Abstract

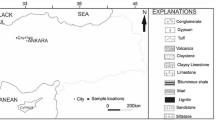

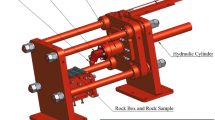

Specific energy (SE) measurements of circular saws were conducted on 12 different carbonate rocks. Rock samples were collected from the factories for laboratory tests. Bulk density, apparent porosity, uniaxial compressive strength, Brazilian tensile strength, flexural strength, Schmidt rebound hardness, Shore hardness, point load strength index, Los Angeles abrasion values, and P-wave velocity values were determined in the laboratory. SE and rock properties were evaluated using simple regression analysis and empirical equations were developed. The equations were verified by statistical tests. Regression analysis showed that high correlations exist between SE and uniaxial compressive strength, Shore and Schmidt hardness, bulk density, apparent porosity, and flexural strength. It was found that the SE value of rocks in cutting process was highest for those rocks having the high density, compressive strength, flexural strength, Schmidt and Shore hardness, point load strength index, and P-wave velocity values.

Similar content being viewed by others

References

Altindag R (2002) Effects of specimen volume and temperature on measurements of Shore hardness. Rock Mech Rock Eng 35(2):109–113

Altindag R, Güney A (2006) ISRM suggested method for determining the Shore hardness value. Int J Rock Mech Min Sci 43:19–22

Brook B (2002) Principles of diamond tool technology for sawing rock. Int J Rock Mech Min Sci 39:41–58

Buyuksagis IS (2007) Effect of cutting mode on the sawability of granites using segmented circular diamond sawblade. J Mater Process Technol 183:399–406

Buyuksagis IS, Goktan RM (2005) Investigation of marble machining performance using an instrumented block-cutter. J Mater Process Technol 169:258–262

Ceylanoglu A, Gorgulu K (1997) The performance measurement results of stone cutting machines and their relations with some material properties. In: Proceedings of the 6th Int. Symp. on Mine Planning and Equipment Selection, pp 393–398

Ersoy A, Atici U (2004) Performance characteristics of circular diamond saws in cutting different types of rocks. Diam Relat Mater 13:22–37

Ersoy A, Atici U (2007) Correlation of P and S-waves with cutting specific energy and dominant properties of volcanic and carbonate rocks. Rock Mech Rock Engng 40(5):491–504

Fener M, Kahraman S, Ozder MO (2007) Performance prediction of circular diamond saws from mechanical rock properties in cutting carbonate rocks. Rock Mech Rock Engng 40(5):505–517

Gunaydin O, Kahraman S, Fener M (2004) Sawability prediction of carbonate rocks from brittleness indexes. J S Afr Inst Min Metall 104:239–243

Guney A (2011) Performance prediction of large-diameter circular saws based on surface hardness tests for Mugla (Turkey) marbles. Rock Mech Rock Eng 44:357–366

ISRM (2007) In: Ulusay R, Hudson JA (eds) The complete ISRM suggested methods for rock characterization, testing and monitoring: 1974–2007: suggested methods prepared by the Commission on Testing Methods, International Society for Rock Mechanics. ISRM Turkish National Group, Kozan Ofset, p 628

Kahraman S, Gunaydin O (2008) Indentation hardness test to estimate the sawability of carbonate rocks. Bull Eng Geol Environ 67:507–511

Kahraman S, Fener M, Gunaydin O (2004) Predicting the sawability of carbonate rocks using multiple curvilinear regression analysis. Int J Rock Mech Min Sci 41(7):1123–1131

Konstanty J (2002) Theoretical analysis of stone sawing with diamonds. J Mater Process Technol 123:146–154

Li Y, Huang H, Shen JY, Xu XP, Gao YS (2002) Cost-effective machining of granite by reducing tribological interactions. J Mater Process Technol 129:389–394

Luo SY, Liao YS (1995) Study of behaviour of diamond sawblade in stone processing. J Mater Process Technol 51:296–308

Sengun N (2009) The effects of fracture toughness and brittleness of rocks on sawing efficiency with circular discs. Ph.D. thesis. (In Turkish) Süleyman Demirel Univ. Isparta, 182p

Snedecor GW (1989) Statistical methods. Iowa State University, Ames, p 503

Tonshoff HK, Ashe J (1997) Wear of metal-bond diamond tools in the machining of stone. Ind Diam Rev 1:7–13

Tonshoff HK, Hillmann-Apmann H (2002) Diamond tools for wire sawing metal components. Diam Relat Mater 11(Issues 3–6):742–748

TS EN 1097–2 (2000) Tests for mechanical and physical properties of aggregates—Part 2: methods for the determination of resistance to fragmentation. Institute of Turkish Standards

TS EN 1926 (2007) Natural stone test methods—determination of uniaxial compressive strength. Institute of Turkish Standards

TS 699 (2009) Natural building stones—methods of inspection and laboratory testing. Institute of Turkish Standards

TS EN 12372 (2007) Natural stone test methods—etermination of flexural strength under concentrated load. Institute of Turkish Standards

Tutmez B, Kahraman S, Gunaydin O (2007) Multifactorial fuzzy approach to the sawability classification of building stones. Constr Build Mater 21(8):1672–1679

Walker RD, Wood MG (1971) Granite sawing techniques. Ind Diam Rev 31:4–7

Wang CY, Clausen R (2002) Marble cutting with single point cutting tool and diamond segments. Int J Mach Tools Manuf 42:1045–1054

Wright DN (1986) The prediction of diamond wear in sawing of stone. Ind Diam Rev 5:213–216

Wright DN, Cassapi VB (1985) Factors influencing stone sawability. Ind Diam Rev 2:84–87

Wright DN, Jennings M (1989) Guidelines for sawing stone. Ind Diam Rev 2:70–75

Xu X (1999) Friction studies on the process in circular sawing of granites. Tribol Lett 7:221–227

Acknowledgments

This paper is part of a research project (project no: 1588-D-07) granted by the Scientific Research Project Unit of Suleyman Demirel University. The authors are deeply grateful for this financial support.

Author information

Authors and Affiliations

Corresponding author

Additional information

Highlights

It was found that the SE value of rocks in cutting process was related to their physical and mechanical properties. The SE values can be predicted by using uniaxial compressive strength, Shore hardness, and bulk density of rocks.

Rights and permissions

About this article

Cite this article

Sengun, N., Altindag, R. Prediction of specific energy of carbonate rock in industrial stones cutting process. Arab J Geosci 6, 1183–1190 (2013). https://doi.org/10.1007/s12517-011-0429-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12517-011-0429-x