiley and Sons, New York (1996).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Han, C., Choi, H. & Kim, B. Nano-attached tungsten particle synthesis and sintering behaviors. Met. Mater. Int. 19, 1035–1039 (2013). https://doi.org/10.1007/s12540-013-5016-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-013-5016-0