Abstract

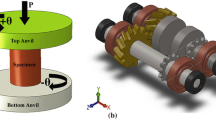

High pressure torsion (HPT) is useful for achieving substantial grain refinement to ultrafine grained/nanocrystalline states in bulk metallic solids. Most publications that analyzed the HPT process used experimental and numerical simulation approaches, whereas theoretical stress analyses for the HPT process are rare. Because of the key role of compression stage for the deformation of HPT, this paper aims to conduct a theoretical analysis and to establish a practical formula for stress and forming parameters of HPT process using the slab analysis method. Three equations were obtained via equations derivation to describe the normal stress states corresponding to the three zones of plastic deformation for HPT process as stick zone, drag zone and slip zone. As to the compression stage of HPT, the stress distribution results using the finite element method agree well with those using the slab analysis method. There are drag and stick zones on the contact surface of the HPT sample, as verified by the finite element method (FEM) and slab analysis method.

Similar content being viewed by others

References

H. S. Kim and Y. Estrin, Appl. Phys. Lett. 79, 4115 (2001).

J. Liu, H. Cui, X. Zhou, X. Wu, and J. Zhang, Met. Mater. Int. 18, 121 (2012).

H. S. Kim, C. Suryanarayana, and S. J. Kim, Powder Metall. 41, 217 (1998).

R. Z. Valiev, Y. Estrin, Z. Horita, T. G. Langdon, M. J. Zehetbauer, and Y. T. Zhu, JOM. 58, 33 (2006).

A. P. Zhilyaev and T. G. Langdon, Prog. Mater. Sci. 53, 893 (2008).

Y. Saito, H. Utsunomiya, N. Tsuji, and T. Sakai, Acta Mater. 47, 579 (1999).

M. I. Latypov, I. V. Alexandrov, Y. E. Beygelzimer, S. Lee, and H. S. Kim, Comput. Mater. Sci. 60, 194 (2012).

A. P. Zhilyaev, K. O. Ishi, T. G. Langdon, and T. R. McNelley, Mater. Sci. Eng. A 410–411, 277 (2005).

K. Edalati, T. Fujioka, and Z. Horita, Mater. Sci. Eng. A 497, 168 (2008).

R. B. Figueiredo, M. T. Aguilar, C. PauloR, and T. G. Langdon, Metall. Mater. Trans. A 42, 3013 (2011).

A. Hohenwarter, A. Bachmaier, B. Gludovatz, S. Scheriau, and R. Pippan, Int. J. Mater. Res. 100, 1653 (2009).

G. Y. Tzou, H. H. Hsu, and Y. H. Hsiao, J. Mater. Proc. Tech. 177, 150 (2006).

L. Huang, H. Yang, M. Zhan, and Y. L. Li, J. Mater. Proc. Tech. 201, 267 (2008).

D. W. Zhang, H. Yang, and Z. C. Sun, J. Mater. Proc. Tech. 210, 258 (2010).

X. C. Tan, Tribolo. Int. 35, 385 (2002).

N. Bay and G. Gerved, J. Mechan. Working Tech. 14, 263 (1987).

D. R. Hayhurst and M. W. Chan, Int. J. Mechan. Sci. 47, 1 (2005).

Y. P. Song, W. K. Wang, D. S. Gao, E. Y. Yoon, D. J. Lee, C. S. Lee, and H. S. Kim, J. Mater. Sci. 48, 4698 (2013).

B. Roberto, P. Henrique, M. Teresa, R. Paulo, and T. G. Terence, Acta Mater. 60, 3190 (2012).

S. C. Yoon, Z. Horita, and H. S. Kim, J. Mater. Proc. Tech. 201, 32 (2008).

T. Hebesberger, H. P. Stuwe, A. Vorhauer, F. Wetscher, and R. Pippan, Acta Mater. 53, 393 (2005).

Y. Cao, Y. B. Wang, S. N. Alhajeri, X. Z. Liao, W. L. Zheng, S. P. Ringer, T. G. Langdon, and Y. T. Zhu, Mater. Sci. 45, 765 (2010).

A. Vorhauer and R. Pippan, Scripta Mater. 51, 921 (2004).

Y. P. Song, E. Y. Yoon, D. J. Lee, J. H. Lee, and H. S. Kim, Mater. Sci. Eng. A 13–14, 4840 (2011).

H. S. Kim, J. Mater. Proc. Tech. 113, 617 (2001).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, W., Song, Y., Gao, D. et al. Analysis of stress states in compression stage of high pressure torsion using slab analysis method and finite element method. Met. Mater. Int. 19, 1021–1027 (2013). https://doi.org/10.1007/s12540-013-5014-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-013-5014-2