Abstract

Glazed decoration in Iran from the Middle Elamite to the Achaemenid periods includes world art milestones. With the exception of Hasanlu IVB, for most sites, comprehensive chemical and mineralogical data are lacking, owing to the generally profound alteration of the vitreous material. To bridge the information gap, and to enable to reconstruct operation production chains in a diachronic fashion, thirty-six glazed artefacts from Qalaichi, Rabat, Hasanlu, Ziwiye, Chogha Zanbil, Susa and Persepolis are studied. The microstructural make-up and alteration phenomena of glazes are characterized by petrographic microscopy, back-scattered electron (BSE) imaging and electron probe microanalysis (WDS-EPMA) on high-quality polished thin sections. Pristine glaze domains at all sites show plant ash soda-lime glass compositions and indicate the use of regionally specific halophyte species for soda production. A distinct feature in the composition of white and turquoise glazes from Qalaichi, Ziwiye and Achaemenid Susa is the employment of sodium-antimonate as white colourant and opacifier. Inter-diffusion and dissolution-precipitation are identified as regionally and temporally contrasting alteration processes.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction and scope of investigation

The foregoing study focuses on the manufacturing technology of glazed architectural elements that occur from Middle-Elamite (1450–1150 BC), Neo-Elamite (1100–646 BC) and Achaemenid (550–330 BC) periods as well as Iron Age north-western Iran (early 1st millennium BC). That three sites with major use of glazed architectural elements (Chogha Zanbil, Persepolis and Susa) are UNESCO World Heritage sites is no coincidence.

From the fourteenth century BC onwards, the use of glazed fired clay (terracotta), including pottery, bricks, wall plaques and wall nails, became widespread in Mesopotamia and Iran. Glaze-producing sites in Mesopotamia include fourteenth BC century Nuzi (Vandiver 1983, 2008; Shortland et al. 2017) and Neo-Assyrian palaces and temples, i.e. Nimrud, Khorsabad, Nineveh and Carchemish (Caubet 2007, 85–99) and in Egypt Amarna (Shortland and Tite 2000), thirteenth century BC Qantir (Rehren and Pusch 2007). Recent excavations in Satu Qala in Iraqi Kurdistan and Tell Nebi Yunus in Nineveh also yielded Neo-Assyrian glazed artefacts (see van Soldt et al. 2013 on Satu Qala; information on recent finds at Tell Nebi Yunus was provided by personal communication from Peter Miglus in November 2019). Middle and Neo-Assyrian glaze technology also recently has again received attention (see, e.g., Pollard and Moorey 1982; Freestone 1991; Nadali 2006, 2014; Fügert and Gries 2020). The monumental splendid Neo-Babylonian glazed terracotta Ishtar gate, the processional way and façade of the throne room at Babylon understandably have attracted the most attention with regard to the technology of ancient glazed bricks (Fitz 1982; Matson 1986; Kaniuth 2013). Fewer experts focus on the glazes and their technology of architectural elements in Iran than Mesopotamia. Iranian cultures pioneered glaze technology applied to terracotta and siliceous bodies outside Mesopotamia. Evidence for the glaze industry in Iran comes from three regions.

First, and most notably, south-western Iran (Khuzestan Province) predominately Haft Tappeh, Chogha Zanbil and Susa during the Middle-Elamite, Neo-Elamite and Achaemenid periods yield important evidence for glaze technology (see Caubet 2007; Caubet 2010 and Heim 1992; Gasche 2010 on Susa; Amiet 1966, 354 and Ghirshman 1968, 48 on Chogha Zanbil; and Ferioli and Fiandra 1979, 310–311 on Haft Tappeh). Middle-Elamite artisans glazed both terracotta and quartz-based siliceous bricks and other architectural elements (bricks, tiles and knobs) at the archaeological sites under discussion (see especially Amiet 1966, 1967; Heim 1989, 1992; Moorey 1994; Caubet 2003; Caubet 2007, 101–148; Daucé 2010; Caubet 2012). Shilhak-Inshushinak proudly states that he renovated or built new monuments in Susa and Chogha Zanbil (ancient Dur Untash) with fired siliceous brick (upkumia), replacing the baked brick (mushi) of his predecessors (Heim 1989, 34; Heim 1992, 123; Caubet 2003, 326).

During the first millennium BC, the Neo-Elamite industry expanded the range of colours corresponding to this development in Mesopotamia (Kaczmarczyk 2007, 36; Caubet 2012, 157–8, 161). At Susa, the Neo-Elamite king Hallushu-Inshushinak (698–693 BC) dedicated a temple to Inshushinak made exclusively of uhna–glazed siliceous brick (Heim 1989, 40–1 for sources). Although Neo-Elamite and Achaemenid craftsmen both used siliceous bricks, in the latter case the temper is coarser (Haerinck 1973, 119 note 51). Achaemenid building inscriptions (especially ‘Dsf’) report international sources of materials and that the artisans of different nationalities carried out specific tasks which has aroused much discussion (see Potts 1999, 328, based on Kent 1953; Kuhrt 2007, 492). Owing to the famous frieze of standing archers in Susa, the Achaemenid period has been described as the triumph of monumental compositions (Razmjou 2004). Considering this and the wider range of colours, the Achaemenid architects were conceivably trying to exceed quid pro quo the glazed brick industry of the Neo-Babylonians and Neo-Assyrians, cost it what it may.

The second region of glaze manufacturing centres is the lowlands of Fars, where early evidence of vitreous material production has appeared. Excavations at Tall-e Malyan level IV yielded materials from the Middle Elamite period (Carter 1996, 32–33). Later key sites which manufactured glazed materials occur in the Achaemenid sites Persepolis (Parsa) and Tol-e Ajori (Razmjou 2004; Askari Chaverdi et al. 2013, 2017, Amadori et al. 2018).

The third area which during the 1st millennium BC produced glazed artefacts comparable with Mesopotamia (especially Assur) and Elam is north-western Iran. The materials occur mainly at three sites: Qalaichi, Rabat (see Kargar 2004; Abdali 2018a, b, Abdali 2019 on Qalaichi; Kargar and Binandeh 2009; Afifi and Heidari 2010; Abdali 2018a, b; Abdali 2019 on Rabat) and Hasanlu (Hakemi and Rad 1950; Dyson 1959, 14). In addition, Ziwiye also yielded glazed artefacts (see Motamedi 1997; Abdali 2019). The more recently discovered glazed architectural elements in Iron Age north-western Iran, which derive from a space which the Neo-Assyrians termed the land of Mannā, are still little known. After the initial recovery in the nineteenth century of glazed architectural elements excavated from archaeological sites in Mesopotamia and Iran, decades later in the 1960s sanctioned excavations at the contemporary sites Qalaichi, Rabat and Ziwiye brought to light comparable glazed architectural elements (Abdali 2018a, 2019). Probably no scholar would dispute that these artefacts belong to mainstream Iron Age Iran. Besides, the glazed artefacts of Hasanlu differ from those of other sites located nominally in the space assigned to Mannā and are more Assyrianising in terms of form and decoration (Abdali 2018a, 235).

Investigation of glazes from Iran during the late second and early first millennia shows different diachronic and regional techniques of manufacture. Nevertheless, in order to make broad generalizations, more material analyses are necessary. The current work aims to provide additional scientific data to shed light on the glaze manufacturing industry in ancient Iran, from the Middle Elamite to the Achaemenid periods. It thereby enables a better understanding of the continuity, similarities, the technical relations as well as the alteration and preservation state of the glazes in each region.

Samples and analytical methods

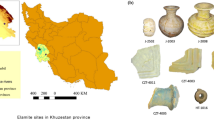

Thirty-eight samples representing fragments of glazed bricks, tiles, knobs, plaques as well as ceramic vessels from seven ancient Iranian sites serve as a basis of this study (Figs. 1, 2 and Table 1). They comprise glazed artefacts from the Middle-Elamite to Achaemenid period. The mineralogical, microstructural and chemical attributes of the glazes and ceramic bodies were studied on high-quality polished thin sections (standard thickness 30 μm). Microscopic examination and back-scattered electron imaging (BSE) focussed on the comprehensive characterization of the nature and conservation status of the glaze, the phenomena of alteration, the nature of the interface connecting the glaze with the ceramic body as well as the mineralogical make-up of the ceramic body. The subsequent chemical analysis of well-characterized pristine and altered glaze domains was done by electron probe microanalysis (EPMA), using a JEOL Superprobe 8200 at the Institute of Geosciences, University of Bonn. The conditions for the quantitative electron probe microanalysis with 5 wavelength dispersive spectrometers were 15 kV acceleration voltage, 15 nA beam current and an electron spot focused to 5 μm. Counting time was 10 s on peak positions (except Na, 5 s) and 2 times 5 s on background positions, respectively. Standards used were well-characterized rhyolitic and basaltic glasses (Si, Al, Fe, Ca, Na: Kα), sanidine (K: Kα), antimonite (Sb: Kα) and metals (Pb, Cu, Co: Kα). ZAF corrections were applied by the built-in software of the instrument. Glaze analyses were corrected for the effect of sodium migration (Na loss) following the recommendations of Morgan and London (2005). Average WDS-analyses representing the compositions of pristine and altered glaze domains and the vitreous interaction layer for each of the studied samples are given in Tables 2, 3, 4, 5 and 6. For each sample, the complete set of spot analyses together with BSE images which document the spot locations within individual pristine and altered glaze domains can be found in Abdali (2018a).

Representative glazed artefacts from Middle-Elamite to Achaemenid excavation sites, which glazed samples were derived from (a) fragment of a glazed tile from Chogha Zanbil (Louvre), (b) fragment of a glazed tile from Susa (Louvre), (c) remnant of a glazed jar from Hasanlu (National Museum of Iran, Tehran), (d) turquoise glazed sample from Qalaichi (Urmia Museum), (e) yellow glazed sample from Rabat (Urmia Museum), (f) fragment of a glazed knob from Ziwiye (Ziwiye Archaeological Research Centre), (g) fragment of a glazed brick from Persepolis (Parse and Pasargadae Research Centre Museum). Scale of bars = 2cm

Results

Ceramic bodies

The compositional and microstructural attributes of ceramic bodies were studied by polarized light microscopy (Quinn 2013). Salient findings of thin section analysis, as summarized below, reveal that ceramic centres at the different archaeological sites used local materials for manufacturing the architectural objects. Impure clayey raw material, mostly calcareous clays, served to manufacture the bodies of glazed architectural elements at Chogha Zanbil, Ziwiye, Rabat Tappeh and Qalaichi, whereas at Susa and Persepolis, glazed architectural elements were exclusively produced with quartz-based ceramic masses.

Chogha Zanbil (Middle-Elamite period)

Architectural elements were produced with fine-grained, straw-tempered calcareous clays. The moderately sintered ceramic matrix contains large fragments of flint, back-reacted calcinated limestone and grog, besides clasts of quartz and black to reddish brown iron-oxide particles. Large elongate voids with remnants of organic matter represent a straw temper component. The spotted reddish colour of the matrix, the calcination of calcite and the moderate intensity of sintering through reaction of the fine-grained clay-quartz fraction and carbonate (with formation of clinopyroxene, gehlenite, anorthite and glass) indicates firing temperatures of 800–850°C (cf. Noll and Heimann 2016). Voids are generally coated with secondary calcite.

Qalaichi (800–600 BC)

The terracotta bodies of glazed architectural elements of the site were manufactured with poorly sorted clayey material. The coarse-grained particulate fraction has a ‘granitic’ affinity and comprises angular to sub-rounded mineral clasts (quartz, microcline, plagioclase) and lithic fragments (altered granite, granophyre, muscovite-quartzite, arkose, schists) set in an argillaceous matrix. The terracotta bodies of few samples (Qa-1, 3, 27) contain poorly sorted coarse inclusions of ‘granitic’ material, felsic to basic volcanic rocks, limestone, shells and iron-oxide set in a calcareous clay matrix.

Rabat Tappeh (800–600 BC)

The terracotta bodies of glazed architectural elements from this site were manufactured with calcareous clayey material rich in poorly sorted particulate inclusions. These comprise a wide spectrum of angular to sub-rounded mineral clasts (perthitic K-feldspar, plagioclase, quartz, white mica, amphibole, clinopyroxene, calcite) and lithic fragments (quartzite, sericite quartzite, limestone/marble, weathered felsic to basic volcanics, serpentinite, amphibolite, ferruginous schists, iron oxide pellets). Extremely fine-grained ‘calcitic’ fragments and particles, some resembling the shape of forams and shells, likely represent back-reacted calcinated limestone/shell fragments, thus indicating firing temperatures of 800–850°C, in agreement with the moderate sintering state of the terracotta.

Ziwiye (800–600 BC)

The terracotta bodies of the two studied glazed artefacts from this site are made up of a reddish-brown clayey matrix embedding poorly sorted subangular lithic fragments (schists, volcanic fragments) and few clasts of feldspar and quartz.

Susa (Neo-Elamite and Achaemenid periods) as well as Persepolis/Parsa (c. 518–480 BC)

The studied glazed architectural objects from the two sites all consist of a siliceous mass comprised of coarse and fine angular quartz grains bounded by intergranular vesicular glass. Local glass domains show prolific crystallization of acicular diopside, and more rarely wollastonite or forsterite, depending on the CaO/MgO ratio of the melt phase. The angular shape and bimodal grain size distribution of quartz grains suggest that the siliceous raw material was produced by crushing coarse quartz rocks (e.g. pebbles of vein quartz, pegmatite and quartzite). The chemical compositions of intergranular glass domains resemble those of plant ash soda-lime glass (Table 2), indicating the use of halophytic plant ash as a fluxing agent and cementing medium of the quartz mass. The observed intergranular CaMg-silicate assemblage, based on experimental firing studies, indicates firing temperatures in the order of 800–900 °C (cf. Noll and Heimann 2016). The vesicles and open voids of the siliceous bodies have been coated with calcite during hydrous alteration during subsoil residence.

Glazes

Blue to greenish blue glazes

(Samples: Qa-26; Ha-21, 22, 23; Ra-07; Cho-51, 52, 53; Su-15, 45; Parsa-12)

The poorly to distinctly vesicular blue glazes of Middle-Elamite to Achaemenid architectural ceramic objects range in thickness from 100 to 1500 microns (average ~500 microns). Translucent glazes are commonly homogeneous and free of inclusions. Some glazes, however, contain inclusions of partly dissolved quartz splinters (Cho-51, 53; Su-15), minute particles of combeite (Na2Ca2Si3O9) (Ha-22, 23) or very few tiny Na-antimonate particles (Qa-26) that may have acted as whitener, providing the glazes an opalescent bluish tint (Fig. 3a–e).

Back-scattered electron images illustrating features of blue glazes of architectural elements from Choga Zanbil, Hasanlu, Qalaichi, Susa and Persepolis. See text for description of glaze features. Image key: a Cho-52, b Cho-53, c Has-23, d Qa-26, e Su-15, f Par-12. Scale of bars = 100 microns. Com, combeite; IAL, interaction layer; Na-ant, sodium-antimonate; Qz, quartz

Blue glazes on clay-based architectural objects from Elamite to Iron Age sites are commonly separated from the reddish-brown terracotta bodies by a thin vitreous layer, interpreted as intentionally applied calcareous-micaceous white slip. These layers may be enriched in calcite grains and alkali feldspar-melt pools or show a criss-cross ‘flaky’ structure and distinct aluminous and potassic composition reminiscent of a fine muscovitic aggregate (Cho-52, Fig. 3a). In few cases, infiltration of fluxing components (Na, K) from the adjoining glaze into the terracotta body produced a thin vitreous boundary layer of distinctly aluminous and iron-rich composition (Qa-26, Fig. 3d and Table 2).

Translucent blue glazes on the quartz-based architectural objects from Achaemenid Susa and Persepolis penetrate the siliceous bodies and merge with intergranular vitreous domains, thus ensuring an efficient bond (Su-15, 45; Parsa-12; Fig. 3e, f). Obviously, they did not require application of a white slip. The chemical compositions of pristine vitreous glaze domains without exception closely match those of typical plant ash soda-lime glasses (Table 2). The blue to greenish blue colour of pristine vitreous domains is caused by the presence of ionic copper (0.5-4.2 wt.% CuO, Table 2), lowest contents characterizing glazes from Chogha Zanbil and highest contents those from Qalaichi and Susa. Cobalt as ionic colourant has not been encountered except of an artefact from Achaemenid Susa where in combination with ionic copper, it causes the deep blue hue of the glaze (Su-15: ~1 wt.% CuO, ~0,4 wt.% CoO; Table 2).

Alteration of the vitreous phase of the glazes varies from minor to complete and was induced through fluid infiltration along the outer and inner surfaces, cross-cutting cracks and the walls of open vesicles. Where alteration occurred through dissolution-precipitation as in the case of glazes from the Middle to Neo-Elamite sites, it produced finely banded colloform domains (Fig. 3a, c) that experienced a complete loss of alkali elements (Na, K), severe depletion of alkali-earth elements (Mg, Ca) and a significant depletion of silica (Table 2). The leached-out colourant agent copper was re-precipitated as secondary Cu-compounds in veinlets, alteration halos of vesicles and surface crusts. Where alteration of the glazes occurred through inter-diffusion as in the case of Achaemenid sites Susa and Persepolis, it produced structureless domains which experienced a complete loss of alkali elements but still preserve pristine abundances of the other elements (Table 2).

Turquoise glazes

(Samples: Qa-04, 25A, 25B; Ra-07; Ziw-37; Su-18)

The poorly to distinctly vesicular turquoise glazes from Iron Age sites Qalaichi, Rabat and Ziwiye range in thickness from 600 to 2300 microns. Some glazes from Qalaichi show a distinct double-layered make-up (Qa-25A, Fig. 4b): a translucent light blue outer layer and an inner strongly vesicular opaque layer richly clouded with precipitated Na-antimonate particles. The opaque turquoise colour results from the superimposed effect of ionic copper which acts as the blue colouring agent in both layers (2.5–4 wt.% CuO) and Na-antimonate acting as white opacifier and efficiently shielding the glaze against the dark terracotta body. Infiltration of fluxing components (Na, K) from the glaze into the adjoining terracotta bodies produced thin vitreous boundary layers of distinctly aluminous and iron-rich composition (Fig. 4e and Table 3). Alteration through fluid infiltration along a branched network of surface-parallel cracks and cross-cutting veins has variously affected the glazes (Fig. 4a–d). The pristine glaze domains preserve typical plant ash soda-lime glass compositions (Table 3). Structureless alteration domains arising from inter-diffusion experienced a strong depletion of sodium, whereas other elemental abundances remain largely unaffected (Qa-04, Qa-25B; Fig. 4a and c and Table 3). Finely banded colloform alteration domains resulting from dissolution-precipitation in the glaze from Ziwiye, on the other hand, exhibit strong to extreme overall elemental depletion (Ziw-37; Fig. 4e and Table 3).

Back-scattered electron images illustrating features of turquoise glazes of architectural elements from Qalaichi, Rabat, Ziwiye and Susa. See text for description of glaze features. Image key: a Qa-04, b Qa-25A, c Qa-25B, d Ra-7, e Ziw-37, f Su-18. Scale of bars = 100 microns. Cu-sil, secondary copper silicate; Fe-sl, microfragments of iron slag; IAL, interaction layer; Na-ant, sodium-antimonate

The vesicular turquoise glaze (100–200 microns thickness) on a quartz-based architectural object from Achaemenid Susa (Su-18) contains minute quartz splinters and vitreous fragments strongly enriched in iron and alkalis, which are interpreted as dissolved fragments of iron slag (Fig. 4f and Table 3). The turquoise glaze colour likely results from the opacifying effects of quartz splinters on the blue to greenish-blue colours caused by the ionic colourant copper, which shows steadily decreasing contents towards the siliceous body (1.3–0.5 wt.% CuO, Table 3), as well as the ionic colourant iron of vitreous fragments. The glaze experienced pervasive structureless alteration causing a complete loss of alkali elements, whereas the other elemental abundances match those of typical plant ash soda-lime glasses (Table 3).

Green glazes

(Samples: Cho-50, Ha-21, Ziw-20, Su-17, Parsa-11)

Artefacts from Iron Age to Achaemenid archaeological sites, with one exception (Su-17), show green glaze colours that cannot be assigned to the presence of traditional colouring compounds (ionic copper and Pb-antimonate). The green colour impression likely resulted from either the profound alteration of formerly blue glazes (Ha-21, Su-46), as indicated by the presence of CuO contents in the order of 1–4 wt. % (Table 4), the combined effect of the ionic colourants iron and copper (Cho-50, Parsa-11, Table 4) and or the presence of colouring mineralic inclusions (Parsa 11).

The vesicular glaze of an artefact from Iron Age Choga Zanbil (Cho-50; 900–1000 microns thickness) contains grains of partly dissolved quartz and K-feldspar (Fig. 5a). Most vesicles are empty, but few are filled or thinly coated with gypsum. A thin vitreous interaction layer of distinctly aluminous and ferrous composition separates the glaze from the terracotta body. Pervasive differential alteration enhanced the turbid-striated flow structure of the glaze and was accompanied by significant depletion of silica and alkali elements, whereas alumina, iron and magnesium became enriched (Table 4). The presence of the ionic colourants copper and iron suggests a green colour of the original pristine glaze (2–3 wt.% Fe2O3, 0.3–1.7 wt.% CuO; Table 4).

Back-scattered electron images illustrating features of green glazes of architectural elements from Choga Zanbil, Ziwiye, Susa and Persepolis. See text for description of glaze features. Image key: (a) Cho-50, (b) Ziw-20, (c) Su-17, (d) Par-11. Scale of bars = 100 microns. Afs-L, melted alkali feldspar grains; Fe-Ox, particles of fayalite-coated iron oxide; IAL, interaction layer; CuMg-sil, grains of cupriferous Mg-silicate; Jd, jadeite; Pb-ant, lead antimonate

The vesicular glaze of an artefact from Iron Age Ziwiye (Ziw-20; 300–400 microns thickness) has been intensely altered, with development of rhythmically zoned domains that exhibit strong to extreme elemental depletion (Fig. 5b). Tiny particles of Na-antimonate are randomly dispersed throughout the glaze but also decorate the walls of open vesicles indicating their late precipitation. Na-antimonate probably acted as opacifying agent. The green-coloured impression of the glaze is due to the presence of strongly coloured colloform domains, extremely enriched in copper (24−43 wt.% CuO; Table 4). A peculiar feature of the glaze are strongly dissolved elongate particles of jadeite (NaAlSi2O6), which likely were added as fluxing agent (Fig. 5b and Table 4). The terracotta at its contact with the glaze developed a thin vitreous interaction layer which preserves its glassy state and pristine aluminous composition (Table 4).

The vesicular green glaze from Achaemenid Susa (Su-17; ~2000 microns thickness) contains ubiquitous minute to large polygranular particles of lead antimonate besides few partly dissolved quartz splinters (Fig. 5c). Penetration into the siliceous body ensures an efficient bond. The combined effect of colloidal Pb-antimonate acting as yellow opacifier and ionic copper as translucent blue colourant produces the opaque green colour of the glaze (~3 wt.% CuO; ~9 wt.% PbO; Table 4). Alteration occurred along the outer surface and produced pronounced alteration halos around the vesicle which may be open or partly to completely mineralized with calcite. The composition of moderately altered glaze domains, except for the strong depletion of alkali elements, resembles the composition of plant ash soda-lime glass (Table 4).

The green polychrome element (Parsa-11; 250–1000 microns thickness) from Achaemenid Persepolis is covered by a frit (250–1000 microns) which is made up of finely crushed splintery quartz, abundant particles of fayalite-coated iron oxide, calcite and a copper-bearing Mg-silicate, all cemented by a strongly altered interstitial vitreous phase (Fig. 5d). The few vesicles are coated with siliceous alteration products. The green colour of the frit largely results from the interstitial melt, which exhibits significant contents of the ionic colourants iron and copper (~6 wt.% FeO, ~2.5 wt.% CuO; Table 4), and possibly is enhanced by the colouring effect of copper-bearing Mg-silicate inclusions.

Yellow glazes

(Samples: Qa-01, 28, 29, Ziw-37, Su-48, 16, Parsa-10b, 11)

The poorly to distinctly vesicular yellow glazes vary in thickness between 300 and 2000 microns (average ~500 microns) and, irrespective of their age and site, are densely loaded with tiny particles to large poly-crystalline fragments of Pb-antimonate (Fig. 6a–f). Obviously, these were added to the glaze slurries as premade yellow colourant and opacifier. High lead contents opposed to low antimony contents of pristine vitreous domains indicate an intentional addition of PbO (litharge) both as flux and ionic yellow colourant.

Back-scattered electron images illustrating features of yellow glazes of architectural elements from Qalaichi, Ziwiye, Persepolis and Susa. Lead-antimonate particles and microfragments as well as layers of colloform alteration and vesicle fillings significantly enriched in lead show up by bright BSE-contrast. See text for description of glaze features. Image key: (a) Qa-01A, (b) Qa-29, (c) Ziw-37, (d) Par-11, (e) Su-48, (f) Su-16. Scale of bars = 100 microns

Glazes from Iron Age Qalaichi and Ziwiye have been variously altered through fluid infiltration along the outer surface, cross-cutting veins and the interface with the smoothened terracotta bodies. Dissolution-precipitation produced finely banded colloform domains that advance from the fluid pathways into the glaze interiors (Fig. 6a–c). Depending on the alteration status of the glazes, vesicles may be empty, thinly coated or completely filled with calcite and/or siliceous alteration products and surrounded by concentric alteration halos. Pristine glaze domains exhibit plant ash soda-lime glass compositions with significant to moderate contents of lead and antimony (36–16 wt.% PbO, 3–2 wt.% Sb2O5) and only minor depletion of alkali elements (Table 5). The dark BSE-contrast bands of colloform alteration domains experienced strong to extreme overall elemental depletion, whereas the bright BSE-contrast bands are strongly enriched in lead (Fig. 6b). The thin interaction layers which separate the glazes from the terracotta bodies preserve their vitreous nature and pristine chemical compositions (Table 5).

Glazes on quartz-based architectural elements from Susa and Parsa may be densely packed with quartz splinters, their penetration into the siliceous bodies ensuring an efficient bond (Fig. 6d–f). Highest lead and low silica contents (36–21 wt.% PbO, ~54 wt.% SiO2; Table 5) characterize quartz-devoid pristine outer domains, whereas the quartz-loaded inner glaze domains show decreased lead and high silica contents (16–6 wt.% PbO, ~78 wt.% SiO2; Table 5). Alteration of the glazes occurred along surface-parallel and cross-cutting cracks, producing structureless domains severely depleted of alkali elements, while other elemental abundances and the significant contents of lead and antimony resemble the composition of typical yellow plant ash soda-lime glass (Table 5).

White glazes

(Samples: Cho-49, Qa-27, Ra-06, Ziw-19, Su-14)

The distinctly vesicular white glazes vary in thickness between 150 and 550 microns. The vesicles are open, coated or completely filled with secondary calcite (rarely gypsum) (Fig. 7a–d). A white slip made up of calcite followed by a fine-grained aggregate of carbonate, quartz and mica may separate glazes from the calcareous terracotta bodies of architectural objects from Iron Age sites (Fig. 7b). Where the terracotta bodies are in direct contact with the glaze, they developed a thin inclusion-free vitreous boundary layer of distinct composition through reaction with the fluxing components of the glaze (Fig. 7c and Table 2). Na-antimonate acts as opacifier and colourant of white glazes from Qalaichi and Ziwiye, where it occurs as abundant tiny particles precipitated from the glaze in clusters and preferably around the vesicles and few polycrystalline fragments (Fig. 7a, c). Abundant, randomly distributed tiny Ca-antimonate particles acted as an opacifier and white colourant of the glaze from Rabat (Ra-6, Fig. 7b). The white glaze from Choga Zanbil (Cho-49) does not carry micron-size particles of Ca- or Na-antimonate, in agreement with the low contents of Ca and Sb of the glaze (Table 6). The white colour impression of the glaze likely is caused by abundant inclusions of partly dissolved angular quartz grains and fragments of grog made up of melilite and melt, as well as forsterite-rich reaction domains separating the glaze from the terracotta. Alteration of the glazes is intense and occurred along surface-parallel cracks, adjacent to the vesicles, along widely spaced cross-cutting cracks and notably along the inner detached boundary (Fig. 7a–c). The pervasively altered glaze domains experienced a complete loss of alkalis and depletion of alkali-earth elements (Table 6).

Back-scattered electron images illustrating features of white glazes of artefacts from Qalaichi, Rabat, Ziwiye, Choga Zanbil and Susa. Bright particles and microfragments are either Na-antimonate (a, c, d) or Ca-antimonate (b). Few very bright small vesicles were filled with lead during thin section polishing (b, d). See text for description of glaze features. Image key: a Qa-27, b Ra-06, c Ziw-19, d Cho-49, e Su-14. Scale of bars = 100 microns. IAL, vitreous interaction layer

The white glaze from Achaemenid Susa (Su-14) exhibits a double-layered make-up: the inner vitreous domain is densely loaded with partly dissolved splintery quartz grains and merges with the intergranular vitreous matrix of the siliceous body, thereby creating a tight interface. Its composition matches those of plant ash soda-lime glass (Table 6). The strongly vesicular main glaze layer carries abundant randomly distributed minute particles of Na-antimonate, which act as white colourant and opacifier (Fig. 7d). Except for the almost complete loss of alkalis, its composition resembles those of plant ash-soda-lime glass (Table 6).

Discussion

The bodies, their nature and interaction with the glaze

Impure clayey raw material, mostly calcareous clays, served to manufacture the bodies of glazed architectural elements at Middle-Elamite Chogha Zanbil, and the Iron Age sites Ziwiye, Rabat Tappeh, as well as Qalaichi. The poorly sorted particulate inclusions of the clays show characteristic petrographic associations which reflect specific provenances of the clastic matter and local sources of the clayey raw materials. Terracotta bodies from Qalaichi and Rabat Tappeh contain particulate inclusions of ‘granitic’ affinity, those from Ziwiye lithic fragments of volcanic rocks and schists, while those from Chogha Zanbil were produced from calcareous clays rich in fragments of limestone, flint, grog and organic temper. Firing temperatures ranging between 800 and 900°C are inferred from the partial to advanced sintered state of the bodies (Noll and Heimann 2016, 102). A refined estimate of firing conditions based on the XRD determination of neoblastic (newly developing) ceramic phases, however, was beyond the scope of this study.

Glazing of the terracotta may have been executed in two ways: either by applying the glazing material (slurry) directly on the dried green bodies or on the biscuit-fired bodies, thus requiring one or two phases of firing, respectively. In this regard, the microstructural attributes of vitreous interaction layers which typically develop at the terracotta-glaze interface may provide crucial information. The interaction layers with no exception preserve a non-vesicular vitreous state, with smooth and undisturbed interfaces with the adjoining terracotta bodies and rare cross-cutting cracks (Fig. 8a-c). Such features strongly indicate their development after the major degassing and sintering reactions and concomitant volume reduction (shrinking) took place in the host ceramic body, which suggests an application of glazing materials on biscuit-fired bodies followed by final firing to 800–900°C. The vitreous interlayers are formed through dissolution of ceramic constituents in a narrow zone infiltrated by the glaze melt, thereby ensuring a firm bond of the glaze to the ceramic body. The metasomatic nature and ceramic affinity of the interlayers are nicely mirrored by the distinctly aluminous and ferrous compositions of the vitreous phase (Tables 2, 3, 4, 5 and 6). The interface with the glaze layer is characterized by steep compositional gradients, with sharply decreasing ceramic constituents (Al2O3, Fe2O3) and increasing fluxing components (Na2O, K2O). Because of the contrasting expansion/contraction properties and alteration behaviour of the two vitreous phases, the interface forms the compositional barrier for aqueous alteration and the common detachment plane of the glaze (Figs. 4e, 7c and 8a).

The BSE images illustrate the development of vitreous interaction layers at the interface of terracotta and glaze. They represent the outermost melted part of the ceramic bodies, triggered by the infiltration of fluxing alkalis into the ceramic body. Because of the contrasting chemical and physical properties of glaze and interaction layers, their mutual interface marks the boundary of hydrous alteration and common detachment site. a Rabat, Ra-30: the glaze has been altered by aqueous infiltration along the detachment plane and fractures, b Qalaichi, Qa-26: a marked chemical gradient characterizes the interface of vitreous glaze and interaction layer, c Ziwiye, Ziw-19: the severely altered, sodium-antimonite loaded glaze adjoins with sharp contact the pristine vitreous interaction layer. Scale of bars = 100 microns; Glz, glaze; IAL, interaction layer; Bdy, ceramic body

Considering economic and technological aspects, the use of clayey material for the production of architectural elements had several advantages: the raw clays could be mined from local sources and used without further beneficiation measures; forming, surface treatment and drying were not challenging. The colours of biscuit-fired bodies, on the other hand, did not provide an ideal canvas for transparent glazes and required the application of opaque glazes or white slips in the case of transparent glazes.

Glazed architectural elements from Susa and Persepolis were exclusively produced with quartz-based ceramic masses. The manufacture followed a long pre-Achaemenid tradition as evidenced by the archaeological record at the Middle and Neo-Elamite sites of Chogha Zanbil and Susa (Caubet 2007 & 2012). Workshops at Middle-Elamite Chogha Zanbil are considered pioneers in the production of quartz-based glazed bodies (Moorey 1994, 175; Caubet 2007, 125, 127). The Middle-Elamite king Shutruk Nahhunte I, in twelfth century BC, proclaimed the invention of a new brick making technique based on highly siliceous masses (Heim 1992, 202). Surprisingly, the glazed bodies from Chogha Zanbil studied in this contribution consist exclusively of calcareous clay-based terracotta, which might indicate their production prior to the twelfth century BC.

Although using quartz-based material was technically more laborious and expensive, it had two advantages: the light colour of ceramic bodies provided an excellent canvas for the application of transparent glazes; infiltration of the glaze into the porous body and coalescence with interstitial alkaline melt ensured a tight bonding of the glaze to the siliceous body. The microscopic examination of studied artefacts revealed that crushed quartz, generally comprising coarse and fine grain size fractions, was used for forming the bodies. The consistently angular shape of quartz grains favours pebbles of coarse-grained quartz-rich rocks (e.g. vein quartz, quartzite and pegmatite) as quartz source. The ashes of halophytic plants were used as intergranular cement, which upon firing produced an intergranular melt phase of alkali-lime composition that provided an excellent vitreous bonding of the siliceous mass. However, hydrous alteration of the glaze and the vesicular intergranular vitreous phase made the porous siliceous bodies vulnerable to weathering.

Glazes

For decades now, archaeological research has focussed on the invention and development of glass-making technology in antiquity (as reviewed in Henderson 2013; Schmidt 2019). Archaeometric studies, boosted by the recent developments of modern instrumental analytical techniques (cf. Janssens 2013), have provided comprehensive data and insights on the materials and technologies of glass-making and glazing. The present data support views on the raw materials and recipes employed for glazing in antiquity by providing data for so far little studied archaeological sites in Iran.

A critical assessment of compositional similarities and contrasts of glazed artefacts from archaeological sites in Iran, however, is hampered by the limited analytical data available for most sites. Moreover, glaze analyses reported for Susa and Persepolis were obtained by EDS-EDX (Jung and Hauptmann 2004; Tite and Shortland 2004; Holakooei 2014) and thus should be regarded as semi-quantitative. The analyses show either low sodium contents (<2 wt.% Na2O) indicating severe alteration of the vitreous objects (Tite and Shortland 2004, 390; McCarthy and Paynter 2008, 192-193) or an extreme spread of analytical totals (48-153 wt.%) (Holakooei 2014, 771) which suggests large analytical errors as well as strong deterioration of some of the glazes.

At present, the most comprehensively studied vitreous artefacts from sites in Iran are those from period IVB Hasanlu (Stapleton 2003, 2011). A surprizing observation is that the WDS-analyses reported for blue and turquoise glasses show significantly higher analytical totals and sodium contents (101-105 wt.%; 17-20 wt.% Na2O) compared to those of blue and turquoise glazes (97-99 wt.%; 9-15 (17) wt.% Na2O), the latter closely matching the glaze analyses of this study (99-100 wt.%; 14-16 wt.% Na2O, Table 2). Although no explanation is offered for the discrepancy, the few analyses of vitreous artefacts from Hasanlu published by Brill (1999, 43), which closely match our glaze analyses, suggest an overcorrection of sodium during analysis of the glasses.

A comparative analysis of published data with those of this contribution is further hampered by the fact that most studies do not document the microstructural make-up and alteration state of analysed vitreous domains. It is obvious that the overall severe alteration of glazes at the studied sites, as well as the presence of inclusions (e.g. opacifier particles, relics of incompletely dissolved quartz), bubbles and mineralized fissures in pristine glaze domains, precludes a determination of pristine glaze compositions through area-scanning SEM-EDS or WDS analysis (Matson 1986; Holakooei 2014) or bulk chemical analysis (e.g. XRF or LA-ICPMS). A meaningful analysis of pristine glaze compositions instead should be based on WDS spot analysis of microdomains, well-characterized by BSE imaging.

Pristine glaze compositions and fluxing agents

The analysed glazes, with exception of lead-rich Achaemenid yellow ones, belong to the soda-lime glass type. They were produced by melting finely crushed quartz pebbles or sand with an alkaline flux, and depending on the desired colour, by adding specific colourants and opacifiers. The ashes of halophytic plants or natron were used as fluxing agents (Brill 1999; Wedepohl 2003; Gratuze 2013; Schmidt 2019). In contrast to natron, the ashes of halophytic plants, depending on the individual genus or species and the environmental growth conditions, exhibit complex compositions, with widely varying contents of sodium and potassium, and significant contents of magnesium and calcium (Brill 1999; Barkoudah and Henderson 2006; Tite and Shortland 2008; Shortland et al. 2006, 2011; Jackson et al. 2018). In the ternary diagram Na2O-(MgO+K2O)-CaO, the two fluxing agents define well-separated compositional fields (Fig. 9a, b). The compositions of natron plot close to the Na2O apex, whereas the halophytic plant ashes show extensive compositional variation along the Na2O-(K2O+MgO) join at rather constant contents of CaO. These chemical features are carried into the glasses/glazes, with only minor modifications caused by impurities of the siliceous component (e.g. feldspars, micas) and the added opacifiers (e.g. sodium- and calcium-antimonates). More significant modifications of the alkali element contents and ratios of the glass may have been caused by the naturally present alkali chlorides in the plant ash, which at high natural chloride contents are controlled by the Na–K exchange between the silicate melt (glass) and a coexisting chloride melt (galle) (Tanimoto and Rehren 2008). As a result, the contents and ratios of alkali elements observed in the glass may not directly reflect the alkali element signatures of the plant ash, thus impeding a straightforward discrimination of halophytic plant species used for fluxing (Barkoudah and Henderson 2006; Tanimoto and Rehren 2008).

a Ternary diagram Na2O-(K2O+MgO)-CaO showing the compositions of pristine and altered blue and turquoise glazes obtained in the present study. Also shown are the composition fields of natron soda-lime glasses (1), plant ash soda-lime glasses (2) (Gratuze 2013; Fig. 5.1.4) and halophytic plant ashes (3). Published analyses of blue and turquoise vitreous artefacts from Nimrud, Hasanlu, Babylon and Susa are plotted for comparison. Symbol key: 1,2, this study; 3, Babylon (Matson 1986); 4, Nimrud (Brill 1999); 5, Susa (Tite and Shortland 2004); 6, Hasanlu, blue glazes (Stapleton 2011); 7,8, Hasanlu, transparent and opaque blue glasses (Stapleton 2011); 9, halophytic plant ashes (Barkoudah and Henderson 2006). b Ternary diagram Na2O-(K2O+MgO)-CaO showing the compositions of pristine and altered green and yellow glazes obtained in the present study. Also shown are the composition fields of natron soda-lime glasses (1), plant ash soda-lime glasses (2) (Gratuze 2013; Fig. 5.1.4) and halophytic plant ashes (3; green stars: analyses from Barkoudah and Henderson 2006, Table 2). Published analyses of green and yellow vitreous artefacts from Nimrud, Hasanlu, Babylon and Susa are shown for comparison. Symbol key: 1,2, pristine and altered green glazes, this study; 3,4, pristine and altered yellow glazes, this study; 5, Susa (Tite and Shortland 2004); 6, Hasanlu, yellow glasses (Stapleton 2011); 7, Babylon (Matson 1986); 8, Nimrud (Brill 1999); 9, halophytic plant ashes (Barkoudah and Henderson 2006)

In spite of these complexities, the compositions of natron soda-lime glasses/glazes straddle close to the Na2O-CaO join of the ternary diagram, whereas soda-lime glasses/glazes using halophytic plant ashes as a fluxing agent show a comparable compositional trend, albeit at distinctly higher MgO+K2O contents of 10-30 wt.% (Fig. 9a, b). Without exception, the analyses of pristine glazes of the studied artefacts plot in the composition field of halophytic plant ash soda-lime glasses. It is obvious that while the halophytic plant ashes used contained sufficient calcium to stabilize the glass/glaze, in the case of natron as fluxing agent, a calcium-rich compound had to be added as stabilizing agent. Furthermore, the compositional restriction of glasses/glazes to (MgO+K2O) contents below 30% excludes potassium-rich halophytic plants of the genus Chenopodium as fluxing agents and indicates the use of halophytic plants of the genera Anabasis, Salsola and Haloxylon (Hammada) (cf. Brill 1999; Wedepohl 2003; Barkoudah and Henderson 2006; Tite and Shortland 2008). To elucidate which of the sodium-rich halophytic plants may have been employed by the glassmakers as a fluxing agent, the compositions of halophytic plant ashes normalized to the average composition of blue glazes appear displayed in a multi-element diagram (spidergram) (Fig. 10a). For this purpose, only the contents of alkali and alkaline-earth elements (recalculated to 100 wt.%) of plant ashes and the blue glaze average are considered. The comparison assumes that impurities (e.g. feldspars, micas) have not modified the average composition of blue glazes and thus reflects the composition of the added fluxing agent and that the plant ash compositions were carried into the blue glazes without fractionation effects caused by the presence of natural chloride compounds. Among the various sodium-rich halophytic plants, Anabasis syriaca, Halopeplis sp. and Arthrocnemum strobilaceum show the closest resemblance with the average composition of blue glazes, the MgO, CaO, Na2O and K2O normalized values scattering close to 1 (Fig. 10a), which would support their use as fluxing agent. To express the compositional deviation of plant ashes in percent of the blue glaze composition, a mass balance diagram has been computed (Fig. 10b). It indicates that in addition to the identified halophytic plants, the most sodic species of the genus Salsola may also have been used as alkaline fluxes, in which case the obvious CaO deficiency would require the addition of a calcium compound (lime, calcite).

a The spidergram shows the variation of alkali and alkali-earth concentrations of halophytic plant ashes (Barkoudah and Henderson 2006, Table 2) normalized to the average composition of blue glazes (this study). b The mass balance diagram displays the deviation in percent of alkali and alkaline-earth concentrations from the average blue glaze composition. Ci = concentration of element I in plant ash (plt) or glaze (glz). For discussion see text

By normalizing the compositions of plant ashes and glazes to Anabasis syriaca, a more differentiated picture emerges. It allows a clearer discrimination of the halophytic fluxing agent (Fig. 11). The spidergrams of glazes show a significant enrichment of Al2O3, Fe2O3 and MnO, which evidently were carried into the glass/glaze by impurities of the siliceous component. The alkali and alkaline-earth element patterns, on the other hand, reflect the chemical contribution of the fluxing agent. The spidergrams of the sodium-rich halophyte species show two contrasting alkali element patterns (Fig. 11). Congruent patterns of the glazes, irrespective of their colour, mirror them.

The first group (type 1 patterns) exhibits somewhat higher sodium and lower potassium contents compared to Anabasis syriaca; it comprises the species Anabasis syriaca, Salsola jordanica, Salsola vermiculata, Salsola sp. and Arthrocnemum strobilaceum (#8a, 8, 15b, 15d, 30; Barkoudah and Henderson 2006). The second group (type 2 patterns) has lower sodium and higher potassium contents and includes the species Salsola vermiculata, Salsola sp. and Halopeplis sp. (#5a, 6, 11a, 12a, 14; Barkoudah and Henderson 2006). The excellent agreement of sodic plant ash patterns with those of the glazes is surprizing, especially when considering that details of soda ash production remain largely unknown, and the extend of alkali fractionation during glaze/glass production unconstrained (Barkoudah and Henderson 2006; Tanimoto and Rehren 2008). The good match of the alkali element patterns therefore may indicate that specific recipes of plant ash production were employed at the different production centres and remained unchanged over an extended period of time. The use of different halophytic plant associations as fluxes could reflect the local diversity of vegetation. A perusal of the data substantiates such spatial and temporal correlations. Glazes with type 1 patterns were produced at the closely spaced production sites of Ziwiye, Qalaichi, Rabat and Hasanlu, whereas those showing type 2 patterns originate from Chogha Zanbil and Susa. In consonance with these findings, the spidergrams for published glass/glaze analyses from Nimrud and with some exceptions also Hasanlu show type 1 patterns, whereas those of glazed elements from Babylon exhibit type 2 patterns (Fig. 12). These results, obtained from the multi-element analysis, are encouraging and should be further explored through field studies and laboratory investigation.

For the Achaemenid lead-rich yellow glazes from Susa and Parsa (Su-16, Parsa-10; Table 5), the use of halophytic plant ash as a fluxing agent appears unlikely, as the pristine vitreous domains exhibit very low to negligible sodium and potassium contents. Minute to large polycrystalline particles of lead-antimonate occur in abundance and were added to the glaze as yellow opacifier. The vitreous phase, on the other hand, shows high lead contents (25–36 wt.% PbO) opposed to low antimony contents (1–1.5 wt.%. Sb2O5), thus strongly suggesting an intentional addition of PbO (litharge) both as flux and ionic yellow colourant. For the bulk of analysed yellow and green glazes, however, elevated alkali contents are evidence for the use of a halophytic plant ash flux (Table 5 and Fig. 11).

To further illustrate the compositional diversity of glazes and the role of colourants and opacifiers, the analytical data are displayed in a series of bivariate and ternary diagrams, separately for blue+turquoise and yellow+green glazes (Figs. 13 and 14). The compositional variation of vitreous objects (glass, glaze) from Hasanlu (Stapleton 2011), Susa (Tite and Shortland 2004), Babylon (Matson 1986) and Nimrud (Brill 1999) is shown for comparison. Semi-quantitative EDS analyses of glazes from Susa reported by Holakooei (2014) were not considered the extreme spread of analytical totals (48-153 wt.%) indicates large analytical errors and strong deterioration of some of the glazes as pointed out before.

Bivariate plots of major elements vs 100*(K2O+MgO)/(K2O+Na2O+MgO+CaO) for pristine and altered blue+turquoise glazes (this study) and published analyses of vitreous artefacts from Babylon (Matson 1986), Nimrud (Brill 1999), Hasanlu (Stapleton 2011) and Susa (Tite and Shortland 2004). Also shown are the compositions of halophytic plant ashes (Barkoudah and Henderson 2006)

Bivariate plots of major elements vs 100*(K2O+MgO)/(K2O+Na2O+MgO+CaO) for pristine and altered green+yellow glazes (this study) and published analyses of vitreous artefacts from Babylon (Matson 1986), Nimrud (Brill 1999), Hasanlu (Stapleton 2011) and Susa (Tite and Shortland 2004; McCarthy and Paynter 2008). Also shown are the compositions of halophytic plant ashes (Barkoudah and Henderson 2006)

Colourants and opacifiers

Transparent blue glaze colours are generated by ionic Cu2+. The glazes were produced by adding small amounts of a copper compound (e.g. cuprite, native copper) to the glazing material and ensuring the absence of antimony to avoid the precipitation of opacifying compounds (e.g. sodium-antimonate). The copper contents of studied glazes vary between 0.5 and 4.2 wt.% CuO, with lowest contents characterizing glazes from Chogha Zanbil and highest contents those from Qalaichi and Susa (Table 2 and Fig. 13). Glazes of dark blue translucent colour require the addition of the ionic colourant Co2+. Except of a dark blue glazed artefact from Achaemenid Susa (Su-15; ~0.4 wt.% Co), cobalt has not been encountered as a blue colourant at the other sites.

All turquoise glazes are opaque. They are generated by the additive effect of the blue ionic colourant copper and a white opacifier: either Ca-antimonate or Na-antimonate. The studied turquoise opaque glazes from Qalaichi, Rabat and Ziwiye result from the superposed effects of the blue ionic colourant Cu2+ (1–4 wt.% CuO) and the white opacifier sodium-antimonate (2.5–3.2 wt.% Sb2O3) (Table 3 and Fig. 13). The minute size of sodium-antimonate particles and their spatial distribution pattern indicates their formation through late-stage precipitation from the vitreous phase. It follows that an antimony compound (probably Sb2O3) was added to the glaze material and completely dissolved during melting.

Green opaque colour shades of glazes as those encountered on glazed siliceous objects from Achaemenid Susa (#17) result from the superposed effects of the blue ionic colourant Cu2+ (2-3 wt.% CuO) and the yellow opacifier lead-antimonate (9–6 wt.% PbO, 2–3 wt.% Sb2O3) (Table 4 and Fig. 14). The occurrence of lead-antimonate as minute to large polycrystalline angular particles, evenly distributed throughout the glaze layer, proves its addition to the glaze material as premade compound. Green transparent shades, however, are also shown by glazes that exhibit significant contents of copper (2.6–4 wt.% CuO) but only negligible contents of lead (glazes Has-21, Parsa-11). The elevated contents of iron (2–6 wt.% Fe2O3) suggest a contribution to the glaze colour by the ionic colourant Fe2+.

Yellow glazes were produced at all studied sites by adding finely grinded premade lead-antimonate to the glazing material (plant-ashes soda flux and crushed quartz). The liquid slurry was then applied on the biscuit-fired terracotta bodies (Gradmann et al. 2015, 330) or pre-fired ornamented siliceous elements (Daucé 2010, 331). As already pointed out above, in several glazes, the lead contents of pristine vitreous domains are much higher than the antimony contents (15–30 wt.% PbO, 1.5–3 wt.% Sb2O3) (Table 5 and Fig. 14). As the angular shape of the polycrystalline lead-antimonate particles precludes their substantial dissolution, an intentional addition of a further lead compound (litharge) appears likely, which dissolved in the glaze melt and thereby produced the ionic yellow colourant Pb2+.

Alteration: phenomena and processes

For all of the glazed artefacts studied, prolonged subsoil embedding resulted in alteration. Back-scattered electron (BSE) imaging of the glazes reveals two contrasting types of alteration, both being well-known from studies of ancient glasses (cf. Cox and Ford 1993, and references therein). They both result from long-term interaction of the vitreous phase with groundwater/moisture but reflect a contrasting processual response to the aqueous medium.

Type A alteration is represented by structureless low BSE contrast domains that developed along the outer glaze surface and a variously complex network of surface-parallel and cross-cutting cracks providing fluid pathways into the glaze interior (Fig. 15). The intensity of alteration varies greatly among the studied samples: from incipient with preservation of larger domains and islands of the pristine vitreous phase to pervasive. Type A alteration has affected glazes of all colours and ages, however, with a preference of glazes from the Achaemenid sites Susa and Persepolis. The chemical modification associated with type A alteration is the almost complete loss of alkali elements, whereas the abundances of other elements remained largely unchanged (Tables 2, 3, 4, 5 and 6, Figs. 13 and 14). The rather uniform deficiency of analytical totals (85±5 wt.%; Tables 2, 3, 4, 5 and 6) corresponds well with the Na2O+K2O contents of pristine glaze domains (13±3 wt.%; Tables 2, 3, 4, 5 and 6) and the alkali element contents of typical halophyte-ash glasses (16–19 wt.%; Brill 1999; Wedepohl 2003; Barkoudah and Henderson 2006). The process envisaged to produce type A alteration domains is a coupled hydration-ion exchange reaction at the glaze-water interface, also referred to as inter-diffusion (cf. Melcher and Schreiner 2013; Gin et al. 2016). It involves the release of the network-modifying monovalent alkali elements (Na+, K+) from terminal -Si-O-M groups of the silicate network into the aqueous solution and the concomitant incorporation of positively charged aqueous species (H+, H3O+) into the terminal -Si-OH groups of the silicate network. Advancing into the glaze interior, this process causes a hydration of the silicate network without destroying its structural entity and the concomitant removal of alkali ions with the aqueous solution. Inter-diffusion is considered to occur as the dominant alteration process in a regime of neutral to acidic, strongly under-saturated aqueous solutions. In contrast to the alkali elements, the bivalent elements (M = Ca2+, Mg2+, Cu2+, Fe2+), which reside in bridging Si-O-M-O-Si groups of the silicate network, exhibit similar abundances in pristine and altered glaze domains (Tables 2, 3, 4, 5 and 6). This suggests that the ion exchange of these elements with the aqueous species requires higher activation energy and thus is kinetically hampered.

BSE images of glazes showing type A alteration phenomena. These are caused by coupled hydration-ion exchange reactions (inter-diffusion) that proceed along the outer glaze surface and a variously complex network of surface-parallel and cross-cutting cracks. For discussion see the text. Sodium-antimonate particles (a–c) and calcite mineralized veins and surface crusts (d) show up by bright colour. Image key: a Qa-25; b,c Qa-04; d Ra-07; e Su-18; f Cho-53. Scale of bars: 100 microns

Type B alteration is represented by finely laminated domains of great morphological diversity which advance into the pristine vitreous glaze from its outer surface and a variously complex network of surface-parallel and cross-cutting cracks (Fig. 16) and obviously formed as a result of fluid infiltration. The extent of alteration varies greatly among the studied samples: from incipient with preservation of larger domains and islands of the pristine vitreous phase to pervasive (Fig. 16). Type B alteration has affected glazes of all colours, with a strong preference of glazes from the Middle and Neo-Elamite sites, while glazes from the Achaemenid sites of Susa and Persepolis, if at all, develop only incipient alteration stages. The chemical modifications associated with type B alteration consist of a complete loss of alkali elements (Na, K), severe depletion of alkali-earth elements (Mg, Ca) and a significant depletion of silica (Tables 2, 3, 4, 5 and 6, Figs. 13 and 14).

BSE images of glazes showing type B alteration phenomena. These are caused by fluid-driven dissolution-precipitation reactions that proceed along the outer glaze surface and a variously complex network of surface-parallel and cross-cutting cracks. For discussion see the text. Alteration domains exhibit finely banded structures of varying BSE contrast. Sodium-antimonate particles and conchoidal alteration domains enriched in Pb and Cu show up by bright colour. Image key: a, b Cho-52; c Qa-29; d Qa-01; e Su-47; f Qa-29. Scale of bars: 100 microns for a-c, f and 50 □m for d, e

The colourant components copper and lead were largely leached out from the laminated alteration domains and re-precipitated as secondary Cu and Pb compounds in veinlets, alteration halos of vesicles and surface crusts. The chemical analyses of alteration domains exhibit low to very low totals (70–50 wt.%; Tables 2, 3, 4, 5 and 6) which cannot be compensated by the contents of leached out elements inferred from pristine glaze compositions. This indicates a significant micro-porosity and the presence of hydrous species in the altered domains, notably in the dark BSE-contrast lamellar domains. The process envisaged to produce type B alteration domains is fluid-driven dissolution-precipitation and is considered to occur as the dominant alteration process in a distinctly alkaline aqueous regime (pH >9) (cf. Melcher and Schreiner 2013; Geisler et al. 2015; Gin et al. 2016, 2020; Lenting et al. 2018). The reaction is initiated at the interface of the vitreous glaze with the aqueous solution (i.e. its outer surface, fissures, cracks and vesicle walls), where the silicate network of the glaze becomes dissolved and the solute glass constituents released into the adjoining solution boundary layer. With rising solute concentration and the concomitant change of pH-regime, the siliceous solutes (SiO, SiOH) are precipitated as amorphous silica spheres, forming a highly porous amorphous siliceous layer. With progressing reaction, the reaction interface continues to migrate into the glaze interior, whereby cyclic reaction conditions produce the observed finely banded structure of the altered glaze domain.

Glazed artefacts from Chogha Zanbil (Cho-49, 50, 53) show alteration features that contrast both the structureless appearance common to type A alteration domains and the finely laminated depletion patterns of type B alteration domains. The inclusion-rich vesicular glaze domains exhibit laminated structures which preserve the undisturbed fine-scale viscous flow structure of the vesicular glaze melt (Fig. 15f). The microstructural observation suggests alteration through a process that did not destroy the fine-scale structural features, i.e. diffusion-controlled ion exchange. The chemical changes accompanying the alteration, however, are more complex and not limited to a loss of alkali elements; they also involved a significant depletion of silica (Tables 2, 3, 4, 5 and 6), which clearly indicates dissolution of the glass network as part of the alteration process. The alkaline-earth elements show a contrasted behaviour, with calcium being strongly depleted, and magnesium (as well as iron) enriched in the silica-depleted higher BSE-contrast domains (Fig. 15f and Tables 2, 3, 4, 5 and 6). The turbid anisotropic appearance of these domains under polarized light observation suggests their recrystallization with precipitation of secondary hydrous MgFe-phases (to be identified by Raman spectroscopy).

The vitreous interaction layers of clay-based bodies, in contradistinction to the glazes, preserve anhydrous pristine compositions (Tables 2, 3, 4, 5 and 6). Their resistance to alteration, even in those cases where the adjoining glaze layers have been severely deteriorated by the aqueous attack, can be explained by the contrasting, distinctly aluminous compositions. Alumino-silicate glasses resembling the interaction layers in composition are characterized by highly polymerized structures, in which the positively charged monovalent and bivalent cations largely reside in the cages of the three-dimensional alumino-silicate network (Mysen and Richet 2019). As a result, the number of terminal and bridging groups, which dominantly host the monovalent and bivalent cations in the silicate network of the glaze, becomes strongly reduced, thereby inhibiting an alteration of the vitreous phase through inter-diffusion or dissolution-precipitation processes. During alteration the vitreous layers remain tightly connected to the ceramic bodies. The transition boundary with the glaze is characterized by a sharp chemical and structural gradient and therefore defines the alteration boundary and detachment plane of the glaze.

Conclusions

-

(1)

Glazed architectural elements from the archaeological sites in Iran rarely are preserved in their original pristine state. With very few exceptions, they underwent moderate to strong hydrous alteration during their extended time of subsoil residence. The limited compositional data available so far for pristine vitreous glazes for most sites, an exception being Hasanlu IVB (Stapleton 2011), impede a rigorous assessment and inter-site comparison of glazing materials and techniques and call for further analytical work on a much larger number of carefully accessed artefacts.

-

(2)

BSE imaging and chemical analyses of glazes document two regionally contrasting processes of alteration. Glazes of architectural elements from Iron Age II–III in north-west Iran (Hasanlu, Qalaichi, Rabat Tappeh and Ziwiye) are most intensely altered and involve dissolution-precipitation as the dominant process. Glazes of artefacts from Middle-Elamite Chogha Zanbil, as well as Achaemenid Susa and Persepolis, on the other hand, are generally less altered, with inter-diffusion as the controlling process. The regionally contrasting processes and intensity of alteration may reflect both the greatly differing time of exposure to the hydrous attack and specific environmental conditions prevailing at the burial sites, factors which require further careful examination. We may first note that north-western Iran and Fars share a similar rate of rainfall. This itself seems not to explain differential alteration.

-

(3)

Pristine vitreous domains of glazed artefacts from all studied sites preserve without exception compositions typical of plant ash soda-lime glasses. The abundances of fluxing elements (Mg, Ca, Na, K) of glazes and halophytic plant ashes, when normalized to the ash composition of Anabasis syriaca, reveal regionally contrasting flux compositions. This strongly suggests the use of specific halophyte species for soda production rather than the application of different recipes for soda production (related to the burning of plants and the purification of ashes, Barkoudah and Henderson 2006, 299) at workshops in north-west vis à vis western Iran. The likely halophyte species employed for plant ash soda production at the ceramic centres of Hasanlu, Qalaichi, Rabat Tappeh and Ziwiye, as well as Nimrud to the west, comprise Anabasis syriaca, Salsola jordanica, Salsola vermiculata, Salsola sp. and Arthrocnemum strobilaceum (#8a, 8, 15b, 15d, 30; Barkoudah and Henderson 2006); whereas those used for soda production at Chogha Zanbil, Susa and Persepolis, as well as Babylon to the west, include Salsola vermiculata, Salsola sp. and Halopeplis sp. (#5a, 6, 11a, 12a, 14; Barkoudah and Henderson 2006). The contrasting associations of halophytic plants indicate regionally differing halophyte vegetation and/or environmental growth conditions, aspects which deserve to be further explored through combined field and laboratory study.

-

(4)

Our limited analyses and the comprehensive set of published analyses (Brill 1999; Stapleton 2011) do not support a change of glazing technology at Hasanlu IVB from plant ash to natron soda flux as suggested by Stapleton (2011, 87), which with very few exceptions plot in the field of plant ash soda-lime glasses (Figs. 8, 12 and 13). Moreover, the glass analyses reported by Stapleton (2011) show too high analytical totals, and sodium contents may have been overcorrected. In terms of artistic style and typology many finds (including glazed ones) from this layer are Mesopotamian imports, particularly from northern Syria and Assyria (Muscarella 1988, 18) which explains their particular technology.

-

(5)

A striking feature in the composition of white and turquoise glazes from Qalaichi, Ziwiye and Achaemenid Susa is the employment of sodium-antimonate as an opacifier. Contrasting with the white and yellow colourants and opacifiers calcium-antimonate and lead-antimonate, which were both added as premade polycrystalline compounds to the glazing material, the sodium-antimonate particles precipitated synchronous or after vesiculation of the glaze through reaction of dissolved sodium and antimony. It indicates the addition of an antimony compound (Sb2O3) to the glaze material, where it became completely dissolved during melting.

-

(6)

That Qalaichi, Rabat and Hasanlu show similarities in glass and glaze production to Assyria is not surprising considering the number of Neo-Assyrian military campaigns across this part of Iran (Röllig and Schlaich 1992; Fuchs 2017). Differences in the chemical traces left by halophytic plants derive from a limited number of sources which suggests locally used ones (north-western Iran vis à vis south-western Iran). Wild plants might have been harvested, or cultivars may have existed for this purpose, as in mediaeval Spain (Glick 1979; Gil Olcina 1975; Girón Pascual 2018). The new Achaemenid conception of glazing light-coloured siliceous bricks instead of previously dark terracotta ones had a radical effect on the production methods used. In the so-called Dsf ‘Foundation Charter’ cuneiform text of the Achaemenid Darius regarding his Susa palace states that, ‘The men who made the bricks were Babylonians, those who coloured the terrace (wall) were Medes and Egyptians’ (Kent 1953, §3f 28–30). As opposed to the artisans from Iron Age north-western Iran, those of Achaemenid Susa were foreigners; the masons used the Greek elle as their unit of measure (Siegler 1975, 24). Such teams worked according to closely defined standards in order to produce a disciplined creation.

-

(7)

For the study of ancient glazed architectural elements in Iran and glazes in general what the future should most profitably bring are glaze samples with a thorough documentation of the context and accompanying soil. While the glazes of Iron Age Qalaichi and Hasanlu are relatively well-known, useful would be more samples to determine the diachronic and synchronic differences between the various sites and their similarities to well-known centres in Assyria and Babylonia.

Data availability

All data generated or analysed during this study are included in this published article.

Code availability

Not applicable.

References

Abdali N (2018a) Iron Age glazed architectural elements from Qalaichi, Rabat Tappeh, Ziwiye and Hasanlu in north-western Iran: archaeological origin, technology, character, unpublished PhD dissertation, Heidelberg University

Abdali N (2018b) Glazed artefacts in Elam and north-western Iran: a common technology? In: B. Mofidi-Nasrabadi (ed.). Elam and its neighbours; recent research and new perspectives, proceeding of the international congress held at Johannes Gutenberg University, Mainz, September 21–23 2016, Elamica 8:153–165

Abdali N (2019) A review on the glaze production technology in northwestern Iran at the beginning of the 1st millennium BCE; case study: two glazed samples from Ziwiye. In: Hassanzadeh V, Vahdati AA, Karimi Z (eds) Proceeding of the 1st international conference of the Iron Age of western Iran in Kurdistan University. Sanandaj, National Museum, Tehran, pp 116–126 (in Persian with an English abstract)

Afifi R, Heidari R (2010) Reflection on glazed bricks from Rabat Tepe II. Iran Aramazd Armenian J Near Eastern Stud 2:152–187

Amadori M et al (2018) Advances in Achaemenid brick manufacturing technology: evidence from the monumental gate at Tol-e Ajori (Fars, Iran). Appl Clay Sci 152:131–142

Amiet P (1966) Elam. Archée Èditeur, Auvers-sur-Oise, France

Amiet P (1967) Éléments émaillées du décor architecturale néo-élamite. Syria 44:27–46

Askari Chaverdi AR, Callieri P, Gondet S (2013) Tol-e Ājori, a new monumental building in Pārsa: preliminary cross interpretations from recent surveys and excavations works around Persepolis (2005–2012), in: Arta, Briant, P (ed.) http://www.achemenet.com/document/ARTA_2013.006-Askari-Callieri-Gondet.pdf. Accessed 18 Feb 2014

Askari Chaverdi AR, Callieri P, Matin E (2017) The monumental gate at Tol-e Ajori, Persepolis (Fars): New archaeological data. Iran Antiq 52:205–258

Barkoudah Y, Henderson J (2006) Plant ashes from Syria and the manufacture of ancient glass: ethnographic and scientific aspects. J Glass Stud 48:297–321

Brill RH (1999) Chemical analyses of early glass, I/II, The catalogue / The tables. In: The Corning Museum of Glass, Corning, New York

Carter E (1996) Excavations at Anshan (Tal-e Malyan): the Middle Elamite period. The University Museum of Archaeology and Anthropology, University of Pennsylvania, Philadelphia

Caubet (2012) A matter of strategy, taste or choice? glazed clay versus siliceous faience. In: Gruber M, Aḥituv S, Lehmann G, Talshir Z (eds) All the wisdom of the East, studies in Near Eastern archaeology and history in honor of Eliezer D. Oren. Acad. Press, Fribourg, pp 157–167

Caubet A (2003) Le temple d’Inshushinak de Suse et l’architecture monumentale en «faïence». In: Potts T, Roaf M, Stein D (eds) Culture through objects: ancient Near Eastern studies in honour of P. R. S. Moorey. Griffith Institute, Oxford, pp 325–332

Caubet A (2007) Faïences et matières vitreuses de l’Orient ancien. Étude physico-chimique et catalogue des œuvres du Département des Antiquités Orientales, Musée du Louvre éditions-Snoek, Paris

Caubet A (2010) From Susa to Egypt: vitreous materials from the Achaemenid period. In: Curtis J, Simpson St J (eds) The world of Achaemenid Persia: History, art and society in Iran and the ancient Near East, Proceedings of a conference at the British Museum 29th September–1st October 2005. I. B. Tauris & Co. Ltd, London, pp 409–416

Cox GA, Ford BA (1993) The long-term corrosion of glass by ground-water. J Mater Sci 28:5637–5647. https://doi.org/10.1007/BF00367840

Daucé N (2010) Le décor de briques glaçurées. In: Perrot P (ed) Le palais de Darius à Suse Presses de l’Univ. de Paris-Sorbonne, Paris, pp 322–342

Dyson RH (1959) Digging in Iran: Hasanlu 1958. Expedition 2:4–17

Ferioli P, Fiandra E (1979) The administrative function of clay sealing in protohistorical Iran. In: Gherardo G, Rossi A (eds.). Iranica 10:307–312

Fitz S (1982) Die Farbglasuren spätbabylonischer Wandverkleidungen / The colored glazes of neo-Babylonian wall facings. Ceram Forum Int: Berichte der Deutschen Keramischen Gesellschaft 59:179–185

Freestone IC (1991) Technical examination of the Neo-Assyrian glazed wall plaques. Iraq 53:55–58 https://www.jstor.org/stable/i389730

Fuchs A (2017) Iran im 1. Jahrtausend v. Chr. aus assyrischer Sicht. In: Helwing B et al (eds) Iran frühe Kulturen zwischen Wasser und Wüste. Hirmer, München, pp 170–175

Fügert A, Gries H (2020) I had baked bricks glazed in lapis lazuli colour–a brief history of the glazed bricks in the ancient Near East. In: Fügert A, Gries H (eds) Glazed brick decoration in the ancient Near East, proceedings of a workshop at the 11th International Congress of the Archaeology of the Ancient Near East (Munich) in April 2018, for the Vorderasiatisches Museum–Staatliche Museen zu Berlin. Archaeopress, Oxford, pp 1–15

Gasche H (2010) Les palais perses achéménides de Babylone. In: Perrot P (ed) Le palais de Darius à Suse une résidence royale sur la route de Persépolis à Babylone, Presses de l’Univ. de Paris-Sorbonne, Paris, pp 446–463

Geisler T et al (2015) The mechanism of borosilicate glass corrosion revisited. Geochim Cosmochim Acta 158:112–129. https://doi.org/10.1016/j.gca.2015.02.039

Ghirshman R (1968) Tchoga Zanbil (Dur-Untash) II. Temenos, temples, palais, tombes, MDP 40, Paris

Gil Olcina A (1975) Explotación y cultivo de las plantas barrilleras en España. Estudios Geográficos 36:138–139

Gin S et al (2016) The controversial role of inter-diffusion in glass alteration. Chem Geol 440:115–123 https://hal-cea.archives-ouvertes.fr/cea-02381000/document

Gin S et al (2020) A general mechanism for gel layer formation on borosilicate glass under aqueous corrosion. J Phys Chem C 2020. https://doi.org/10.1021/acs.jpcc.9b10491

Girón Pascual RM (2018) Cenizas, cristal y jabón. El comercio de la barrilla y sus derivados entre España e Italia a finales del siglo XVI (1560-1610). eHumanista: Journal of Iberian Studies 38:215–232

Glick, T (1979) Islamic and Christian Spain in the Early Middle Ages. Princeton University Press, 1979

Gradmann R, Berthold C, Schüssler U (2015) Composition and colouring agents of historical Islamic glazes measured with EPMA and μ-XRD2. Europ Jour Miner 27(3):325–335. https://doi.org/10.1127/ejm/2015/0027-2456

Gratuze B (2013) Provenance analysis of glass artefacts. Chapter 5.1. In: Janssens K (ed) Modern methods for archaeological and historical glass, first edition. Wiley, Chichester, pp 311–343

Haerinck E (1973) Le palais Achéménide de Babylone. Iran Antiq 10:108–131

Hakemi A, Rad M (1950) Rapport et resultats de fouilles scientifiques à Hasanlu. Solduz, Iranian Center, Tehran 87–103 (in Persian)

Heim S (1989) Glazed architectural elements in Elam and related material from Luristan. PhD thesis, New York University, New York, University Microfilms, Ann Arbor

Heim, S (1992) Glazed objects and the Elamite glaze industry. In: P. O. Harper, J. Aruz, F. Tallon (ed.), The royal city of Susa, Metropolitan Museum of Art, New York, 202–210

Henderson J (2013) Ancient glass, an interdisciplinary exploration. University Press, Cambridge

Holakooei P (2014) A technological study of the Elamite polychrome glazed bricks at Susa, south-western Iran. Archaeometry 56(5):764–783. https://doi.org/10.1111/arcm.1233

Jackson CM, Paynter S, Nenna MD (2018) Degryse P (2018) Glassmaking using natron from el-Barnugi (Egypt); Pliny and the Roman glass industry. Archaeol Anthropol Sci 10:1179–1191. https://doi.org/10.1007/s12520-016-0447-4

Janssens K (2013) Modern methods for analysing archaeological and historical glass, Vols. 1 & 2. Wiley, Chichester

Jung M, Hauptmann A (2004) Report on the scientific examination of a glazed brick from Susa: colours. In: Stöllner T, Slotta R, Vatandoust A (eds) Persiens antike Pracht, Band 2. Deutschen Bergbau Museums Bochum, Bochum, pp 390–392

Kaczmarczyk A (2007) Historical and regional variations in composition. In: Caubet A (ed) Faïences et matières vitreuses de l’Orient ancient étude physico-chimique et catalogue des oeuvres du Département des Antiquités Orientales. Louvre, Paris, pp 29–37

Kaniuth K (2013) Spätbabylonische Glasurziegelreliefs aus Borsippa. Mitt Dt Orient-Gesellschaft 145:53–82

Kargar B (2004) Qalaichi/Izirtu: Mannean capital, period Ib. In: Masoud Azarnoush (ed.), Proceedings of International Symposium on Iranian Archaeology: Northwestern Region, Tehran (in Persian), 229–245

Kargar B, Binandeh A (2009) A preliminary report of excavations at Rabat Tepe, Northwestern Iran. Iran Antiq 44:113–129. https://doi.org/10.2143/IA.44.0.2034377

Kent R (1953) Old Persian: grammar, texts, lexicon. AOS, New Haven, p 33

Kuhrt A (2007) The Persian Empire: a corpus of sources from the Achaemenid period. Routledge, London