Abstract

A group of a well-known polychrome glazed ceramic, widespread in the western Mediterranean in the eleventh and first half of the twelfth centuries, has been analysed for the first time using Optical Microscopy (OM) and a Field Emission Scanning Electron Microscopy (FE-SEM) with Energy-Dispersive X-ray Spectroscopy (EDS), in order to shed some light on the materials, production technology and provenance, about which there are various hypotheses. This ware is characterised by a perfectly drawn and varied iconography, with often stylised zoomorphic and anthropomorphic and nautical motifs. It was produced in an as yet unidentified workshop in North Africa or the Iberian Peninsula. The pottery analysed was found in an archaeological excavation in the Barrio Andalusi of Almería (south-east of Spain). Technologically, the ceramics are fairly homogeneous, with copper-green and manganese-brown pigments applied over the raw tin glaze filled with large undissolved quartz particles. The use of quartz is consistent with a Fatimid-Zirid contribution from Ifriqiya, the use of tin is consistent with an Andalusi Umayyad-Taifas contribution, and the green and brown colours on a white ground to either Ifriqiya or Andalusi. Our study has shown that the use of quartz on the decorated glazed surface is not related to the need for an opacifier, but rather to the need for a highly viscous melt that limits the spread of the pigments during the firing allowing a finer and more detailed drawing. This fusion of different techniques has been identified for the first time. It is intriguing from the historical point of view of medieval technology, and provides the first insights into understanding the technological transfers and technical solutions that took place in the Mediterranean basin during this period.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

There is a type of Islamic polychrome glazed ware that was widespread in the western Mediterranean and which, according to archaeological contexts, is usually dated in the middle centuries of the Middle Ages, in the chronological arc from the mid-eleventh century to the mid- twelfth century. It is a testimony of the commercial boom experienced by the westernmost coastal regions of the Mediterranean in those medieval centuries. It is a very characteristic and easily identifiable glazed pottery that appears mainly in the main ports of the western Mediterranean, both in al-Andalus and in North Africa. These are mainly Islamic harbours, such as Valencia, Denia, Mallorca, Alicante, Cartagena, Almería, Málaga, Ceuta and Argel (Azuar 2019; Hita and Villada 2007; Stiti and Souq 2010), although it has also been documented in some river ports, such as Seville (Rodríguez and Castelló 2008) or Mértola (Gómez 2014), in inland areas of Algeria, such as Sétif or Qala Beni Hammad (Mohamedi et al. 1991; Djellid 2011), and has also been found in the Christian church of San Zeno in Pisa (Berti and Tongiorgi 1981) (see map in Fig. 1).

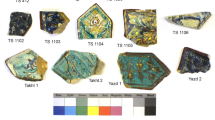

This ware circulated throughout the western Mediterranean, travelling in the cargoes of ships, along with other types of goods that are not usually preserved, mainly foodstuffs and craft products such as cloth (Wickham 2023), as evidenced by the fact that most of the objects are found in ports. It was the fashionable ware of the time, a semi-luxury ceramic (Fig. 2), which was consumed in urban environments, possibly by the merchant bourgeoisie. As far as we know, it has not been found in enclaves in the eastern Mediterranean or beyond the great sea.

This glazed ware is represented by open forms, mainly ataifores (serving dishes), but also some alcadafes (basins). The most characteristic shape is a large and deep bowl with a thick ring feet, curved bodies and flat everted rims. The inside surface is decorated with a very rich and perfectly drawn iconography, with an abundance of often stylised zoomorphic and anthropomorphic representations: gazelles, lions, elephants, greyhounds, birds, sailors, soldiers and rulers. There are also boats, plants, geometric motifs and two- and three-string braids (Djellid and Salinas 2022). Some compositions are abstract in style. The drawings are executed in brown on a white ground, with some areas filled in with green, and with semicircles drawn in brown and filled in green at the flat everted rims (see Fig. 2). The undecorated side is covered with a green or white monochrome glaze.

It is a polychrome ware that has aroused great deal of interest because it is found in many parts of the Mediterranean, but it is not known where it was made, as the centre of production has not yet been identified. There are various hypotheses, which can be divided into two main groups: (1) North African origin, proposed to be Kairouan (Ifriqiya, Tunisia) or Qala Beni-Hammad (Algeria); 2) Andalusi origin, proposed to be Denia, Mallorca, Málaga (Spain) or the Algarve (Portugal) (Azuar 2012; Djellid 2019; Gisbert 2018; Gonçalves 2010; Rosselló 1985).

Ignorance of its origin or technology of production has led to a lack of consensus on what to call it, and it has been referred to by several names in the international scientific community: ceramic from Qayrawān, Ḥamādῑd pottery, ceramic from around Kairouan, Sabra and Carthage, Qayrawān-Túnez imitation pottery, “céramique à glaçure opaque à l’étain”, “verde y manganeso” glazed ware, and so on. We have chosen to avoid labelling it according to its possible origin or technology, and have decided to call it “Western Mediterranean Polychrome Glaze” (WMPG), since it uses various colours and is mainly found in different parts of the western Mediterranean.

The aim of this article is to characterise the technology of this production, and in particular how the fine polychrome decorations were produced: the type of glaze, the opacifier used, the way in which the pigments were applied, etc. This is indeed a period that has been little studied from the point of view of glazing technology in the western Mediterranean, unlike earlier (Pechina, Cordoba, Bir Ftouha) and later (Barcelona, Pisa, Orvieto) periods.

A second objective will be to shed more light on the possible origin of this ware, by comparing it with the polychrome glazed tradition of al-Andalus (medieval Islamic Spain and Portugal) and other North African regions, in order to confirm or rule out any technological link.

In order to carry out this study, a collection of fifteen ceramics of this ware was selected from a recent excavation of the archaeological site of Barrio Andalusí in Almería (Spain).

Historical and archaeological context

From the late tenth and eleventh century, there were changes in the western Mediterranean that had been brewing since the ninth century. The Mediterranean regions began to be more closely linked by trade routes and there was a great deal of movement of goods between seaports.

One of the most important western Mediterranean ports of the time was al-Mariyya, the Islamic city of Almería, located in the southeast of Spain. Its importance as a commercial hub is described both by authors of the time, such as al-Rušāṭῑ, and by the documents of the Genizah of Cairo, which tell us of the important connection between Almería and Alexandria, in which Jewish merchants played a protagonist role (Goitein 1967-93; Friedman 2016). This commercial and economic leading role began to develop in the eleventh century, under the Almerian king of the Taifa, Abu Yahya al-Mustasim (1052–1091), and reached its peak during the Almoravid reign (from 1091). However, it was interrupted in 1147 when a coalition of Iberian Christian kings, French crusaders, Genoese and Pisans conquered the city. Although the Christian hiatus lasted only ten years, as the Almohads reconquered al-Mariyya again in 1157, it was enough to wipe out the market niches, which were then largely taken over by the Italians.

In those years, between the second half of the eleventh century and the first half of the twelfth century, a new quarter was built in a privileged enclave of al-Mariyya, within the walled enclosure of the medina, at the foot of the citadel and overlooking the harbour. The neighbourhood has a peculiar Islamic urban layout, with the dwellings arranged in horizontal terraces to adapt to the terrain, and combining dwellings with rammed earth walls and a central courtyard with rooms caved into the rock (Alemán 2023).

Part of this quarter was abandoned after the Christian conquest in 1147 and there is no evidence that it was ever occupied again. In the collapse and abandoned strata of some of the houses, shards of the polychrome glazed ware that is the subject of our study (WMPG) have been found. Sixty-five fragments of this ware have been counted so far in this neighbourhood, a small number in relation to the total amount of pottery (around 1%) and the total number of glazed ware fragments recovered (around 3%), but higher than in the Citadel (Ramos 2022) and in other parts of the city (Azuar 2016; Ramos 2022). Outside Almeria, the same pattern is repeated in other Andalusi settlements, where the WMPG represents a very small number of fragments, in some cases only one counted (e.g. Seville), with the exception of Denia, where the number of fragments is slightly higher, similar to the case of Almería (Gisbert 2018).

Despite some finds in other parts of Almería, WMPG is not present in the high concentrations of other ceramics produced in the potteries of al-Mariyya, such as ‘cuerda seca’ or manganese-painted jugs (Flores et al. 1999). Luxurious lustreware was also produced at al-Mariyya (Flores and Navarro 2013). Both cuerda seca and lustreware from Almeria have been found in Egypt (Rosser-Owen 2013) and southern Portugal (Gómez 2014), demonstrating Almeria’s integration into the Mediterranean and Atlantic trade circuits of the time. However, no archaeological evidence has been found for the production of the WMPG in Almería. Therefore, it is important to analyse it and find any possible material or technological trade that could help us relate it to a specific region.

Western Mediterranean Polychrome Opaque Glazed ware

As far as we know, al-Andalus was the first place in the western Mediterranean, around 900 (Salinas and Pradell 2018), where tin was used to achieve an opaque white background in glazes, a time before the Umayyads proclaimed themselves caliphs (929). Contemporary with the time when the Fatimids took control of the central Maghreb and Ifriqiya (909), defeating the Rustumids and Aghlabids, who did not produce opaque glazes but transparent polychrome glazes (Djellid et al. 2023; Salinas et al. 2020). The study of well-contextualised sites (Salinas et al. 2020, 2022) has shown that contrary to popular belief, the Fatimids did not master the technology of tin opacification either, at least before they left Ifriqiya to settle in Egypt (973). However, they did invent a solution with a similar effect, which consisted of opacification by means of undissolved quartz grains (Salinas et al. 2020). Their successors, the Zirids, continued with the same technology of quartz opacification until at least the first half of the 11th century (Salinas et al. 2022) (Table 1) (Fig. 3).

However, as only a few glazed pottery assemblages from well-contextualised excavations have been analysed, there are still many gaps to be filled. For example, in the 11th century, the Hammadids (Maghreb, Northwest Africa) used a polychrome glazed ware (Djellid 2019) that may have been produced locally, possibly opaque, but as it has not been analysed, we do not know how it was made. We also do not know when tin glazes began to be used in the Maghreb, nor is there any evidence that quartz opacification was used in al-Andalus.

Materials and methods

Samples

Fifteen polychrome glaze sherds found in the collapse strata of the dwellings of the archaeological excavation of the Barrio Andalusí Archaeological site (Almería) were selected and are shown in Fig. 4. All correspond to open forms. Five are of the everted flat rim type with semicircles decoration (MG3, MG4, MG9, MG11, MG15) and one has a different undeveloped rim (MG5), one ring foot (MG2) and the rest correspond to the curved body parts (MG1, MG6, MG7, MG8, MG10, MG12, MG13, MG14).

Analytical techniques

Polished sections through the glazes and into the bodies of the sherds were prepared. The polished sections were examined in reflected light (dark and bright field) with an optical microscope, and in a SEM with attached EDS (Pradell and Molera 2020). A crossbeam workstation (Zeiss Neon 40) equipped with SEM GEMINI (Shottky FE) column and EDS (Ultim EDS Detector, Oxford Instruments. Aztec Oxford Instruments), operated at 20 kV accelerating voltage with 1.1 nm lateral resolution, 20 nA current with 120s measuring times. The glaze and body microstructures were studied and recorded in backscatter mode (BSE) in which the different phases present could be distinguished on the basis of their average atomic number contrast.

Chemical compositions of the bodies were determined by analysing a minimum of two areas, about 3 mm x 2 mm. Because of the porosity of the bodies, the analyses were normalised to 100 wt%, and then averaged. For the glazes, the areas analysed were somewhat smaller, and as far.

as possible, were chosen to avoid areas of weathered glaze and areas near to the glaze-body interface, although this was not always possible in view of the heavily weathered glazes on some of the samples; the results were again averaged. A selection of the non-plastic inclusions within the bodies, and opacifier and other particles in the glazes were also analysed. The EDS system was calibrated using oxide and mineral standards with secondary high lead (K229) and alkali (SRM612) glass standards being used to validate the data. Typical absolute detection limits are 0.1% for Na, Mg, Al, P, K, Ca, Ti, Mn and Fe, 0.2% for Si and Cu, 0.3% for Sn and 0.4% for Pb. In most of the cases this is well below the natural dispersion of the elements both in ceramic fabrics and glazes.

Results

The average and standard deviation of the chemical analyses of the fabrics, obtained by SEM-EDS, are given in Table 2 (full analyses are shown in Supplementary materials Table S1). The average and standard deviation of the chemical composition of the glazes is given in Tables 3 and 4 (full analyses are shown in Supplementary materials Table S2).

Analysis of the ceramic fabrics

The ceramic fabrics (Table 2) of the polychrome glazed wares consist of fairly homogeneous calcareous clays (12.5% CaO, 3.6% MgO, 53.1% SiO2 and 16.8% Al2O3) characterised by a relatively high sodium (2.1% NaO2) and iron (7.0% FeO) and low potassium (1.7% K2O) content.

The ceramic bodies are characterised by a buff-coloured calcareous fabric (Fig. 5A), in some cases with central reddish areas (Fig. 5B), rounded porosity and different types of inclusions, such as red clay fragments (mudstone) (Fig. 5C, D), red iron oxide particles, rose quartz grains (Fig. 5E), biotite micas (Fig. 5F), voids, some glaze fragments and fossils (Fig. 5G, H). This microstructure differs from that of the Almería ceramics, which show abundant micas and some white quartz grains in a reddish calcareous fabric (see Fig. S1).

The homogeneity of the chemical composition and the similarity of the microstructure and inclusions suggest that, despite the richness and variety of the decorative motifs, we may be dealing with a single production.

The presence of cream-coloured areas near to the ceramic surface, while reddish colours are found in the inner areas, Fig. 5A, suggests the use of two firings, one for the ceramic fabric and the second for the glaze. The creamy colours of the calcareous fabrics are due to the greater ceramic transformation of the surface areas compared to the inner areas of the ceramics. This transformation can also be enhanced by the addition of a flux, most commonly salt (NaCl), which melts and the liquid increases the reactivity between the particles. The reaction of the calcium oxide particles with the clay minerals leads to the formation of calcium silicates and aluminosilicates, which tend to incorporate iron into their structure, leaving less free iron oxide responsible for the red colour. Nevertheless, even without the addition of salt, the easy access of the hot gases from the kiln also results in a greater ceramic transformation of the surface areas, and of the development of a creamy surface. This creamy surface is clearly visible as a lighter/creamy coloured layer over the reddish ceramic body in thick ceramics, and can extend to the full thickness in thin ceramics (Molera et al. 1998). However, this only happens when the ceramic is fired without the glaze, i.e. biscuit fired, and the glaze is fired in a second firing process. This means that the ceramics were submitted to two firings, one for the ceramic body and a second one for the glaze.

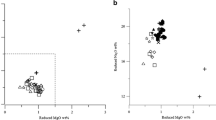

If we compare the petrography and the chemical composition of the local fine ceramics found in two contemporary different workshops of the Almeria pottery quarter with that of our WMPG ceramics, we find important differences, as shown in Fig. 6. The ceramic fabrics corresponding to the glazed tableware products found in Almeria from the 11th and 12th centuries namely, monochrome transparent, cuerda seca and lustre ware, are markedly distinctive. Figure S1 in the Supplementary Materials shows the fabric corresponding to a lustre fragment retrieved from a local workshop (unpublished data). The local fabric is characterised by a fine texture and greater compactness, with an orange clayey matrix containing abundant biotitic micas, with small white sub-angular quartz and a few small fossils. On the other hand, the WMPG fabrics have different inclusions and lower calcium contents compared to the Almeria ceramics. The aforementioned factors, in conjunction with the relatively low percentage of WMPG fragments recovered from archaeological excavations within the city, lead us to posit that the WMPG ceramics were imported.

Analysis of the glazes

The chemical analysis of the glazes is shown in Table 3 and the average and standard deviation of the different coloured areas in Table 4. Details with regard to the identification of the crystalline compounds from the SEM-EDX data are given in Supplementary materials Fig. S2.

The glazes are rich in lead (> 50% PbO) and contain micrometric particles of cassiterite (SnO2) as opacifier. Tin is present in lower amounts (< 1.2% SnO2) or even absent in the glaze corresponding to the undecorated side compared to the that of the decorated side (about 4–10% SnO2). The undecorated glazes are homogeneous and well fused, containing slightly higher amounts of calcium, sodium, potassium, magnesium and iron, and lower amounts of lead, most probably due to the fact that the glaze on the undecorated side is also thinner, around 100 μm, compared to the decorated side (between 200 μm and 400 μm). Some of the ceramic is dissolved in the glaze during the firing, and, so the thinner the glaze, the lower the concentration of lead.

If we compare the composition of the different coloured areas after removing the colouring agents (copper, manganese and iron, which is also associated with manganese), Fig. 7, we can see that the same recipe was used for the white, green and brown areas. This suggests that the pigments were applied over the glaze, either directly or mixed with some glaze to aid adhesion. On the undecorated side of the object, the glaze is similar but contains less tin and more clay, probably to reduce cost.

Another important difference between the undecorated and the decorated glazes is the presence of large quartz particles as can be seen in Fig. 8A, particularly evident in the decorated areas, Fig. 8B and C, and less so in the edges of the ceramics. The large difference in the thickness of the glaze from the undecorated side to the decorated side is also related to the smaller amount of large quartz particles in the undecorated areas. In addition, the presence of trapped bubbles and characteristic cracks around the quartz particles made the glaze particularly fragile and prone to alteration, leading to the accidental removal of the quartz grains and adjacent areas of glaze, particularly during the preparation of the polished cross sections.

A BSE image of the white area of the decorated side of MG11 (B) Dark field (top left) and Bright field (bottom left and top right) OM and BSE (bottom right) images of the brown design of MG13. (C) Dark field (top left) and bright field (bottom left) OM and BSE (bottom right) of the green design of MG8. We can see the presence of large quartz particles in the glaze surrounded by cracks, some of which fell during the sample polishing, and are missing. The brown design on the surface area of the glaze shows large crystallites of kentrolite and bixbyite

The presence of quartz particles in a glaze is not uncommon and can be caused by many factors, including particles that are too large to be completely dissolved during firing, too low a firing temperature and/or too short a firing time (underfiring). In our case, however, the large quantities of quartz particles present, which would require a very high temperature to dissolve completely in the glaze, and the fact that they only appear in the decorated glaze areas, strongly suggest that they were deliberately added.

The analyses show that the brown and green designs were made using manganese and copper pigments. We can also see that the brown and green designs, were applied overglaze, i.e. painted over the raw dry glaze before firing. The high concentration of manganese in the brown areas resulted in the precipitation of kentrolite, Pb2Mn2Si2O9, crystallites (grey crystals in the bright field OM and BSE images) together with some manganese oxide (bixbyite, Mn2O3) crystallites (white crystallites in the bright field OM and dark in the BSE images) as shown in Fig. 8B. The presence of kentrolite is due to the reaction of the lead silicate melt with the manganese oxide over a wide temperature range, between 700ºC and 950ºC (Molera et al. 2013, 2022). Copper acts as a flux dissolving more of the quartz particles and diffusing more widely in the glaze, making it much more difficult to determine whether the pigment has been applied over the raw glaze; the high concentration of copper in the outermost surface area of the glaze is usually the only evidence. However, in one of the samples examined, MG14, the green pigment was applied in such a high concentration that the precipitation of a lead-copper silicate and of copper oxide crystallites near the surface can be observed, Fig. 9. Finally, in the decorated glazes, cassiterite is present throughout the whole glaze, so it was most probably added as a lead-tin calx (ash made roasting lead and tin) together with the quarzitic sand.

Consequently, WMPG ware shows that both technologies tin oxide and quartz particles, are combined, to produce the opaque glaze. Moreover, the decorations are applied over the raw glaze, as shown in Fig. 3; Table 1.

Discussion

The presence of large quantities of undissolved quartz particles has already been noted in polychrome glazed wares from the second half of the 10th and first half of the 11th centuries in Sicily and Tunisia (Salinas et al. 2020, 2022). In these cases, the large quartz particles replaced tin oxide as opacifier, as they increased the opacity of the glaze concealing the colour of the ceramic body. The use of large quartz particles for the opacification has been linked to the absence of tin at a time when trade was not as important as it would be a century later. In the case of the WMPG ware, however, the opacity is already provided by the presence of cassiterite particles, so the addition of quartz is not necessary and may be related to tradition.

When quartz was used as a white opacifier, the decoration was applied over the raw glaze, since the presence of large dissolving particles of quartz would increase the silica content of the melt and, thus, its viscosity, making it very difficult for the brown and green colours to show when applied underglaze. This explains the change from underglaze to over the raw glaze painting when quartz began to be added to the glazes in the tenth century in Ifriqiya (Fatimid Sabra decorated glazed wares) with continuity in the eleventh century (Salinas et al. 2020, 2022).

This is not necessary if the glaze contains tin oxide as opacifier. Tin oxide reacts with lead oxide to form a lead-tin oxide, which dissolves as soon as the first melt is formed, and then, due to the high insolubility of tin oxide in a lead-silicate melt, cassiterite microcrystals precipitate (Molera et al. 1999; Tite et al. 2008). Pigments can therefore diffuse to the surface even when applied underglaze. However, this is not compulsory and, in fact, overglaze painting was also the preferred method of decorating ceramics in al-Andalus in the tenth century ‘verde y manganeso’ (green and manganese) polychrome tin-glazed ware of Umayyad Cordoba. Nevertheless, later under the Almoravid-Almohade rule, in al-Andalus the polychrome ‘verde y manganeso’ tin-glazed ware began to be painted underglaze.

The use of quartz as opacifier therefore seems to have originated in Ifriqiya and may have spread from there to other production centres in the central Maghreb or Sicily. On the other hand, no local polychrome ceramics opacified with quartz have been identified in al-Andalus, since from the beginning (Umayyad Emirate, late ninth century) the white glazes were opacified with tin, a tradition that continued throughout the Umayyad Caliphate, Taifa, Almoravid and Almohad periods (tenth to thirteenth centuries) (Molera et al. 2001; Salinas and Pradell 2018; Salinas and Pradell 2020). Consequently, the only places where the use of quartz for opacification is documented are in Tunisia (see citations above) and Palermo (Sicily) (Testolini 2018).

The peculiarity of the WMPG ware lies in the fact that it is the first time that both technologies tin oxide and quartz particles, are combined, which would not be necessary, as either of them would be sufficient. This suggests that the potters were already familiar with this technique.

Another characteristic is that the combination of the two, is mainly confined to the decorated areas, less obvious on the edges of the objects and absent or nearly absent on the undecorated side. WMPG is a semi-luxury ware, characterised above all by its meticulous drawing, with a very rich decorative programme full of details, made by skilled potters and painters who were well versed in this type of technique. Even for a good painter, the spreading of the pigments after the firing would cause the designs to blur. Applying a harder glaze (with more quartz), would prevent the designs from blurring. Therefore, this may also be a reason why a glaze enriched with quartz was applied to the areas of the object to be decorated, mainly on the inner surfaces of the dishes.

With regard to the undecorated side, the WMPG ceramics found in Almeria contains very little tin and some quartz. The North African ceramics use the same quartz-opaque white glaze than in the decorated side. On the other hand, although a white tin-opaque glaze was applied to the undecorated side of the earliest Emirate Andalusi tin-glazed ceramics of the “verde y manganeso”, it was soon replaced by a transparent honey-coloured lead glaze, in some cases containing a small amount of tin, undoubtedly to reduce costs, since tin was an expensive commodity (Salinas and Pradell 2020). Quartz, however, was never used.

From a technical point of view, it seems unlikely that the WMPG ware was made in al-Andalus, although it shares some characteristics. It is true, however, that there are few technological studies of eleventh- and twelfth-century glazed ceramics and that a more in-depth study has yet to be undertaken. This problem is not unique to the Iberian Peninsula, but also applies to other regions of the western Mediterranean, such as Tunisia, Algeria, Morocco or southern Italy.

What is also clear is that there is a fusion of techniques in the WMPG (Fig. 3; Table 1), the use of quartz appears to be an Ifriqiyah Fatimid-Zirid contribution, the use of tin an Andalusi Umayyad-Taifas contribution, while the use of green and brown polychromy on a white ground is either Ifriqiyah or Andalusi. The variety of motifs was common in several western Mediterranean regions, including Sicily, the shape is more reminiscent of North African models (Djellid 2019; Gragueb Chatti 2013; Louhichi 2003), and the execution of the designs and composition recalls a style specific to the Hammadids of the Qal’à of the Banu Hammad in the central Maghreb (Algeria) (Djellid and Salinas 2022).

Thus, pending the identification of the production centre/centres, further studies are needed to technologically characterise the polychrome glazed wares of the other western Mediterranean regions, which will help to understand the technological transfers between them.

Conclusion

The decorated glazes of the WMPG ware show a fusion of techniques; the use of quartz as an opacifier would correspond to an Ifriqiya Fatimid-Zirid tradition, the use of tin to an Andalusi Umayyad-Taifas tradition, the green and brown polychromy applied over the raw glaze to either Ifriqiya or Andalusi and the meticulous drawing, with a very rich decorative programme full of detail to the Hammamids of the central Maghreb. In fact, the use of quartz in the decorated glazed surface may also be related to the need for a highly viscous melt that limits the spread of the pigments during the firing, allowing for finer and more detailed drawing. This fusion of techniques is documented for the first time in al-Andalus. It is also the first time that the technology of these polychrome glazed ceramics, about which so much has been written, has been characterised.

The small number of pieces of WMPG ware found in Almería, their greater concentration in this district of the Madina, which was built in the late eleventh or early twelfth century, when Almería had an active role as a major commercial hub in the Mediterranean, and the differences in the ceramic fabrics compared with local production, suggest that the WMPG ware was not a local production, but rather a product of maritime trade. This also confirms, from an archaeological point of view, the importance of the port of Almería as an entrepôt, as recorded in Arabic and Jewish written sources, since this polychrome glazed ware does not appear to be a local production.

The combination of different techniques is interesting from the historical point of view of medieval technology, as it helps to understand how technological transfers and technical solutions worked in the Mediterranean basin during this period.

The analysis of a repertoire of polychrome glazed wares, WMPG, provided initial information on their unique new ‘fusion technology’, suggesting a link and distribution by sea between the eleventh and twelfth centuries along the trade routes of the western Mediterranean.

Data availability

No datasets were generated or analysed during the current study.

References

Alemán B (2023) El barrio andalusí del yacimiento arqueológico del Mesón Gitano. In VV.AA. Historia de Almería 2. La huella de al-Andalus. Almería: 388–389

Azuar R (2012) Cerámicas en ‘verde y manganeso’, consideradas norteafricanas, en al-Andalus (ss. X-XI d.C). Arqueología y Territorio Medieval 19:59–90

Azuar R (2016) La Taifa de Almería en el comercio mediterráneo del siglo XI. In Cuando Almería era Almariyya. Mil años en la historia de un reino. Almería: 293–312

Azuar R (2019) Las Taifas del Sharq al-Andalus en las rutas y el mercado mediterráneo del siglo XI. Valencia

Berti G, Tongiorgi L (1981) I bacini ceramici medievali delle chiese di Pisa, L'ERMA di Bretschneider. Roma

Djellid A (2011) La céramique islamique du Haut Moyen Âge en Algérie (IXe-Xe siècles): les problèmes de son étude. In P. Cressier & E. Fentress (dir.) Céramique maghrébine du haut Moyen Âge (VIII-X siècle): état des recherches, problèmes et perspectives. Collection de l’École française de Rome. Rome, pp 147–158

Djellid A (2019) La céramique à glaçure du Maghreb central entre le IXe et le XVe siècles. Etude typolologique et décorative (texte arabe). Thèse de doctorat, Université d’Alger 2

Djellid A, Salinas E (2022) Du Maghreb central à al-Andalus et d’al-Andalus au Maghreb central: état de la question de la céramique islamique glaçurée et émaillée. In T. Amraoui & A Quevedo (dirs.), D’une rive à l’autre: circulations et échanges entre la Maurétanie césarienne et le sud-est de l’Hispanie (Antiquité-Moyen-âge). Archaeopress: 117–131

Djellid A, Pradell T, Salinas E (2023) An early example of glaze technology diffusion in North Africa: The Islamic workshop of Tahert (central Maghreb, Algeria). J Archaeol Sci Rep 52:104252. https://doi.org/10.1016/j.jasrep.2023.104252

Flores I, Navarro AD (2013) Moldes y cerámica moldada y dorada fabricada en Almería, I Congreso Internacional Red Europea de Museos de Arte Islámico (Alhambra, 25–27 April 2012). Grenade, pp 325–342

Flores I, Muñoz MM, Lirola J (1999) Las producciones de un alfar islámico en Almería. Arqueología y Territorio Medieval 6:207–239

Friedman MA (2016) La sociedad comercial de un mercader de la India en Almería (1139). Sefarad 76(1):75–96

Gisbert JA (2018) Cerámicas del siglo XI, presentes en la Qal’a de los Banû Hammad (Argelia) y procedentes del entorno de Cairuán, Sabra y Cartago (Túnez), en Denia y en al-Andalus. Grupos 1 y 2. In B. Sarr (ed.), Ṭawâ’if. Historia y Arqueología de los reinos de taifas (siglo XI), Granada, pp 273–320

Goitein SD (1967-93) A Mediterranean society, vol 6. Berkeley

Gómez S (2014) Cerámica islámica de Mértola. Museu de Mértola, Mértola

Gonçalves MJ (2010) Objetos de troca no mediterrâneo antigo: cerâmica «verde e manganês» de um arrabalde islâmico de Silves. Arqueologia Medieval 11:25–41

Gragueb Chatti S (2013) La céramique islamique de la citadelle byzantine de Ksar Lemsa (Tunisie Centrale), Africa XXIII, Institut National du Patrimoine 23:263–300

Hita JM, Villada E (2007) Un decenio de arqueología en Ceuta, 1996–2006 (Catálogo de la Exposición). Ceuta

Louhichi A (2003) La céramique de l’Ifriqiya du IXe Au XIe siècle d’après une collection inédite de Sousse. In: VIIe Congrés International sur la Céramique Médiévale en Méditerranée. Thessaloniki, 11–16 Octobre 1999. Athènes, pp 669–682

Mohamedi A, Benmansour A, Amamra A, Fentress E (1991) Fouilles de Sétif: 1977–1984. 5eme supplément au Bulletin d’archéologie algérienne

Molera J, Pradell T, Vendrell-Saz M (1998) The colours of Ca-rich ceramic pastes: origin and characterization. Appl Clay Sci 13(3):187–202. https://doi.org/10.1016/S0169-1317(98)00024-6

Molera J, Pradell T, Salvadó N, Vendrell-Saz M (1999) Evidence of tin oxide recrystallization in opacified lead glazes. J Am Ceram Soc 82(10):2871–2875. https://doi.org/10.1111/j.1151-2916.1999.tb02170.x

Molera J, Vendrell M, Arantegui J (2001) Chemical and textural characterization of Tin glazes in Islamic ceramics from Eastern Spain. J Archaeol Sci 28:331–340. https://doi.org/10.1006/jasc.2000.0606

Molera J, Coll J, Labrador A, Pradell T (2013) Manganese brown decorations in 10th to 18th century Spanish tin glazed ceramics. Appl Clay Sci 82:86–90. https://doi.org/10.1016/j.clay.2013.05.018

Molera J, Colomer J, Vallcorba O, Pradell T (2022) Manganese crystalline phases developed in high lead glazes during firing. J Eur Ceram Soc 42(9):4006–4015. https://doi.org/10.1016/j.jeurceramsoc.2022.03.028

Pradell T, Molera J (2020) Ceramic technology. How to characterise ceramic glazes. Anthropol Archaeol Sci 12:189. https://doi.org/10.1007/s12520-020-01136-9

Ramos M (2022) Almariyya, Puerta de Oriente: catálogo de la exposición: Museo de Almería, del 22 de abril al 25 de octubre de 2015. Sevilla

Rodríguez A, Castelló Mª F (2008) Intervención Arqueológica Preventiva en c/ San Luis 70 – Ruiz de Gijón 6 de Sevilla. Anuario Arqueológico de Andalucía 2008:581

Rosselló G (1985) Un ataifor norteafricano: un ensayo de interpretación iconográfica. Sharq al-Andalus 2:191–205

Rosser-Owen M (2013) From the Mounds of Old Cairo: Spanish ceramics from Fustat in the collections of the Victoria and Albert Museum, I Congreso Internacional Red Europea de Museos de Arte Islámico (Alhambra, 25–27 April 2012). Grenade, pp 163–187

Salinas E, Pradell J (2018) The transition from lead transparent to tin opacified productions in the western islamic lands: al-Andalus, c. 875–929 CE. J Archaeol Sci 94:1–11. https://doi.org/10.1016/j.jas.2018.03.010

Salinas E, Pradell J (2020) Madīnat al-Zahrā’ or Madīnat Qurtuba? First evidences of the Caliphate tin glaze production of ‘verde y manganeso’ ware. Archaeol Anthropol Sci 12:207. https://doi.org/10.1007/s12520-020-01170-7

Salinas E, Reynolds P, Tite M, Pradell T (2020) Polychrome glazed ware production in Tunisia during the fatimid-zirid period: New data on the question of the introduction of tin glazes in western islamic lands. J Archaeol Science: Rep 34:102632. https://doi.org/10.1016/j.jasrep.2020.102632

Salinas E, Reynolds P, Pradell T (2022) Technological changes in the glazed wares of northern Tunisia in the transition from Fatimid to Zirid rule. Archaeol Anthropol Sci 14:224. https://doi.org/10.1007/s12520-022-01690-4

Stiti K, Souq F (2010) Alger, Place de Martyrs. Évolution depuis l’Antiquité d’un quartier de la basse Casbah d’Alger. Rapport final d’opération. Diagnostic archéologique. Inrap Méditerranée, Nîmes

Testolini V (2018) Ceramic technology and cultural change in Sicily from the 6th to the 11th century AD. PhD thesis, University of Sheffield. http://etheses.whiterose.ac.uk/24131/, https://doi.org/10.15131/shef.data.11567910

Tite M, Pradell T, Shortland A (2008) Discovery, production and use of tin-based opacifiers in glasses, enamels and glazes from the late iron age onwards: a reassessment. Archaeometry 50(1):67–84. https://doi.org/10.1111/j.1475-4754.2007.00339.x

Wickham C (2023) The Donkey and the Boat: Reinterpreting the Mediterranean Economy. Oxford University Press, pp 950–1180. https://doi.org/10.1093/oso/9780198856481.001.0001

Funding

Open Access funding provided thanks to the CRUE-CSIC agreement with Springer Nature. This work was financially supported by Ministerio de Ciencia e Innovación (Spain, PID2022-137783OB-I00 and PID2021-124325OA-I00), CNS2023-145440 and MCIN/AEI/10. 13039/5011000011033 (CEX2023-001300), Generalitat de Catalunya (2021 SGR 00343) and Junta de Andalucía (PROYEXCEL_00990).

Author information

Authors and Affiliations

Contributions

E.S and T.P wrote the main manuscript text and prepared figures and tables. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Below is the link to the electronic supplementary material.

ESM 1

(DOCX 871 KB)

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Salinas, E., Pradell, T. The secret is quartz: technology of production of an eleventh-twelfth century western Mediterranean polychrome glazed ware. Archaeol Anthropol Sci 16, 135 (2024). https://doi.org/10.1007/s12520-024-02040-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12520-024-02040-2