Abstract

Various types of conical picks in different shapes are produced and widely employed on mechanical excavators. Depending on the mechanical and abrasivity properties of rocks, appropriate shape of pick is selected. In order to obtain maximum efficiency from the pick during excavation, the interaction between the pick and rock and the cutting mechanism play very important role. In this context, linear cutting tests were conducted by using a conical pick at the cutting depths between 3 and 18 mm and also at the various line spacings on sandstones exhibiting different mechanical properties. The results indicated that cutting depth and line spacing have significant influences on the tool forces acting on the pick, the ratio of normal to cutting force, and the specific energy. Accordingly, strong correlations and empirical models were developed. In conclusion, the empirical models proposed for estimating the forces and specific energy would be used for producing the conical bits and also designing the cutter heads of mechanical excavators on soft and medium-hard strength sandstones.

Similar content being viewed by others

References

Balci C, Demircin MA, Copur H, Tuncdemir H (2004) Estimation of optimum specific energy based on rock properties for assessment of roadheader performance. J Sou Afri Inst Min Metal 104(11):633–642

Balci C, Bilgin N (2007) Correlative study of linear small and full-scale rock cutting tests to select mechanized excavation machines. Int J Rock Mech Min Sci 44(3):468–476. https://doi.org/10.1016/j.ijrmms.2006.09.001

Bilgin N (1977) Investigations into the mechanical cutting characteristics of some medium and high strength rocks, PhD thesis, University of Newcastle upon Tyne, Newcastle, p 332

Bilgin N, Demircin MA, Copur H, Balci C, Tuncdemir H, Akcin N (2006) Dominant rock properties affecting the performance of conical picks and the comparison of some experimental and theoretical results. Int J Rock Mech Min Sci 43(1):139–156. https://doi.org/10.1016/j.ijrmms.2005.04.009

Bilgin N, Copur H, Balci C (2014) Mechanical excavation in mining and civil industries. 1st edn. CRC Press, New York

Bao RH, Zhang LC, Yao QY, Lunn J (2011) Estimating the peak indentation force of the edge chipping of rocks using single point-attack pick. Rock Mech Rock Eng 44(3):339–347. https://doi.org/10.1007/s00603-010-0133-2

Copur H, Bilgin N, Balci C, Tumac D, Avunduk E (2017) Effects of different cutting patterns and experimental conditions on the performance of a conical drag tool. Rock Mech Rock Eng 50(6):1585–1609. https://doi.org/10.1007/s00603-017-1172-8

Evans I (1984) A theory of the cutting force for point-attack. Int J Min Eng 2(1):63–71. https://doi.org/10.1007/BF00880858

Hekimoglu OZ (2017) A pick force calculation method suggested for tool lacing of mechanical excavators employing drag tools. Int J Min Recl Envir:1–22. https://doi.org/10.1080/17480930.2017.1317946

Haeri H, Marji MF (2016) Simulating the crack propagation and cracks coalescence underneath TBM disc cutters. Arab J Geo 9(2):1–10

Hasanpour R, Ozcelik Y, Yilmazkaya E, Sohrabian B (2016) DEM modeling of a monowire cutting system. Arab J Geo 9(20):738–740

He X, Xu C (2015) Specific energy as an index to identify the critical failure mode transition depth of rock cutting. Rock Mech Rock Eng 49(4):1461–1478

Jang JS, Yoo W, Kang H, Cho JW, Jeong MS, Lee SK, Cho YJ, Lee JW, Rostami J (2016) Cutting head attachment design for improving the performance by using multibody dynamic analysis. Int J Pre Eng Manuf 17(3):371–377. https://doi.org/10.1007/s12541-016-0046-4

ISRM (1981) In: Brown TT (ed) ISRM suggested methods. Rock characterization testing and monitoring. Pergamon Press, Oxford, 211 p

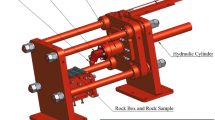

Kang H, Cho JW, Park JY, Jang JS, Kim JH, Kim KW, Rostami J, Lee JW (2016) A new linear cutting machine for assessing the rock-cutting performance of a pick cutter. Int J Rock Mech Min Sci 88:129–136

Karakurt I, Aydin G, Aydiner K (2014) An investigation on the kerf width in abrasive waterjet cutting of granitic rocks. Arab J Geo 7(7):2923–2932

Menezes PL (2017) Influence of cutter velocity, friction coefficient and rake angle on the formation of discontinuous rock fragments during rock cutting process. Int J Adv Manuf Technol 90(9-12):3811–3827. https://doi.org/10.1007/s00170-016-9694-x

Menezes PL, Lovell MR, Avdeev IV, Higgs CF (2014) Studies on the formation of discontinuous rock fragments during cutting operation. Int J Rock Mech Min Sci 71:131–142

Sengun N, Altindag R (2013) Prediction of specific energy of carbonate rock in industrial stones cutting process. Arab J Geo 6(4):1183–1190

Shao W, Li XS, Sun Y, Huang H (2017) Parametric study of rock cutting with SMART*CUT picks. Tunnel Undergr Space Technol 61:134–144. https://doi.org/10.1016/j.tust.2016.09.012

Yang DL, Li JP, Wang LP, Gao KD, Tang YH, Wang XX (2015) Experimental and theoretical design for decreasing wear in conical picks in rotation-drilling cutting process. Int J Adv Manu Technol 77(9-12):1571–1579. https://doi.org/10.1007/s00170-014-6472-5

Zichella L, Bellopede R, Marini P, Tori A, Stocco A (2017) Diamond wire cutting: a methodology to evaluate stone workability. Mater Manuf Proc 32(9):1034–1040. https://doi.org/10.1080/10426914.2016.1269912

Zhou L, Wang CY, Qin Z (2009) Investigation of chip formation characteristics in orthogonal cutting of graphite. Mater Manuf Proc 24(12):1365–1372. https://doi.org/10.1080/10426910902997399

Funding

The authors gratefully acknowledge the Open Fund of Chongqing Key Laboratory of Manufacturing Equipment Mechanism Design and Control (Grant No. KFJJ2016032), the Chongqing Science and Technology Innovation leading talent support plan (Grant No. CSTCCXLJRC201709), and the National Science and Technology Major Project of China (Grant No. 2016ZX05043005).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Wang, X., Su, O., Wang, QF. et al. Effect of cutting depth and line spacing on the cuttability behavior of sandstones by conical picks. Arab J Geosci 10, 525 (2017). https://doi.org/10.1007/s12517-017-3307-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12517-017-3307-3