Abstract

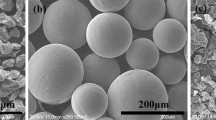

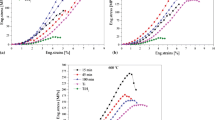

Three similar varieties of pure Ti hydride-dehydried (HDH) powders were tested for the understanding of the variables that have an influence on the compaction process of Ti powders. The study shows that small differences in the characteristics of the powders lead to very different behaviours in the compaction stage. Compressibility curves, friction with the die walls and ejection forces are discussed in this study. The results are compared with a commercial iron powder as a reference to complete the discussion, as well as to show the enhancements and modifications that should be performed in Ti powders to design an optimized powder suitable for being pressed in an industrial process.

Similar content being viewed by others

References

M. J. Donachie (ed.), Titanium. A Technical Guide, p. 1–4, ASM International, Metals Park, OH, USA (1988).

G. Lütjering and J. C. Williams, Titanium. Engineering Materials and Processes, p. 15, Springer, Berlin-Heidelberg (2003).

EHKTechnologies, Summary of Emerging Titanium Cost Reduction Technologies, A Study Performed for US Department of Energy and Oak Ridge National Laboratory, Subcontract 4000023694, USA (2004).

G. Crowley, Adv. Mater. Process. 161, 25 (2003).

G. Z. Chen, D. J. Fray, and T. W. Farthing, Nature 407, 361 (2000).

EHK Technologies, Opportunities for Low Cost Titanium in Reduced Fuel Consumption, Improved Emissions, and Enhanced Durability Heavy-Duty Vehicles. Subcontract 4000013062, USA (2002).

C. A. Lavender, Low-Cost Titanium Evaluation (ed., F. P. Report) Automotive Lightweighting Materials, Contractor: Pacific Northwest national laboratory (2004).

T. E. Norgate and G. Wellwood, Jom 58, 58 (2006).

J. C. Williams and E. A. Starke, Acta mater. 51, 5775 (2003).

D. Raabe, B. Sander, M. Friak, D. Ma, and J. Neugebauer, Acta mater. 55, 4475 (2007).

S. L. Zhu, X. M. Wang, F. X. Qin, and A. Inoue, Mater. Sci. Eng. A 459, 233 (2007).

M. Karanjai, R. Sundaresan, G. V. N. Rao, T. R. R. Mohan, and B. P. Kashyap, Mater. Sci. Eng. A 447, 19 (2007).

H. J. Rack and J. I. Qazi, Mater. Sci. Eng. C 26, 1269 (2006).

Y. Hovanski, C. A. Lavender, and K. Scott Weil, Proc. 2008 World Congress on Powder Metallurgy & Particulate Materials (ed., MPIF), Washington D.C., USA (2008).

S.-T. Hong, Y. Hovanski, C. A. Lavender, and K. S. Weil, J. Mater. Eng. Perform. 13, 382 (2008).

A. Simchi and G. Veltl, Powder Metall. 49, 281 (2006).

A. Laptev, O. Vyal, M. Bram, H. P. Buchkremer, and D. Stover, Powder Metall. 48, 358 (2005).

H. Takamiya, M. Kondoh, and T. Saito, Cost-Affordable Titanium (eds., F. H. Froes, M. Ashraf, and D. Fray), p. 185–192, TMS, Warrendale, PA (2004).

MPIF Standard 04, Method for Determination of Apparent Density of the Free-Flowing Metal Powders using the Hall Apparatus, Metal Powder Industries Federation (1985).

MPIF Standard 28, Method for Determination of Apparent Density of Non-the Free-Flowing Metal Powders using the Carney Apparatus, Metal Powder Industries Federation (1985).

Powder Testing Center model PTC-03DT, User’s Manual V-20 (1996).

S. St-Laurent, F. Chagnon, and Y. Thomas, Advances in Powder Metallurgy and Particulate Materials (eds., H. Ferguson and D. T. Whychell), p. 79–91, Metal Powder Industries Federation, Princeton, NJ (2000).

P.-E. Mongeon, S. Pelletier, and A. Ziani, U.S. Patent No. 6299690 (2001).

P. Lemieux, S. Pelletier, P.-E. Mongeon, L. P. Lefebvre, Y. Thomas, and F. Chagnon, Advances in Powder Metallurgy and Particulate Materials (eds., B. Eisen and S. Kassam), p. 1–13, Metal Powder Industries Federation, Princeton, NJ (2001).

S. Roure, D. Bouvard, P. Dor’emus, and E. Pavier, Powder Metall. 42, 164, (1999).

P. Mosbah, D. Bouvard, F. Ouedraogo, and P. Stutz, Powder Metall. 40, 269 (1997).

Y. Thomas, S. Pelletier, and J. M. McCall, Advances in Powder Metallurgy and Particulate Materials (eds., J. J. Oakes and J. H. Reinshagen), p. 11.25–11.38, Metal Powder Industries Federation, Princeton, NJ, USA (1998).

Y. Thomas, L. Azzi, T. Baazi, and S. Pelletier, Advanced in Powder Metallurgy and Particulate Materials (eds., C. Ruas and T. A. Tomlin), p. 3.84–3.96, Metal Powder Industries Federation, Princeton, NJ, USA (2005).

S. Turenne, C. Godère, Y. Thomas, and P. E. Mongeon, Powder Metall. 42, 263 (1999).

E. Fukasawa, R. Murayama, and W. Kagohashi, Titanium’ 92: Science and Technology, Vol. 1–3 (eds., F. H. Froes and I. L. Caplan), p. 919–926, TMS, USA (1993).

H. Conrad, Prog. Mater. Sci. 26, 123 (1981).

R. I. Jaffee, H. R. Ogden, and D. J. Maykuth, Transactions of the American Institute of Mining and Metallurgical Engineers 188, 1261–1266 (1950).

R. I. Jaffee, I. E. Campbell, T. Am. I. Min. Met. Eng. 185, 646 (1949).

L. P. Lefebvre and E. Baril, Adv. Eng. Mater. 10, 868 (2008).

M. Textor, C. Sittig, V. Frauchiger, S. Tasatti, and D. M. Brunette, Titanium in Medicine, p. 171, Springer, Berlin Heidelberg (2001).

M. Ward and J. C. Billington, Powder Metall. 22, 201 (1979).

E. Klar and P. Samal, Powder Metallurgy of Stainless Steels: Processing, Microstructures, and Properties, p. 39, ASM International, Materials Park, OH, USA (2007).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Esteban, P.G., Thomas, Y., Baril, E. et al. Study of compaction and ejection of hydrided-dehydrided titanium powder. Met. Mater. Int. 17, 45–55 (2011). https://doi.org/10.1007/s12540-011-0207-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-011-0207-z