Abstract

Microwave sterilization has seen many innovative solutions to solve its primary problem of non-uniform heating. Since its initial studies in the late 1940s, there were solutions that were put forward to address, such as using mechanical holders to contain the inner pressure of the package with food materials, use of fluids instead of mechanical holders, use of strong containers or polymeric packages, and use of monolayer and multilayer packaging. But even all these solutions could not entirely solve the problem of non-uniform heating. After the 2000s, the rise in numerous numerical simulations and modelling software, opened the doors to further explore this field of research with more details and to numerically model the multi-physics phenomenon. However, studies have still not been sufficient to commercially deploy microwave sterilization systems to their full potential. Challenges such as temperature measurement, pressure measurement and control, usage of the right packaging material, and homogeneous heat distribution are still to be addressed, all while developing an energy-efficient process using numerical modelling and simulation tools. Hence, this review aims to study the microwave sterilization systems since the early days of research and the packaging aspect during the microwave sterilization process. The review also explores the potential held by the numerical simulation and modelling tools in this field of microwave sterilization.

Adapted from Loh and Breene [62]

Adapted from Resurreccion et al. [68]

Adapted from Patel et al. [82]. CPP: cast polypropylene; ONy: Biaxially oriented nylon 6

Adapted from Long et al. [57]. This packaging was developed so that the pressure generated inside the package during microwave sterilization is released through a partial opening at the top

Adapted from Loh and Breene [62]. This packaging container was made of glass for the maximum transmission of microwaves to reach the product

Adapted from Wang et al. [2]. This packaging container utilized polymers due to its lightweight nature and also microwave transparency

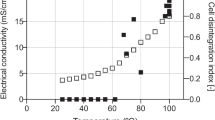

Adapted from Yang et al. [137]

Similar content being viewed by others

Availability of Data and Materials

This declaration is not applicable.

Abbreviations

- B:

-

magnetic field

- c:

-

speed of light in free space (~3 × 108 m.s-1)

- C:

-

concentration of microbial population (CFU.g-1)

- \({C}_{p}\) :

-

specific heat capacity of product (J.kg-1.K-1)

- d:

-

dipole rotation

- \({d}_{p}\) :

-

penetration depth (m)

- D:

-

electric displacement (C.m-2)

- \({D}_{T}\) :

-

decimal reduction time (s)

- E:

-

electric field intensity (V.m-1)

- \({E}_{a}\) :

-

activation energy (J.mol-1)

- f:

-

frequency (Hz)

- \({f}_{c}\) :

-

critical frequency (Hz)

- F :

-

F-value (s)

- \({h}_{c}\) :

-

convection heat-transfer coefficient (W.m-2.K-1)

- H:

-

magnetic field strength (A.m-1)

- \(\dot{I}\) :

-

phase change term

- J:

-

electrical current

- k:

-

thermal conductivity of product (W.m-1.K-1)

- \({k}_{b}\) :

-

Boltzmann constant (1.38 × 10− 23 J.K-1)

- \({k}_{cw}\) :

-

complex wavenumber

- \({k}_{r}\) :

-

reaction rate constant (s-1)

- K:

-

global heat transfer coefficient which takes into account both heat resistance by conduction and convection due to presence of container wall and external surrounding air (W.m-2.K-1)

- \({K}_{evap}\) :

-

evaporation velocity (s-1)

- n:

-

gradient normal to surface

- \({n}_{r}\) :

-

order of reaction

- N:

-

number of nodes used in discretization in Finite Element Method (FEM)

- \({N}_{1}\) :

-

initial concentration of microorganisms at the beginning of thermal process

- \({N}_{2}\) :

-

final concentration of microorganisms at the end of thermal process

- \({Q}_{ev}\) :

-

heat loss due to evaporation (W.m-2)

- \({Q}_{M}\) :

-

heat source term (W.m-3)

- Rg:

-

universal gas constant (8.3145 J.mol-1.K-1)

- \({S}_{g}\) :

-

saturation of gas phase

- T:

-

temperature (K)

- \({T}_{ext}\) :

-

temperature of the fluid away from the surface (K)

- \({T}_{ref}\) :

-

reference temperature (121 °C)

- \({T}_{s}\) :

-

temperature at the surface of product (K)

- t:

-

time (s)

- V:

-

volume of a molecule (m3)

- z:

-

z-value (°C)

- \(\varepsilon\) :

-

dielectric permittivity

- \({\varepsilon }_{r}^{*}\) :

-

complex relative permittivity

- \({\varepsilon }_{r}^{,}\) :

-

relative dielectric constant

- \({\varepsilon }_{r}^{,,}\) :

-

relative dielectric loss factor

- \({\varepsilon }_{d}^{,,}\) :

-

dielectric loss factor due to dipole rotation of water molecules

- \({\varepsilon }_{\sigma }^{,,}\) :

-

dielectric loss factor due to ionic conductivity effects

- \({\varepsilon }_{o}\) :

-

permittivity of free space or vacuum (8.854 ×10–12 F/m)

- \({\varepsilon }_{\infty }\) :

-

optical dielectric constant

- \({\varepsilon }_{s}\) :

-

static dielectric constant

- \(\sigma\) :

-

ionic conductivity (S.m-1)

- \({\sigma }_{s}\) :

-

specific conductivity (S.m-1)

- \(\tau\) :

-

relaxation time (s)

- \(\eta\) :

-

dynamic viscosity (Pa.s)

- \({\eta }_{o}\) :

-

initial viscosity (Pa.s)

- \({\eta }_{global}\) :

-

global energy efficiency of a microwave heating system

- \({\eta }_{gen}\) :

-

electricity-to-microwave conversion efficiency

- \({\eta }_{abs}\) :

-

microwave-to-heat conversion efficiency

- \(\rho\) :

-

density of product (kg.m-3)

- \({\rho }_{e}\) :

-

charge function

- \({\rho }_{v}\) :

-

density of vapor (kg.m-3)

- \({\rho }_{v,eq}\) :

-

equilibrium density (kg.m-3)

- \(\mu\) :

-

magnetic permeability (H.m-1)

- \({\mu }_{0}\) :

-

magnetic permeability for vacuum (\(4\pi \times {10}^{-7}{\text{H}}.{{\text{m}}}^{-1}\))

- \({\mu }_{r}\) :

-

relative magnetic permeability

- \(\phi\) :

-

porosity

- \({\varnothing }_{i}\) :

-

scalar basis function (test function for FEM)

- \(\lambda\) :

-

vaporization heat (J.kg-1)

- \(\upgamma\) :

-

complex propagation constant

- \(\omega\) :

-

angular frequency (rad.s-1)

References

Decareau RV (1968) Sterilization In: ECBT-MPE (ed) OKRESS. Academic Press, pp 98–100. https://doi.org/10.1016/B978-1-4831-9679-4.50016-1

Wang Y, Wig TD, Tang J, Hallberg LM (2003) Sterilization of foodstuffs using radio frequency heating. J Food Sci 68(2):539–544

Fleming H (1944) Effect of high-frequency fields on micro-organisms. Electr Eng 63(1):18–21. https://doi.org/10.1109/EE.1944.6440109

Brown GH, Hoyler CN, Bierwirth RA (1947) Theory and application of radio-frequency heating. In Theory and application of radio-frequency heating. D. van Nostrand Company, Inc. https://www.cabdirect.org/cabdirect/abstract/19476600390

Brown GH, Morrison WC (1956) An exploration of the effects of strong radio-frequency fields on micro-organisms in aqueous solutions. IRE Transactions on Medical Electronics, vol. PGME-4, pp. 16–16. https://doi.org/10.1109/IRET-ME.1956.5008553

Proctor BE, Goldblith SA (1951) Electromagnetic radiation fundamentals and their applications in food technology. In Advances in Food Research (Vol. 3, pp. 119–196). https://www.sciencedirect.com/science/article/abs/pii/S0065262808602608

Tang J, Hong Y-K, Inanoglu S, Liu F (2018) Microwave pasteurization for ready-to-eat meals. Curr Opin Food Sci. https://doi.org/10.1016/J.COFS.2018.10.004

Johnson JH (1947) The electrical aspects of the pasteurization of wine by dielectric heating [Oregon State College]. https://ir.library.oregonstate.edu/concern/graduate_thesis_or_dissertations/qr46r419t?locale=zh

Yang HY, Johnson JH, Wiegand EH (1947) Electronic pasteurization of wine. Fruit Prod Jour 26:295–299

Jeppson MR (1964) Techniques of continuous microwave food processing. Cornell Hotel and Restaurant Administration Quarterly 5(1):60–64

Jackson JM (1947) Electronic sterilization of canned foods. Food Eng 19(5):124

Chang XL, Zhang LX, Xu Q, Zheng ZQ, Wang RF, Li ZY (2022) Continuous flow microwave heating and sterilization for liquid food. Int J Food Eng. https://doi.org/10.1515/ijfe-2022-0130

Soni A, Smith J, Thompson A, Brightwell G (2020) Microwave-induced thermal sterilization- A review on history, technical progress, advantages and challenges as compared to the conventional methods. Trends Food Sci Technol. https://doi.org/10.1016/J.TIFS.2020.01.030

Tang J (2015) Unlocking potentials of microwaves for food safety and quality. J Food Sci 80(8):E1776–E1793. https://doi.org/10.1111/1750-3841.12959

Bach SA (1965) Biological sensitivity to radio-frequency and microwave energy. Fed Proc 24:22–26

Robe K (1966) Improve flavor of pasteurized products. Food Proc. and Marketing 27(3):84–86

Decareau RV (1965) For microwave heating tune to 915 mc or 2450 mc. Food Eng 37(7):54

Goldblith SA (1966) Basic Principles of Microwaves and Recent Developments. In: Chichester CO, Mrak EM, TA GFB, Stewart FR (eds) Advances in Food Research, vol 15. Academic Press, pp 277–301

Asia Food Journal (2021) Sinnovatek introduces new microwave sterilization systems. https://asiafoodjournal.com/sinnovatek-introduces-new-microwave-sterilization-systems/

Reverte-Ors JD, Pedreño-Molina JL, Fernández PS, Lozano-Guerrero AJ, Periago PM, Díaz-Morcillo A (2017) A novel technique for sterilization using a power self-regulated single-mode microwave cavity. Sensors 17(6):1309. https://doi.org/10.3390/s17061309

Stanley RA, Petersen K (2017) Microwave-assisted pasteurization and sterilization—commercial perspective. In The Microwave Processing of Foods (Second Edition). https://doi.org/10.1016/B978-0-08-100528-6.00010-3

Water Europe (2023) The value of water: towards a water-smart society. https://watereurope.eu/

Zhou X, Pedrow PD, Tang Z, Bohnet S, Sablani SS, Tang J (2023) Heating performance of microwave ovens powered by magnetron and solid-state generators. Innov Food Sci Emerg Technol 83:103240. https://doi.org/10.1016/j.ifset.2022.103240

Chandrasekaran S, Ramanathan S, Basak T (2013) Microwave food processing—A review. Food Res Int 52(1):243–261. https://doi.org/10.1016/j.foodres.2013.02.033

Dutta SJ (2022) Understanding the fundamentals of microwave processing: a brief study of basic engineering mathematical models. The Chemical Axis 21(1):84. https://doi.org/10.5281/zenodo.6635049

Ramaswamy H, Tang J (2008) Microwave and radio frequency heating. Food Sci Technol Int 14(5):423–427

Metaxas AC, Meredith RJ (1983) Industrial microwave heating (Issue 4). Peter Peregrinus Ltd., London. IET. https://www.scirp.org/reference/referencespapers?referenceid=2031283

Sosa-Morales ME, Valerio-Junco L, López-Malo A, García HS (2010) Dielectric properties of foods: reported data in the 21st Century and their potential applications. LWT Food Sci Technol. https://doi.org/10.1016/J.LWT.2010.03.017

Tang J, Resurreccion FP (2009) 1 - Electromagnetic basis of microwave heating In: Lorence MW, PSBT-D of P, P for U in MO Pesheck (eds) Woodhead Publishing, pp 3–38. https://doi.org/10.1533/9781845696573.1.3

Nelson SO (1973) Electrical properties of agricultural products-A critical review. Trans ASAE 16(2):384–400

Tang J (2005) Dielectric properties of foods. Microwave Proc Foods 22–38. https://www.scopus.com/inward/record.uri?eid=2-s2.0-85107971425&partnerID=40&md5=95918bb72c7591330606a75ed2853297

Ikediala JN, Tang J, Drake SR, Neven LG (2000) Dielectric properties of apple cultivars and codling moth larvae. Trans ASAE 43(5):1175–1184. https://elibrary.asabe.org/abstract.asp?aid=3010

Mudgett RE (1986) Electrical properties of foods. Eng Properties Foods 2:389–455

Wang Y, Wig TD, Tang J, Hallberg LM (2003) Dielectric properties of foods relevant to RF and microwave pasteurization and sterilization. J Food Eng 57(3):257–268. https://doi.org/10.1016/S0260-8774(02)00306-0

Komarov V, Wang S, Tang J (2005) Permittivity and measurements. In: The Wiley Encyclopedia of RF and Microwave Engineering. John Wiley & Sons, Inc., pp. 3693–3711. https://onlinelibrary.wiley.com/doi/book/10.1002/0471654507

Nelson SO (1996) Review and assessment of radio-frequency and microwave energy for stored-grain insect control. Trans ASAE 39(4):1475–1484

Ryynänen S (1995) The electromagnetic properties of food materials: A review of the basic principles. J Food Eng 26(4):409–429. https://doi.org/10.1016/0260-8774(94)00063-F

Eves E, Yakovlev V (2002) Analysis of operational regimes of a high power water load. J Microw Power Electromagn Energy 37(3):127–144

Gezahegn YA, Tang J, Sablani SS, Pedrow PD, Hong Y-K, Lin H, Tang Z (2021) Dielectric properties of water relevant to microwave assisted thermal pasteurization and sterilization of packaged foods. Innov Food Scie Emerg Technol 74:102837. https://doi.org/10.1016/j.ifset.2021.102837

Kaatze U, Uhlendorf V (1981) The dielectric properties of water at microwave frequencies. zeitschrift für physikalische chemie 126(2):151–165. https://doi.org/10.1524/zpch.1981.126.2.151

Kumar P, Coronel P, Simunovic J, Sandeep KP (2008) Thermophysical and dielectric properties of salsa con queso and its vegetable ingredients at sterilization temperatures. Int J Food Prop 11(1):112–126

Meredith RJ (1998) Engineers’ handbook of industrial microwave heating (Issue 25). Power Engineering Journal Iet

Wang Y, Tang J, Rasco B, Wang S, Alshami AA, Kong F (2009) Using whey protein gel as a model food to study dielectric heating properties of salmon (Oncorhynchus gorbuscha) fillets. LWT Food Sci Technol 42(6):1174–1178. https://doi.org/10.1016/j.lwt.2009.01.005

Zhang H, Bhunia K, Munoz N, Li L, Dolgovskij M, Rasco B, Tang J, Sablani SS (2017) Linking morphology changes to barrier properties of polymeric packaging for microwave-assisted thermal sterilized food. J Appl Polym Sci 134(44):45481. https://doi.org/10.1002/app.45481

Frabetti ACC, Thillier A, Curto H, Boillereaux L, Rouaud O, Garnault T, Curet S (2023) Dielectric properties of low moisture foods measured by open-ended coaxial probe and cavity perturbation technique. Eur Food Res Technol 249:2861–2873. https://doi.org/10.21203/rs.3.rs-2496586/v1

Bhattacharya M, Basak T (2006) On the analysis of microwave power and heating characteristics for food processing: Asymptotes and resonances. Food Res Int 39(10):1046–1057. https://doi.org/10.1016/j.foodres.2006.09.012

Datta AK, Sumnu G, Raghavan GSV (2014) Dielectric properties of foods. In Engineering properties of foods. CRC Press, pp 523–588

Nelson SO, Datta AK (2001) Dielectric properties of food materials and electric field interactions. In: Handbook of microwave technology for food application. CRC Press, pp 93–138. https://www.taylorfrancis.com/chapters/edit/10.1201/9781482270778-9/dielectric-properties-food-materials-electric-field-interactions-stuart-nelson-ashim-datta

Kubo MTK, Curet S, Augusto PED, Boillereaux L (2018) Artificial neural network for prediction of dielectric properties relevant to microwave processing of fruit juice. J Food Process Eng 41(6). https://doi.org/10.1111/jfpe.12815

Ohlsson T, Bengtsson NE (1975) Dielectric food data for microwave sterilization processing. J Microw Power 10(1):94–108

Roebuck BD, Goldblith SA, Westphal WB (1972) Dielectric properties of carbohydrate-water mixtures at microwave frequencies. J Food Sci 37(2):199–204

Prakash A, Nelson SO, Mangino ME, Hansen PMT (1992) Variation of microwave dielectric properties of hydrocolloids with moisture content, temperature and stoichiometric charge. Food Hydrocolloids 6(3):315–322

Tang J, Liu F, Pathak SK, Eves IIEE (2006) Apparatus and method for heating objects with microwaves (Patent No. 7,119,313.). US Patent and Trademark Office, Washington, DC. https://patents.google.com/patent/WO2005023013A2/en

Zhou X, Gezahegn Y, Zhang S, Tang Z, Takhar PS, Pedrow PD, Sablani SS, Tang J (2023) Theoretical reasons for rapid heating of vegetable oils by microwaves. Current Res Food Sci 7:100641. https://doi.org/10.1016/j.crfs.2023.100641

Spencer PL (1950) Method of treating food stuff (Patent No. 2495429A). US Patent and Trademark Office, Washington, DC. https://patents.google.com/patent/US2495429A/en

Landy JJ (1965) Method of sterilizing food in sealed containers (Patent No. 3,215,539). US Patent and Trademark Office, Washington, DC. https://patents.google.com/patent/US3215539A/en

Long FE, Shaw FB, Lisle HC (1966) Microwave sterilization and vacuumizing of products in flexible packages and apparatus therefor (Patent No. 3,261,140.). US Patent and Trademark Office, Washington, DC. https://patents.google.com/patent/US3261140A/en

Jeppson MR, Harper JC (1967) Microwave heating of substances under hydrostatic pressure (Patent No. 3,335,253). US Patent and Trademark Office, Washington, DC. https://patents.google.com/patent/US3335253A/en

Kenyon EM, Westcott DE, La Casse P, Gould JW (1971) A system for continuous thermal processing of food pouches using microwave energy. J Food Sci 36(2):289–293. https://doi.org/10.1111/j.1365-2621.1971.tb04045.x

Hirschey JA, Reeve ML, Cassel JM, Brejcha LJ, Legan JD, Mohr LM (2017) A microwave retort system, a process for heating food products using a microwave retort system, and food products formulated for microwave retort (Patent No. International Application No. PCT/US2015/050650). https://patentscope.wipo.int/search/en/detail.jsf?docId=WO2016044571

Lin CC, Li CF (1971) Microwave sterilization of oranges in glass-pack. J Microwave Power 6(1):45–47

Loh J, Breene WM (1983) A laboratory microwave sterilizer and its possible application toward improving texture of sterilized vegetables. J Food Process Preserv 7(2):77–92

Williams A (1993) New technologies in food preservation and processing: part I. Nutr Food Sci 93(6):16–19. https://doi.org/10.1108/EUM0000000001007

Prakash A, Kim HJ, Taub IA (1997) Assessment of microwave sterilization of foods using intrinsic chemical markers. J Microw Power Electromagn Energy 32(1):50–57. https://doi.org/10.1080/08327823.1997.11688323

Pathak SK, Liu F, Tang J (2003) Finite difference time domain (FDTD) characterization of a single mode applicator. J Microw Power Electromagn Energy 38(1):37–48. https://doi.org/10.1080/08327823.2003.11688486

Chen H, Tang J, Liu F (2006) Coupled simulation of an electromagnetic heating process using the finite difference time domain method. J Microw Power Electromagn Energy 41(3):50–68. https://doi.org/10.1080/08327823.2006.11688563

Chen H, Tang J, Liu F (2008) Simulation model for moving food packages in microwave heating processes using conformal FDTD method. J Food Eng. https://doi.org/10.1016/J.JFOODENG.2008.02.020

Resurreccion FP, Tang J, Pedrow P, Cavalieri R, Liu F, Tang Z (2013) Development of a computer simulation model for processing food in a microwave assisted thermal sterilization (MATS) system. J Food Eng 118(4):406–416. https://doi.org/10.1016/j.jfoodeng.2013.04.021

Tang Z, Mikhaylenko G, Liu F, Mah J-H, Pandit R, Younce F, Tang J (2008) Microwave sterilization of sliced beef in gravy in 7-oz trays. J Food Eng. https://doi.org/10.1016/J.JFOODENG.2008.04.025

Barbosa-Cánovas GV, Medina-Meza I, Candoğan K, Bermúdez-Aguirre D (2014) Advanced retorting, microwave assisted thermal sterilization (MATS), and pressure assisted thermal sterilization (PATS) to process meat products. Meat Sci. https://doi.org/10.1016/J.MEATSCI.2014.06.027

Mcavoy BR (1971) Solid state microwave oven (Patent No. U.S. Patent No. 3,557,333). US Patent and Trademark Office. https://patents.google.com/patent/US3557333A/en

Atuonwu JC, Tassou SA (2018) Quality assurance in microwave food processing and the enabling potentials of solid-state power generators: A review. J Food Eng 234:1–15. https://doi.org/10.1016/j.jfoodeng.2018.04.009

Taghian Dinani S, Hasić M, Auer M, Kulozik U (2020) Assessment of uniformity of microwave-based heating profiles generated by solid-state and magnetron systems using various shapes of test samples. Food Bioprod Process 124:121–130. https://doi.org/10.1016/j.fbp.2020.08.013

Nget S, Mith H, Boué G, Curet S, Boillereaux L (2023) The development of a digital twin to improve the quality and safety issues of cambodian pâté: the application of 915 MHz microwave cooking. Foods 12(6):1187. https://doi.org/10.3390/foods12061187

Zhou X, Tang Z, Pedrow PD, Sablani SS, Tang J (2023) Microwave heating based on solid-state generators: New insights into heating pattern, uniformity, and energy absorption in foods. J Food Eng 357. https://doi.org/10.1016/j.jfoodeng.2023.111650

Taghian Dinani S, Kubbutat P, Kulozik U (2020) Assessment of heating profiles in model food systems heated by different microwave generators: Solid-state (semiconductor) versus traditional magnetron technology. Innovative Food Science & Emerging Technologies 63. https://doi.org/10.1016/j.ifset.2020.102376

Thanakkasaranee S, Sadeghi K, Seo J (2022) Packaging materials and technologies for microwave applications: a review. Critic Rev Food Sci Nutr:1–20. https://doi.org/10.1080/10408398.2022.2033685

Ayoub J, Berkowitz D, Kenyon E, Wadsworth C (1974) Continuous microwave sterilization of meat in flexible pouches. J Food Sci 39:309–313. https://doi.org/10.1111/j.1365-2621.1974.tb02882.x

Al-Ghamdi SM (2020) Flexible and semirigid packaging for high pressure and microwave-based pasteurization and sterilization processes (S. S. Sablani, J. Tang, & B. Rasco (eds.))

Ayvaz H, Schirmer S, Parulekar Y, Balasubramaniam VM, Somerville JA, Daryaei H (2012) Influence of selected packaging materials on some quality aspects of pressure-assisted thermally processed carrots during storage. LWT - Food Sci Technol 46(2):437–447. https://doi.org/10.1016/j.lwt.2011.12.004

Parhi A, Bhunia K, Rasco B, Tang J, Sablani SS (2019) Development of an oxygen sensitive model gel system to detect defects in metal oxide coated multilayer polymeric films. J Food Sci 84(9):2507–2519. https://doi.org/10.1111/1750-3841.14755

Patel J, Sonar CR, Al-Ghamdi S, Tang Z, Yang T, Tang J, Sablani SS (2021) Influence of ultra-high barrier packaging on the shelf-life of microwave-assisted thermally sterilized chicken pasta. LWT 136. https://doi.org/10.1016/j.lwt.2020.110287

Chen M, Siochi EJ, Ward TC, McGrath JE (1993) Basic ideas of microwave processing of polymers. Polym Eng Sci 33(17):1092–1109. https://doi.org/10.1002/pen.760331703

Maddah HA (2016) Polypropylene as a promising plastic: A review. Am J Polym Sci 6(1):1–11

Farah S, Anderson DG, Langer R (2016) Physical and mechanical properties of PLA, and their functions in widespread applications — A comprehensive review. Adv Drug Deliv Rev 107:367–392. https://doi.org/10.1016/j.addr.2016.06.012

Dhawan S, Varney C, Barbosa-Cánovas GV, Tang J, Selim F, Sablani SS (2014) The impact of microwave-assisted thermal sterilization on the morphology, free volume, and gas barrier properties of multilayer polymeric films. J Appl Polym Sci. https://doi.org/10.1002/APP.40376

Ramalingam R, VA S, George J, SN S (2015) Effect of pasteurization and retort processing on spectral characteristics, morphological, thermal, Physico-Mechanical, barrier and optical properties of Nylon-Based food packaging materials. Packag Technol Sci 28(5):425–436

Halim L, Pascall MA, Lee J, Finnigan B (2009) Effect of pasteurization, high-pressure processing, and retorting on the barrier properties of nylon 6, nylon 6/ethylene vinyl alcohol, and nylon 6/nanocomposites films. J Food Sci 74(1):N9–N15. https://doi.org/10.1111/j.1750-3841.2008.00990.x

Fleckenstein BS, Sterr J, Langowski H-C (2016) The influence of high pressure treatment and thermal pasteurization on the surface of polymeric packaging films. Packag Technol Sci 29(6):323–336. https://doi.org/10.1002/pts.2213

Bhunia K, Zhang H, Liu F, Rasco B, Tang J, Sablani SS (2016) Morphological changes in multilayer polymeric films induced after microwave-assisted pasteurization. Innov Food Sci Emerg Technol 38:124–130. https://doi.org/10.1016/j.ifset.2016.09.024

Mokwena KK, Tang J, Dunne CP, Yang TCS, Chow E (2009) Oxygen transmission of multilayer EVOH films after microwave sterilization. J Food Eng 92(3):291–296. https://doi.org/10.1016/j.jfoodeng.2008.11.011

Simon FE, Green FR, Iliescu KA (1999) Metal container and use thereof in a microwave oven (Patent No. 5,961,872.). US Patent and Trademark Office, Washington, DC. https://patents.google.com/patent/US5961872A/en

Sharma R, Knudsen KF (2013) Microwave food packaging (Patent No. 2007255524). US Patent and Trademark Office, Washington, DC. https://patents.google.com/patent/US20090208614A1/en

Micvac (n.d.) Micvac Packaging. https://www.micvac.com/method/packaging/

Richardson M, Jason K, Hirsch V (2013) Microwavable metallic container (Patent No. US 2006/091821). US Patent and Trademark Office, Washington, DC. https://patents.google.com/patent/US7378625B2/en

Sadiku MNO (2001) Elements of electromagnetics, 3rd edn. Oxford University Press, New York

Halder A, Datta AK (2012) Surface heat and mass transfer coefficients for multiphase porous media transport models with rapid evaporation. Food Bioprod Process 90(3):475–490. https://doi.org/10.1016/j.fbp.2011.10.005

Al-Baali AA, Farid MM(2007) Sterilization of food in retort pouches. Springer Science & Business Media. https://link.springer.com/book/10.1007/0-387-31129-7

Lau W (2015) Numerical modelling of heat and mass transfer in a steam-air sterilisation process inside an industrial autoclave. UNSW Sydney. https://unsworks.unsw.edu.au/entities/publication/15a59b7a-3bb6-405f-be7f-e2bcc8d60a55

Abdul Ghani AG, Farid MM, Chen XD, Richards P (1999) Numerical simulation of natural convection heating of canned food by computational fluid dynamics. J Food Eng 41(1):55–64. https://doi.org/10.1016/S0260-8774(99)00073-4

Auksornsri T, Bornhorst ER, Tang J, Tang Z, Songsermpong S (2018) Developing model food systems with rice based products for microwave assisted thermal sterilization. LWT Food Sci Technol. https://doi.org/10.1016/J.LWT.2018.05.054

Auksornsri T, Tang J, Tang Z, Lin H, Songsermpong S (2018) Dielectric properties of rice model food systems relevant to microwave sterilization process. Innov Food Sci Emerg Technol. https://doi.org/10.1016/J.IFSET.2017.09.002

Bornhorst ER, Tang J, Sablani SS, Barbosa-Cánovas GV (2017) Thermal pasteurization process evaluation using mashed potato model food with Maillard reaction products. LWT Food Sci Technol 82:454–463. https://doi.org/10.1016/j.lwt.2017.04.019

Bornhorst ER, Liu F, Tang J, Sablani SS, Barbosa-Cánovas GV (2017) Food quality evaluation using model foods: a comparison study between microwave-assisted and conventional thermal pasteurization processes. Food Bioprocess Technol. https://doi.org/10.1007/S11947-017-1900-9

Lau MH, Tang J, Taub IA, Yang TCS, Edwards CG, Mao R (2003) Kinetics of chemical marker formation in whey protein gels for studying microwave sterilization. J Food Eng 60(4):397–405. https://doi.org/10.1016/S0260-8774(03)00063-3

Sobreiro PH, Sato LNI, Gut JAW (2018) Model food for microwave-assisted pasteurization of fruit juices and nectars at 915 and 2,450 MHz. J Food Process Eng 41(7). https://doi.org/10.1111/jfpe.12858

Jain D, Tang J, Liu F, Tang Z, Pedrow PD (2018) Computational evaluation of food carrier designs to improve heating uniformity in microwave assisted thermal pasteurization. Innov Food Sci Emerg Technol. https://doi.org/10.1016/J.IFSET.2018.06.015

Bhuwan Pandit R, Tang J, Liu F, Mikhaylenko G (2007) A computer vision method to locate cold spots in foods in microwave sterilization processes. Pattern Recogn 40(12):3667–3676. https://doi.org/10.1016/j.patcog.2007.03.021

Pandit RB, Tang J, Mikhaylenko G, Liu F (2006) Kinetics of chemical marker M-2 formation in mashed potato—a tool to locate cold spots under microwave sterilization. J Food Eng 76(3):353–361. https://doi.org/10.1016/j.jfoodeng.2005.05.032

Zhang H, Tang Z, Rasco B, Tang J, Sablani SS (2016) Shelf-life modelling of microwave-assisted thermal sterilized mashed potato in polymeric pouches of different gas barrier properties. J Food Eng 183:65–73. https://doi.org/10.1016/J.JFOODENG.2016.03.021

Zhang W, Tang J, Liu F, Bohnet S, Tang Z (2014) Chemical marker M2 (4-hydroxy-5-methyl-3(2H)-furanone) formation in egg white gel model for heating pattern determination of microwave-assisted pasteurization processing. J Food Eng 125:69–76. https://doi.org/10.1016/j.jfoodeng.2013.10.020

Komarov V, Yakovlev V (2001) Simulations of components of microwave heating applicators by FEMLAB, MicroWaveLab and QuickWave-3D. 36th Annual Microwave Symposium, Proceedings, San Francisco, CA, USA

Segui J (2013) Equation-based modelling, a custom model of a beating heart. https://www.comsol.fr/blogs/equation-based-modelling-a-custom-model-of-a-beating-heart/

Jain D (2017) Electromagnetic and thermal analysis of microwave heating in 915 mhz single mode cavity systems: microwave assisted thermal sterilization and pasteurization. ProQuest Dissertations Publishing. https://www.proquest.com/openview/6891a0c85973e63a9b718a38aa2aa0ed/1?pq-origsite=gscholar&cbl=18750

Celuch M, Kopyt P (2009) Development of packaging and products for use in microwave ovens. Woodhead Publishing, pp. 305–348. https://doi.org/10.1533/9781845696573.4.305

Geedipalli SSR, Rakesh V, Datta AK (2007) Modelling the heating uniformity contributed by a rotating turntable in microwave ovens. J Food Eng 82(3):359–368. https://doi.org/10.1016/j.jfoodeng.2007.02.050

Yang H, Yan B, Meng L, Jiao X, Huang J, Gao W, Zhao J, Zhang H, Chen W, Fan D (2022) Mathematical modelling of continuous microwave heating of surimi paste. J Food Eng 315:110797. https://doi.org/10.1016/j.jfoodeng.2021.110797

Su T, Zhang W, Zhang Z, Wang X, Zhang S (2021) Numerical investigation of the deformable porous media treated by the intermittent microwave. Processes 9(5). https://doi.org/10.3390/pr9050757

Zhang H, Datta AK, Taub IA, Doona C (2001) Electromagnetics, heat transfer, and thermokinetics in microwave sterilization. AIChE J 47(9):1957–1968. https://doi.org/10.1002/aic.690470907

Pitchai K (2011) Electromagnetic and heat transfer modelling of microwave heating in domestic ovens. University of Nebraska. https://digitalcommons.unl.edu/foodscidiss/38/

Teleken JT, Dutra AC, Laurindo JB, Carciofi BAM (2023) Numerical modelling of heating tomato pulp in continuous flow microwave-assisted thermal processing: Estimation of quality parameters. J Food Process Eng 46(2). https://doi.org/10.1111/jfpe.14216

Lespinard AR, Arballo JR, Badin EE, Mascheroni RH (2019) Comparative study between conventional and microwave-assisted pasteurization of packaged milk by finite element modelling. J Food Process Preserv 43(11). https://doi.org/10.1111/jfpp.14207

Zhu J, Kuznetsov AV, Sandeep KP (2007) Mathematical modelling of continuous flow microwave heating of liquids (effects of dielectric properties and design parameters). Int J Therm Sci 46(4):328–341. https://doi.org/10.1016/j.ijthermalsci.2006.06.005

Curet S, Rouaud O, Boillereaux L (2008) Microwave tempering and heating in a single-mode cavity: Numerical and experimental investigations. Chem Eng Process 47(9):1656–1665. https://doi.org/10.1016/j.cep.2007.09.011

De Albuquerque CD, Curet S, Boillereaux L (2021) Influence of heating rate during microwave pasteurization of ground beef products: Experimental and numerical study. J Food Process Eng 44(7). https://doi.org/10.1111/jfpe.13722

Luan D, Tang J, Pedrow PD, Liu F, Tang Z (2016) Analysis of electric field distribution within a microwave assisted thermal sterilization (MATS) system by computer simulation. J Food Eng. https://doi.org/10.1016/J.JFOODENG.2016.05.009

Cherbański R, Rudniak L (2013) Modelling of microwave heating of water in a monomode applicator – Influence of operating conditions. Int J Therm Sci. https://doi.org/10.1016/J.IJTHERMALSCI.2013.07.001

Ye J, Hong T, Wu Y, Wu L, Liao Y, Zhu H, Yang Y, Huang K(2017) Model stirrer based on a multi-material turntable for microwave processing materials. Materials 10(2). https://doi.org/10.3390/ma10020095

Mohekar AA (2018) Computational modelling of triple layered microwave heat exchanger [Worcester Polytechnic Institute]. In MS Thesis. https://core.ac.uk/download/pdf/212999298.pdf

Birla S, Pitchai K, Raj JD, Jones D, Subbiah J, Komarov V (2011) A comparison of COMSOL and QUICKWAVE software for modelling of microwave heating in domestic oven. 45th Annual microwave power symposium (IMPI 45). http://microwavepasteurization.wsu.edu/mwp-main/conferences/IMPI/IMPI45/IMPI_Symposium_Brochure_Final.pdf

Ames WF (2014) Numerical methods for partial differential equations (3rd ed.). Academic press. https://doi.org/10.1016/B978-0-12-056760-7.50001-3

Bathe KJ, Wilson EL (1976) Numerical methods in finite element analysis. Prentice-Hall. https://cir.nii.ac.jp/crid/1130282272328853376

Celuch M, Kopyt P, Olszewska-Placha M (2020) Modelling of cavities and loads with FDTD and FEM methods. In Development of packaging and products for use in microwave ovens (pp. 459–511). https://doi.org/10.1016/B978-0-08-102713-4.00018-9

Kunz KS, Luebbers RJ (1993) The finite difference time domain method for electromagnetics. CRC Press

Rycroft MJ (1996) Computational electrodynamics, the finite-difference time-domain method. J Atmos Terr Phys 15(58):1817–1818

Dibben D (2001) Electromagnetics: fundamental aspects and numerical modelling. In Handbook of microwave technology for food application (pp. 25–56). CRC press. https://doi.org/10.1201/9781482270778

Yang H, Yan B, Chen W, Fan D (2023) Prediction and innovation of sustainable continuous flow microwave processing based on numerical simulations: A systematic review. Renew Sustain Energy Rev 175:113–183. https://doi.org/10.1016/j.rser.2023.113183

Acknowledgement

The authors are grateful to Oniris, GEPEA UMR CNRS 6144, France; CTCPA, France, and SAIREM, France for providing the necessary infrastructure and resources to conduct this study. This research work is a part of the CIFRE industrial thesis of Sadhan Jyoti Dutta. The authors thank the Association Nationale Recherche Technologie (ANRT) for financial support to this study (CIFRE convention N° 2022/1042).

Funding

This work received funding from Association Nationale Recherche Technologie (ANRT) as a part of CIFRE industrial thesis of Sadhan Jyoti Dutta (CIFRE convention N° 2022/1042).

Author information

Authors and Affiliations

Contributions

Conceptualization: Olivier Rouaud, Patrice Dole, Sadhan Jyoti Dutta, Sebastien Curet; Methodology: Olivier Rouaud, Patrice Dole, Sadhan Jyoti Dutta; Sebastien Curet; Formal analysis and investigation: Olivier Rouaud, Sadhan Jyoti Dutta, Sebastien Curet; Writing - original draft preparation: Sadhan Jyoti Dutta; Writing - review and editing: Nicolas Belaubre, Olivier Rouaud, Patrice Dole, Sadhan Jyoti Dutta, Sebastien Curet; Funding acquisition: Olivier Rouaud, Patrice Dole, Sebastien Curet; Resources: Alexandre Thillier, Nicolas Belaubre, Olivier Rouaud, Patrice Dole, Sadhan Jyoti Dutta, Sebastien Curet; Supervision: Nicolas Belaubre, Olivier Rouaud, Patrice Dole, Sebastien Curet.

Corresponding author

Ethics declarations

Ethical Approval

This declaration is not applicable.

Competing Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Dutta, S.J., Rouaud, O., Dole, P. et al. Microwave Sterilization: Interlinking Numerical Modelling, Food Packaging, and Engineering Solutions. Food Eng Rev (2024). https://doi.org/10.1007/s12393-024-09370-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12393-024-09370-w