Abstract

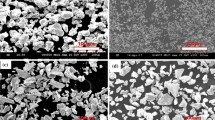

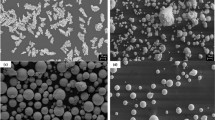

Copper powder was cryomilled for 12 hours to achieve particle size in the range of 2 μm to 25 μm, which powder was subsequently used as feedstock for the deposition of nanocrystalline (nc) Cu coating via cold spraying. The as-milled copper powder was characterized by X-ray diffraction (XRD), scanning electron microscopy (SEM) and high resolution transmission electron microscopy (HRTEM). The particle size of the cryomilled Cu powder was detected by laser scattering. The microstructure of the coating was analyzed using SEM and scanning transmission electron microscopy (STEM). The XRD and HRTEM analysis showed that the grain size of the cryomilled Cu powder was about 5 to 40 nm. This nanoscale structure was retained after the cold spraying. The nanoindentation analysis showed that the nc Cu coating hardness value reached 3.3 GPa, which was higher than that of its coarse grained counterpart.

Similar content being viewed by others

References

H. Gleiter, Prog. Mater. Sci. 33, 223 (1989).

M. A. Meyers, A. Mishra, and D. J. Benson, Prog. Mater. Sci. 51, 427 (2006).

D. B. Witkin and E. J. Lavernia, Prog. Mater. Sci. 51, 1 (2006).

E. J. Lavernia, B. Q. Han, and J. M. Schoenung, Mater. Sci. Eng. 493, 207 (2008).

J. H. He and J. M. Schoenung, Mater. Sci. Eng. 336, 274 (2002).

A. Papyrin, V. Kosarev, S. Klinkov, A. Alkhimov, and V. Fomin, Cold Spray Technol., p. 1, Elsevier Science, Amsterdam (2007).

V. K. Champagne Jr., The Cold Spray Materials Deposition Process, p. 1, Woodhead Publishing, Cambridge (2007).

G. Bae, Y. M. Xiong, S. Kumar, K. Kang, and C. H. Lee, Acta Mater. 56, 4858 (2008).

G. Bae, S. Kumar, S. H. Yoon, K. Kang, H. Na, H. J. Kim, and C. H. Lee, Acta Mater. 57, 5654 (2009).

P. C. King, G. Bae, S. H. Zahiri, M. Jahedi, and C. H. Lee, J. Thermal Spray Technol. 19, 620 (2010).

G. Bae, K. Kang, J. J. Kim, and C. H. Lee, Mater. Sci. Eng. A 527, 6313 (2010).

G. Bae, K. Kang, H. Na, J. J. Kim, and C. H. Lee, Surf. Coat. Technol. 204, 3326 (2010).

Y. Zou, W. Qin, E. Irissou, J. G. Legoux, S. Yue, and J. A. Szpunar, Scr. Mater. 61, 899 (2009).

S. Kumar, G. Bae, and C. H. Lee, Appl. Surf. Sci. 255, 3472 (2009).

K. Spencer and M.-X. Zhang, Scr. Mater. 61, 44 (2009).

J. Cho, J. Kim, S. Y. Hwang, and C. H. Lee, Rev. Adv. Mater. Sci. 18, 50 (2008).

S. H. Yoon, H. J. Kim, and C. H. Lee, Surf. Coat. Technol. 200, 6022 (2006).

S. H. Yoon, Y. M. Xiong, H. Kim, and C. H. Lee, Appl. Phys. 42, 1 (2009).

S. H. Yoon, G. Bae, Y. M. Xiong, S. Kumar, K. Kang, J. J. Kim, and C. H. Lee, Acta Mater 57, 6191 (2009).

K. Spencer, D. M. Fabijanic, and M.-X. Zhang, Surf. Coat. Technol. 204, 336 (2009).

H. J. Kim, D. H. Jung, J. H. Jang, and C. H. Lee, Mater. Sci. Forum 534, 441 (2007).

H. Na, G. Bae, S. Shin, S. Kumar, H. J. Kim, and C. H. Lee, Compos. Sci. Technol. 69, 463 (2009).

L. Ajdelsztajn, B. Jodoin, G. E. Kim, and J. M. Schoenung, Metall. Mater. Trans. A 36, 657 (2005).

P. Richer, B. Jodoin, L. Ajdelsztajn, and E. J. Lavernia, J. Thermal Spray Technol. 15, 246 (2006).

L. Ajdelsztajn, A. Zúñiga, B. Jodoin, and E. J. Lavernia, J. Thermal Spray Technol. 15, 184 (2006).

A. C. Hall, L. N. Brewer, and T. J. Roemer, J. Thermal Spray Technol. 17, 352 (2008).

W.-Y. Li and C.-J. Li, Appl. Surf. Sci. 256, 2193 (2010).

L. Ajdelsztajn, B. Jodoin, and J. M. Schoenung, Surf. Coat. Technol. 201, 1166 (2006).

R. S. Lima, J. Karthikeyan, C. M. Kay, J. Lindemann, and C. C. Berndt, Thin Solid Films 416, 129 (2002).

C.-J. Li, G.-J. Yang, P.-H. Gao, J. Ma, Y.-Y. Wang, and C.-X. Li, J. Thermal Spray Technol. 16, 1011 (2007).

P. Sudharshan Phani, V. Vishnukanthan, and G. Sundararajan, Acta Mater. 55, 4741 (2007).

S. R. Bakshi, V. Singh, K. Balani, D. G. McCartney, S. Seal, and A. Agarwal, Surf. Coat. Technol. 202, 5162 (2008).

Y.-M. Xiong, K. Kang, S. H. Yoon, and C. H. Lee, J. Nanosci. Nanotechnol. 8, 5561 (2008).

J. S. Cheng, H. Cui, H. B. Chen, B. Yang, J. Z. Fan, and J. S. Zhang, J. Univ. Sci. Technol. 14, 523 (2007).

H. Cui, K. Tao, X. L. Zhou, and J. S. Zhang, Rare Met. 27, 418 (2008).

K. Tao, X.-L. Zhou, H. Cui, H.-B. Chen, Y.-B. Li, and J.-S. Zhang, Int. J. Min. Met. Mater. 16, 77 (2009).

Z. Zhang, F. Zhou, and E. J. Lavernia, Metall. Mater. Trans. A 34, 1349 (2003).

J. Milligan, R. Vintila, and M. Brochu, Mater. Sci. Eng. A 508, 43 (2009).

X. D. Li and B. Bhushan, Mater. Charact. 48, 11 (2002).

C. A. Schuh, Mater. Today 9, 32 (2006).

V. L. Tellkamp, A. Melmed, and E. J. Lavernia, Metall. Mater. Trans. A 32, 2335 (2001).

J. Chen, L. Lu, and K. Lu, Scr. Mater. 54, 1913 (2006).

Y. M. Wang, K. Wang, D. Pan, K. Lu, K. J. Hemker, and E. Ma, Scr. Mater. 48, 1581 (2003).

R. Z. Valiev, I. V. Alexandrov, Y. T. Zhu, and T. C. Lowe, J. Mater. Res. 17, 5 (2002).

Y. Champion, S. Guérin-Mailly, J.-L. Bonnentien, and P. Langlois, Scr. Mater. 44, 1609 (2001).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Liu, J., Cui, H., Zhou, X. et al. Nanocrystalline copper coatings produced by cold spraying. Met. Mater. Int. 18, 121–128 (2012). https://doi.org/10.1007/s12540-012-0014-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-012-0014-1