Abstract

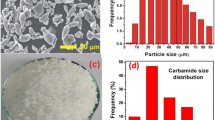

Aluminum foam has been produced by sintering and dissolution processes using NaCl powders as a space holder. In this research, glycerin is used as a novel lubricant along with acetone. The effects of the processing parameters including compacting pressure, sintering temperatures (620, 640 and 650 °C), size, and volume fraction of the space holder, on the physical and mechanical properties of the produced foams have been investigated. Due to segregation of the Al and NaCl powders at high compaction pressures, spalling of Al foams was observed. Meanwhile, adding small amounts of acetone and glycerin to the mixture ensures homogeneity and prevents segregation of dissimilar powders at varying pressure. Moreover, the addition of glycerin provides an improved homogenous stress distribution within the produced foams during mechanical testing, which in turn halts crack propagation. Meanwhile, an alternative technique to remove NaCl particles during the dissolution stage has been proposed. The results showed that high quality foams were successfully produced under a compaction pressure range of 250–265 MPa and sintering temperature of 650 °C.

Similar content being viewed by others

References

M. F. Ashby, A. G. Evans, N. A. Fleck, L. J. Gibson, J. W. Hutchinson, and H. N. G. Wadley, Metal foams: a design guide, pp. 1–5, Butterworth-Heinemann, USA (2000).

H. Bafti and A. Habibolahzadeh, Mater. Des. 31, 4122 (2010).

Y. Haijun, G. Zhiqiang, L. Bing, and Y. Guangchun, Mater. Sci. Eng. A 454–455, 542 (2007).

Y. Y. Zhao and D. X. Sun, Scr. Mater. 44, 105 (2001).

Y. Zhao, H. Fusheng, and T. Fung, Mater. Sci. Eng. A 364, 117 (2004).

R. Surace, L. A. C. De Filippis, A. D. Ludovico, and G. Boghetich, Mater. Des. 30, 1878 (2009).

N. Michailidis and F Stergioudi, Mater. Des. 32, 1559 (2011).

H. A. Kuchek, US Patent 3,236, 706 (1966).

C. Gaillard, J. F. Despois, and A. Mortensen, Mater. Sci. Eng. A 374, 250 (2004).

M. Mazli and M. Othman, National Postgraduate Symp., p.48, Universiti Teknologi Petronas, Tronoh, Perak, Malaysia (2008).

D. Lehmhus and J. Banhart, Mater. Sci. Eng. A 349, 98 (2003).

C. Y. Wu, B. C. Hancock, A. Mills, A. C. Bentham, S. M. Best, and J. A. Elliott, Powder Technol. 181, 121 (2008).

C. Y. Wu, O. M. Ruddy, A. C. Bentham, B. C. Hancock, S. M. Best, and J. A. Elliott, Powder Technol. 152, 107 (2005).

D. X. Sun and Y. Y. Zhao, Metall. Mater. Trans. B 34, 69 (2002).

Y. J. Yang, F. S. Han, D. K. Yang, and K. Zeng. Mater. Sci. Technol. 23, 502 (2007).

Y. Sirong, L. Jiaan, W. Ming, L. Yanru, Z. Xianyong, and L. Yaohui, Mater. Des. 30, 87 (2009).

J. Banhart, Prog. Mater. Sci. 46, 559 (2001).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gilani, H., Jafari, S., Gholami, R. et al. Effect of processing parameters and glycerin addition on the properties of Al foams. Met. Mater. Int. 18, 327–333 (2012). https://doi.org/10.1007/s12540-012-2018-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-012-2018-2