Abstract

This review aims to approach the secondary shelf life (SSL) issue by providing an overview of the studies currently available on the subject and suggesting a theoretical framework to model the dependence of the SSL on the residual shelf life (RSL), a new concept introduced in this study. As it will be discussed later, to date, there are no systemic approaches and no guidelines to predict the dependence of the SSL on the RSL, even though the SSL is closely related to RSL. The few articles on the topic available in the literature are limited to assess the SSL of food, and its dependence on packaging systems or storage conditions after the package opening. The new approach based on the RSL can give a valid tool to industrial and scientific operators in the food sector for a more appropriate prediction of SSL. The enhanced awareness about a correct SSL prediction might lead to lower food waste generation.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

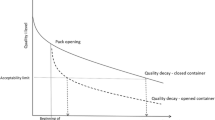

The consumption of a food at consumer level or the use of raw materials or semi-processed food at industrial level, after package opening, can be extended over a certain length of time. Theoretically, the package opening provokes a rapid modification of the storage conditions because the food loses the sterility. In addition, some concrete changes can be observed in terms of atmosphere around the product, oxygen, and moisture availability, and in terms of temperature. These modifications also depend on the time the product remains at room temperature and the time during which the package remains open. Therefore, when the package is opened an acceleration of the kinetic decay of food can occur. Due to these phenomena, in addition to primary shelf life (PSL), the secondary shelf life (SSL) needs to be considered.

PSL refers to the time interval between the moment when the food is packaged and the moment when the packaged food becomes no longer acceptable, whereas the SSL represents the time interval between the moment when the package is opened and the moment when the unpackaged food becomes no longer acceptable for consumption. For a given product, due to the above-mentioned modifications occurring after package opening, the SSL is shorter than the PSL, and sometimes much shorter.

While the PSL is abundantly discussed, scarce attention has been still paid to SSL. Currently, the SSL concept gains importance because it is strictly related to the household food waste, and to handling of raw materials or semi-manufactured products, used at industrial level after package or tank opening. In fact, when you are unable to consume or transform a product that is no longer packaged within the times set on the label, both at a domestic and industrial level, waste is generated. It is also worth noting that waste is easily generated also because SSL is often underestimated [1, 2]. Therefore, especially for foods that deteriorate rapidly after opening, accurately predicting the SSL means avoiding generating waste.

According to the most recent assessment, approximately 53% of global food waste is generated by households in the EU [3]. The FUSIONS project (Food Use for Social Innovation by Optimizing Waste Prevention Strategies) reported an amount of household food waste per capita/per year equal to 92 kg (FUSIONS, 2016), even though these ratios can be slightly different depending on the geographical location. This is true also at industrial level.

Considering that food waste is a critical issue worldwide, any prevention strategy for a proper food management after package opening is highly desired [4,5,6,7]. In this regard, legislation on expiration dates should be reviewed, not only from the perspective of product safety and quality, but also from the environmental and social impact [8]. Unfortunately, at legislative level, no guidelines or indications concerning how to predict the SSL of foods are available now. EU Regulation 1169/2011 only defines the concept of minimum durability of food and, at the most, it brings the concept of “use by date” for food product highly perishable. These indications refer to packaged food and therefore give consumers only information about PSL.

As said before, at research level, SSL is a topic scarcely studied. A few papers have been found and most of them are focused on SSL dependence on packaging materials or storage conditions used after the package opening, without suggesting protocols or systemic approach for a proper SSL prediction. To date, the unique review on the topic was proposed by Nicoli and Calligaris [9], who critically discussed the SSL by giving both consumer and food industry perspectives and suggesting a sort of decision tool to be used after package opening. According to the review of Nicoli and Calligaris [9], foods can be divided into two categories, foods without significant differences between PSL and SSL, and foods that, after opening, can be changed by the environmental conditions. In the first category, the quality decay scarcely depends on the package and storage conditions; therefore, the evaluation of SSL coincides with that of PSL. On the contrary, in the second category, the food quality is strongly affected by the package and storage conditions; therefore, after opening the food, the loss rate remarkably changes. The two above authors assessed that in these last cases, SSL assessment is needed. In this regard, in the last part of the review, Nicoli and Calligaris [9] listed the procedures used to assess the SSL. It is reported that the deterministic approach is the most common and economic method to estimate SSL at lab scale, by carrying out shelf life test under the worst-case scenario. Another possibility is based on simulation study of home habits, repeating the container opening and closure. The above two authors finally discussed about further potential smart technologies to be adopted to assess the SSL, i.e., the accelerated shelf life test and the real-time monitoring systems (time–temperature indicators or RFID systems), tools already consolidated for determining the PSL.

Considering the relevance of the topic, the first part of the current work is aimed to give an overview of the studies reported in the literature, thus underlining the approach adopted up to now from the researchers to determine the SSL of foods. Therefore, this first part gives the current state of the art analyzing the content of 16 available research articles published between 2001 and 2022. Scopus was used to map literature information, being a database with a broader spectrum of publications.

The second part of this review has been dedicated to assessing how the SSL is influenced by the extent of deteriorative reactions at the package opening (i.e., the extent to which the reactions responsible for food quality loss proceeded when the package is unsealed). Even though this topic is of crucial importance for the SSL study, a very few works found in the literature focused on this very important subject. Specifically, it has been found that only two studies made a reference to this specific aspect. The first is the article of Cesa et al. [10], who studied the SSL of infant formula. These authors analyzed samples according to a wide experimental plan to consider different storage conditions and different storage time before opening the package, starting from samples analyzed immediately after manufacturing to a maximum of 12 months of storage before opening the box, considering infant milk formula with a PSL of about 2 years. The approach used by Cesa et al. [10] proves the attention of the researchers to assess the dependence of the SSL on the extent of deteriorative reactions at the package opening. In an attempt to make the same evaluation, Nicosia et al. [11] carried out a study dealing with UHT milk. As will be better discussed later, this is another example from literature that takes into account the importance of the moment when the package is opened during the shelf life period. In fact, these authors carried out two tests, considering in the first one the containers opened just after its packaging, and another one at the end of the PSL. The reason of this experimental plan was due to the attention of the authors to study what happens after package opening and verify if the moment of the package is opened could affect the value of SSL. Even though interesting information was recorded from both these two above papers, none of them laid the foundations of a systemic approach able to predict the influence of the storage time before package opening on the value of SSL. Therefore, due to this lack of information, the second part of the current review focuses on a possible theoretical approach to be adopted for the SSL estimation. Considering the relevance to predict the SSL, and that there is no manuscript in the literature focused on systemic approach for SSL estimation, the current review aims to fill this gap, thus providing a mathematical model to describe the dependence of the SSL on the extent of deteriorative reactions at the package opening.

The Effect of Post Opening Packaging on the SSL: Case Studies from Literature

Literature data relevant to SSL studies can be divided in two main groups, one relative to microbiologically stable foods, the majority, and another one relative to food suffering from microbial spoilage after opening. In the first group, coffee, wine, extra virgin olive oil, powder milk, and croissant were considered. In the second group, the case studies relative to liquid milk, cooked ham, and Pesto alla Genovese will be presented.

To provide the key for reading this paragraph, few more definitions are in order: the primary packaging is the packaging system used to package the food, it is able to hold up the food quality decay kinetic during its storage; the secondary packaging is the packaging system used right after the primary packaging is opened, in most cases it simply consists in the unsealed primary packaging; the primary storage conditions are temperature, light exposure, relative humidity, etc., under which the food is stored before its opening; the secondary storage conditions are temperature, light exposure, relative humidity, water activity, etc., under which the food is stored when unpackaged; a mechanism of deterioration is a physical phenomenon that contributes to decrease the packaged food quality during the storage period. On the basis of the above-mentioned definitions, a classification of all the case studies analyzed in this paragraph is reported in Table 1.

Among the microbiologically stable food, the roasted coffee is the most studied. It is characterized by several compounds able to confer, after roasting, a specific aroma, and color to the product [12], and therefore, primary packaging and storage conditions are strategic for preserving its quality during storage [13]. However, the rate of coffee qualiy decay may suddenly increase after the packaging has been opened due to the changed storage conditions. Therefore, the evaluation of the SSL may imply better quality control during consumption. The first study dealing with SSL of coffee is the work of Cappuccio et al. [14], who found a correspondence between sensory perception of staleness and aroma determined by chemical tool in roasted and ground coffee after opening the package and storing coffee at room conditions, in the refrigerator and at elevated temperature. The authors found a great correlation between sensory and chemical. Specifically, when the sample was stored in a refrigerator, they found aroma preservation for a longer time and a kinetic decrease of the staling. On the contrary, when the coffee was stored at high temperature a faster deterioration was detected.

In 2006, Anese, Manzocco, and Nicoli [15] calculated the SSL of coffee by using a zero-order kinetic model. The authors assumed that the kinetic constant is proportional to the external water activity. In such a way they related the SSL to the secondary storage conditions (i.e., the external water activity after package opening), thus making possible to say that the authors studied SSL by changing the secondary storage conditions. In fact, they monitored the changes responsible for coffee unacceptability at different values of external water activity. The authors used fresh dark-roasted ground coffee; once the package was opened, the coffee was stored at 30 °C, and at increasing water activity values up to reach 0.44. The coffee was kept in that condition for 1 month. To simulate home usage, every day, the coffee package was opened for a short time and then closed. After the opening, coffee staling and its sensory quality were assessed. Both sensory and instrumental data were used to calculate the zero-order kinetic constant and its dependence on external water activity. The calculated parameter was used to assess the dependence of the SSL of the investigated coffee stored at 30 °C on the external water activity, i.e., on the secondary storage conditions.

Later, Tušek, Benkovic, and Bauman [16] estimated the parameters of a zero- and first-order kinetics for color changes after the primary packaging system opening. The authors used roasted ground coffee and simulated household storage conditions after the primary packaging system opening. In this case, the influence of the secondary packaging system (simply consisting in the unsealed primary packaging) on the SSL was assessed. The color changes were monitored as the main quality parameters. Two types of secondary packaging materials were used, tin cans and triplex bags. A zero-order kinetic model was proposed as the most appropriate to describe the evolution of the ground roasted coffee color after package opening. A significant difference was detected in the fitting parameters relative to the two tested packaging materials. Overall, zero and first kinetic models described much better the data when triplex bag was used as secondary packaging system. The comparison among kinetic parameters allowed the authors to state that tin can was preferred as better color and light barrier system.

In 2018, some of the above authors [17] developed and compared non-linear and linear regression models for describing the evolution of color changes experimentally determined in ground coffee powder during 6 months of storage after the first opening. Also in this case, the above-mentioned two different secondary packaging systems were used, tin cans and triplex bags. To the aim, ground roasted coffee was first closed in the two types of packaging and, after opening, was stored at room temperature in a dark cupboard, as happens at home. Packaging was opened once a month, for 6 months of storage subsequent to the first opening of the primary packaging system. Once opened, moisture content, relative air humidity, air temperature, and color parameters of the samples were monitored. The authors concluded that both non-linear and linear models highlighted that moisture content, relative humidity, and temperature greatly influenced color change in ground roasted coffee. Non-linear model was the most suitable to describe the evolution of color changes after the primary package opening. Triplex packaging represented the most appropriate system for coffee preservation after pack opening.

A very recent study on freshly roasted coffee that demonstrates the influence of SSL from consumer habits is the research of Smrke et al. [18]. The authors compared four different storage methods of whole roasted beans after the primary package opening. As can be inferred, also in this case, the authors studied the SSL considering the influence of the secondary packaging system on the product quality decay after the opening. The first secondary packaging system tested was based on the transfer after primary package opening of beans into airtight canister; the second one, in closing the primary package with tape; the third one, in closing the primary package with clip; and the last one in using a secondary system with an incorporated screw cap. To compare the above secondary packaging systems, specific freshness indices were monitored after package opening by gas chromatography/mass spectrometry. Results demonstrated that among the proposed solutions, the screw cap was the most interesting.

As regards secondary shelf life of wine, two long-standing studies were published. The first one by Fu, Lim, and Mcnicholas [19] is a research paper dealing with the effects of secondary storage conditions, and in particular storage temperature (22, 35, and 45 °C), on the quality of white wine packaged in bag-in-box after the primary package opening. The secondary packaging system consisted in the unsealed bag-in-box. Therefore, these authors aimed to assess the influence of the secondary storage conditions on the SSL. To this aim, the authors monitored the kinetics of main quality parameters after the package opening. The bag-in-box, compared to the more traditional bottles made up of multilayer systems and laminated cartons, was selected as primary and secondary packaging system because it offers improved distribution efficiency, enhanced end-use convenience, and increased cost-effectiveness [20]. This packaging system consists in a bag made with one or more high-barrier flexible films, reinforced by an external paperboard carton. To dispense the product, a valve fitment is attached to the bag. After the primary packaging system is opened, a potential temperature abuse and oxygen ingress can affect product quality. Degradation of freshness in terms of fruity traits and browning reactions can occur [21,22,23]. The study of Fu et al. [19] monitored and correlated several enological parameters (color and contents of free and total SO2, total aldehyde, and total phenol) to the oxygen transmission rate and the Fourier transform infrared spectral data [24]. Results demonstrated important correlations among wine quality parameters. In fact, the authors assessed the chemometric approach to analyze Fourier transform infrared spectral data as valid device for determining wine quality. The authors assessed that wine quality changes were significantly affected by the gas barrier properties of the secondary packaging system. Finally, they concluded that the secondary packaging conditions, such as the exposure of wines packaged in the bag-in-box to elevated temperature and oxygen, can influence the evolution of the enological parameters after the opening.

Two years later, Lee, Kang, and Park [25] published a paper dealing with the effects of oxygen on volatile and sensory characteristics of cabernet sauvignon after the primary package opening. To the aim, four different oxidation conditions were used. The wine quality was monitored during a 1-week period after the primary package opening. The authors approached the SSL issue by considering the influence of the secondary storage conditions on the quality kinetic after package opening. To the aim, they used headspace solid-phase microextraction coupled to gas chromatography–quadrupole mass spectrometry and sensory tests, in addition to proper statistical analysis of data. During the storage period after the pack opening, the differences among samples highly depended on the wine oxidation level [26]. Results demonstrated proper correlation of chemical data with sensory perception, thus suggesting that the statistical tools adopted for data elaboration were appropriate to determine the oxidation level of wine during SSL.

The quality loss of extra virgin olive oil (EVOO) after the primary packaging system opening was also studied. EVOO is very hostile for microorganisms, so it generally does not undergo microbial decay. Oxidation is the main problem [27]. In the literature, three articles were reported on the topic. The first one is by Krichene et al. [28], who studied EVOO stability during a term storage of 8 months after the opening, under temperature abuse (50 °C) to accelerate oxidation reactions. To the aim, four different monovarietal of Tunisian oils, differing in fatty acid profile and content of natural antioxidants, were used. Later, some of the above authors [29] studied the stability of virgin olive oil phenolic compounds during 18 months after the first opening, at different secondary storage conditions, i.e., at 5, 15, 25, and 50 °C. The authors demonstrated that oil stored under temperature lower than the usual commercial conditions (20–25 °C) is better preserved. The same four oil varieties investigated in the previous study were considered. Results of both these studies gave information about the degradation rate of oil after package opening as affected by both oil characteristics and secondary storage conditions.

Garrido-Delgato et al. [30] assessed the SSL of EVOO as influenced by the secondary packaging system and secondary storage conditions. The samples were monitored for 11 months after the package opening. To the aim, the authors used a single variety of EVOO. The primary packaging systems were bag-in-box, metal, dark glass, clear glass, and polyethylene terephthalate containers. It is worth noting that also in this case the secondary packaging system consists in the unsealed primary packaging. To simulate home use, after the first opening, the oils were opened periodically. On the other hand, to simulate storage conditions on market shelves, other containers were kept sealed. The results highlighted that physico-chemical and instrumental parameters recorded on the investigated secondary packaging systems were comparable. Among the systems studied, the best secondary packaging was the bag-in-box container, able to preserve EVOO quality for 11 months after the first opening.

Another food category to be considered in the group of microbiologically stable foods is that of the infant milk formula, being particularly prone to autoxidation. Infant milk formulations are made of 33% fats and are very rich in polyunsaturated fatty acids (PUFAs), important elements for the newborn development [31]. Decay of foods rich in lipids involves first peroxides formation, and then progress of off-flavored and potentially toxic, mutagen, and carcinogenic secondary products, with consequent loss of food nutritional value [32]. For this reason, the formulation, the storage temperature, and both primary and secondary packaging systems of infant formula are of crucial importance to avoid autoxidative decomposition. Among the various quality attributes, the malondialdehyde (MDA) is the most preferred [33], as valid food oxidation index [34]. In this context, Cesa et al. [10] evaluated the stability of infant milk formulas, supplemented with PUFAs, under different primary and secondary storage conditions, through the monitoring of MDA after the box opening. As reported in the introduction section, for the first time these authors stressed not only the importance of the storage conditions after package opening but also the influence of the moment when the primary package was opened on the SSL. Therefore, in this study for the first time, the authors investigated the SSL as influenced by the extent of deteriorative reactions at the package opening. To this aim, the authors used an experimental plan with 30 different samples of powder milk formulas differing in the time at which the primary package was opened (samples opened immediately after manufacturing, after 6 months of storage, and after 10 months of storage), in the primary storage conditions (i.e., the temperature at 20, 40, and 55 °C before box opening), and in the secondary storage conditions (i.e., the temperature at 20 and 28 °C after box opening). Results on milk formula analyzed immediately after manufacturing and stored for 3 months after opening at 40 °C showed less oxidate samples. When samples were stored for 2 weeks after opening at 55 °C, high level of MDA was detected. A very similar trend was also recorded in samples analyzed after 1 year of storage before opening at 20 °C. Therefore, storage conditions after opening, extent of deteriorative reactions at the package opening, and temperature at which samples are stored before opening the container can play a key role on the SSL.

Codurso et al. [35] also published a study focused on the quality decay of both powdered infant formula (PIF, bovine milk), and lactose-free PIF (lactose-free product based on glucose syrup) during the period after the primary packaging system opening. Contrary to the previous study, in this work, the authors investigated the product quality after package opening, using the label indications for the milk reconstitution and therefore mixing milk in water at 70 °C, 80 °C, and 90 °C. They did not consider the effect of the extent of deteriorative reactions at the package opening on the secondary shelf life. In fact, only samples after 5 months from processing were considered for the tests. To the aim of the work, Maillard reaction level and changes in lipid peroxidation were monitored up to the expiration date (i.e., at 0, 7, 15, 30, and 37 days). Results from this study highlighted that hot water could promote lipid peroxidation, and therefore, the water temperature for infant formula reconstitution plays a key role. Due to the above findings [35], SSL no more than 15 days should be indicated for infant formula with a composition similar to that of those analyzed in this case study.

Regarding the three types of microbiologically unstable foods, the case of liquid milk (pasteurized and UHT) was investigated by different authors. First, Dortey, Aboagye, and Tuah [36] studied the quality decay of processed liquid milk after package opening, as affected by both the secondary packaging and secondary storage conditions. Milk is a very perishable product. It can be spoiled and can provoke public health consequences [37, 38]. The research of Dortey et al. [36] specifically refers to Ghana situation, with many people at risk of milk-borne illnesses for improper use of milk after opening. Therefore, to give proper suggestions about product storage, the authors conducted this research investigating different secondary packaging systems for processed liquid milk. The authors assessed the milk quality after package opening and during the subsequent week of storage. To this aim, they focused attention on two highly utilized milk products. These samples were stored after opening using different methods: refrigerated with their tin in a closed storage bowl, refrigerated with their tin inside a sealed rubber, refrigerated directly in their tin, and put with their tin in a cup containing water at room temperature. The first three practices differ for the secondary package, whereas the last one for the secondary storage conditions. After the primary package opening, the microbiological quality and pH of milks were assessed for 7 days. Results suggested that different evolutions were recorded in the various proposed solutions, even though in all the packaging the SSL was equal to 2 days. Enteric bacteria and Salmonella represent the main pathogens that can affect milk acceptability after 2 days. The best system for maintaining a high microbiological quality of both processed liquid milks within a week post-opening is represented by the tin with a covered storage bowl. The lack of real changes in terms of color, taste, smell, and pH does not imply milk acceptability from the microbiological point of view. Moreover, from the study of Dortey et al. [36], it can be inferred that if processed liquid milk must be consumed within 2 days from its opening, the storing at room temperature, in a cup with water, is the best method.

More recently, Nicosia et al. [11] assessed the SSL of UHT milk to reduce the waste at household level. To the aim, the authors used two UHT milk types simulating homemade habits in terms of first opening and storage. As reported in the “Introduction” section, this is another example from the literature where the impact of the extent of deteriorative reactions at the package opening on SSL was considered. In fact, the authors carried out two different tests, one where samples were opened right after their commercialization and another one with samples opened at the expiration date reported on the packaging. To determine the SSL, the researchers monitored in both tests the main quality parameters during few days of storage after the first opening. The authors simulated two types of secondary domestic storage conditions, based on numerous and lesser use repetitions. The comparisons between the two tests highlighted the influence of the extent of deteriorative reactions at the package opening on SSL. In fact, the sample opened right after the commercialization recorded SSL (12–13 days) higher than that of milk opened at the end of the PSL and stored under the same secondary storage conditions (6–7 days). Anyhow, results from the current study demonstrated that SSL of UHT milk is generally underestimated. Considering the general 3–4 days reported on most UHT milk packages, the authors stated that the SSL could be amplified [39]. Nicosia et al. [11] demonstrated that SSL under proper storage refrigerated conditions could be prolonged up to 6–7 days. Therefore, the experimental findings of the current study, properly diffused to final consumers, suggest that a re-assessment of milk SSL on the packaging could prevent food waste. The authors also underlined that results from their research could gain relevance also at industrial level because the longer SSL could mean higher sustainability and better market position.

Sliced cooked ham is another fresh product which, after package opening, is highly susceptible to microbial proliferation [40]. It is generally stored in a plastic tray under modified atmosphere conditions. Usually, gas mixture of 70% N2 and 30% CO2 is able to control quality decay and assure primary shelf life of about 30 days [41,42,43]. When we open the package, the headspace gas composition changes and the food lost the packaging protection; therefore, the SSL is significantly shorter than PSL. Spampinato et al. [44] recently investigated the quality decay kinetics of cooked ham produced by 5 companies. The samples were monitored for 12 days after the primary package opening. During storage, the samples in the unsealed primary packaging bag were put in a domestic refrigerator at 5.2 ± 0.6 °C. Samples with at least 2 weeks from the expiration date were selected, and with the indication to consume the food after a maximum of 3 days after the primary package opening. Specifically, the authors monitored microbial, physical, chemical, and sensory quality of sliced cooked ham after the bag opening. They found that products became unacceptable after 12 days from the package opening, even though after the first 8 days some defects started to appear. Main volatile metabolites that describe the undesired profile evolution of the samples were detected and high microbial load, already at the opening of the package, was found. In particular, a high concentration of lactic acid bacteria was counted, thus justifying lack of other microbial species. However, this experimental evidence suggested that the proliferation that occurred after the primary package opening did not derive from environmental cross-contamination at the tray opening. Thus, the research puts the industrial operators on the alert since it highlights that production and packaging are crucial steps to manage the safety issue after the pack opening.

The last case study regards the Pesto alla Genovese, a traditional Italian sauce made from basil, grated hard cheese, pine seeds, olive oil, salt, and garlic. It is packaged in glass jars and has been considered a stable product. Primary shelf life is 2–3 years [45]. The study carried out by Nicosia et al. [46] aimed to assess the SSL of pesto to verify if the information given on the label about the use of the product after jar opening is appropriate or underestimates the SSL. Therefore, the current research also aims to avoid useless household food waste. To this aim, the authors, using a deterministic approach, selected two types of pesto, with 1 year from the expiration date reported on the label, and SSL of 5 days reported on the label. They assessed the influence of secondary storage conditions on the SSL by simulating the real opening and storage conditions in five domestic environments under two scenarios, based on the repetitions and duration of each opening. Microbial proliferation, sensory properties, color changes, pH, and volatiles profile were used to assess the quality decay kinetic after the jar opening. The interesting results recorded highlighted that for both types of pesto, SSL higher than 20 days was found, being the product bacteriologically stable. Color parameters and sensory properties did not change significantly after the jar opening. Based on these findings, the authors suggested the possibility to significantly prolong SSL. They also suggested that industrial operators could skip SSL indications on the label, with benefic consequence on food sustainability because both household stock turnover and domestic food waste could be advantageously reduced.

The Dependence of SSL on the Extent of Deteriorative Reactions at the Package Opening: a Theoretical Approach

In this paragraph, an attempt is made to provide the theoretical background for modeling the dependence of SSL on the extent of deteriorative reactions at the package opening. To this end, the introduction of the notion of residual shelf life (RSL) is in order, being a measure of the extent of deteriorative reactions at the package opening. To define RSL, let us consider a given time (t), ranging between 0, i.e., the moment when the food is packaged, and the moment when the packaged food become no longer acceptable (i.e., PSL). By definition, RSL at the time t (bounded between 0 and PSL) is the difference between the primary shelf life of the packaged food and the time t (i.e., RSL = PSL − t). In other words, RSL at time t is how long the packaged product will take at time t, if stored under the primary storage conditions, to become no longer acceptable. According to this definition, RSL spans between 0 and PSL, being 0 when t is equal to PSL, and being equal to the packaged food primary shelf life when t is equal to 0. For the sake of clarity, in this study, when t is the time when the package is opened, it will be referred to as t*, and the residual shelf life will be referred to as RSL*. It is worth noting that a substantial difference between SSL and RSL* can be observed only when the primary packaging and the storage conditions significantly affect the PSL. This is the case of food products packaged under modified atmosphere conditions, foods that undergo a thermal treatment after their package, foods packaged in aseptic conditions, etc. In all these cases, a change in the primary packaging and in the storage conditions (i.e., the opening of the primary packaging) brings about a marked increase in the rate at which the phenomena that cause food unacceptability proceed. In turn, this makes the SSL much lower that the RSL*. In all the above-mentioned cases, it may be extremely useful to find a correlation between SSL and RSL*.

It is well known that for a given primary packaging and a given packaged food, the PSL value of the packaged food only depends on the used primary storage conditions. On the contrary, the SSL depends on the secondary packaging and storage conditions, as well as on the RSL* value. In fact, the RSL* value is a valuable parameter, as it indirectly brings with it the information on the primary packaging and storage conditions, and consequently on the extent, at the time the package is opened, of the mechanism of deterioration, thus contributing to decrease the packaged food quality during its storage. It must be underlined that only the dependence of SSL on RSL* will be considered in the following; it implies that it is assumed that all the other variables on which SSL depends are set constant.

Concerning the dependence of SSL on the \({\mathrm{RSL}}^{*}\), one can say that when \({\mathrm{RSL}}^{*}\) is equal to PSL (i.e., the package is opened right after the food has been packaged), SSL reaches its maximum value (\({\mathrm{SSL}}_{\mathrm{max}}\)); on the other hand, if RSL* is equal to 0 (i.e., the packaged is opened as soon as the food becomes no longer acceptable), then SSL is equal to 0. Therefore, it can be stated that the SSL has to be an increasing function of RSL*. In principle, any function can be used to describe the dependence of \(SSL\) on \({\mathrm{RSL}}^{*}\); Eq. (1) is proposed, being a very simple approach:

where \(\beta\) is a constant, with dimension of a time, and the same units of RLS*. In fact, Eq. (1) is a first-order type equation used in this study to describe the dependence of \(\mathrm{SSL}\), the dependent variable from \({\mathrm{RSL}}^{*}\), the independent variable. The model parameters are \({\mathrm{SSL}}_{\mathrm{max}}\) and \(\beta\).

In Fig. 1, the SSL is designed as a function of RSL*, the curves are Eq. (1) using a PSL value of 20 days, and a \({\mathrm{SSL}}_{\mathrm{max}}\) of 10 days (for example, a fresh dairy cheese), each curve refers to a different value of b. To better understand the physical meaning of the parameter b appearing in Eq. (1), let us consider a given value of RSL*, for instance, 5 days. For the sake of clarity, a vertical dashed line has been drawn in Fig. 1 at RSL* equal to 5 days. The intercept of the vertical line with the curves shown in the figure gives the value of the SSL of each curve at RLS* equal to 5 days.

SSL as function of RSL*. The curves were obtained by means of Eq. (1) using a PSL value of 20 days, and a \({\mathrm{SSL}}_{\mathrm{max}}\) of 10 days. Each curve refers to a different value of b

As one can observe, as the values of b decrease, the values of SSL at 5 days increase. Based on this observation, it can be stated that the lower b is, the slower the SSL will reach 0 as the RSL* decreases (i.e., t* increases to reach the PSL value). In fact, for very small value of b, SSL is close to its maximum value, even when the package opening takes place close to its primary shelf life (i.e., when the packaged food is about no longer acceptable for consumption).

As reported earlier, both SSL and RSL* are lower and upper bounded. In fact, SSL spans between 0 and \({\mathrm{SSL}}_{\mathrm{max}}\), whereas RSL* spans between 0 and PSL.

Based on this observation, Eq. (1) can be rearranged as follows:

which in turn can be rearranged in the following expression:

where \(\overline{\mathrm{SSL} } = \frac{\mathrm{SSL}}{{\mathrm{SSL}}_{\mathrm{max}}}\) is the normalized secondary shelf life, \(\overline{{\mathrm{RSL} }^{*}}= \frac{{\mathrm{RSL}}^{*}}{\mathrm{PSL}}\) is the normalized RSL*, and \(\overline{\beta }=\frac{k}{\mathrm{PSL}}\) is the dimensionless version of the parameter b. In fact, both \(\overline{\mathrm{SSL} }\) and \(\overline{{\mathrm{RSL} }^{*}}\) span between 0 and 1, when \(\overline{{\mathrm{RSL} }^{*}}\) is 0 the same does \(\overline{\mathrm{SSL} }\), and when \(\overline{{\mathrm{RSL} }^{*}}\) is equal to 1 the \(\overline{\mathrm{SSL} }\) assumes the same value.

In Fig. 2, the \(\overline{\mathrm{SSL} }\) is plotted as a function of \(\overline{{\mathrm{RSL} }^{*}}\) and the curves are Eq. (3), considering different values of \(\overline{\beta }\).

\(\overline{\mathrm{SSL} }\) as a function of \(\overline{{\mathrm{RSL} }^{*}}\). The curves are Eq. (3) with different values of b

As one can observe, Fig. 2 is the normalized version of Fig. 1, as the values of \(\overline{\beta }\) used to draw the curves shown in Fig. 2 were obtained by dividing the ones used in Fig. 1 by 20 days (i.e., the PSL value used to plot the curves shown in Fig. 1). The advantage of using Eq. (3) in place of the more intuitive Eq. (1) is that a single curve can embrace a much bigger number of case studies. As an example, in Fig. 3, two different case studies are plotted; Fig. 3a shows SSL plotted vs RSL* using Eq. (1), whereas Fig. 3b shows the same case studies plotted in the normalized form using Eq. (3). The values of PSL, SSLmax, and b of these case studies were chosen in such a way that they can be represented by the same curve when plotted \(\overline{\mathrm{SSL} }\) vs \(\overline{{\mathrm{RSL} }^{*}}\).

Concluding Remarks

The deep knowledge about the proper time to consume a food after first package opening could have relevant outcomes. It is important to correctly assess the SSL without making underestimation, because lack/incorrect information on the label promotes food waste. Therefore, strategies aimed to increase SSL also mean paying attention to a more sustainable food chain. SSL is a topic still underestimated, even though in the last years a vigorous increase of publications dealing with food waste was recorded. A reinforcement of research on the SSL appears strategic to control the food waste and add new information to the existing studies of the literature, still limited to a small range of commodities. SSL and waste prevention have not to be treated separately; there are opportunities for their integration not always considered. Today, food safety indicator (“Use-by date”) or food quality indicator (“Best before date”) represent similar information for the generic consumer because both are perceived as safety label communication. This lack of knowledge promotes undesired food waste. Similarly, unproper information on SSL can lead to excessive waste generation. It is not easy to produce appropriate labels for the myriad of food. Great efforts are necessary because data on the label about SSL could increase consumer awareness. Specifically, the explications of conditions to be respected after package opening (immediate closing, immediate storing under refrigerated temperature, etc.) could really prevent food waste, together with its negative impact on the environment.

More attention must be paid to advance the knowledge about main factors responsible for food quality decay after package opening. The concept of RSL needs to be carry out in practical food applications to become a valid tool for SSL estimation, and to select the best approach for SSL prevision. In the second part of the present study, a deterministic approach is proposed to relate the SSL to the RSL*. The proposed approach is intended for all those cases where the opening of the package induces an increase in the rate at which the phenomena that cause food unacceptability proceed. A simple model based on a first-order type equation is also proposed. The model has two parameters: \({\mathrm{SSL}}_{\mathrm{max}}\) and b. The former is the maximum value that the SSL can reach when \({\mathrm{RSL}}^{*}\) is equal to PSL (i.e., the package is opened right after the food has been packaged). The other model parameter, b, is a measure of how fast the SSL tends to 0 as the RSL* tends to 0 (i.e., t* tends to the PSL value). In particular, it has been shown that the lower b is the slower SSL tends to 0 as the RSL* tends to 0.

Data Availability

No data was used for the research described in the article.

References

Lourenco CE, Porpino G, Lobo Araujo CM, Marques VL, Matzembacher DE (2022) We need to talk about infrequent high volume household food waste: a theory of planned behaviour perspective. Sustainable Prod Consump 33:38–48

Oláh J, Kasza G, Szabó-Bódi B, Szakos D, Popp J, Lakner Z (2022) Household food waste research: the current state of the art and a guided tour for further development. Front Env Sci 10:916601

FUSIONS (2016) Estimates of European food waste levels. Stockholm: Eu-fusions

Manzocco L, Alongi M, Sillani S, Nicoli MC (2016) Technological and consumer strategies to tackle food wasting. Food Eng Rev 8:457–467

Dusoruth V, Peterson HH (2020) Food waste tendencies: behavioral response to cosmetic deterioration of food. PLoS ONE 15(5):e0233287

Lusk JL, Ellison B (2020) Economics of household food waste. Can J of Agric Econom 68:379–386

Rolker H, Eisler M, Cardenas L, Deeney M, Takahashi T (2022) Food waste interventions in low-and-middle-income countries: a systematic literature review. Res Cons Rec 186:106534

Graham-Rowe E, Jessop DC, Sparks P (2014) Identifying motivations and barriers to minimizing household food waste. Res Conserv & Recycl 84:15–23

Nicoli MC, Calligaris S (2018) Secondary shelf life: an underestimated issue. Food Eng Rev 10:57–65

Cesa S, Casadei MA, Cerreto F, Paolicelli P (2015) Infant milk formulas: effect of storage conditions on the stability of powdered products towards autoxidation. Foods 4:487–500

Nicosia C, Fava P, Pulvirenti A, Licciardell F (2022) Secondary shelf life assessment of UHT milk and its potential for food waste reduction. Food Pack Shelf Life 33:100880

Bicho NC, Leitao AE, Ramalho JC, Lidon FC (2012) Use of colour parameters for roasted coffee assessment. Food Sci Technol (Campinas) 32:436–442

Rendon MY, Garcia Salva T, Bragagnolo N (2014) Impact of chemical changes on the sensory characteristics of coffee beans during storage. Food Chem 147:279–286

Cappuccio R, Full G, Lonzarich V, Savonitti O. (2001) Staling of roasted and round coffee at different temperatures: combining sensory and GC analysis. Proceedings of the 19th International Scientific Colloquium on Coffee, Trieste, Italy, 2001:1–11

Anese M, Manzocco L, Nicoli MC (2006) Modeling secondary shelf life of ground roasted coffee. J Agric Food Chem 54:5571–5576

Tusek AJ, Benkovic M, Bauman I (2015) Kinetics of colour change in roasted ground coffee during secondary shelf-life. J Process Energy Agric 19:1

Benkovic M, Tusek, AJ (2018) Regression models for description of roasted ground coffee powder color change during secondary shelf-life as related to storage conditions and packaging material. Bever 4(1)

Smrke S, Adam J, Muhlemann S, Lantz I, Yeretzian C (2022) Effects of different coffee storage methods on coffee freshness after opening of packages. Food Pack Shelf Life 33:100893

Fu Y, Lim LT, Mcnicholas PD (2009) Changes on enological parameters of white wine packaged in bax-in-box during secondary shelf life. J Food Sci 74:608–618

Doyon GJ, Oulet PC, Chalifoux L, Pascat B (1995) Measurement of valve oxygen diffusion for bag in-box applications under three possible ambient conditions. Pack Technol Sci 8(4):171–193

Hernanz D, Gallo V, Recamales AF, Melendez-Martinez AJ, Gonzalez-Miret ML, Heredia FJ (2009) Effect of storage on the phenolic content, volatile composition and colour of white wines from the varieties Zalema and Colombard. Food Chem 113:530–537

Salacha MI, Kallithraka S, Tzourou I (2008) Browning of white wines: correlation with. Technol Sci 8:171–193

Sioumis N, Kallithraka S, Makris DP, Kefalas P (2006) Kinetics of browning onset in white wines: influence of principal redox-active polyphenols and impact on the reducing capacity. Food Chem 94:98–104

Urbano Cuadrado M, Luque de Castro MD, Perez JPM, Gomez-Nieto MA (2005) Comparison and joint use of near infrared spectroscopy and Fourier transform mid infrared spectroscopy for the determination of wine parameters. Talanta 66:218–224

Lee DH, Kang BS, Park HJ (2011) Effect of oxygen on volatile and sensory characteristics of cabernet sauvignon during secondary shelf life. J Agric Food Chem 59:11657–11666

du Toit WJ, Marais J, Pretorius IS, du Toit M (2006) Oxygen in must and wine: a review. Int J Food Sci Technol 43:1073–1077

Mancebo-Campos V, Salvador MD, Fregapane G (2022) Modelling virgin olive oil potential shelf-life from antioxidants and lipid oxidation progress. Antiox 11:539

Krichene D, Allalout A, Macebo-Campos V, Salvador M, Zarrouk M, Fregapane G (2010) Stability of virgin olive oil and behaviour of its natural antioxidants under medium temperature accelerated storage conditions. Food Chem 121:171–177

Krichene D, Salvador M, Fregapane G (2015) Stability of virgin olive oil phenolic compounds during long-term storage (18months) at temperatures of 5–50 degrees C. J Agric Food Chem 63:6779–6786

Garrido-Delgato R, Mar Dobao-Prieto M, Arce L, Aguilar J, Cumplido JL, Valcarce M (2015) Ion mobility spectrometry versus classical physico-chemical analysis for assessing the shelf life of extra virgin olive oil according to container type and storage conditions. J Agric Food Chem 63:2179–2188

Koletzko B, Lien E, Agostoni C, Boehles H, Campoy C, Cetin I, Decsi T, Dudenhausen JW, Dupont C, Forsyth S, Hoesli I, Holzgreve W, Lapillonne A, Putet G, Secher NJ, Symonds M, Szajewska H, Willatts P, Uauy R (2008) The roles of long-chain polyunsaturated fatty acids in pregnancy, lactation and infancy: Review of current knowledge and consensus recommendations. J Perin Med 36:5–14

Rodriguez-Alcalà LM, Garcia-Martinez M, Cachon F, Marmesat S, Alonso L, Marquez-Ruiz G, Fontecha J (2007) Changes in the lipid composition of powdered infant formulas during long-term storage. J Agric Food Chem 55:6533–6538

Cesa S (2004) Malondialdehyde contents in infant milk formulas. J Agric Food Chem 52:2119–2122

Yin H, Porter NA (2005) New insights regarding the autoxidation of polyunsaturated fatty acid. Antiox Redox Signal 7:170–184

Condurso C, Cincotta F, Merlino M, Stanton C, Verzera A (2020) Stability of powdered infant formula during secondary shelf-life and domestic practices. Int Dairy J 109:104761

Dortey MD, Aboagye G, Tuah B (2020) Effect of storage methods and duration of storage on the bacteriological quality of processed liquid milk post-opening. Scient African 10:e00555

Barbano DM, Ma Y, Santos MV (2006) Influence of raw milk quality on fluid milk shelf life. J Dairy Sci 89:15–19

De Jonghe V, Coorevits A, Van Hoorde K, Messens W, Van Landschoot A, De Vos P, Heyndrickx M (2011) Influence of storage conditions on the growth of pseudomonas species in refrigerated raw milk. Appl Envir Microbiol 77:460–470

Bezie A (2019) The effect of different heat treatment on the nutritional value of milk and milk products and shelf-life of milk products. A review. J Dairy Veter Scie 11(5)

Dušková M, Kameník J, Laèanin I, Šedo O, Zdráhal Z (2016) Lactic acid bacteria in cooked hams–sources of contamination and chances of survival in the product. Food Control 61:1–5

Holm ES, Adamsen AP, Feilberg A, Schäfer A, Løkke MM, Petersen MA (2013) Quality changes during storage of cooked and sliced meat products measured with PTR-MS and HS-GC-MS. Meat Sci 95:302–310

Kreyenschmidt J, Hübner A, Beierle E, Chonsch L, Scherer A, Petersen B (2010) Determination of the shelf life of sliced cooked ham based on the growth of lactic acid bacteria in different steps of the chain. J Applied Microbiol 108:510–520

Leroy F, Vasilopoulos C, Van Hemelryck S, Falony G, De Vuyst L (2009) Volatile analysis of spoiled, artisan-type, modified-atmosphere packaged cooked ham stored under different temperatures. Food Microbiol 26:94

Spampinato G, Candeliere F, Ameretti A, Licciardello F, Rossi M, Raimondi S (2022) Microbiota survey of sliced cooked ham during the secondary shelf life. Front Microbiol 13:842390

Zardetto S, Barbanti D (2020) Shelf life assessment of fresh green pesto using an accelerated test approach. Food Pack Shelf Life 25:100524

Nicosia C, Fava P, Pulvirenti A, Antonelli A, Licciardello F (2021) Domestic use simulation and secondary shelf life assessment of industrial Pesto alla Genovese. Foods 10:1948

Funding

Open access funding provided by Università di Foggia within the CRUI-CARE Agreement.

Author information

Authors and Affiliations

Contributions

Conceptualization, M.A.D. and A.C.; bibliographic research, A.C.; modeling, M.A.D.; writing—original draft preparation, A.C. and M.A.D.; writing—review and editing, M.A.D. and A.C.; supervision, A.C. All authors have read and agreed to the published version of the manuscript.

Corresponding author

Ethics declarations

Competing Interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Alessandro Del Nobile, M., Conte, A. Secondary Shelf Life of Foods: State of the Art and Future Perspective. Food Eng Rev 15, 748–762 (2023). https://doi.org/10.1007/s12393-023-09360-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12393-023-09360-4