Abstract

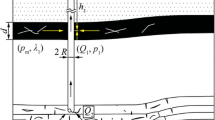

In order to solve the shortcomings of existing negative-pressure water-discharge devices (e.g., small bearing pressure, poor dust removal, slag discharge effect, and large pressure loss), we designed and optimized a new type of gas-drainage and dust-removal device for gas-extraction pipelines. Through the FLUENT software, we used the k-ε renormalization group turbulence model and the discrete phase model to carry out numerical simulations, studying the internal flow field, as well as the pressure and the dust particle distribution induced by the proposed gas-drainage and dust-removal device. The results show that the new device is capable of automatic stage draining and self-cleaning through its mechanical structure, and it can effectively reduce the energy consumption of extraction, improve the utilization rate of gas resources, protect the environment, and improve economic benefits, while saving installation space. When the radius of the diversion pipe is equal to the radius of the unconstrained inner cyclone at the bottom of the diversion pipe, the overall pressure loss caused by the diversion pipe is the lowest. After optimizing the new gas-extraction pipe-drainage and dust-removal device under 20 kPa, we found that it can achieve a negative pressure suction loss < 2.5% and a dust-removal efficiency > 90%. Hence, this device can ensure a high dust collection efficiency, while reducing the pressure loss, saving installation space, and reducing the amount of dust attached inside the pipe blockage when compared to existing negative-pressure water-discharge devices.

Similar content being viewed by others

References

Gao D, Jin B, Qu Y (2019) Numerical simulation of a new dry dust collector with different permeability [J]. Mining R and D 39(10):108–112. https://doi.org/10.13827/j.cnki.kyyk.2019.10.022

Tang L, Zhang Y, Du C (2018) Numerical simulation of internal flow field of cyclone separator based on FLUENT [J]. Coal Technol 37(04):270–272. https://doi.org/10.13301/j.cnki.ct.2018.04.10

Yao X, Xu K, Zhang X, Xu Q, Li L, Li J (2018) Numerical study on capture process of biomass ash in cyclone separator under high temperature[J]. J Saf Sci Technol 14(04):187–192. https://doi.org/10.11731/j.issn.1673-193x.2018.04.029

Li Q 2008 Study on optimal design and separation characteristics of cyclone [D].Changsha:Central South University

Jiang M, Wang B, Chen Y, Xu D (2012) Selection of numerical approaches to calculate the high-speed rotating flow field within a cyclone separator [J]. Chin J Environ Eng 6(08):2736–2744

Chen X, Ge S, Ge F, Zhang W (2014) Study on novel micro-fog & cyclonic system for removing fine particulate [J]. China Saf Sci J 24(09):122–127. https://doi.org/10.16265/j.cnki.issn1003-3033.2014.09.003

Deng Z. 2014 Numerical simulation and structural parameter optimization of negative pressure drain [D]. Fuxin: Liaoning University of engineering and technology

Reed WR, Shahan M, Ross G et al (2020) Field comparison of a roof bolter dry dust collection system with an original designed wet collection system for dust control[J]. Mining Metall Explor 37:1885–1898. https://doi.org/10.1007/s42461-020-00290-x

Nekrasov AV, Romanyuk EV, Kargashilov DV (2017) Mathematical model for the motion of precipitated dust particles in a high-efficiency cyclone dust collector for explosion-hazardous production[J]. Chem Pet Eng 53:190–194. https://doi.org/10.1007/s10556-017-0320-z

Ogawa A, Anzou H, Yamamoto S et al (2015) Contributions of the secondary jet to the maximum tangential velocity and to the collection efficiency of the fixed guide vane type axial flow cyclone dust collector[J]. J Therm Sci 24:503–509. https://doi.org/10.1007/s11630-015-0815-x

Ogawa A (2010) Estimations of the maximum tangential velocity V θm in the vortex core region and also the mean rotational velocity V oi near the concave wall surface in the returned flow type cyclone dust collector[J]. J Therm Sci 19:553–560. https://doi.org/10.1007/s11630-010-0423-8

Plashikhin SV (2016) Computer simulation of the hydrodynamic processes of cyclone dust collectors[J]. J Eng Phys Thermophys 89:1093–1102. https://doi.org/10.1007/s10891-016-1472-y

Ogawa A, Arakawa M (2006) Control of collection efficiency for axial flow cyclone dust collectors with fixed guide vanes and with funnel shaped exit pipes[J]. J Therm Sci 15:240–250. https://doi.org/10.1007/s11630-006-0240-2

Misyulya DI (2012) New designs of devices for a decrease in power consumption of cyclone dust collectors[J]. Russ J Non-Ferr Met 53:67–72. https://doi.org/10.3103/S1067821212010166

Jiongtian L, Hongxiang X, Xiaobing L (2013) Cyclonic separation process intensification oil removal based on microbubble flotation[J]. Int J Min Sci Technol 23:415–422. https://doi.org/10.1016/j.ijmst.2013.05.010

Sunil KT, Sharath KB, Murthy Rama Y (2017) Processing of chromite ultra-fines in a water only cyclone[J]. Int J Min Scie Technol 27:1057–1063. https://doi.org/10.1016/j.ijmst.2017.06.015

Zhang J, Xu D, Che P, Ren J, Pan W (2016) Influences of taper on main performances of cyclone separator [J]. Chin J Environ Eng 10(05):2507–2512

Li B, Zhang H, Wei L, Wei J, Wang Y (2019) Study on gas-solid flow characteristics of cyclone dust collector based on CFD - DEM [J]. J Saf Sci Technol 15(11):151–157. https://doi.org/10.11731/j.issn.1673-193x.2019.11.024

Xiao Y, Wu C, Chen Z (2020) Numerical simulation of a new type of swirling flow dust collector based on improved cyclone composite dust collector[J]. Min R and D 40(07):135–139. https://doi.org/10.13827/j.cnki.kyyk.2020.07.027

Wang Z (2021) Negative pressure automatic drain device based on intrinsically safe DC electric valve [J]. Saf Coal Mines 52(02):161–164. https://doi.org/10.13347/j.cnki.mkaq.2021.02.031

Wang W, Chen X, Yang G, Li D (2017) Study on visual drainage and slag removal system of gas extraction pipeline [J]. Coal Technol 36(01):193–195. https://doi.org/10.13301/j.cnki.ct.2017.01.075

Yu H. 2019 Construction and application of intelligent drainage system for gas drainage pipeline [D]. China University of Mining and Technology

Zhou G, Cheng W, Chen L, Nie W (2010) Numerical simulation and its application of dust concentration spatial distribution regularities in fully-mechanized caving face [J]. J China Coal Soc 35(12):2094–2099. https://doi.org/10.13225/j.cnki.jccs.2010.12.026

Funding

This work was supported by the National Natural Science Foundation of China [52074173, 51604168, 51934004], the Key Research and Development Plan of Shandong Province, China [2019GSF111033], Major Program of Shandong Province Natural Science Foundation [ZR2018ZA0602], Taishan Scholars Project Special Funding [TS20190935], and Development plan of Excellent Youth Innovation Team in Colleges and universities of Shandong Province [2019KJH006].

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Responsible Editor: Murat Karakus

Rights and permissions

About this article

Cite this article

Liu, Z., Li, H., Yang, H. et al. A new type of drainage and dust removal device for extraction pipeline is adopted to improve the utilization rate of methane in the process of coal mining. Arab J Geosci 15, 883 (2022). https://doi.org/10.1007/s12517-022-10191-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12517-022-10191-6