Abstract

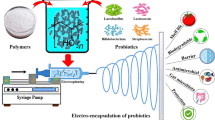

This comprehensive review highlights the innovative applications of eco-friendly nanofibers in facilitating microbial activity and functionality for the advancement of sustainable agri-food systems. It provides an in-depth exploration of nanofiber-based biocomposites, with a specific focus on the encapsulation of bacterial cells within nanofibers. The review emphasizes the pivotal role of advanced 3D nanostructured scaffolds, appropriately designed for the encapsulation and survivability of these bacterial cells in response to specific environmental triggers. Furthermore, this paper delves into the utilization of nanofibers as nanocarriers to enhance the functionality of bacteria. It illustrates the need for comprehensive safety assessments, especially considering the potential risks involved. The assessment establishes a connection between the technical discussions and the environmental regulations that support the implementation of sustainable practices within the agri-food sector. The review highlights the vital role played by international guidelines, such as those established by the United Nations Environment Program (UNEP) and the Food and Agriculture Organization (FAO), in guiding the formulation of national and regional policies. By interconnecting these strategic principles with technological advancements in nanofiber technology, the review favors the incorporation of “green”, eco-friendly nanofiber production via an electrospinning method to revolutionize the agri-food sector. This holistic approach aims to address current challenges, paving the way for sustainable progress.

Similar content being viewed by others

Availability of Data and Materials

Not applicable.

References

Chen X, Cheng L, Li H et al (2018) Magnetic Nanofibers: Unique Properties, Fabrication Techniques, and Emerging Applications. ChemistrySelect 3:9127–9143. https://doi.org/10.1002/slct.201702480

Turky AO, Barhoum A, MohamedRashad M, Bechlany M (2017) Enhanced the structure and optical properties for ZnO/PVP nanofibers fabricated via electrospinning technique. J Mater Sci: Mater Electron 28:17526–17532. https://doi.org/10.1007/s10854-017-7688-6

Nagarajan S, Bechelany M, Kalkura NS et al (2019) Electrospun Nanofibers for Drug Delivery in Regenerative Medicine. In: Mohapatra SS, et al. (eds) Applications of Targeted Nano Drugs and Delivery Systems. Elsevier, Amsterdam, pp 595–625. https://doi.org/10.1016/C2017-0-00274-4

Buzgo M, Mickova A, Rampichova M, Doupnik M (2018) Blend electrospinning, coaxial electrospinning, and emulsion electrospinning techniques. In: Focarete ML, Anna Tampieri A (eds) Core-Shell Nanostructures for Drug Delivery and Theranostics. Elsevier, Amsterdam, pp 325–347. https://doi.org/10.1016/B978-0-08-102198-9.00011-9

Noruzi M (2016) Electrospun anofibers in agriculture and the food industry: a review. J Sci Food Agric 96:4663–4678. https://doi.org/10.1002/jsfa.7737

Farhaj S, Conway BR, Ghori MU (2023) Nanofibres in Drug Delivery Applications Fibers 11:21. https://doi.org/10.3390/fib11020021

Ghajarieh A, Habibi S, Talebian A (2021) Biomedical Applications of Nanofibers. Russ J Appl Chem 94:847–872. https://doi.org/10.1134/S1070427221070016

Mercante LA, Pavinatto A, Pereira TS et al (2021) Nanofibers interfaces for biosensing: Design and applications. Sensors and Actuators Reports 3:100048. https://doi.org/10.1016/j.snr.2021.100048

Göksen G, Fabra MJ, Ekiz HI, López-Rubio A (2020) Phytochemical-loaded electrospun nanofibers as novel active edible films: Characterization and antibacterial efficiency in cheese slices. Food Control 112:107133. https://doi.org/10.1016/j.foodcont.2020.107133

Smith S, Goodge K, Delaney M et al (2020) A Comprehensive Review of the Covalent Immobilization of Biomolecules onto Electrospun Nanofibers. Nanomaterials 10:2142. https://doi.org/10.3390/nano10112142

Fahami A, Fathi M (2018) Development of cress seed mucilage/PVA nanofibers as a novel carrier for vitamin A delivery. Food Hydrocoll 81:31–38. https://doi.org/10.1016/j.foodhyd.2018.02.008

Loh B, Gondil VS, Manohar P et al (2021) Encapsulation and Delivery of Therapeutic Phages. Appl Environ Microbiol 87:e01979-20. https://doi.org/10.1128/AEM.01979-20

Barhoum A, Rasouli R, Yousefzadeh M et al (2018) Nanofiber Technology: History and Developments. Handbook of Nanofibers. Springer International Publishing, Cham, pp 1–42

Sahu S, Sharma A, Mukherjee S et al (2021) Role of Nanofibers in Encapsulation of the Whole Cell. Int J Polym Sci 2021:1–9. https://doi.org/10.1155/2021/4250122

Krogstad EA, Ramanathan R, Nhan C et al (2017) Nanoparticle-releasing nanofiber composites for enhanced in vivo vaginal retention. Biomaterials 144:1–16. https://doi.org/10.1016/j.biomaterials.2017.07.034

Zupančič Š, Preem L, Kristl J et al (2018) Impact of PCL nanofiber mat structural properties on hydrophilic drug release and antibacterial activity on periodontal pathogens. Eur J Pharm Sci 122:347–358. https://doi.org/10.1016/j.ejps.2018.07.024

Khoshnevisan K, Maleki H, Samadian H et al (2018) Cellulose acetate electrospun nanofibers for drug delivery systems: Applications and recent advances. Carbohydr Polym 198:131–141. https://doi.org/10.1016/j.carbpol.2018.06.072

Wagner I, Nagy ZK, Vass P et al (2015) Stable formulation of protein-type drug in electrospun polymeric fiber followed by tableting and scaling-up experiments. Polym Adv Technol 26:1461–1467. https://doi.org/10.1002/pat.3569

Lapponi MJ, Méndez MB, Trelles JA, Rivero CW (2022) Cell immobilization strategies for biotransformations. Curr Opin Green Sustain Chem 33:100565. https://doi.org/10.1016/j.cogsc.2021.100565

Pilar-Izquierdo MC, López-Fouz M, Ortega N, Busto MD (2023) Immobilization of Rhodococcus by encapsulation and entrapment: a green solution to bitter citrus by-products. Appl Microbiol Biotechnol 107:6377–6388. https://doi.org/10.1007/s00253-023-12724-9

Seroski DT, Hudalla GA (2018) elf-Assembled Peptide and Protein Nanofibers for Biomedical Applications. Biomedical Applications of Functionalized Nanomaterials. Elsevier, Amsterdam, pp 569–598

Kenry LB (2018) Recent Advances in Biodegradable Conducting Polymers and Their Biomedical Applications. Biomacromol 19:1783–1803. https://doi.org/10.1021/acs.biomac.8b00275

Fijałkowski K, Peitler D, Rakoczy R, Żywicka A (2016) Survival of probiotic lactic acid bacteria immobilized in different forms of bacterial cellulose in simulated gastric juices and bile salt solution. LWT Food Sci Technol 68:322–328. https://doi.org/10.1016/j.lwt.2015.12.038

Phromthep K, Leenanon B (2017) Survivability of immobilized Lactobacillus plantarum cells within bacterial cellulose in mamao juice. Int Food Res J 24(3):939–949

FAO (2023) https://www.fao.org/sustainability/en/. Aapplied 31 May 2023

FDA (2023) https://www.fda.gov/. Applied 31 May 2023

Shi Z, Zhang Y, Phillips GO, Yang G (2014) Utilization of bacterial cellulose in food. Food Hydrocoll 35:539–545. https://doi.org/10.1016/j.foodhyd.2013.07.012

UNEP (2023) https://www.unep.org/. Applied 31 May 2023

Lee JKY, Chen N, Peng S et al (2018) Polymer-based composites by electrospinning: Preparation & functionalization with nanocarbons. Prog Polym Sci 86:40–84. https://doi.org/10.1016/j.progpolymsci.2018.07.002

Ding J, Zhang J, Li J et al (2019) Electrospun polymer biomaterials. Prog Polym Sci 90:1–34. https://doi.org/10.1016/j.progpolymsci.2019.01.002

Sultankulov B, Berillo D, Sultankulova K et al (2019) Progress in the Development of Chitosan-Based Biomaterials for Tissue Engineering and Regenerative Medicine. Biomolecules 9:470. https://doi.org/10.3390/biom9090470

Shalumon KT, Sheu C, Chen C-H et al (2018) Multi-functional electrospun antibacterial core-shell nanofibrous membranes for prolonged prevention of post-surgical tendon adhesion and inflammation. Acta Biomater 72:121–136. https://doi.org/10.1016/j.actbio.2018.03.044

Aggarwal U, Goyal AK, Rath G (2017) Development and characterization of the cisplatin loaded nanofibers for the treatment of cervical cancer. Mater Sci Eng C 75:125–132. https://doi.org/10.1016/j.msec.2017.02.013

Singbumrung K, Motina K, Pisitsak P et al (2018) Preparation of Cu-BTC/PVA Fibers with Antibacterial Applications. Fibers and Polymers 19:1373–1378. https://doi.org/10.1007/s12221-018-8072-8

Ramezani MR, Ansari-Asl Z, Hoveizi E, Kiasat AR (2019) Polyacrylonitrile/Fe(III) metal-organic framework fibrous nanocomposites designed for tissue engineering applications. Mater Chem Phys 229:242–250. https://doi.org/10.1016/j.matchemphys.2019.03.031

Irani M, Sadeghi GMM, Haririan I (2017) The sustained delivery of temozolomide from electrospun PCL-Diol-b-PU/gold nanocompsite nanofibers to treat glioblastoma tumors. Mater Sci Eng C 75:165–174. https://doi.org/10.1016/j.msec.2017.02.029

Song B, Wu C, Chang J (2015) Ultrasound-triggered dual-drug release from poly(lactic-co-glycolic acid)/mesoporous silica nanoparticles electrospun composite fibers. Regen Biomater 2:229–237. https://doi.org/10.1093/rb/rbv019

Blantocas GQ, Alaboodi AS, Mekky AH (2018) Synthesis of Chitosan–TiO2 Antimicrobial Composites via a 2-Step Process of Electrospinning and Plasma Sputtering. Arab J Sci Eng 43:389–398. https://doi.org/10.1007/s13369-017-2695-8

Lai W-Y, Feng S-W, Chan Y-H et al (2018) In Vivo Investigation into Effectiveness of Fe3O4/PLLA Nanofibers for Bone Tissue Engineering Applications. Polymers (Basel) 10:804. https://doi.org/10.3390/polym10070804

Ahmed R, Tariq M, Ali I et al (2018) Novel electrospun chitosan/polyvinyl alcohol/zinc oxide nanofibrous mats with antibacterial and antioxidant properties for diabetic wound healing. Int J Biol Macromol 120:385–393. https://doi.org/10.1016/j.ijbiomac.2018.08.057

Zhang J, Zheng T, Alarçin E et al (2017) Porous Electrospun Fibers with Self-Sealing Functionality: An Enabling Strategy for Trapping Biomacromolecules. Small 13:1701949. https://doi.org/10.1002/smll.201701949

Jurić M, Donsì F, Maslov Bandić L, Jurić S (2023) Natural-based electrospun nanofibers: Challenges and potential applications in agri-food sector. Food Biosci 56:103372. https://doi.org/10.1016/j.fbio.2023.103372

Rasouli R, Barhoum A, Bechelany M, Dufresne A (2019) Nanofibers for Biomedical and Healthcare Applications. Macromol Biosci 19:1800256. https://doi.org/10.1002/mabi.201800256

Lv X, Zhang Y, Wang Y et al (2021) Formation of carbon nanofibers/nanotubes by chemical vapor deposition using Al2O3/KOH. Diam Relat Mater 113:108265. https://doi.org/10.1016/j.diamond.2021.108265

Li Z, Qi S, Liang Y et al (2018) Plasma Surface Functionalization of Carbon Nanofibres with Silver, Palladium and Platinum Nanoparticles for Cost-Effective and High-Performance Supercapacitors. Micromachines (Basel) 10:2. https://doi.org/10.3390/mi10010002

Mihut DM, Lozano K, Foltz H (2014) Fabrication and characterization of silver- and copper-coated Nylon 6 forcespun nanofibers by thermal evaporation. J Vac Sci Technol 32:061401. https://doi.org/10.1116/1.4896752

Moise C, Rachmani L, Mihai G et al (2021) Pulsed Laser Deposition of SWCNTs on Carbon Fibres: Effect of Deposition Temperature. Polymers (Basel) 13:1138. https://doi.org/10.3390/polym13071138

Park C, Xue R, Lannutti JJ, Farson DF (2016) Ablation characteristics of electrospun core-shell nanofiber by femtosecond laser. Mater Sci Eng C 65:232–239. https://doi.org/10.1016/j.msec.2016.04.046

Barhoum A, Pal K, Rahier H et al (2019) Nanofibers as new-generation materials: From spinning and nano-spinning fabrication techniques to emerging applications. Appl Mater Today 17:1–35. https://doi.org/10.1016/j.apmt.2019.06.015

Sun L, Yuan G, Gao L et al (2021) Chemical vapour deposition. Nature Reviews Methods Primers 1:5. https://doi.org/10.1038/s43586-020-00005-y

Rodriguez CAD, Tremiliosi-Filho G (2013) Electrochemical Deposition. Encyclopedia of Tribology. Springer, US, Boston, MA, pp 918–922

Dong H, Chen Y-C, Feldmann C (2015) Polyol synthesis of nanoparticles: status and options regarding metals, oxides, chalcogenides, and non-metal elements. Green Chem 17:4107–4132. https://doi.org/10.1039/C5GC00943J

Huang W, Wang M-J, Liu C-L et al (2014) Phase separation in electrospun nanofibers controlled by crystallization induced self-assembly. J Mater Chem A Mater 2:8416. https://doi.org/10.1039/c4ta00417e

Ghayempour S, Montazer M (2018) A modified microemulsion method for fabrication of hydrogel Tragacanth nanofibers. Int J Biol Macromol 115:317–323. https://doi.org/10.1016/j.ijbiomac.2018.04.037

Garibay-Alvarado J, Farías R, Reyes-López S (2019) Sol-Gel and Electrospinning Synthesis of Lithium Niobate-Silica Nanofibers. Coatings 9:212. https://doi.org/10.3390/coatings9030212

Chan JX, Wong JF, Hassan A et al (2020) Green hydrothermal synthesis of high aspect ratio wollastonite nanofibers: Effects of reaction medium, temperature and time. Ceram Int 46:22624–22634. https://doi.org/10.1016/j.ceramint.2020.06.025

He JH, Liu Y, Mo LF, Wan YQ, Xu L (2008) Electrospun Nanofibres and Their Applications. Smithers, Shawbury, UK

Baji A, Agarwal K, Oopath SV (2020) Emerging Developments in the Use of Electrospun Fibers and Membranes for Protective Clothing Applications. Polymers (Basel) 12:492. https://doi.org/10.3390/polym12020492

Sun Y, Cheng S, Lu W et al (2019) Electrospun fibers and their application in drug controlled release, biological dressings, tissue repair, and enzyme immobilization. RSC Adv 9:25712–25729. https://doi.org/10.1039/C9RA05012D

Matricardi P, Di Meo C, Coviello T et al (2013) Interpenetrating Polymer Networks polysaccharide hydrogels for drug delivery and tissue engineering. Adv Drug Deliv Rev 65:1172–1187. https://doi.org/10.1016/j.addr.2013.04.002

Sahraro M, Barikani M, Daemi H (2018) Mechanical reinforcement of gellan gum polyelectrolyte hydrogels by cationic polyurethane soft nanoparticles. Carbohydr Polym 187:102–109. https://doi.org/10.1016/j.carbpol.2018.01.028

Torabi A, Sahraro M, Barikani M, Daemi H (2019) Green synthesis of in situ forming alginate-urethane hydrogel through Schiff base reaction. Mater Lett 254:194–197. https://doi.org/10.1016/j.matlet.2019.07.052

Kumar Sharma G, Rachel James N (2023) Electrospinning: The Technique and Applications. In: Khan M, Chelladurai SJS (eds) Recent Developments in Nanofibers Research. IntechOpen, Rijeka. https://doi.org/10.5772/intechopen.105804

Kenry LCT (2017) Nanofiber technology: current status and emerging developments. Prog Polym Sci 70:1–17. https://doi.org/10.1016/j.progpolymsci.2017.03.002

Thakkar S, Misra M (2017) Electrospun polymeric nanofibers: New horizons in drug delivery. Eur J Pharm Sci 107:148–167. https://doi.org/10.1016/j.ejps.2017.07.001

Abu Owida H, Al-haj Moh’d B, Al Takrouri M (2022) Designing an Integrated Low-cost Electrospinning Device for Nanofibrous Scaffold Fabrication. HardwareX 11:e00250. https://doi.org/10.1016/j.ohx.2021.e00250

Zhang B, Yan X, He H-W et al (2017) Solvent-free electrospinning: opportunities and challenges. Polym Chem 8:333–352. https://doi.org/10.1039/C6PY01898J

Taemeh MA, Shiravandi A, Korayem MA, Daemi H (2020) Fabrication challenges and trends in biomedical applications of alginate electrospun nanofibers. Carbohydr Polym 228:115419. https://doi.org/10.1016/j.carbpol.2019.115419

Li D, Xia Y (2004) Electrospinning of Nanofibers: Reinventing the Wheel? Adv Mater 16:1151–1170. https://doi.org/10.1002/adma.200400719

Bubakir MM, Li H, Barhoum A, Yang W (2019) Advances in Melt Electrospinning Technique. Handbook of Nanofibers. Springer International Publishing, Cham, pp 125–156

Xu H, Yamamoto M, Yamane H (2017) Melt electrospinning: Electrodynamics and spinnability Polymer (Guildf) 132:206–215. https://doi.org/10.1016/j.polymer.2017.11.006

Mirjalili M, Zohoori S (2016) Review for application of electrospinning and electrospun nanofibers technology in textile industry. J Nanostructure Chem 6:207–213. https://doi.org/10.1007/s40097-016-0189-y

Li X-Y, Zheng Z-B, Yu D-G et al (2017) Electrosprayed anofiber ethylcellulose nanoparticles for an improved sustained-release profile of anticancer drug. Cellulose 24:5551–5564. https://doi.org/10.1007/s10570-017-1498-0

Vellayappan MV, Venugopal JR, Ramakrishna S et al (2016) Electrospinning applications from diagnosis to treatment of diabetes. RSC Adv 6:83638–83655. https://doi.org/10.1039/C6RA15252J

Ji Y, Zhao H, Liu H et al (2023) Electrosprayed Stearic-Acid-Coated Ethylcellulose Microparticles for an Improved Sustained Release of Anticancer Drug. Gels 9:700. https://doi.org/10.3390/gels9090700

Bognitzki M, Czado W, Frese T et al (2001) Nanostructured Fibers via Electrospinning. Adv Mater 13:70–72. https://doi.org/10.1002/1521-4095(200101)13:1%3c70::AID-ADMA70%3e3.0.CO;2-H

Mailley D, Hébraud A, Schlatter G (2021) A Review on the Impact of Humidity during Electrospinning: From the Nanofiber Structure Engineering to the Applications. Macromol Mater Eng 306:2100115. https://doi.org/10.1002/mame.202100115

Zhang A, Bai H, Li L (2015) Breath Figure: A Nature-Inspired Preparation Method for Ordered Porous Films. Chem Rev 115:9801–9868. https://doi.org/10.1021/acs.chemrev.5b00069

Wang P, Lv H, Cao X et al (2023) Recent Progress of the Preparation and Application of Electrospun Porous Nanofibers. Polymers (Basel) 15:921. https://doi.org/10.3390/polym15040921

Mehraban M, Zadhoush A, Abdolkarim Hosseini Ravandi S et al (2013) Preparation of porous nanofibers from electrospun polyacrylonitrile/calcium carbonate composite nanofibers using porogen leaching technique. J Appl Polym Sci 128:926–933. https://doi.org/10.1002/app.38091

Ehrmann A (2021) Non-Toxic Crosslinking of Electrospun Gelatin Nanofibers for Tissue Engineering and Biomedicine—A Review. Polymers (Basel) 13:1973. https://doi.org/10.3390/polym13121973

Shao Y, Luo C, Deng B et al (2020) Flexible porous silicone rubber-nanofiber nanocomposites generated by supercritical carbon dioxide foaming for harvesting mechanical energy. Nano Energy 67:104290. https://doi.org/10.1016/j.nanoen.2019.104290

Li Q, Hatakeyama M, Kitaoka T (2022) Bioadaptive Porous 3D Scaffolds Comprising Cellulose and Chitosan Nanofibers Constructed by Pickering Emulsion Templating. Adv Funct Mater 32:2200249. https://doi.org/10.1002/adfm.202200249

Jung JT, Kim JF, Wang HH et al (2016) Understanding the non-solvent induced phase separation (NIPS) effect during the fabrication of microporous PVDF membranes via thermally induced phase separation (TIPS). J Memb Sci 514:250–263. https://doi.org/10.1016/j.memsci.2016.04.069

Duarte ARC, Santo VE, Alves A et al (2013) Unleashing the potential of supercritical fluids for polymer processing in tissue engineering and regenerative medicine. J Supercrit Fluids 79:177–185. https://doi.org/10.1016/j.supflu.2013.01.004

Falua KJ, Pokharel A, Babaei-Ghazvini A et al (2022) Valorization of Starch to Biobased Materials: A Review. Polymers (Basel) 14:2215. https://doi.org/10.3390/polym14112215

Gromov OI, Kostenko MO, Petrunin AV et al (2021) Solute Diffusion into Polymer Swollen by Supercritical CO2 by High-Pressure Electron Paramagnetic Resonance Spectroscopy and Chromatography. Polymers (Basel) 13:3059. https://doi.org/10.3390/polym13183059

Machmudah S, Wahyudiono, Kanda H, Goto M (2019) 5. Supercritical fluid-assisted electrospinning. In: Horzum N, Demir MM, Muñoz-Espí R, Crespy D (eds) Green Electrospinning. De Gruyter, Berlin, pp 99–128. https://doi.org/10.1515/9783110581393-005

Li L, Jiang Z, Pan Q, Fang T (2013) Producing Polymer Fibers by Electrospinning in Supercritical Fluids. J Chem 2013:1–6. https://doi.org/10.1155/2013/508905

Ashraf R, Sofi HS, Malik A et al (2019) Recent Trends in the Fabrication of Starch Nanofibers: Electrospinning and Non-electrospinning Routes and Their Applications in Biotechnology. Appl Biochem Biotechnol 187:47–74. https://doi.org/10.1007/s12010-018-2797-0

Mirtič J, Balažic H, Zupančič Š, Kristl J (2019) Effect of Solution Composition Variables on Electrospun Alginate Nanofibers: Response Surface Analysis. Polymers (Basel) 11:692. https://doi.org/10.3390/polym11040692

Zhuang C, Jiang Y, Zhong Y et al (2018) Development and characterization of nano-bilayer films composed of polyvinyl alcohol, chitosan and alginate. Food Control 86:191–199. https://doi.org/10.1016/j.foodcont.2017.11.024

Daemi H, Mashayekhi M, Pezeshki Modaress M (2018) Facile fabrication of sulfated alginate electrospun nanofibers. Carbohydr Polym 198:481–485. https://doi.org/10.1016/j.carbpol.2018.06.105

Bhattarai N, Li Z, Edmondson D, Zhang M (2006) Alginate-Based Nanofibrous Scaffolds: Structural, Mechanical, and Biological Properties. Adv Mater 18:1463–1467. https://doi.org/10.1002/adma.200502537

Saquing CD, Tang C, Monian B et al (2013) Alginate-Polyethylene Oxide Blend Nanofibers and the Role of the Carrier Polymer in Electrospinning. Ind Eng Chem Res 52:8692–8704. https://doi.org/10.1021/ie302385b

Davarcı F, Turan D, Ozcelik B, Poncelet D (2017) The influence of solution viscosities and surface tension on calcium-alginate microbead formation using dripping technique. Food Hydrocoll 62:119–127. https://doi.org/10.1016/j.foodhyd.2016.06.029

İspirli Doğaç Y, Deveci İ, Mercimek B, Teke M (2017) A comparative study for lipase immobilization onto alginate based composite electrospun nanofibers with effective and enhanced stability. Int J Biol Macromol 96:302–311. https://doi.org/10.1016/j.ijbiomac.2016.11.120

Yalcinkaya F, Yalcinkaya B, Jirsak O (2016) Dependent and Independent Parameters of Needleless Electrospinning. In: Haider S, Haider A (eds) Electrospinning – Material, Techniques, and Biomedical Applications. IntechOpen, Rijeka. https://doi.org/10.5772/65838

de Almeida DS, Duarte EH, Hashimoto EM et al (2020) Development and characterization of electrospun cellulose acetate nanofibers modified by cationic surfactant. Polym Test 81:106206. https://doi.org/10.1016/j.polymertesting.2019.106206

Rieger KA, Birch NP, Schiffman JD (2016) Electrospinning chitosan/poly(ethylene oxide) solutions with essential oils: Correlating solution rheology to nanofiber formation. Carbohydr Polym 139:131–138. https://doi.org/10.1016/j.carbpol.2015.11.073

Kong L, Ziegler GR (2013) Quantitative relationship between electrospinning parameters and starch fiber diameter. Carbohydr Polym 92:1416–1422. https://doi.org/10.1016/j.carbpol.2012.09.026

Peer P, Zelenkova J, Filip P, Lovecka L (2021) An Estimate of the Onset of Beadless Character of Electrospun Nanofibers Using Rheological Characterization. Polymers (Basel) 13:265. https://doi.org/10.3390/polym13020265

Liu G, Gu Z, Hong Y et al (2017) Electrospun starch nanofibers: Recent advances, challenges, and strategies for potential pharmaceutical applications. J Control Release 252:95–107. https://doi.org/10.1016/j.jconrel.2017.03.016

Balaji A, Vellayappan MV, John AA et al (2015) An insight on electrospun-nanofibers-inspired modern drug delivery system in the treatment of deadly cancers. RSC Adv 5:57984–58004. https://doi.org/10.1039/C5RA07595E

Macossay J, Marruffo A, Rincon R, Eubanks, et al (2007) Effect of needle diameter on nanofiber diameter and thermal properties of electrospun poly(methyl methacrylate). Polym Adv Technol 18:180–183. https://doi.org/10.1002/pat.844

Huan S, Liu G, Han G et al (2015) Effect of Experimental Parameters on Morphological, Mechanical and Hydrophobic Properties of Electrospun Polystyrene Fibers. Materials 8:2718–2734. https://doi.org/10.3390/ma8052718

Drosou C, Krokida M, Biliaderis CG (2018) Composite pullulan-whey protein nanofibers made by electrospinning: Impact of process parameters on fiber morphology and physical properties. Food Hydrocoll 77:726–735. https://doi.org/10.1016/j.foodhyd.2017.11.014

Haider A, Haider S, Kang I-K (2018) A comprehensive review summarizing the effect of electrospinning parameters and potential applications of nanofibers in biomedical and biotechnology. Arab J Chem 11:1165–1188. https://doi.org/10.1016/j.arabjc.2015.11.015

Xu H, Yagi S, Ashour S et al (2023) A Review on Current Nanofiber Technologies: Electrospinning, Centrifugal Spinning, and Electro‐Centrifugal Spinning. Macromol Mater Eng 308. https://doi.org/10.1002/mame.202200502

Vass P, Hirsch E, Kóczián R et al (2019) Scaled-Up Production and Tableting of Grindable Electrospun Fibers Containing a Protein-Type Drug. Pharmaceutics 11:329. https://doi.org/10.3390/pharmaceutics11070329

Pillay V, Dott C, Choonara YE et al (2013) A Review of the Effect of Processing Variables on the Fabrication of Electrospun Nanofibers for Drug Delivery Applications. J Nanomater 2013:1–22. https://doi.org/10.1155/2013/789289

Putti M, Simonet M, Solberg R, Peters GWM (2015) Electrospinning poly(ε-caprolactone) under controlled environmental conditions: Influence on fiber morphology and orientation. Polymer (Guildf) 63:189–195. https://doi.org/10.1016/j.polymer.2015.03.006

Jóźwiak T, Filipkowska U, Szymczyk P et al (2017) Effect of ionic and covalent crosslinking agents on properties of chitosan beads and sorption effectiveness of Reactive Black 5 dye. React Funct Polym 114:58–74. https://doi.org/10.1016/j.reactfunctpolym.2017.03.007

Nematidil N, Sadeghi M, Nezami S, Sadeghi H (2019) Synthesis and characterization of Schiff-base based chitosan-g-glutaraldehyde/NaMMTNPs-APTES for removal Pb2+ and Hg2+ ions. Carbohydr Polym 222:114971. https://doi.org/10.1016/j.carbpol.2019.114971

Pereira MBB, França DB, Araújo RC et al (2020) Amino hydroxyapatite/chitosan hybrids reticulated with glutaraldehyde at different pH values and their use for diclofenac removal. Carbohydr Polym 236:116036. https://doi.org/10.1016/j.carbpol.2020.116036

Yun Y-H, Lee C-M, Kim Y-S, Yoon S-D (2017) Preparation of chitosan/polyvinyl alcohol blended films containing sulfosuccinic acid as the crosslinking agent using UV curing process. Food Res Int 100:377–386. https://doi.org/10.1016/j.foodres.2017.07.030

Nataraj D, Sakkara S, Meghwal M, Reddy N (2018) Crosslinked chitosan films with controllable properties for commercial applications. Int J Biol Macromol 120:1256–1264. https://doi.org/10.1016/j.ijbiomac.2018.08.187

Tacias-Pascacio VG, García-Parra E, Vela-Gutiérrez G et al (2019) Genipin as An Emergent Tool in the Design of Biocatalysts: Mechanism of Reaction and Applications. Catalysts 9:1035. https://doi.org/10.3390/catal9121035

Campiglio CE, Ponzini S, De Stefano P et al (2020) Cross-Linking Optimization for Electrospun Gelatin: Challenge of Preserving Fiber Topography. Polymers (Basel) 12:2472. https://doi.org/10.3390/polym12112472

Miraftab M, Saifullah AN, Çay A (2015) Physical anofibersat of electrospun poly(vinyl alcohol) anofibers: comparative study on methanol and heat-based crosslinking. J Mater Sci 50:1943–1957. https://doi.org/10.1007/s10853-014-8759-1

Bhattacharjee P, Ahearne M (2021) Significance of Crosslinking Approaches in the Development of Next Generation Hydrogels for Corneal Tissue Engineering. Pharmaceutics 13:319. https://doi.org/10.3390/pharmaceutics13030319

Adamiak K, Sionkowska A (2020) Current methods of collagen cross-linking: Review. Int J Biol Macromol 161:550–560. https://doi.org/10.1016/j.ijbiomac.2020.06.075

Haugh MG, Jaasma MJ, O’Brien FJ (2009) The effect of dehydrothermal treatment on the mechanical and structural properties of collagen-GAG scaffolds. J Biomed Mater Res A 89A:363–369. https://doi.org/10.1002/jbm.a.31955

Chau DYS, Collighan RJ, Verderio EAM et al (2005) The cellular response to transglutaminase-cross-linked collagen. Biomaterials 26:6518–6529. https://doi.org/10.1016/j.biomaterials.2005.04.017

Sengor M, Ozgun A, Gunduz O, Altintas S (2020) Aqueous electrospun core/shell nanofibers of PVA/microbial transglutaminase cross-linked gelatin composite scaffolds. Mater Lett 263:127233. https://doi.org/10.1016/j.matlet.2019.127233

Meng L, Arnoult O, Smith M, Wnek GE (2012) Electrospinning of in situ crosslinked collagen nanofibers. J Mater Chem 22:19412. https://doi.org/10.1039/c2jm31618h

Barnes CP, Pemble CW, Brand DD et al (2007) Cross-Linking Electrospun Type II Collagen Tissue Engineering Scaffolds with Carbodiimide in Ethanol. Tissue Eng 13:1593–1605. https://doi.org/10.1089/ten.2006.0292

Dong B, Arnoult O, Smith ME, Wnek GE (2009) Electrospinning of Collagen Nanofiber Scaffolds from Benign Solvents. Macromol Rapid Commun 30:539–542. https://doi.org/10.1002/marc.200800634

Torres-Giner S, Gimeno-Alcañiz JV, Ocio MJ, Lagaron JM (2009) Comparative Performance of Electrospun Collagen Nanofibers Cross-linked by Means of Different Methods. ACS Appl Mater Interfaces 1:218–223. https://doi.org/10.1021/am800063x

Mu C, Liu F, Cheng Q et al (2010) Collagen Cryogel Cross-Linked by Dialdehyde Starch. Macromol Mater Eng 295:100–107. https://doi.org/10.1002/mame.200900292

Ullah S, Hashmi M, Hussain N et al (2020) Stabilized nanofibers of polyvinyl alcohol (PVA) crosslinked by unique method for efficient removal of heavy metal ions. Journal of Water Process Engineering 33:101111. https://doi.org/10.1016/j.jwpe.2019.101111

Göksen G, Fabra MJ, Pérez-Cataluña A et al (2021) Biodegradable active food packaging structures based on hybrid cross-linked electrospun polyvinyl alcohol fibers containing essential oils and their application in the preservation of chicken breast fillets. Food Packag Shelf Life 27:100613. https://doi.org/10.1016/j.fpsl.2020.100613

Mozaffari A, Parvinzadeh Gashti M, Mirjalili M, Parsania M (2021) Argon and Argon-Oxygen Plasma Surface Modification of Gelatin Nanofibers for Tissue Engineering Applications. Membranes (Basel) 11:31. https://doi.org/10.3390/membranes11010031

Bigi A, Cojazzi G, Panzavolta S et al (2001) Mechanical and thermal properties of gelatin films at different degrees of glutaraldehyde crosslinking. Biomaterials 22:763–768. https://doi.org/10.1016/S0142-9612(00)00236-2

Lu W, Ma M, Xu H et al (2015) Gelatin nanofibers prepared by spiral-electrospinning and cross-linked by vapor and liquid-phase glutaraldehyde. Mater Lett 140:1–4. https://doi.org/10.1016/j.matlet.2014.10.146

Kuijpers AJ, Engbers GHM, Krijgsveld J et al (2000) Cross-linking and anofibersation of gelatin matrices for biomedical applications. J Biomater Sci Polym Ed 11:225–243. https://doi.org/10.1163/156856200743670

Chang J-Y, Lin J-H, Yao C-H et al (2007) In Vivo Evaluation of a Biodegradable EDC/NHS-Cross-Linked Gelatin Peripheral Nerve Guide Conduit Material. Macromol Biosci 7:500–507. https://doi.org/10.1002/mabi.200600257

Skopinska-Wisniewska J, Tuszynska M, Olewnik-Kruszkowska E (2021) Comparative Study of Gelatin Hydrogels Modified by Various Cross-Linking Agents. Materials 14:396. https://doi.org/10.3390/ma14020396

Jalaja K, Kumar PRA, Dey T et al (2014) Modified dextran cross-linked electrospun gelatin anofibers for biomedical applications. Carbohydr Polym 114:467–475. https://doi.org/10.1016/j.carbpol.2014.08.023

Bigi A, Cojazzi G, Panzavolta S et al (2002) Stabilization of gelatin films by crosslinking with genipin. Biomaterials 23:4827–4832. https://doi.org/10.1016/S0142-9612(02)00235-1

Yi JB, Kim YT, Bae HJ et al (2006) Influence of Transglutaminase-Induced Cross-Linking on Properties of Fish Gelatin Films. J Food Sci 71:E376–E383. https://doi.org/10.1111/j.1750-3841.2006.00191.x

Cui S, Yao B, Gao M et al (2017) Effects of pectin structure and crosslinking method on the properties of crosslinked pectin nanofibers. Carbohydr Polym 157:766–774. https://doi.org/10.1016/j.carbpol.2016.10.052

Song F, Zhang L-M, Yang C, Yan L (2009) Genipin-crosslinked casein hydrogels for controlled drug delivery. Int J Pharm 373:41–47. https://doi.org/10.1016/j.ijpharm.2009.02.005

Qin Z, Jia X, Liu Q et al (2020) Enhancing physical properties of chitosan/pullulan electrospinning nanofibers via green crosslinking strategies. Carbohydr Polym 247:116734. https://doi.org/10.1016/j.carbpol.2020.116734

Fanchen S, Jing G, Qiang Y et al (2020) Preparation and biocompatibility of EDC-NHS crosslinked chitosan-polyethyleneoxide-silk fibroin electrospun nanofibers. Acta Materiae Compositae Sinica 37(11):2889–2896

Yang X, Wang X, Yu F et al (2016) Hyaluronic acid/EDC/NHS-crosslinked green electrospun silk fibroin nanofibrous scaffolds for tissue engineering. RSC Adv 6:99720–99728. https://doi.org/10.1039/C6RA13713J

Egli T (2015) Microbial growth and physiology: a call for better craftsmanship. Front Microbiol 06:287. https://doi.org/10.3389/fmicb.2015.00287

Jurić S, Jurić M, Režek Jambrak A, Vinceković M (2021) Tailoring Alginate/Chitosan Microparticles Loaded with Chemical and Biological Agents for Agricultural Application and Production of Value-Added Foods. Appl Sci 11:4061. https://doi.org/10.3390/app11094061

Vinceković M, Jalšenjak N, Topolovec-Pintarić S et al (2016) Encapsulation of Biological and Chemical Agents for Plant Nutrition and Protection: Chitosan/Alginate Microcapsules Loaded with Copper Cations and Trichoderma viride. J Agric Food Chem 64:8073–8083. https://doi.org/10.1021/acs.jafc.6b02879

Jurić S, Tanuwidjaja I, Fuka MM et al (2021) Encapsulation of two fermentation agents, Lactobacillus sakei and calcium ions in microspheres. Colloids Surf B Biointerfaces 197:111387. https://doi.org/10.1016/j.colsurfb.2020.111387

Ghasemlou M, Daver F, Ivanova EP et al (2021) Surface modifications of nanocellulose: From synthesis to high-performance nanocomposites. Prog Polym Sci 119:101418. https://doi.org/10.1016/j.progpolymsci.2021.101418

Mondal S (2017) Preparation, properties and applications of nanocellulosic materials. Carbohydr Polym 163:301–316. https://doi.org/10.1016/j.carbpol.2016.12.050

Frone AN, Berlioz S, Chailan J-F, Panaitescu DM (2013) Morphology and thermal properties of PLA–cellulose nanofibers composites. Carbohydr Polym 91:377–384. https://doi.org/10.1016/j.carbpol.2012.08.054

Narita C, Okahisa Y, Yamada K (2019) A novel technique in the preparation of environmentally friendly cellulose nanofiber/silk fibroin fiber composite films with improved thermal and mechanical properties. J Clean Prod 234:200–207. https://doi.org/10.1016/j.jclepro.2019.06.215

Lahiri D, Nag M, Dutta B et al (2021) Bacterial Cellulose: Production, Characterization, and Application as Antimicrobial Agent. Int J Mol Sci 22:12984. https://doi.org/10.3390/ijms222312984

Aswini K, Gopal NO, Uthandi S (2020) Optimized culture conditions for bacterial cellulose production by Acetobacter senegalensis MA1. BMC Biotechnol 20:46. https://doi.org/10.1186/s12896-020-00639-6

Yao J, Chen S, Chen Y et al (2017) Macrofibers with High Mechanical Performance Based on Aligned Bacterial Cellulose Nanofibers. ACS Appl Mater Interfaces 9:20330–20339. https://doi.org/10.1021/acsami.6b14650

Zhai X, Lin D, Li W, Yang X (2020) Improved characterization of nanofibers from bacterial cellulose and its potential application in fresh-cut apples. Int J Biol Macromol 149:178–186. https://doi.org/10.1016/j.ijbiomac.2020.01.230

Göktürk I, Tamahkar E, Yılmaz F, Denizli A (2018) Protein depletion with bacterial cellulose nanofibers. J Chromatogr B 1099:1–9. https://doi.org/10.1016/j.jchromb.2018.08.030

Meneguin AB, da Silva BH, Sábio RM et al (2020) Spray-dried bacterial cellulose nanofibers: A new generation of pharmaceutical excipient intended for intestinal drug delivery. Carbohydr Polym 249:116838. https://doi.org/10.1016/j.carbpol.2020.116838

Parit M, Du H, Zhang X et al (2020) Polypyrrole and cellulose nanofiber based composite films with improved physical and electrical properties for electromagnetic shielding applications. Carbohydr Polym 240:116304. https://doi.org/10.1016/j.carbpol.2020.116304

Wang J, Lu X, Ng PF et al (2015) Polyethylenimine coated bacterial cellulose nanofiber membrane and application as adsorbent and catalyst. J Colloid Interface Sci 440:32–38. https://doi.org/10.1016/j.jcis.2014.10.035

Samrot AV, Samanvitha SK, Shobana N et al (2021) The Synthesis, Characterization and Applications of Polyhydroxyalkanoates (PHAs) and PHA-Based Nanoparticles. Polymers (Basel) 13:3302. https://doi.org/10.3390/polym13193302

Mutlu G, Calamak S, Ulubayram K, Guven E (2018) Curcumin-loaded electrospun PHBV nanofibers as potential wound-dressing material. J Drug Deliv Sci Technol 43:185–193. https://doi.org/10.1016/j.jddst.2017.09.017

Martínez-Sanz M, Lopez-Rubio A, Villano M et al (2016) Production of bacterial nanobiocomposites of polyhydroxyalkanoates derived from waste and bacterial nanocellulose by the electrospinning enabling melt compounding method. J Appl Polym Sci 133:n/a–n/a. https://doi.org/10.1002/app.42486

Melendez-Rodriguez B, Castro-Mayorga JL, Reis MAM et al (2018) Preparation and Characterization of Electrospun Food Biopackaging Films of Poly(3-hydroxybutyrate-co-3-hydroxyvalerate) Derived From Fruit Pulp Biowaste. Front Sustain Food Syst 2:38. https://doi.org/10.3389/fsufs.2018.00038

Zupančič Š, Škrlec K, Kocbek P et al (2019) Effects of Electrospinning on the Viability of Ten Species of Lactic Acid Bacteria in Poly(Ethylene Oxide) Nanofibers. Pharmaceutics 11:483. https://doi.org/10.3390/pharmaceutics11090483

Brandelli A (2020) The interaction of nanostructured antimicrobials with biological systems: Cellular uptake, trafficking and potential toxicity. Food Sci Human Wellness 9:8–20. https://doi.org/10.1016/j.fshw.2019.12.003

Diep E, Schiffman JD (2021) Encapsulating bacteria in alginate-based electrospun nanofibers. Biomater Sci 9:4364–4373. https://doi.org/10.1039/D0BM02205E

Škrlec K, Zupančič Š, Prpar Mihevc S et al (2019) Development of electrospun nanofibers that enable high loading and long-term viability of probiotics. Eur J Pharm Biopharm 136:108–119. https://doi.org/10.1016/j.ejpb.2019.01.013

Zhang C, Yuan X, Wu L et al (2005) Study on morphology of electrospun poly(vinyl alcohol) mats. Eur Polym J 41:423–432. https://doi.org/10.1016/j.eurpolymj.2004.10.027

Mi H-Y, Salick MR, Jing X et al (2015) Electrospinning of unidirectionally and orthogonally aligned thermoplastic polyurethane nanofibers: Fiber orientation and cell migration. J Biomed Mater Res A 103:593–603. https://doi.org/10.1002/jbm.a.35208

Kargar M, Wang J, Nain AS, Behkam B (2012) Controlling bacterial adhesion to surfaces using topographical cues: a study of the interaction of Pseudomonas aeruginosa with nanofiber-textured surfaces. Soft Matter 8:10254. https://doi.org/10.1039/c2sm26368h

Ye Z, Kim A, Mottley CY et al (2018) Design of Nanofiber Coatings for Mitigation of Microbial Adhesion: Modeling and Application to Medical Catheters. ACS Appl Mater Interfaces 10:15477–15486. https://doi.org/10.1021/acsami.8b02907

Biagini F, Calvigioni M, De Maria C et al (2022) Study of the Adhesion of the Human Gut Microbiota on Electrospun Structures. Bioengineering 9:96. https://doi.org/10.3390/bioengineering9030096

Jin X, Marshall JS (2020) Mechanics of biofilms formed of bacteria with fimbriae appendages. PLoS ONE 15:e0243280. https://doi.org/10.1371/journal.pone.0243280

Hamdan N, Yamin A, Hamid SA et al (2021) Functionalized Antimicrobial Nanofibers: Design Criteria and Recent Advances. J Funct Biomater 12:59. https://doi.org/10.3390/jfb12040059

Hsu LC, Fang J, Borca-Tasciuc DA et al (2013) Effect of Micro- and Nanoscale Topography on the Adhesion of Bacterial Cells to Solid Surfaces. Appl Environ Microbiol 79:2703–2712. https://doi.org/10.1128/AEM.03436-12

Mortimer CJ, Burke L (2016) Microbial Interactions with Nanostructures and their Importance for the Development of Electrospun Nanofibrous Materials used in Regenerative Medicine and Filtration. J Microb Biochem Technol 8:195–201. https://doi.org/10.4172/1948-5948.1000285

Zhang C-L, Yu S-H (2014) Nanoparticles meet electrospinning: recent advances and future prospects. Chem Soc Rev 43:4423. https://doi.org/10.1039/c3cs60426h

Lee S, Jin G, Jang J-H (2014) Electrospun nanofibers as versatile interfaces for efficient gene delivery. J Biol Eng 8:30. https://doi.org/10.1186/1754-1611-8-30

Letnik I, Avrahami R, Rokem JS et al (2015) Living Composites of Electrospun Yeast Cells for Bioremediation and Ethanol Production. Biomacromol 16:3322–3328. https://doi.org/10.1021/acs.biomac.5b00970

Miller RJ, Chan CY, Rastogi A et al (2018) Combining electrospun nanofibers with cell-encapsulating hydrogel fibers for neural tissue engineering. J Biomater Sci Polym Ed 29:1625–1642. https://doi.org/10.1080/09205063.2018.1479084

Stojanov S, Berlec A (2020) Electrospun Nanofibers as Carriers of Microorganisms, Stem Cells, Proteins, and Nucleic Acids in Therapeutic and Other Applications. Front Bioeng Biotechnol 8:130. https://doi.org/10.3389/fbioe.2020.00130

Batt CA (2014) Lactobacillus. In: Batt C, Tortorello M-L (eds) Encyclopedia of food microbiology. Elsevier, Amsterdam, pp. 409–412.

ZsK N, Wagner I, Suhajda A et al (2014) Nanofibrous solid dosage form of living bacteria prepared by electrospinning. Express Polym Lett 8:352–361. https://doi.org/10.3144/expresspolymlett.2014.39

Ceylan Z, Meral R, Karakaş CY et al (2018) A novel strategy for probiotic bacteria: Ensuring microbial stability of fish fillets using characterized probiotic bacteria-loaded nanofibers. Innov Food Sci Emerg Technol 48:212–218. https://doi.org/10.1016/j.ifset.2018.07.002

Guan N, Liu L (2020) Microbial response to acid stress: mechanisms and applications. Appl Microbiol Biotechnol 104:51–65. https://doi.org/10.1007/s00253-019-10226-1

Fung W-Y, Yuen K-H, Liong M-T (2011) Agrowaste-Based Nanofibers as a Probiotic Encapsulant: Fabrication and Characterization. J Agric Food Chem 59:8140–8147. https://doi.org/10.1021/jf2009342

López-Rubio A, Sanchez E, Sanz Y, Lagaron JM (2009) Encapsulation of Living Bifidobacteria in Ultrathin PVOH Electrospun Fibers. Biomacromol 10:2823–2829. https://doi.org/10.1021/bm900660b

Jayani T, Sanjeev B, Marimuthu S, Uthandi S (2020) Bacterial Cellulose Nano Fiber (BCNF) as carrier support for the immobilization of probiotic, Lactobacillus acidophilus 016. Carbohydr Polym 250:116965. https://doi.org/10.1016/j.carbpol.2020.116965

Kumuthan M, Lakshmanan A, Sabarinathan K et al (2021) Immobilization and characterization of Bacillus subtilis in PVA-chitosan composite Nanofiber Pharma Innov 10:1541–1545. https://doi.org/10.22271/tpi.2021.v10.i12v.9616

Zhang Y, Huang X, Duan B et al (2007) (2007) Preparation of electrospun chitosan/poly(vinyl alcohol) membranes. Colloid Polym Sci 285:855–863. https://doi.org/10.1007/s00396-006-1630-4

Knop K, Hoogenboom R, Fischer D, Schubert US (2010) Poly(ethylene glycol) in Drug Delivery: Pros and Cons as Well as Potential Alternatives. Angew Chem Int Ed 49:6288–6308. https://doi.org/10.1002/anie.200902672

Bodzen A, Jossier A, Dupont S et al (2021) Design of a new lyoprotectant increasing freeze-dried Lactobacillus strain survival to long-term storage. BMC Biotechnol 21:66. https://doi.org/10.1186/s12896-021-00726-2

Feng K, Zhai M-Y, Zhang Y et al (2018) Improved Viability and Thermal Stability of the Probiotics Encapsulated in a Novel Electrospun Fiber Mat. J Agric Food Chem 66:10890–10897. https://doi.org/10.1021/acs.jafc.8b02644

Tao T, Ding Z, Hou D et al (2019) Influence of polysaccharide as co-encapsulant on powder characteristics, survival and viability of microencapsulated Lactobacillus paracasei Lpc-37 by spray drying. J Food Eng 252:10–17. https://doi.org/10.1016/j.jfoodeng.2019.02.009

Feng K, Huang R, Wu R et al (2020) A novel route for double-layered encapsulation of probiotics with improved viability under adverse conditions. Food Chem 310:125977. https://doi.org/10.1016/j.foodchem.2019.125977

Grilc NK, Zidar A, Kocbek P et al (2023) Nanofibers with genotyped Bacillus strains exhibiting antibacterial and immunomodulatory activity. J Control Release 355:371–384. https://doi.org/10.1016/j.jconrel.2023.01.082

Ghalehjooghi HD, Tajik H, Shahbazi Y (2023) Development and characterization of active packaging nanofiber mats based on gelatin-sodium alginate containing probiotic microorganisms to improve the shelf-life and safety quality of silver carp fillets. Int J Food Microbiol 384:109984. https://doi.org/10.1016/j.ijfoodmicro.2022.109984

Nawaz A, Irshad S, Walayat N et al (2023) Fabrication and Characterization of Apple-Pectin–PVA-Based Nanofibers for Improved Viability of Probiotics. Foods 12:3194. https://doi.org/10.3390/foods12173194

Fareed F, Saeed F, Afzaal M et al (2022) Fabrication of electrospun gum Arabic–polyvinyl alcohol blend nanofibers for improved viability of the probiotic. J Food Sci Technol 59:4812–4821. https://doi.org/10.1007/s13197-022-05567-1

Ghorbani S, Maryam A (2021) Encapsulation of lactic acid bacteria and Bifidobacteria using starch-sodium alginate nanofibers to enhance viability in food model. J Food Process Preserv 45:e16048. https://doi.org/10.1111/jfpp.16048

Chang X, Lambo MT, Liu D, Li X (2021) The study of the potential application of nanofiber microcapsules loading lactobacillus in targeted delivery of digestive tract in vitro. LWT 148:111692. https://doi.org/10.1016/j.lwt.2021.111692

Hirsch E, Pantea E, Vass P et al (2021) Probiotic bacteria stabilized in orally dissolving nanofibers prepared by high-speed electrospinning. Food Bioprod Process 128:84–94. https://doi.org/10.1016/j.fbp.2021.04.016

Yu H, Liu W, Li D et al (2020) Targeting Delivery System for Lactobacillus Plantarum Based on Functionalized Electrospun Nanofibers. Polymers (Basel) 12:1565. https://doi.org/10.3390/polym12071565

Akbar Z, Zahoor T, Huma N et al (2018) Electrospun probiotics: an alternative for encapsulation. J Biol Regul Homeost Agents 32:1551–1556

Xu C, Ma J, Wang W et al (2022) Preparation of pectin-based nanofibers encapsulating Lactobacillus rhamnosus 1.0320 by electrospinning. Food Hydrocoll 124:107216. https://doi.org/10.1016/j.foodhyd.2021.107216

Klein S, Kuhn J, Avrahami R et al (2009) Encapsulation of Bacterial Cells in Electrospun Microtubes. Biomacromol 10:1751–1756. https://doi.org/10.1021/bm900168v

Xie S, Tai S, Song H et al (2016) Genetically engineering of Escherichia coli and immobilization on electrospun fibers for drug delivery purposes. J Mater Chem B 4:6820–6829. https://doi.org/10.1039/C6TB01165A

Yilmaz MT, Taylan O, Karakas CY, Dertli E (2020) An alternative way to encapsulate probiotics within electrospun alginate nanofibers as monitored under simulated gastrointestinal conditions and in kefir. Carbohydr Polym 244:116447. https://doi.org/10.1016/j.carbpol.2020.116447

Salalha W, Kuhn J, Dror Y, Zussman E (2006) Encapsulation of bacteria and viruses in electrospun nanofibres. Nanotechnology 17:4675–4681. https://doi.org/10.1088/0957-4484/17/18/025

Liu H, Gong J, Chabot D et al (2018) Improved survival of Lactobacillus zeae LB1 in a spray dried alginate-protein matrix. Food Hydrocoll 78:100–108. https://doi.org/10.1016/j.foodhyd.2017.07.004

Kim J, Muhammad N, Jhun BH, Yoo J-W (2016) Probiotic delivery systems: a brief overview. J Pharm Investig 46:377–386. https://doi.org/10.1007/s40005-016-0259-7

Zepeda-Hernández A, Garcia-Amezquita LE, Requena T, García-Cayuela T (2021) Probiotics, prebiotics, and synbiotics added to dairy products: Uses and applications to manage type 2 diabetes. Food Res Int 142:110208. https://doi.org/10.1016/j.foodres.2021.110208

Ranadheera C, Vidanarachchi J, Rocha R et al (2017) Probiotic Delivery through Fermentation: Dairy vs. Non-Dairy Beverages Fermentation 3:67. https://doi.org/10.3390/fermentation3040067

Naseem Z, Mir SA, Wani SM et al (2023) Probiotic-fortified fruit juices: Health benefits, challenges, and future perspective. Nutrition 115:112154. https://doi.org/10.1016/j.nut.2023.112154

Lasta EL, da Silva Pereira Ronning E, Dekker RFH, da Cunha MAA (2021) Encapsulation and dispersion of Lactobacillus acidophilus in a chocolate coating as a strategy for maintaining cell viability in cereal bars. Sci Rep 11:20550. https://doi.org/10.1038/s41598-021-00077-0

Ceylan Z, Meral R, Cavidoglu I et al (2018) A new application on fatty acid stability of fish fillets: Coating with probiotic bacteria-loaded polymer-based characterized nanofibers. J Food Saf 38:e12547. https://doi.org/10.1111/jfs.12547

Durazzo A, Nazhand A, Lucarini M et al (2020) An Updated Overview on Nanonutraceuticals: Focus on Nanoprebiotics and Nanoprobiotics. Int J Mol Sci 21:2285. https://doi.org/10.3390/ijms21072285

Qi W, Liang X, Yun T, Guo W (2019) Growth and survival of microencapsulated probiotics prepared by emulsion and internal gelation. J Food Sci Technol 56:1398–1404. https://doi.org/10.1007/s13197-019-03616-w

Khaji F, Mousavi ZE, Kiani H, Razavi SH (2020) The investigation of probiotics viability, physicochemical and rheological properties of a probiotic dessert based on sesame paste (Tahini). J Food Bioprocess Eng 4:105–11. https://doi.org/10.22059/jfabe.2021.317525.1080

Homayouni A, Azizi A, Ehsani MR et al (2008) Effect of microencapsulation and resistant starch on the probiotic survival and sensory properties of synbiotic ice cream. Food Chem 111:50–55. https://doi.org/10.1016/j.foodchem.2008.03.036

Atraki R, Azizkhani M (2021) Survival of probiotic bacteria nanoencapsulated within biopolymers in a simulated gastrointestinal model. Innov Food Sci Emerg Technol 72:102750. https://doi.org/10.1016/j.ifset.2021.102750

Mojaveri SJ, Hosseini SF, Gharsallaoui A (2020) Viability improvement of Bifidobacterium animalis Bb12 by encapsulation in chitosan/poly(vinyl alcohol) hybrid electrospun fiber mats. Carbohydr Polym 241:116278. https://doi.org/10.1016/j.carbpol.2020.116278

Anselmo AC, McHugh KJ, Webster J et al (2016) Layer-by-Layer Encapsulation of Probiotics for Delivery to the Microbiome. Adv Mater 28:9486–9490. https://doi.org/10.1002/adma.201603270

Zare M, Dziemidowicz K, Williams GR, Ramakrishna S (2021) Encapsulation of Pharmaceutical and Nutraceutical Active Ingredients Using Electrospinning Processes. Nanomaterials 11:1968. https://doi.org/10.3390/nano11081968

Selatile MK, Ojijo V, Sadiku R, Ray SS (2020) Development of bacterial-resistant electrospun polylactide membrane for air filtration application: Effects of reduction methods and their loadings. Polym Degrad Stab 178:109205. https://doi.org/10.1016/j.polymdegradstab.2020.109205

Deng L, Zhang H (2020) Recent Advances in Probiotics Encapsulation by Electrospinning. ES Food and Agroforestry 2:3–12. https://doi.org/10.30919/esfaf1120

Varishetty MM, Qiu W, Gao Y, Chen W (2010) Structure, electrical and optical properties of (PVA/LiAsF 6) polymer composite electrolyte films. Polym Eng Sci 50:878–884. https://doi.org/10.1002/pen.21437

Huang H, Song Y, Zhang Y et al (2022) Electrospun Nanofibers: Current Progress and Applications in Food Systems. J Agric Food Chem 70:1391–1409. https://doi.org/10.1021/acs.jafc.1c05352

Eng A, Borenstein E (2019) Microbial community design: methods, applications, and opportunities. Curr Opin Biotechnol 58:117–128. https://doi.org/10.1016/j.copbio.2019.03.002

Wassermann B, Abdelfattah A, Cernava T et al (2022) Microbiome-based biotechnology for reducing food loss post harvest. Curr Opin Biotechnol 78:102808. https://doi.org/10.1016/j.copbio.2022.102808

Jurić S, Đermić E, Topolovec-Pintarić S et al (2019) Physicochemical properties and release characteristics of calcium alginate microspheres loaded with Trichoderma viride spores. J Integr Agric 18:2534–2548. https://doi.org/10.1016/S2095-3119(19)62634-1

Jurić S, Sopko Stracenski K, Król-Kilińska Ż et al (2020) The enhancement of plant secondary metabolites content in Lactuca sativa L. by encapsulated bioactive agents. Sci Rep 10:3737. https://doi.org/10.1038/s41598-020-60690-3

Jurić S, Šegota S, Vinceković M (2019) Influence of surface morphology and structure of alginate microparticles on the bioactive agents release behavior. Carbohydr Polym 218:234–242. https://doi.org/10.1016/j.carbpol.2019.04.096

Vinceković M, Jurić S, Đermić E, Topolovec-Pintarić S (2017) Kinetics and Mechanisms of Chemical and Biological Agents Release from Biopolymeric Microcapsules. J Agric Food Chem 65:9608–9617. https://doi.org/10.1021/acs.jafc.7b04075

Spasova M, Manolova N, Naydenov M et al (2011) Electrospun biohybrid materials for plant biocontrol containing chitosan and Trichoderma viride spores. J Bioact Compat Polym 26:48–55. https://doi.org/10.1177/0883911510391446

Vinceković M, Maslov Bandić L, Jurić S et al (2019) The enhancement of bioactive potential in Vitis vinifera leaves by application of microspheres loaded with biological and chemical agents. J Plant Nutr 42:543–558. https://doi.org/10.1080/01904167.2019.1568467

Jurić S, Jurić M, Król-Kilińska Ż et al (2022) Sources, stability, encapsulation and application of natural pigments in foods. Food Rev Intl 38:1735–1790. https://doi.org/10.1080/87559129.2020.1837862

Lee K, Lee S (2012) Multifunctionality of poly(vinyl alcohol) nanofiber webs containing titanium dioxide. J Appl Polym Sci 124:4038–4046. https://doi.org/10.1002/app.34929

Krishnamoorthy V, Rajiv S (2017) Potential Seed Coatings Fabricated from Electrospinning Hexaaminocyclotriphosphazene and Cobalt Nanoparticles Incorporated Polyvinylpyrrolidone for Sustainable Agriculture. ACS Sustain Chem Eng 5:146–152. https://doi.org/10.1021/acssuschemeng.6b01088

Hussain Z, Khan MA, Iqbal F et al (2019) Electrospun Microbial-Encapsulated Composite-Based Plasticized Seed Coat for Rhizosphere Stabilization and Sustainable Production of Canola ( Brassica napus L.). J Agric Food Chem 67:5085–5095. https://doi.org/10.1021/acs.jafc.8b06505

Raja K, Prabhu C, Subramanian KS, Govindaraju K (2021) Electrospun polyvinyl alcohol (PVA) nanofibers as carriers for hormones (IAA and GA3) delivery in seed invigoration for enhancing germination and seedling vigor of agricultural crops (groundnut and black gram). Polym Bull 78:6429–6440. https://doi.org/10.1007/s00289-020-03435-6

Castañeda LMF, Genro C, Roggia I et al (2014) Innovative Rice Seed Coating (Oryza Sativa) with Polymer Nanofibres and Microparticles Using the Electrospinning Method. Journal of Research Updates in Polymer Science 3:33–39. https://doi.org/10.6000/1929-5995.2014.03.01.5

Farias BV, Pirzada T, Mathew R et al (2019) Electrospun Polymer Nanofibers as Seed Coatings for Crop Protection. ACS Sustain Chem Eng 7:19848–19856. https://doi.org/10.1021/acssuschemeng.9b05200

Mukiri C, Raja K, Senthilkumar M et al (2022) Immobilization of beneficial microbe Methylobacterium aminovorans in electrospun nanofibre as potential seed coatings for improving germination and growth of groundnut Arachis hypogaea. Plant Growth Regul 97:419–427. https://doi.org/10.1007/s10725-021-00737-1

Zainul Armir NA, Zulkifli A, Gunaseelan S et al (2021) Regenerated Cellulose Products for Agricultural and Their Potential: A Review. Polymers (Basel) 13:3586. https://doi.org/10.3390/polym13203586

Saito H, Yamashita Y, Sakata N et al (2021) Covering Soybean Leaves With Cellulose Nanofiber Changes Leaf Surface Hydrophobicity and Confers Resistance Against Phakopsora pachyrhizi. Front Plant Sci 12:726565. https://doi.org/10.3389/fpls.2021.726565

Walsh B, Ciais P, Janssens IA et al (2017) Pathways for balancing CO2 emissions and sinks. Nat Commun 8:14856. https://doi.org/10.1038/ncomms14856

Agostino V, Massaglia G, Gerosa M et al (2020) Environmental electroactive consortia as reusable biosensing element for freshwater toxicity monitoring. N Biotechnol 55:36–45. https://doi.org/10.1016/j.nbt.2019.09.005

Eroglu E, Agarwal V, Bradshaw M et al (2012) Nitrate removal from liquid effluents using microalgae immobilized on chitosan nanofiber mats. Green Chem 14:2682. https://doi.org/10.1039/c2gc35970g

Massaglia G, Sacco A, Chiodoni A et al (2021) Living Bacteria Directly Embedded into Electrospun Nanofibers: Design of New Anode for Bio-Electrochemical Systems. Nanomaterials 11:3088. https://doi.org/10.3390/nano11113088

Wang M, Hou J, Yu D-G et al (2020) Electrospun tri-layer nanodepots for sustained release of acyclovir. J Alloys Compd 846:156471. https://doi.org/10.1016/j.jallcom.2020.156471

Wang M, Li D, Li J et al (2020) Electrospun Janus zein–PVP nanofibers provide a two-stage controlled release of poorly water-soluble drugs. Mater Des 196:109075. https://doi.org/10.1016/j.matdes.2020.109075

Sanchez J-L, Laberty-Robert C (2021) A novel microbial fuel cell electrode design: prototyping a self-standing one-step bacteria-encapsulating bioanode with electrospinning. J Mater Chem B 9:4309–4318. https://doi.org/10.1039/D1TB00680K

Quaglio M, Chiodoni A, Massaglia G et al (2018) Electrospinning-on-Electrode Assembly for Air-Cathodes in Microbial Fuel Cells. Adv Mater Interfaces 5:1801107. https://doi.org/10.1002/admi.201801107

Aiswarya Devi S, Harshiny M, Matheswaran M (2018) Role of Nanofibers in Bioremediation. Springer link, pp 99–114

Sarioglu OF, Keskin NOS, Celebioglu A et al (2017) Bacteria encapsulated electrospun nanofibrous webs for remediation of methylene blue dye in water. Colloids Surf B Biointerfaces 152:245–251. https://doi.org/10.1016/j.colsurfb.2017.01.034

Lv H, Liu Y, Bai Y et al (2023) Recent Combinations of Electrospinning with Photocatalytic Technology for Treating Polluted Water. Catalysts 13:758. https://doi.org/10.3390/catal13040758

Zamel D, Khan AU (2021) Bacterial immobilization on cellulose acetate based nanofibers for methylene blue removal from wastewater: Mini-review. Inorg Chem Commun 131:108766. https://doi.org/10.1016/j.inoche.2021.108766

Rossi M, Cubadda F, Dini L et al (2014) Scientific basis of nanotechnology, implications for the food sector and future trends. Trends Food Sci Technol 40:127–148. https://doi.org/10.1016/j.tifs.2014.09.004

EFSA (2023) https://efsa.onlinelibrary.wiley.com/. Applied 31 May 2023

More S, Bampidis V, Benford D et al (2021) Guidance on risk assessment of nanomaterials to be applied in the food and feed chain: human and animal health. EFSA Journal 19:e06768. https://doi.org/10.2903/j.efsa.2021.6768

Liu L, Kong F (2021) The behavior of nanocellulose in gastrointestinal tract and its influence on food digestion. J Food Eng 292:110346. https://doi.org/10.1016/j.jfoodeng.2020.110346

ECHA (2023) https://echa.europa.eu/about-us. Applied 31 May 2023

EPA (2023) https://www.epa.gov/. Applied 31 May 2023

ISO (2023) https://www.iso.org/home.html. Applied 31 May 2023

OECD (2023) https://www.oecd.org/. Applied 31 May 2023

Gottardo S, Mech A, Drbohlavová J et al (2021) Towards safe and sustainable innovation in nanotechnology: State-of-play for smart nanomaterials. NanoImpact 21:100297. https://doi.org/10.1016/j.impact.2021.100297

Manžuch Z, Akelytė R, Camboni M, Carlander D, García RP, Kriščiūnaitė G, Baun A, Kaegi R (2021) Study on the Product Lifecycles, Waste Recycling and the Circular Economy for Nanomaterials. European Chemicals Agency, pp 80–85

Jeevanandam J, Barhoum A, Chan YS et al (2018) Review on nanoparticles and nanostructured materials: history, sources, toxicity and regulations. Beilstein J Nanotechnol 9:1050–1074. https://doi.org/10.3762/bjnano.9.98

Sanhueza C, Acevedo F, Rocha S et al (2019) Polyhydroxyalkanoates as biomaterial for electrospun scaffolds. Int J Biol Macromol 124:102–110. https://doi.org/10.1016/j.ijbiomac.2018.11.068

George J, Sabapathi SN (2015) Cellulose nanocrystals: synthesis, functional properties, and applications. Nanotechnol Sci Appl 2015:45–54. https://doi.org/10.2147/NSA.S64386

Figueiredo P, Lintinen K, Hirvonen JT et al (2018) Properties and chemical modifications of lignin: Towards lignin-based nanomaterials for biomedical applications. Prog Mater Sci 93:233–269. https://doi.org/10.1016/j.pmatsci.2017.12.001

Keshavarz S, Okoro OV, Hamidi M et al (2022) Synthesis, surface modifications, and biomedical applications of carbon nanofibers: Electrospun vs vapor-grown carbon nanofibers. Coord Chem Rev 472:214770. https://doi.org/10.1016/j.ccr.2022.214770

Kulkarni D, Musale S, Panzade P et al (2022) Surface Functionalization of Nanofibers: The Multifaceted Approach for Advanced Biomedical Applications. Nanomaterials 12:3899. https://doi.org/10.3390/nano12213899

Yang D, Faraz F, Wang J, Radacsi N (2022) Combination of 3D Printing and Electrospinning Techniques for Biofabrication. Adv Mater Technol 7:2101309. https://doi.org/10.1002/admt.202101309

Valdivia-Rivera S, Ayora-Talavera T, Lizardi-Jiménez MA et al (2021) Encapsulation of microorganisms for bioremediation: Techniques and carriers. Rev Environ Sci Biotechnol 20:815–838. https://doi.org/10.1007/s11157-021-09577-x

Machado D, Almeida D, Seabra CL et al (2020) Nanoprobiotics: When Technology Meets Gut Health. Springer link, pp 389–425

Paiva T, Ribeiro M, Coutinho P (2020) R&D Collaboration, Competitiveness Development, and Open Innovation in R&D. Journal of Open Innovation: Technology, Market, and Complexity 6:116. https://doi.org/10.3390/joitmc6040116

Ciaramella A, Dall’Orso M (2021) How Can We Drive Innovation? Springer link, pp 37–53. https://doi.org/10.1007/978-3-030-67623-0_4

Cristofoli NL, Lima AR, Tchonkouang RDN et al (2023) Advances in the Food Packaging Production from Agri-Food Waste and By-Products: Market Trends for a Sustainable Development. Sustainability 15:6153. https://doi.org/10.3390/su15076153

Funding

The work of Marina Jurić has been fully supported by the “Young Researchers’ Career Development Project - Training of Doctoral Students” of the Croatian Science Foundation (HRZZ-DOK-09-2018). This research was partly carried out within the Agritech National Research Center and received funding from the European Union Next-GenerationEU (PIANO NAZIONALE DI RIPRESA E RESILIENZA (PNRR) – MISSIONE 4 COMPONENTE 2, INVESTIMENTO 1.4 – D.D. 1032 17/06/2022, CN00000022).

Author information

Authors and Affiliations

Contributions

Marina Jurić: Conceptualization; Methodology; Data curation; Writing – original draft. Gulden Goksen: Writing – review & editing. Francesco Donsì: Writing – review & editing. Slaven Jurić: Conceptualization; Methodology; Visualization; Writing – original draft; Writing – review & editing.

Corresponding author

Ethics declarations

Ethical Approval

Not applicable.

Conflicts of Interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Jurić, M., Goksen, G., Donsì, F. et al. Innovative Applications of Electrospun Nanofibers Loaded with Bacterial Cells Towards Sustainable Agri-Food Systems and Regulatory Compliance. Food Eng Rev (2024). https://doi.org/10.1007/s12393-024-09369-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12393-024-09369-3