Abstract

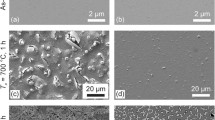

Effects of vacuum conditions on the oxygen content and microstructure of Mo layers used with Cu gate lines as thin-film transistor-liquid crystal display diffusion barriers were investigated. Mo was deposited using ion-beam sputtering at 1.0 × 10−5 and 7.0 × 10−7 Torr. The Mo layer oxygen content and the microstructure and changes in chemical composition of the Cu/Mo/SiO2/Si layer during annealing were examined. The Mo layer microstructure was influenced by oxygen; increasing concentration increased the energy required for secondary grain growth. Growth was suppressed at high oxygen levels. Therefore, diffusion barrier performance is enhanced by finer Mo layer grain sizes.

Similar content being viewed by others

Reference

N. Ibaraki, Materials chemistry and physics 43, 220 (1996).

J. Echigoya, J. Enoki, T. Satoh, T. Waki, T. Ohmi, M. Otsuki, and T. Shibata, Appl. Surf. Sci. 56–58, 463 (1992).

I. M. Park, S. J. Hwang, J. H. Lee, and Y. C. Joo, Met. Mater. Int. 15, 661 (2009).

S. Chambers, V. Loebs, and K. Chakravorty, J. Vac. Sci. Tec. A: Vacuum, Surfaces, and Films 8, 875 (1990).

C. K. Hu, B. Luther, F. B. Kaufman, J. Hummel, C. Uzoh, and D. J. Pearson, Thin Solid Films 262, 84 (1995).

W. A. Lanford, P. J. Ding, W. Wang, S. Hymes, and S. P. Muraka, Thin Solid Films 262, 234 (1995).

T. Tsujimura, H. Kitahara, A. Makita, P. M. Fryer, and J. Batey, Proc. Int. Display Research, pp.424–427, Society for Information Display, San Jose (1994).

J. D. McBrayer, R. Swanson, and T. Sigmon, J. Electrochem. Soc. 133, 1242 (1986).

S. M. Yi, J. U. An, S. S. Hwang, J. R. Yim, Y. H. Huh, and Y. B. Park, Thin Solid Films 516, 2325 (2008).

P. J. Ding, W. A. Lanford, S. Hymes, and S. P. Muraka, Appl. Phys. Lett. 64, 2897 (1994).

J. Li, J. Mayer, and E. Colgan. J. Appl. Phys. 70, 2820 (1991).

H. Ono, T. Nakano, and T. Ohta. Appl. Phys. Lett. 64, 1511 (1994).

Chang, C.-C., J. S. Chen, and W.-S. Hsu, J. Electrochem. Soc. 151, 746 (2004).

C. M. Cho, J. H. Kim, S. R. Hwang, Y. H. Youn, and Y. J. Oh, Korean J. Met. Mater. 48, 1116 (2010).

P. Majumder and C. G. Takoudis, Appl. Phys. Let. 91, 62108 (2007).

C. Cabral Jr., C. Lavoie, J. M. E. Harper, and J. Jordan-Sweet, Thin Solid Films 397, 194 (2001).

C. V. Thompson, Annu. Rev. Mater. Sci. 30, 159 (2000).

D. S. Gianola, B. G. Mendis, X. M. Cheng, and K. J. Hemker, Mat. Sci. Eng. A 483, 637 (2008).

L. A. Clevenger, N. A. Bojarczuk, K. Holloway, J. M. E. Harper, C. Cabral, R. G. Schad, F. Cardone, and L. Stolt, J. Appl. Phys. 73, 300 (1993).

T. Laurila, K. Zeng, J. K. Kivilahti, J. Molarius, and I. Suni, J. Appl. Phys. 88, 3377 (2000).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gu, G.H., Park, S.M. & Park, C.G. Impurity-controlled Mo films as diffusion barriers for Cu metallization. Met. Mater. Int. 18, 517–520 (2012). https://doi.org/10.1007/s12540-012-3021-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-012-3021-3