Abstract

A rapidly increasing number of bronze mirrors dated to the Chinese Han dynasty (202 BC – AD 220), known for their unique decorative patterns and highly developed alloying techniques, have been widely discovered in both China and beyond, providing fresh materials and scientific data to revisit their geological provenance, production and circulation network along the ancient Silk Road. In this paper, 47 bronze mirrors unearthed in the southeastern provinces of China, including Zhejiang, Anhui and Fujian provinces, have been characterized by typo-chronology, lead isotopic analysis, compositional analysis and metallography. A much wider comparative study is also carried out through a combination of data from China, Japan, Central Asia, and Southeast Asia, leading to a more updated lead isotopic database of the Han mirrors spreading out of China in various directions. Compared with the traditional ‘optimal’ model based on the Han mirrors recovered in Japan, the current study contributes several key changes in the bronze mirror production of the Han dynasty. The systematic analysis of the alloy composition, trace elements and typological studies shows that the bronze mirror industry shifted towards a more standardized production in the middle to late Western Han Dynasty. In contrast to the substantial change of non-mirror bronze productions, the similar distribution of lead isotope data in early and middle to late Western Han mirrors suggests that the ‘official monopoly of salt and iron’ policy was less effective for the management of lead involved in mirror production. Bronze mirrors dated to middle to late Western Han discovered outside Han-China, such as Japan, Thailand, Afghanistan, Xiongnu and the ancient Dian Kingdom, appear to be subjected to a more specific type of lead as a result of the state-centralized policy of the Western Han court.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

As one crucial type of bronze artefacts for both ritual and daily use, the history of bronze mirrors in China can be traced back to beyond 4,000 years BP. Although mirrors provide critical links between the Central Plains of China and the northwest regions (Li 1988; Song 1997; Mei 2005), it was only with the rise of the Han dynasty (202 BC – AD 220) that bronze mirrors became widespread in Japan, Southeast Asia, Mongolia, Eastern Europe and further (Loubo-Lesnitchenko 1973; Bai 2010; Cahill 2011; Treister and Ravich 2021).

A range of pioneering studies focused on mirrors of the Chinese Han dynasty were in fact promoted by Japanese scholars, partially due to the fact that thousands of Han mirrors have been unearthed from different archaeological contexts dated to the Yayoi (300 BC - AD 250) or Kofun periods (AD 250–592) in Japan (Mabuchi et al. 1985). For example, the origin of the Kofun-period ‘triangular-rimmed mirrors with divinity and animal figures (TRDA mirrors)’ has been the subject of a heated debate in East Asian archaeology due to its potential association with the rise of state in Japan (Kobayashi 1971; Higuchi 1985; Wang 1981, 1994, 2000; Xu 2022). In addition to typology, studies of associated production techniques and mirror inscriptions began to be published since 1970s. The subsequent decades witnessed the application of lead isotope (LI) analysis by Japanese scholars to Han mirrors, as well as what here referred to as the ‘optimal’ model, with the Western Han (WH) mirrors discovered in Japan (JW) being made from ‘Northern Chinese lead’ on one hand and the Eastern Han (EH) mirrors in Japan (JE) being made from ‘Southern Chinese lead’ on the other hand (Mabuchi and Hirao 1982, 1983; Mabuchi et al. 1985; Mabuchi 2011). The boundary between the two, as shown in subsequent figures, is taken to be 208Pb/206Pb below c. 2.15 and 207Pb/206Pb below c. 0.865 for Eastern Han, with Western Han above these values.

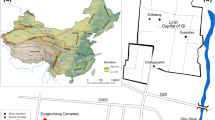

Recent decades have seen an increasing trend in the use LI in order to pinpoint the geological source of the bronze mirrors within China (Fig. 1; Cui et al. 2009; Zhangsun et al. 2017; Chen et al. 2019, 2020a, b; Luo et al. 2023; Yang et al. 2023). Although it is rather reasonable to assume that LI represent the source of lead, since the percentage of lead in these bronze mirrors are in most cases beyond impurity levels, pinpointing their geological sources is yet possible. The lead deposits are clearly more ubiquitous than copper and tin, with the latter being predominately located along the Yangtze region and further south (Fig. 1). Moreover, many of the lead deposits are much less distinguishable purely by lead isotopic data.

Nevertheless, an emerging consensus in the literature is that LI are extremely useful for characterizing metal objects in antiquity and detecting the diachronic changes in their sources (e.g., Bray et al. 2015; Jin et al. 2017). Whilst the current databank of Han mirror LI values has seen a substantial expansion in the last two decades, interpretation is still dominated by the traditional optimal model of ‘WH-EH contrast’, which springs from relatively limited analyses of Han mirrors excavated only in Japan. It is increasingly imperative to ask the degree to which this model can explain the new data from mirrors excavated in China.

One more related question is whether bronze mirrors, like other types of metal artefacts, were also regulated by the state policy of ‘official monopoly of salt and iron’. This policy was introduced by the Emperor Wu in the middle to late WH at around 110BC, as documented in the Records of the Grand Historian 史记 and the Book of the Han 汉书. Its prime objective was to centralize and regulate the collection and management of salt and iron resources, with the purpose of accumulating capital for military campaigns against Xiongnu. The exploitation and circulation of iron and copper ore were officially regulated by the establishment of ‘copper officials 铜官’ and ‘iron officials 铁官’, who were also responsible for prohibiting private mining or casting. However, the policy became gradually less effective in the late WH period due to increasing complaints from the ordinary class that it extracted exorbitant profit (Jin 2010). The most recent publication (Yang et al. 2023) showed a more convergent pattern in the distribution of LI of the bronze objects in the noble burials of WH, based on which they argued for a profound impact of the ‘official monopoly of salt and iron’ on bronze production under the reign of the Emperor Wu (141 to 87 BC). This regulation also appears to have been extended to the control of leaded bronze production, providing an intriguing question that to what extent this policy affected the production of mirrors. Unlike other bronze objects, mirrors require more specific and advanced alloying and casting technology to be pragmatically functional.

A third question derives from the widespread distribution of the Han mirrors. Despite its great archaeological interests, the current discussion on the sources of the Han mirrors unearthed outside Han China, including Afghanistan (Mabuchi et al. 1985), Xiongnu territory (Chen et al. 2020a) and Thailand (Pryce et al. 2014), is also deeply rooted in the interpretational model derived from the Japanese Han mirrors. However, it is reasonable to ask whether the updated database could paint a different picture than the traditional one.

Samples and typo-chronology

Samples

The samples in the current research provide a complete chronological sequence from WH to EH. They derive primarily from four regions in Southeastern China, namely, Anji in Zhejiang province (22 pieces), Shouxian (16 pieces) and Fuyang (six pieces) in Anhui province, and Wuyishan (three pieces) in Fujian province (Fig. 1).

The 22 bronze mirrors from Anji in northwestern Zhejiang province were all excavated from the tombs of the Han dynasty in this area, though many of them could also be dated to the Warring States period (475 − 221 BC; Cheng 2010). Anji was once the major city of the Zhang state 鄣郡 set up in the early WH and later merged into the Danyang state 丹阳郡 during the reign of Emperor Wu. The Danyang state is also known from ‘Danyang produced high-quality copper during Han 汉有善铜出丹阳’ in the inscription of the bronze mirrors. It is thought to be located at the conjunction of the southern part of Anhui province, southwestern of Jiangsu province and northwestern of Zhejiang province according to historical geographers (Tan 1982).

The 16 bronze Shouxian mirrors are part of the Shouxian Museum collection, most probably from the vicinity of Shouxian in Anhui province. Shouxian was the last capital of the Chu State during the Warring States period and was the capital of the Huainan State 淮南国 (196–122 BC) during WH. Panchi mirrors (Fig. 2) are found in large quantities in Shouxian and the surrounding Huai River region, which have been called ‘Huai-type mirror’ by previous researchers (Karlbeck 1926).

The 6 bronze mirrors from the Fuyang Museum most probably came from the vicinity of Fuyang in Anhui province, which is where the Ruyin Marquis State 汝阴侯国 (201–115 BC) of the Han dynasty was located. More than 300 bronze mirrors were found around Fuyang, and a monograph on Han mirrors in Fuyang has been published (Yang 2017).

The 3 bronze mirrors excavated from the Minyue Wangcheng site, also known as the Chengcun Hancheng site, are located in Chengcun village, Wuyishan city, Fujian province. Minyue Wangcheng site was the core city of Minyue State 闽越国 (202–110 BC) in the early WH (Yang 1990). Since the first excavation in 1958, massive building foundations and a significant number of Han tiles, pottery, iron and bronze ware have been recovered (Fujian Museum et al. 2004).

Typo-chronology of Han mirrors

Whilst the chronology of these bronze mirrors can be inferred according to their excavation context and associated materials, these factors approximate the date of their last use or ‘death’. However, the ‘birth’ of the mirrors is of more interest since it is closely related to their production and circulation. Through a comprehensive analysis of the images and inscriptions of Han mirrors, Okamura has established a refined chronology for the Han mirrors, which classified them into seven phases (Okamura 1984, 1993, 2014). This was followed by Mabuchi who illustrated the variation of LI of Han mirrors throughout these seven phases (Mabuchi 2011). This paper follows Okamura’s chronological framework, permitting a direct comparison to be carried out between the new and legacy data.

Through comparison with previous typo-chronology results concerning the images and inscriptions of samples, this paper divides the newly sampled mirrors into phases I-VII defined by Okamura.

The early WH comprises Phase I and II when the Panchi mirrors were predominant, followed by the Caoye mirrors. The Phase III and IV belong to the middle and late WH, respectively, in which the more sophisticated images and inscription started to appear on the reverse of the mirror. In this case, Xingyun mirrors were the dominant type, followed by Huilong, Riguang and Zhaoming mirrors. The early to late EH is in line with Phase V, VI and VII, respectively. The TLV mirror and the Shoudai mirrors were still prevalent in Phase V and Phase VI, and there were Bafeng mirrors in Phase VII. The sample information and the typological chronology are showing in Table 1.

Methods

Composition analysis

Major alloy compositional analyses of the samples showing a metallic composition were carried out at the Archaeometry Laboratory of the University of Science and Technology of China (USTC), and the samples were measured for their chemical composition using energy-dispersive X-ray fluorescence spectrometry (ED-XRF) after polishing. The experimental instrument was manufactured by Shimadzu Corporation, Japan, model EDX-8100, which was used for the quantitative analysis of the fundamental parameter method tests under the following operating conditions: atmospheric vacuum, collimator of 1–10 mm, and rhodium (Rh) X-ray tube target, each sample tested three times to obtain the average as the final result. The tube voltage was 50 kV, the tube current was 1000 µA, and the analysis time was 7 min each test.

Trace elemental analysis was carried out using a JSM-5910 scanning electron microscope (SEM) (JEOL Ltd, Japan) combined with EDS (Oxford Instruments, UK) with INCA software at the University of Oxford Archaeology and Art History Research Laboratory. For each sample, 8–10 different squares of equal areas were selected as test zones and their average values were calculated as final results. The parameters are set as voltage for 20KV, spot size for 32 μm, test time for 120s, and dead time for 30 ~ 40%. The minimum detect limit is 0.1% for most of the trace elements except arsenic, zinc and bismuth of 0.15–0.2% (for detailed data see Liu 2016).

Metallographic structure observation

The samples were prepared in line with a standard procedure of metallographic samples. The metallographic microstructure observation was carried out in the Archaeometry Laboratory of USTC, using the Axio Observer inverted metallographic microscope (Carl Zeiss, Germany) to observe the metallographic microstructure of the sample before and after etching in 3% FeCl3 in alcohol solution.

LI analysis

The pre-treatment of the samples for LI was carried out in the Archaeometry Laboratory of USTC. All samples were washed with ultrasound to remove dust or glue stains, then 30 mg of each sample is dissolved in concentrated nitric acid solution. Under the condition of weak acid solution, lead was extracted by electrochemical method and dissolved in 2% nitric acid. In the Key Laboratory of Crust and Mantle Materials and Environment, Chinese Academy of Sciences, USTC, concentrations were tested by ICP-MS then diluted the lead solution to 200 ppb. The LI ratio was determined by Neptune Plus MC-ICP-MS, School of Earth and Space Sciences, USTC. During the experiment, 200 ppb of NBS 981 standard lead solution was inserted into every 5 samples to correct the LI ratio. Repeated measurements of the standard samples and samples showed that the instrument’s 2σ standard error was lower than ± 0.001 for the three lead isotopic ratios.

Results

The new analytical results of typological chronology, elemental composition and LI are summarized in Table 2. The elemental compositions of the 17 bronze mirror samples with sound metal body show that the Cu content ranges between 62.9 and 71.4%, Sn between 21.9 and 30.9%, and Pb content between 0.3 and 6.7%. Except AJ-01 and AJ-04, which contain lead lower than 1%, other samples all contain lead at a level of 3–7% therefore are characterized as copper-tin-lead ternary alloys (threshold = 2%). Apart from these two mirrors with low lead, the compositional analysis revealed a stable copper-tin-lead ratio of 14:5:1 for mirrors (Zhangsun et al. 2017), suggesting the standardized mirror recipe of alloys.

The metallographic analyses of all the 17 samples illustrate a typical structure of high-tin bronze with α-phase and (α + δ) phase. Because of the high content of tin, the (α + δ) phase increases and interconnects into matrix, leading to the strip-like and needle-like distribution of the α-phase (Cu-Sn alloy; Fig. 3a). While mirrors with higher lead content present a different microstructure, in which lead is formed as spherical or irregular particles on intredendritic boundaries (Fig. 3b, Cu-Sn-Pb alloy).

LI results show that the data range of the 47 samples is 17.625–18.579 for 206Pb/204Pb, 15.521–15.733 for 207Pb/204Pb, and 38.220–38.980 for 208Pb/204Pb respectively, all of which fall into the category of common lead (Jin 2008; Liu et al. 2018). Because almost all the mirrors contain more than 2% lead, the LI data presented here represent that of the lead source, as opposed to trace values of lead in the copper (Jin et al. 2017).

Discussion

Comparison of LI between Chinese and Japanese Han Mirrors

The interpretation of lead isotopes in Han mirrors is overwhelmingly dominated by the traditional model that Western Han mirrors are defined by the distribution in the Japanese Western Han (JW) region and Eastern Han mirrors by the Japanese Eastern Han (JE) region: a model purely based on the Han mirrors excavated in Japan (Fig. 4; Mabuchi 2011). This could become a circular argument, in that bronze mirrors isotopically falling into the JW ‘field’ are automatically assumed to be dated to the Western Han (Chen et al. 2020a).

Following the chronological phases, Fig. 4 illustrates a comparison of the distribution of LI data between Japanese and Chinese Han mirrors. From Phase I to Phase V (Fig. 4a-e), corresponding to various periods of WH and early EH, the distribution of lead isotopes for Chinese Han mirrors obviously stretches over both the JW and JE regions, which is rather different from the traditional optimal model. This is especially true of Phases II-III, when virtually no Han mirror excavated from Japan falls into the range of JE (inserts of Fig. 4b & c; Table S1). A crucial shift occurred in Phase VI (middle EH, Fig. 4f), when Han mirrors belonging to JW completely disappear, as attested by both the new and legacy data (Fig. 4f; Mabuchi 2011). This pattern remains the same in Phase VII (late EH, Fig. 4g). The data of the Han mirrors excavated from Japan, though comprehensive and extremely thought-provoking, still appears unable to represent the overall production of bronze mirrors during the Han dynasty. Meanwhile, the distinctive data distribution of Japanese Han mirrors also raises more archaeologically interesting questions regarding the apparently selective exportation of bronze mirrors from Han China to Japan.

The ‘Official monopoly of salt and Iron’ policy on bronze mirrors

A number of bronze vessels or weapons produced since the Qin state show clear inscription of the manufacturer in the form of ‘XX 造 (made by someone)’, offering important materials for the study of the underlying production and management model. However, the bronze mirrors produced in WH, though cast with various types of inscriptions, primarily auspicious expression, contain little information on manufacture. Occasionally, some WH mirrors show the exact date of production. More technologically related inscriptions can be seen from the bronze vessels of WH, as systematically summarized by Wu (2005). He identified a three-tier production model for the bronze vessels of the early WH, encompassing the central government departments (shaofu 少府, zhongguan 钟官) at the top, the vassal states (e.g., Zhongshan State 中山国, Ruyin Marquis State 汝阴侯国, Changsha State 长沙国) in the middle and local merchants (e.g., Luoyang 洛阳, Handan 邯郸) at the bottom, which largely followed the political structure at that time. During the middle to late WH when the political power of the vassal states declined radically, the production of the bronze vessels changed to a two-tier model, meaning that they were predominantly produced under the supervision of the Gongguan 工官 (managers of craftspeople) of the central government (Shangfang 尚方, Kaogong 考工 and Shanglin 上林), and the local governments (Hedong 河东 and Luoyang 洛阳). EH saw an increasing proportion of bronzes vessels marked with the exact surname of the craftsmen but giving less information of the related governmental departments, implying the rise of the private bronze production.

The extent to which these models and changes are applicable to bronze mirror production remains uncertain. Even though one can extract slightly more information from EH mirrors, such as the production centres (e.g., Kuaiji, Jiangxia and Guanghan, Fig. 1; Kong and Liu 1984), the vast majority were still made without these inscription details. Consequently, in addition to the excavations of the bronze mirror workshops (Bai et al. 2004), the only method to resolve the issue of production and circulation appears to be the chemical and lead isotopic analyses of the bronze mirrors themselves.

Control of alloying composition is of critical importance of mirrors. Proper addition of tin (and lead) not only creates ideal colour for mirrors, but also reduces the melting point that permits longer time for alloying liquid to fulfil the moulds and form fine decorations. The comparison of the major elements of mirrors from northern and southern China dated to the Warring States period, the early WH, the middle to late WH and the EH is presented in Fig. 5. The distribution of alloy compositions is plotted against copper to avoid the unit sum issue (Liu et al. 2020; Pollard and Liu 2023). Clearly, leaded bronze was the prevailing alloying pattern for the mirrors. The reason to include the Warring States period is to highlight the continuity and contrast with the early WH, considering the scarcity of data on the northern mirrors in the early WH. Showing these four periods together underlines the similarity of alloys for the mirrors between northern and southern China dated to middle and late WH, whereas the bronze mirror production in northern and southern China of the Warring States period illustrates a bimodal distribution. In spite of the limited number of data, and these northern mirrors show a more restricted range of compositions in the EH (Fig. 5a), though more data are required.

The trace elemental data, though in an admittedly limited size, indicates a diversity in terms of grouping, which broadly echoes the alloying composition. In this case, we employ the Oxford system of copper groups and semi-quantitative analysis (Bray et al. 2015; Liu et al. 2019; Fig. 6). Essentially these copper groups are characterized by four key trace elements arsenic, antimony, silver and nickel. It is during the middle to late WH that saw predominance of CG15 (As-Ag-Ni, 7 out of 10 objects), while other periods were occupied with multiple copper groups, corresponding to different types of trace elemental pattern that were more likely derived from geological sources of various regions.

The distribution of the whole range of trace elements in different regions presented in Fig. 6. Although they all look similar at the very first glance, there are a few interesting changes in the trace elemental data. First, the variation of As became increasingly narrower from the early WH (~ 0.1–0.9%) to mid-late WH (~ 0.2–0.5%), whereas the amount of Sb, which is in fact rather rare in Chinese bronzes of Shang and Zhou dynasties, became more observable, at lease in EH, leading to a wider diversity of the trace elemental patterns (or copper groups). These changes in data may be caused by various factors, such as switching of ore sources, improved smelting/refining technologies, or the ‘official monopoly of salt and iron’ policy that led to more mixing and recycling.

Yang et al. (2023) observed a convergence of LI data of the non-mirror bronze, including vessels, coins, weights and measures from the early WH to the middle and late WH, which was probably driven by the state policy (Fig. 7c-d). However, the lead isotopic data of mirrors shows a similar LI distribution (Fig. 7a-b).

Given the distinction of the lead isotopic data between mirrors and non-mirror types of bronzes during WH, a binary structure was introduced to characterize lead alloying for WH bronze production. Ranging approximately between 206Pb/204Pb 17.20–18.00, 207Pb/204Pb 15.40–15.60 and 208Pb/204Pb 37.60–38.60, type A refers to the sort of lead that was used for production of both mirror and non-mirror bronzes, which overlaps with JW or ‘Northern Chinese lead’. It dominates in non-mirror bronzes with up to 98.3% after the middle to late WH (Table 3), which is contemporary with the implementation of the ‘official monopoly of salt and iron’ policy. The type B lead is represented by the bronze mirrors that fall outside the type A scope, characterized approximately by 206Pb/204Pb 18.00-18.50, 207Pb/204Pb 15.55–15.75 and 208Pb/204Pb 38.20–39.00, which overlaps with JE or ‘Southern Chinese lead’.

As summarized in Table 3, the proportions of type A and B lead are essentially the same in the early WH and the middle to late WH mirrors, with only 3.1% difference, while non-mirror bronzes exhibit substantial changes (over ca. 20%). Despite the difference in the percentages of type A and type B in the four phases of EWH-MLWH, the Pearson Chi-square tests (the value is 1.276, and P = 0.735 > 0.05; see detailed reports in Figure S1-S3) rejects any statistically significant difference in the mirror production between the two periods. Meanwhile, Chi-square test also indicates clear distinction in the metal supply for non-mirror bronze production affected by the ‘official monopoly of salt and iron’ policy in WH (mirrors versus others).

The LI data of the non-mirror bronzes suggests that Type A lead appears highly likely the result of centralized state management (Yang et al. 2023). It is yet ascertained that such lead was either derived from one exceptionally large lead deposit or mixing of raw metal or objects from various places. By contrast, the circulation of type B probably implies some degree of relaxation of the ‘official monopoly of salt and iron’ policy. The difference in LI between mirrors and other types of bronzes implies that the implementation of the ‘official monopoly of salt and iron’ policy is stricter in non-mirror bronze production than in the mirrors. If this holds true, it also should be noted that control of lead as such was not at all mentioned in any text associated with of the ‘official monopoly of salt and iron’ policy so far.

Revisiting the LI data of Imported Han mirrors in Japan

The new data that integrated many more analyses of mirrors excavated within China sets up a new framework within which to re-evaluate the exchange between China and Japan during the Han dynasty. In the early WH, Linzi in northern China mainly produced Caoye and Panchi mirrors of the Han style, while Shouxian in southern China mainly produced Panchi mirrors of the Warring States style (Okamura 1984). The overseas export of the Han mirrors from this period was mainly to Japan, with the major type being the Caoye mirrors. As illustrated in Fig. 8c, all LI of Caoye mirrors fall into the region of type A lead, and the Han mirrors in Japan during this period were concentrated in the lower left of type A lead (Fig. 8a), demonstrating a substantial overlap with Linzi Han mirrors. It also makes sense in terms of the geographic location of Linzi, which is probably the closest Chinese mirror foundry to Japan, with multiple routes linking these two regions (Chen et al. 2018; Duan 2020).

In the middle to late WH, under the influence of the ‘official monopoly of salt and iron’ policy, the production of Han mirrors changed from the multi-tier production mode to the state-centralized management, as demonstrated by their gradually unified alloy composition, trace elemental patterns. During this period, whilst some mirrors in Chang’an, Linzi, Hunan and Anji still used type B lead (Fig. 8b), they accounted for a rather small proportion. Meanwhile, the majority of exported mirrors to Japan, Thailand, Xiongnu and Afghanistan were dominated by type A lead, which is similar to non-mirror bronzes (Fig. 8b).

Bronze mirror distribution: a multi-directional network

In WH, to the south, a large quantity of Han mirrors has been found in Vietnam, Thailand, and Indonesia (Fig. 1; Fu 2021). During the Qin and Han dynasties, annexation to the Yunnan region requested substantial goods and gifts by the Han dynasty to local leaders in the early WH. At around 110 BC, the conquest to northern Vietnam by Emperor Wu, greatly facilitated the spread of Han culture to the southeast Asia. Given virtually no records of bronze mirror casting in the local regions (Li 2001), the fact that the LI of the bronze mirrors found in Yunnan and Thailand almost completely overlap with those of Chang’an and Linzi (Fig. 8b) could be the results of unified production by the Han government which were subsequently exported to the local groups along with the expansion of Han culture.

To the north and northwest, the Han mirrors were also found in tombs of the Minusinsk Basin, Mongolia, Afghanistan, Kazakhstan (Li 1992; Loubo-Lesnitchenko 1973). In the tombs of the Xiongnu in Xinjiang, Han mirrors were also used as burial objects in the form of broken mirrors due to the rarity of bronze mirrors, and the mirrors mainly associated with necromancy ceremonies (Ma 2015). The mirrors involve Riguang, Qingbai and Lianhu mirrors dated to the middle to late WH style. Imitations were also produced in these areas but show clear differences in terms of both design and casting quality (Higuchi 1992). The LI of Han mirrors found in Afghanistan and Xiongnu tombs in Xinjiang (Fig. 8b) all use state-centralized type A lead of the middle and late WH, adding another layer of probability that these mirrors were produced within Han China and exported as finished products.

In EH, as the traditional optimal model suggests, the LI distribution of Japanese Han mirrors shifts closer to those from southern China (Fig. 4f-g). The LI distribution of Han mirrors of northern China (e.g., Chang’an) during Phase VI became more concentrated that those of southern China (Fig. 4f, blue circles vs. colourful circles). Intriguingly, the northern Han mirrors appear to show lower Pb/Cu ratio (Fig. 5) as well as decline in design and quality during Phase VI (Okamura 1993, 2014). One potential explanation is that as the result of the movement of economic centre of EH from north to south, the centres of mirror casting, craftspeople were also moved southwards (Kong and Liu 1984). Moreover, the rise of maritime technology development during EH may well contribution to the thriving exchange between southern China and Japan, of which an increasing number of bronze mirrors flowed into Japan from southern China, such as the mirror casting centre Kuaiji along the Yangtze River (Wang 2018).

Conclusion

This study analysed 47 Han mirrors from southeastern China, all of which were made of high tin bronze and common lead. It reveals key differences in the distribution of LI data of the Chinese and Japanese mirrors in WH. Building on the traditional optimal model, the new database illustrates a more complete and complex picture of the production and circulation of Han mirrors, particularly for WH.

The systematic analysis of the alloy composition, trace elements and typological studies of Han mirrors unearthed across China shows that in the middle to late WH, under the restriction of the ‘official monopoly of salt and iron’ policy, the bronze mirror industry underwent a change towards a more standardized production. Similar distribution of LI data between the early WH mirrors and the middle to late WH mirrors compared to substantial changes in non-mirrors bronzes shows that the ‘official monopoly of salt and iron’ policy was probably less effective for management of lead in mirror production.

The distribution of Han mirrors outside Han China depicts active international network. The early WH mirrors exported to Japan were mainly Caoye mirrors produced from Linzi. In the middle to late WH, given the ‘official monopoly of salt and iron’ policy, the Han mirrors discovered in Japan, Yunnan, Vietnam, Thailand, Xiongnu, and Afghanistan were all made from the same type of lead (type A), demonstrating lead isotopes as a useful tool to distinguish the Han mirrors and local imitations outside Han China. During EH, the southward movement of the political and economic centre also brought the casting centre of Han mirrors to southern China. The consistency of lead isotopic composition between EH bronze mirrors and those discovered in Japan suggests that during EH Japan started to import bronze mirrors mainly from southern China.

Geographical coordinates

Anji County (30.638791,119.680145).

Shouxian Museum (32.564137,116.801838).

Fuyang Museum (32.857799,115.800892).

Minyue Wangcheng site (27.540507,118.055185).

Data availability

No datasets were generated or analysed during the current study.

References

Bai Y (2010) Discovery and identification of Han-style bronze mirrors in central Asia. Cult Relics 1:78–86

Bai Y, Wei C, Wang H (2004) Investigation on the site of a Han mirror casting workshop in the Imperial City of Qi, Linzi, Shandong. Archaeology 4:29–36+102

Bray P, Cuénod A, Gosden C et al (2015) Form and flow: the ‘karmic cycle’ of copper. J Archaeol Sci 56:202–209

Cahill S (2011) The Lloyd Cotsen study collection of Chinese bronze mirrors volume II: Studies. Cotsen Institute of Archaeology

Chen D, Luo W, Zeng Q et al (2018) The lead ores circulation in central China during the early western Han dynasty: a case study with bronze vessels from the Gejiagou site. PLoS ONE 11:e205866

Chen D, Luo W, Bai Y (2019) The social interaction between China and Japanese archipelago during western Han dynasty: comparative study of bronze mirrors from Linzi and Yayoi sites. Archaeol Anthropol Sci 7:3449–3457

Chen D, Luo W, Zhang J et al (2020a) Archaeometallurgical perspectives on breaking mirror tomb of Xiongnu culture in Xinjiang during the WESTERN HAN Dynasty. Eur Phys J Plus 135(4):363

Chen D, Zeng Q, Cui B et al (2020b) Source change of lead material for mirror-making industry in western Han, China: evidence from Nanyang bronze mirrors. Curr Sci 118(9):1442–1447

Cheng Y (2010) Research on bronze mirrors unearthed in Anji of Han Dynasty. Oriental Museum 1:85–90

Cui J, Wu X, Bai Y et al (2009) An analysis of the lead isotope ratios of the western Han bronze mirrors from the Linzi city-site of the Qi state in Shandong. Archaeology 4:85–89

Duan Y (2020) Han mirrors discovered in Southern Korean Peninsula. China’s Frontier Archaeol 02:235–255

Fu X (2021) Han mirrors discovered in Southeast Asia. Archaeol Cult Relics 06:92–98

Fujian Museum MW, Museum F (2004) Excavation report on the Han City Site of Chengcun, Wuyishan. Fujian People’s Publishing House. Fuzhou 1–6

Higuchi T (1985) The nature of TRDA mirrors in east Asia and Japan in the 3rd century. Consider Anc Times 39:1–17

Higuchi T (1992) Analytical analysis of TRDA mirrors. Shinchosha Publishing Co Ltd, Tokyo

Huang M, Wu X, Chen X et al (2021) Wuchuan bronzes and cinnabar mining immigrants during the Qin and Han dynasties—new perspectives from typological and lead isotope analysis. Archaeol Anthropol Sci 13:198

Jin Z (2008) Lead isotope archaeology in China. University of Science and Technology of China, Hefei

Jin W (2010) Sang Hongyang and the salt and iron official camp of the western Han Dynasty. J Jiangsu University: Social Sci Ed 12(4):38–42

Jin Z, Liu R, Rawson J et al (2017) Revisiting lead isotope data in Shang and Western Zhou bronzes. Antiquity 360:1574–1587

Karlbeck O (1926) Notes on some early Chinese bronze mirrors. China J Sci Arts 4(1):3

Kobayashi Y (1971) Research on TRDA Mirror: type classification compilation. Res Notes Department Literature Kyoto Univ 13:96–170

Kong X, Liu Y (1984) Ancient Chinese bronze mirrors. Cultural Relics Press, Beijing

Li H (1988) The origin and early spread of Chinese bronze mirrors. J Shandong Univ Philos Social Sci Ed 2:51–54+45

Li X (1992) A Han mirror unearthed in Silbargan. Afghanistan Wenbo 05:15–16

Li K (2001) Yunnan arts history. Yunnan Education, Kunming

Liu R (2016) Capturing changes: applying the Oxford system to further understand the movement of metal in Shang China. Doctoral dissertation. University of Oxford

Liu Y, Chen K, Mei J et al (2015) Scientific analysis of bronze mirrors unearthed from the Xinfeng Qin Tomb in Lintong, Shaanxi Province, 4 edn. Central Plains Cultural relics

Liu R, Rawson J, Pollard A et al (2018) Beyond ritual bronzes: identifying multiple sources of highly radiogenic lead across Chinese history. Sci Rep 8(1):11770

Liu R, Pollard AM, Rawson J et al (2019) Panlongcheng, Zhengzhou and the movement of metal in early bronze age China. J World Prehistory 32:393–428

Liu R, Pollard A, Cao Q et al (2020) Social hierarchy and the choice of metal recycling at Anyang, the last capital of Bronze Age Shang China. Sci Rep 10(1):18794

Loubo-Lesnitchenko E (1973) Imported mirrors in the Minusinsk Basin. Artibus Asiae 35:25–61

Luo Z, Fan A, Jin Z et al (2022) Scientific analysis and research on the Warring States bronze mirrors unearthed from Changsha Chu Cemetery, Hunan province, China. Archaeometry 64(5):1187–1201

Luo Z, Jin Z, Zhao Z et al (2023) Lead isotope reveals the mineral source change of late bronze age bronze mirrors excavated in Hunan province, southern China. J Archaeol Sci: Rep 49:103994

Ma L (2015) A comparative study of the Mirror Destruction practices of the huns and the Tuoba Xianbei. J Zhengzhou Univ (Philos Soc Sci Ed) 06:140–145

Ma D, Wang N, Li P et al (2024) How the metal supply for mintage shifts in the transforming monetary system of the Han Empire: Archaeometallurgical study of the Wuzhu Coins from the Guanghuacun cemetery, Chengdu, Southwest China. J Archaeol Sci: Rep 53:104341

Mabuchi (2007) Thirty Year’s studies in ancient bronze objects by lead isotope method: reconsideration of the bronze materials in the late Yayoi Period. Archaeol Nat Sci 55:1–29

Mabuchi H (2011) Studies on some chemical aspects of Chinese Han-style mirrors: transition of lead isotope patterns from ‘Western-Han mirror type’ to ‘Eastern-Han mirror type’. Archaeol Nat Sci 62:43–63

Mabuchi H, Hirao Y (1982) Study of Han style mirrors by lead isotope method. Museum 370:4–12

Mabuchi H, Hirao Y (1983) Study of Han-style mirrors by lead isotope method (2). Museum 382:16–30

Mabuchi H, Hirao Y, Nishida M (1985) Lead isotope approach to the understanding of early Japanese bronze culture. Archaeometry 27:131–159

Mei J (2005) Some problems on the study of early bronze mirrors unearthed in Xinjiang. The second International Symposium on Turpan Studies

Okamura H (1984) The chronology and style of earlier Han’s mirrors. J History 67(5):661–702

Okamura H (1993) The chronology of later Han mirrors. Res Rep Natl Museum History Folklore 55:39–83

Okamura H (2014) Staging study of Han mirror. Han Mirror Culture Study. Peking University, Beijing, pp 46–110

Pollard A, Liu R (2023) Predicting bronze casting recipes in ancient China: ternary copper-lead–tin alloys and the unit sum problem. Archaeol Anthropol Sci 15(5):55

Pryce T, Baron S, Bellina B et al (2014) More questions than answers: the southeast Asian lead isotope project 2009–2012. J Archaeol Sci 42:273–294

Song X (1997) Early Chinese bronze mirror and its related problems. J Archaeol 2:147–169

Tan Q (1982) Historical atlas of China. Sinomap Press, Beijing

Treister M, Ravich I (2021) Chinese mirrors from the burials of the nomads of Eastern Europe of the second half of the 1st millennium BC–first centuries AD: typology, chronology, distribution and technology of manufacture. Adv Archaeomaterials 02:24–48

Wang Z (1981) Questions about the Japanese TRDA mirrors. Archaeology 4:346-358+395–396

Wang Z (1994) On the four gods mirror unearthed in Japan - and on the TRDA mirror made in Japan by Wu craftsmen of China. Archaeology 8:727–735

Wang Z (2000) On the Nature of the Japanese ‘Imitation TRDA mirror’ and Its Relationship with the So-Called ‘Imported TRDA mirror’. Archaeology 1:78–88+104

Wang K (2018) Overseas trade in kuaiji county during the six dynasties-centering on a sea route between China and Japan in ancient times. Chin Lit Hist Ser 2:28

Wu X (2005) Archaeological study of Han Dynasty bronze vessels. Yuelu Book Society, Changsha

Xu J (2022) Review of the TRDA Mirror: from the history of gemology, material evidence to historical archaeology. Acad Mon 54(03):193–200

Yang C (1990) On the age and nature of Han city in Chong’an Cheng Village Han. Archaeology 10:915–924

Yang Y (2017) Research on bronze mirrors of Han Dynasty in Fuyang. University of Technology, Hefei

Yang D, Wu X, Liu R et al (2023) From diversity to monopoly: major economic policy change in the western Han dynasty revealed by lead isotopic analysis. Archaeol Anthropol Sci 3:37

Zhangsun Y, Liu R, Jin Z et al (2017) Lead isotope analyses revealed the key role of Chang’an in the mirror production and distribution network during the Han Dynasty. Archaeometry 59(4):685–713

Funding

The research was supported by the National Natural Science Foundation of China (12035017&41473010). Ruiliang Liu acknowledges the financial support provided by ERC synergy project Horsepower (101071707) co-funded by ERC and UKRI (EP/X042332/1).

Author information

Authors and Affiliations

Contributions

X. Wang: conceptualization, methodology, formal analysis, investigation, data curation, writing—original draft, visualization, project administration

R. L. Liu: conceptualization, methodology review and editing, formal analysis, grant application, writing—original draft

J. Gao: writing—original draft, review and editing

A. M. Pollard: review and editing

A. C. Fan: review and editing

F. Huang: data quality monitor.

R. L. Li: sample providing

S. X. Zhang: sample providing

F. L. Hua: sample providing

Z. Y. Jin: conceptualization, methodology, formal analysis, writing—original draft, project administration, funding acquisition.

Corresponding authors

Ethics declarations

Consent for publication

Written informed consent was obtained from all the participants prior to the publication of this study.

Ethics approval

Not applicable.

Consent to participate

Written informed consent was obtained from all the participants prior to the enrolment of this study.

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Wang, X., Liu, R., Gao, J. et al. Reconstructing the trade history: provenance study of Han bronze mirrors in and out of Han China. Archaeol Anthropol Sci 16, 110 (2024). https://doi.org/10.1007/s12520-024-02016-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12520-024-02016-2