Abstract

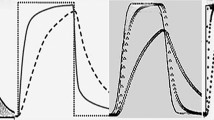

Traditionally, the effect of temperature on the rate of biochemical reactions and biological processes in foods, and on the mechanical properties of biopolymers including foods, has been described by the Arrhenius equation which has a single adjustable parameter, namely the “energy of activation.” During the last three decades, this model has been frequently replaced by the WLF equation, borrowed from Polymer Science, which has two adjustable parameters and hence better fit to experimental data. It is demonstrated that the WLF model (and hence also the VTF model) is identical to an expanded version of the Arrhenius equation where the absolute temperature is replaced by an adjustable reference temperature. Both versions imply that the curve describing a process or reaction’s rate rise with temperature or the viscosity or modulus drop with temperature must have the same characteristic upper concavity above and below the glass transition temperature, Tg, however it is defined and determined. Nevertheless, at least some reported experimental data recorded at or around the transition regime suggest otherwise and in certain cases even show concavity direction inversion. The mathematical description of such relationships requires different kinds of temperature-dependence models, and two such alternatives are described. Also suggested are two different ways to present the temperature as a dimensionless independent variable which enables to lump and compare different transition patterns in the same graph. The described approach is purely formalistic; no fit considerations are invoked and neither model is claimed to be exclusive.

Similar content being viewed by others

References

Peleg M, Normand MD, Corradini MG (2012) The Arrhenius equation revisited. Crit Rev Food Sci Nutr 52:830–851

Levine H, Slade L (1990) Influence of the glassy and rubbery states on the thermal, mechanical, and structural properties of dough and baked products. Springer

Slade L, Levine H, Reid DS (1991) Beyond water activity: recent advances based on an alternative approach to the assessment of food quality and safety. Crit Rev Food Sci Nutr 30:115–360

Abiad MG, Carvajal MT, Campanella OH (2009) A review on methods and theories to describe the glass transition phenomenon: applications in food and pharmaceutical products Food Eng Rev 1:105–132

Roos YH (2010) Glass transition temperature and its relevance to food processing. Ann Rev Food Sci Technol 1:469–496

Roos YH, Drusch S (2015) Phase transitions in foods. Academic Press

Rahman MS (2020) Glass transition concept in food preservation. In: handbook of food preservation 3rd Ed. CRC Press

Rahman MS (2010) Food stability determination by macro–micro region concept in the state diagram and by defining a critical temperature. J Food Eng 99:402–416

Peleg M, Engel R, Gonzalez Martinez C, Corradini MG (2002) Non-Arrhenius and non-WLF kinetics in food systems. J Sci Food Agric 82:1346–2155

Barsa C, Normand MD, Peleg M (2012) On models of the temperature effect on the rate of chemical reactions and biological processes in foods. Food Eng Rev 4:191–202

Peleg M (1992) On the use of the WLF model in polymers and foods. Crit Rev Food Sci Nutr 32:59–66

Angel CA (1997) Why C1=16-17 in the WLF equation is physical – and the fragility of polymers. Polymer 38:6261–6266

Peleg M (2018) Temperature - viscosity models reassessed. Crit Rev Food Sci Nutr 58:2663–2672

Angel CA (1995) Formation of glass from liquids and biopolymers. Science 267:1924–1935

Parker R, Ring SG (1995) Diffusion in maltose-water at temperatures close to the glass transition. Carbohyd Res 273:147–155

Ashokan BK, Kokini J (2005) Determination of the WLF constants of cooked soy flower and their dependence on the extent of cooking. Rheol Acta 45:192–201

Ubbink J, Dupas-Langlet M (2020) Rheology of carbohydrate blends close to the glass transition: temperature and water content dependence of the viscosity relation to fragility and strength. Food Res Intnl 38:109801

Peleg M (1994) A model of mechanical changes in biomaterials at and around their glass transition. Biotechnol Prog 10:385–388

Peleg M (1994) Mathematical characterization and graphical presentation of the stiffness-temperature-moisture relationship of gliadin. Biotechnol Progr 10:652–654

Peleg M (2015) Crunchiness loss and moisture toughening in puffed cereals and snacks. J Food Sci 80:E1988–E1996

Acknowledgements

The author expresses his deep gratitude to Mark D. Normand who programmed the Wolfram Demonstrations cited in this review.

Author information

Authors and Affiliations

Contributions

Micha Peleg: Suggested the idea, wrote the manuscript and created the figures.

Corresponding author

Ethics declarations

Conflict of Interest

The author declares no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix

Appendix

The expanded Arrhenius and WLF equations are the same model.

From [13]

where \({C}_{1}=\frac{a}{Ln\left[10\right] (Tref+b)}\) and \({C}_{2}=Tref+b\)

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Peleg, M. On Modeling the Temperature Effects on Biopolymers and Foods Undergoing Glass Transition without the WLF Equation. Food Eng Rev 15, 381–392 (2023). https://doi.org/10.1007/s12393-023-09345-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12393-023-09345-3