Abstract

Separation of two fluids or particles from an emulsion is a fundamental process in many applications such as creaming of milk in dairy sector and extraction of various oils (avocado oil, palm oil, etc.) among many others. The aim of this paper is to elaborate on the development of various methods and technologies employed for the separation process including gravity, chemical, and centrifugation as well as the newer acoustic separation technology. Influential parameters affecting the performance, advantages, and disadvantages for each method will be discussed and compared. Various transducer configurations and corresponding experimental set-ups and operating parameters are also examined for acoustic separation. Accordingly, the future trend is proposed for introducing new transducer configurations to diminish or preferably eliminate the current disadvantages and barriers and to improve the separation process performance.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The process of separation is widely used both at laboratory and industrial scales for many different applications ranging from food industry including various edible oil extraction and milk creaming, to crude oil recovery from water in oil industry and to biological cell separation applications in biomedical industry [1,2,3,4]. A wide range of applications necessitates ongoing research into the development of more efficient, cost-effective, and low-maintenance separation techniques. Currently, there are many techniques available in the literature and industry for separation of two mixed liquids or particles in liquids such as gravity separation [5], chemical separation [6] and centrifugation [7]. These will be separately reviewed in the following sections with examples of their specific application areas, advantages, and disadvantages which cause some limitations in their use. A relatively newer technique has also been studied called acoustic separation, which involves the use of acoustic waves to accelerate the process of coalescence and agglomeration of suspended particles in a stationary fluid [8]. Compared to previous techniques, this process decreases the processing time and the power consumption [2]. An advantage to this technique is that the particle size distribution in the fluids treated with acoustic waves is adjustable with the frequency and acoustic strength and is scalable and modular. It also has a low machinery and maintenance cost.

Considering all the potential, research has been concentrating more on acoustic separation to further develop and establish suitable transducers for various applications. In order to generate acoustic waves, one or multiple piezoelectric transducers are needed depending on the nature of the application [9]. The use of different transducer shapes such as square or rectangular plates, circular plates, horn transducers and cylindrical shells for separation and its respective configurations such as parallel square plates, perpendicular plates, and interaction between plates and horn transducers, have been investigated. The use of cylindrical transducers has been associated with the increase of the strength of the acoustic field due to better focus and interference of the radiated waves as a result of a suitable vibration mode shape [10,11,12]. Also, piezoelectric cylindrical transducers with geometrical variations in the form of stepped-thickness have shown much stronger acoustic fields at the same input power compared to identical non-stepped-thickness transducers [13,14,15,16,17,18]. To the best of the authors’ knowledge, application of these cylindrical transducers has been limited to very few studies on ultrasonic drying of foodstuff, water particle disintegration for airway humidification and separation of suspended microparticles in a fluid simulating blood conditions at a laboratory scale [10, 19, 20]. The geometry of a hollow cylindrical transducer makes it an attractive alternative for dynamic applications where a flowing fluid is required to pass through the transducer, and it can be fit in-line with the incoming flow. However, more research is required to develop suitable transducers for each application.

The aim of this review is to elaborate on various techniques with a focus on acoustic separation in the dairy sector. Conventional industrial techniques and newer approaches at research stage will be discussed and compared to elucidate advantages and disadvantages. Accordingly, the future trend for the development of potential transducers will be presented which can be more cost-effective and require lower initial and maintenance costs.

Separation Methods

This section introduces various separation techniques employed in the food industry and discusses investigations into the influential parameters for each according to the available literature. Current methods can be classified into gravity separation, centrifugation, chemical separation, and acoustic separation.

Gravity Separation

The difference in densities between two substances in an emulsion makes the lighter substance rise when the emulsion is settled for an extended period. The use of this phenomenon for separation is called gravity separation and it is applicable for emulsions and colloids. This technique is still considered a crucial step in some cheese making factories. The use of this separation method creates a gradient of fat content with the greater content at the top comprising of larger size fat globules. However, this method is time consuming. For example, the separation of fat and milk could take over 22 h to achieve up to 80% of fat content in the top layer of the milk sample. The process can be accelerated by changing the temperature of the milk [5]. A disadvantage is the extended processing time required to achieve the separation in comparison with other available techniques. To further investigate and clarify this, an experiment was designed to compare the particle size distribution in separation of fat from milk by gravity separation and centrifugation [21]. Two temperatures were selected for gravity separation, 4 and 15 °C, finding a faster rate of separation at 15 °C. The fat globule volume mean diameter was 2.80 µm for gravity separation at 4 °C after 48 h and 3.14 µm for centrifugation, making gravity separation technique more suitable for cheese making. Although the use of gravity separation ensures a uniform particle size distribution with small mean globule size, the processing time is considerably higher than centrifugation. Around 24 h is required to achieve 25% of fat content in the top layer of the milk sample. This is unsuitable and infeasible and finding alternative solutions seems crucial.

Centrifugation

Separation of milk and fat using centrifugation is one of the most common methods currently used in the industry. The application of centrifugal forces in emulsions speeds up the natural separation of the emulsion by densities where the lightest substance moves towards the center of the centrifuge. This force can generate physical and chemical changes in the substances. A study was conducted to determinate the effects of skimming process in buttermilk and butter serum, and to characterize the efficiency of centrifugation for lipid recovery [7]. The study was conducted with 33 samples of buttermilk and 24 of butter serum both at industrial scale and pilot scale, the pilot scale with a continuous flow of 500 L/h. It was found that the efficiency of the skimming process is proportional to the fat content in the fluid. A minimum lipid concentration has been reported below which the centrifugation process is not effective. Regardless of the lipid content in the samples, total separation of lipids was not achieved. This is one of the limitations of centrifugation in industrial applications. Centrifugation method for lipid separation has proven incapable of removing fat globules with a diameter smaller than 1 µm. Results showed that centrifugation is not completely efficient, and the lipid recovery depends on the concentration of globules and the character of the sample.

Another investigation was conducted to evaluate the efficiency of separation at two different conditions for 15-min centrifugation at 3000 rpm (at room temperature and at 2 °C) versus 24-h refrigerated gravity separation (at 2 °C) [22]. For these experiments, 31 samples of low-fat breast milk were used. The refrigerated gravity separation method was the least effective among the three cases compared in this study, while the refrigerated centrifuge method was the most effective one. Overall, centrifugation is faster than gravity separation. However, its efficiency depends on the concentration of the emulsion and complete separation is not possible.

In another study, centrifugation and microfiltration were compared [23]. Bovine cream was collected, stored at 5 °C and pasteurized at 75 °C for 20 s. Before microfiltration, the samples were washed in a three-step procedure with fluctuations in temperature, starting at 75 °C, then 50 °C and finally 75 °C. The washing procedure included a dilution-concentration operation for each washing-step. After being washed, the samples passed through a microfiltration process which was under a controlled temperature between 50 and 55 °C. Samples for each cycle were taken and stored at 8 °C before analysis. Three cycles were performed for both techniques, microfiltration, and centrifugation. The centrifugation treatment was executed in a disk stack centrifugal separator. On average, the processing time was 3.5 h for centrifugation and around 5.5 h for microfiltration. For both techniques, the results indicated changes in the fat globule membrane which modified the milk fat globules surface charge and released components from the milk fat membrane as a result of a decrease in the zeta potential in the samples after processing. Further, both techniques were reported destructive to shear-sensitive milk components with centrifugation being more detrimental [24]. Long shear exposure in microfiltration reduces the mean fat droplet size in cream MF [25] and similar decrease has been reported in different studies for the droplet size of an oil-in-water emulsion upon microfiltration [26] indicating that microfiltration can destroy native milk fat globules.

Chemical Separation

Chemical separation involves the use of surfactants to decrease the interfacial tension between fluids of different densities. This method has become popular in several industrial applications. The effectiveness of this technique is affected by the change of temperature and becomes inefficient at temperatures below 30 °C and above 120 °C. At temperatures lower than this, surfactants would precipitate, become ineffective and drop out of the aqueous solution. According to most experiments in the literature, temperatures above 120 °C result in either degradation or precipitation of most of the surfactant. In addition, the salinity level of the emulsion is another factor to consider as well as the concentration of the surfactant in the emulsion, which must be above the critical micelle concentration [6]. A high salinity level decreases the performance of separation. The reported literature is not in favour of separation of emulsions when the concentration of the surfactant in the sample is very close to critical concentration [27]. Co-solvents are used in order to improve the conditions of the separation and smooth the interface of the emulsion. Another disadvantage to the use of surfactants is that it can result in different types of pollution. For instance, to extract edible oil from oilseeds, hexane is used as the solvent which can result in the emission of volatile organic compounds (VOCs). These VOCs can react with other pollutants in the atmosphere and produce ozone which is hazardous and contributes to the greenhouse effect [1].

Remarks on Existing Common Methods

Table 1 summarizes the advantages and disadvantages of the above three methods, namely gravity separation, chemical separation, and centrifugation. As per this table, each method has numerous disadvantages and limitations which need careful consideration to be able to achieve efficient separation within a reasonable time. Hence, a relatively newer method, namely acoustic separation, has been introduced which is discussed in the following section.

Acoustic Separation

Suspended particles in a stationary fluid medium can be separated based on the difference in the density and compressibility of the particle and the medium. This process can be accelerated when an acoustic standing wave is applied to the fluid [2]. A standing wave is created from the interaction of the incident and reflected waves in a medium. Its key features are a region of maximum vibration called displacement antinodes (pressure nodes) and a region of minimal vibration called displacement nodes (pressure antinodes) in which the particles will be aligned depending on their acoustic contrast factor \(\varphi\) defined by [28],

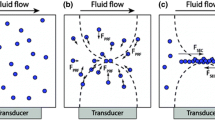

where \({\rho }_{p}\), \({\rho }_{m}\), \({\beta }_{p}\), and \({\beta }_{m}\) are the particles density, medium (fluid) density, particle compressibility and fluid compressibility, respectively. When the particles have a positive acoustic contrast factor, they move towards a pressure node (Fig. 1); for example, the lipid particles suspended in a watery medium possess a negative acoustic contrast factor, consequently, they move towards pressure antinodes [29].

a Particles distribution before sonication. b Fat globules and air bubbles move towards pressure antinodes under the influence of acoustic standing wave created between ultrasonic transducer (T) and reflector (R). c Fat globules aggregate and rise [32]

It has been shown that in an acoustic field, the acoustic pressure creates a force acting on the particles due to the momentum transfer from the acoustic waves to the particles [30]. Acoustic radiation forces consist of primary and secondary forces. The primary force is responsible for moving particles towards the nodes or antinodes to form bands of particles, while counterbalancing gravity, buoyancy, drag and damping forces in the field. This force can be expressed as [28],

where \(\lambda\), \(P\), \(V,\ k\), and \(x\) are the wavelength, acoustic pressure amplitude, particle volume, wavenumber, and distance between particles and nodes, respectively. On the other hand, the secondary acoustic force, or Bjerknes force, may lead to further aggregation of particles through balancing the sound waves scattered by neighboring particles. Incorporating these two acoustic forces, in the following sections, various effective parameters and phenomena in ultrasonic treatment will be elaborated on.

Turbulence and Cavitation

When a fluid medium is under the influence of an acoustic field, ultrasound creates cavitation bubbles by imposing negative pressure on nano-meter gas pockets (diluted air bubbles) in the fluid forming bigger bubbles. The collapse of these cavitation bubbles under the effect of upcoming high-pressure incident waves generates shockwaves with conspicuous fluctuations in the pressure leading to turbulence in the fluid and changes in its temperature [31]. The presence of bubbles during sonication decreases the energy transmission by the acoustic standing wave. Figure 2 schematically illustrates acoustic energy density versus frequency considering the cavitation and acoustic streaming thresholds. Although high acoustic power might be suitable for large-scale acoustic separation at short residence times, the graph in Fig. 2 suggests that it should be below a certain level to avoid acoustic streaming in particular at high frequencies disrupting particle alignment. However, to interact with small particles or particles with low acoustic contrast factor (i.e., whenever acoustic radiation force is low), higher power levels are needed. Further, low frequencies give rise to cavitation and should be avoided. When milk is sonicated in the cavitation regimen, the oxidation process is accelerated and there is a reduction in nutritious antioxidants. Localized high-temperature zones and shear stresses close to the cavitation bubble affect molecules and their structure [32]. It has also been reported that cavitation may increase deposition of micro and nano sized metal particles from the transducer and/or vessel surface into the sample [33]. According to all these restrictions and requirements, a relatively narrow frequency range should be considered at a high enough energy density generating sufficient acoustic radiation force, as the striped region in Fig. 2. However, cavitation and these chemical changes in fluids due to sonication can be controlled by modifying other parameters involved in the process such as residence time and temperature in the system as well as frequency and acoustic power applied to the fluid [32, 34, 35]. For instance, Johansson et al. evaluated the effects of cavitation in milk under sonication at 1 and 2 MHz in a 1.2-L cubical vessel using one ultrasonic plate transducer with an active area of 100 cm2 and one reflector parallel to the transducer [32]. The input power for the transducer was configured to 0, 20, 40, 60, 80, and 100%. Luminol was used as the cavitation measurement method. Samples were preheated at 25 °C and then sonicated for 1 min and 10 min. Sonication under a cavitation or a non-cavitation regimen did not significantly affect the oxidation process in the samples; however, there was an increase in temperature due to sonication; at 1 MHz got to 6 °C for 1 min and 18 °C for 10 min, and at 2 MHz got to 4 °C for 1 min and 12 °C for 10 min. High cavitation levels were reported for irradiation at 1 MHz with power input levels above 40% while cavitation at 2 MHz with power input levels above 40% was described as low, as shown in Fig. 3.

Schematic of acoustic energy density versus frequency considering cavitation and acoustic streaming thresholds [32]

Side views of the reactor, original picture (upper) and digital processed image (lower). a 1 MHz 100% power, b 1 MHz 20% power, c ‘black reference’ 1 MHz 0% power, d 2 MHz 100% power and e 2 MHz 80%, f ‘black reference’ 2MHz 0% (and 20%,40% and 60% power) [32]

The acoustic power applied during sonication changes with the transducer type which influences the presence of cavitation in the sonicated samples. Juliano et al. used three different set-ups including a horn transducer at 20 kHz, a plate/disk transducer at 400, 1000, 1600, and 2000 kHz as well as a horn transducer at 20 kHz in a flow-through chamber as in Fig. 4. The horn type transducer delivered three times more sound power into the sample and increased the production of free radicals [34]. This transducer also triggered the collapse of large cavitation bubbles causing localized high temperature zones, which may also initiate the oxidation processes. These might be attributed to the focused high intensity acoustic fields near the tip of the transducer. In contrast, plate and disk transducers delivered sound power to the system evenly. The number of bubbles and their collapse intensity determine the number of free radicals in a sample which are both frequency dependent. Low frequencies generate large cavitation bubbles with high intensity collapse. An increase in frequency results in the formation of numerous smaller bubbles which release less energy as they collapse, however, as there are a number of these small bubbles, an increase is observed in the number of free radicals. This trend has been observed to peak within the range 400–800 kHz and any further increase in the frequency leads to a decrease in the formation of free radicals as the energy released from the collapse of very tiny bubbles is insufficient. However, formation of free radicals has been reported up to around 1.7 MHz. Extended ultrasonication for longer duration (from 5 to 20 min) has also been reported to increase formation of free radicals by around four times at 400 kHz and 1000 kHz. In addition, keeping the ultrasonication time constant, the free radical formation increases with increased specific energy irrespective of the frequency.

Schematic of set-ups used by [34]: a horn transducer at 20 kHz; b plate/disk transducer at 400, 1000, 1600 and 2000 kHz; c horn transducer at 20 kHz in a flow-through chamber

In another study, the presence of free radicals in milk samples after sonication was also related to the ultrasonication process conditions. High radical levels were reported in samples sonicated at 400 kHz and 20 kHz where three different set-ups were evaluated [36]: (i) A cylindrical reactor with a 20 kHz horn transducer submerged in the middle of a cylindrical vessel operated with 101 kW/m2 via radial direction for 15 min. (ii) A 1.6-MHz nebulizer placed at the bottom (horizontal) of the cylinder operated for 34 min with 11 kW/m2. (iii) A rectangular metallic vessel with dimensions 20 × 4 × 14.5 cm3 and an ultrasonic plate transducer placed against one of the vertical side walls. This stainless-steel transducer was configured to work at 400 kHz for 17 min with 8.6 kW/m2. The volumes of the samples sonicated were 100 ml for the 20-kHz transducer, 25 ml for the 1.6 MHz setup, and 300 ml for the 400-kHz plate transducer. However, all the setups worked under constant acoustic pressure levels and the same specific energy input of 286 kJ/kg. Higher frequencies were reported to generate more but smaller active bubbles which resulted in smaller forces due to the implosion of cavitation bubbles. The formation of soluble aggregates was also found to be lower with the increase of frequency. The initial pH of the sample affected the protein structure in the milk and its effect increased under ultrasound processing at low frequencies. This was a consequence of the high levels of cavitation present at lower frequencies [36].

Temperature Fluctuations

Another phenomenon to consider when separating particles using ultrasound is the fluctuation of temperature that the fluid experiences while being processed. Leong et al. studied the effect of temperature when separating fat from milk under sonication at 600 kHz and 1 MHz operated at nominal power (700 and 343 W, respectively) in a steel vessel with dimensions 18.2 × 24.2 × 6.2 cm3 (Fig. 5) [37]. The samples were sonicated at 3 different temperatures 5 °C, 25 °C, and 40 °C for 5 min. The increase in temperature due to sonication went from 5 to 18 °C, 25 to 40 °C and from 40 to 52 °C, respectively. Those ranges of temperature did not differ from regular conditions of milk centrifugation in industrial scale. It is worth noting that the temperature increase for both cases is not exactly the same and slightly differs. There are two graphs provided in Fig. 2 of [37] where the results are presented for both 600 kHz and 1 MHz with statistic results and error bars. The temperature increase for the 600 kHz case is slightly more which can be justified by the fact that higher power for the 600 kHz case (700W versus 343W for 1 MHz) causes more cavitation and higher temperature increase. Further, lower frequencies generally cause higher cavitation with larger bubbles which increase temperature upon their collapse [37]. It was demonstrated that the primary radiation force increased at high temperatures, thus promoting faster separation and reduction in the required fluid residence time inside the ultrasound reactor. Even though samples preheated at 40 °C presented a greater separation rate than the rest of the samples, the difference was not outstanding in comparison with samples preheated at 25 °C.

Stainless steel vessel in a temperature-controlled bath for acoustic fat-milk separation [37]

In another work, aqueous extraction of residual oil from canola was investigated using ultrasound as an alternative to hexane extraction [38]. The temperature was varied from 60 to 80 °C with frequencies of 0.4 MHz, 1 and 2 MHz, treatment time of 10–30 min, and solid concentration of 10–30%. It was demonstrated that with 10% solids, a frequency of 2 MHz and a sonication time of 30 min at a temperature of 80 °C was the most suitable condition providing approximately 50% oil extractability. It was also concluded that the effect of temperature on the separation performance was independent of the frequency and that separation increases at higher temperatures.

Generally, lower frequencies cause higher cavitation and localized high temperature zones and temperature fluctuations due to the collapse of large high intensity bubbles. Increased sonication/residence time also increases turbulence and cavitation and results in temperature increase. Transducer shape also affects temperature, for instance, horn type transducers deliver the power to the fluid medium through the tip of the transducer, hence, create large high intensity cavitation bubbles and localized high temperature zones near the tip. Higher power also creates more cavitation and causes temperature increase due to the high intensity collapse of bubbles in particular at lower frequencies.

Residence Time

Residence time affects cavitation and temperature fluctuations which are present in ultrasound processing. It has been reported that decreasing the sonication time decreases cavitation, turbulence and temperature fluctuations. Leong et al. reported that there is an optimal time of sonication after which any further processing does not have a considerable improvement in the separation process [9]. For a sample of 1.8 L milk, they used two ultrasonic plate transducers under different operating configurations (Fig. 6): one active transducer and one reflector with 100% power at (i) 1 MHz and (ii) 2 MHz; dual active transducers one with 1 MHz and the other with 2 MHz at (iii) 50% and (iv) 100% power; dual active transducers at 2 MHz with (v) 50% and (vi) 100% power. Each transducer had an active area of 100 mm2. The sample was preheated to approximately 25 °C. A water chamber surrounding the milk container was kept at approximately 25 °C to decrease the temperature changes produced by sonication. After every five minutes of sonication, the content of the vessel was divided into 5 sections to evaluate the concentration of particles in each depending on the sonication time and the globule size distribution in the vessel. Increasing the duration of sonication enhanced the differentiation between the collected partitions, particularly when comparing those collected near the bottom to those at the top. Sonication for 10 min considerably improved differentiation to the particle size and fat concentration across these sections compared with control sample at 5-min sonication. However, the improvement with 20 min of sonication was not significant compared with the case of 10 min sonication.

The vessel including the cooling and processing regions as well as transducer configurations [9]

Luo et al. also investigated the concept of optimal processing time [39]. They designed an experiment to separate water droplets from mineral oil for which the experimental set-up was based on an acoustic chamber that contained a one-dimensional acoustic field, generated by a piezoelectrical transducer placed at the bottom of the chamber. This transducer was controlled by a high-frequency power amplifier which was connected to a waveform generator, configurated to provide a sinusoidal signal. A hydrophone was placed in the middle of the acoustic chamber to measure the acoustic pressure amplitude. After sonication, the emulsion was transferred to a 50-ml conical centrifuge tube over one hour at 50 °C. It was found that the maximum dehydration rate was not obtained with the longest irradiation time. There was an optimal irradiation time which allowed the higher separation rate and avoided the acoustic cavitation phenomenon or changes in the fluid temperature that affected the acoustic cavitation threshold.

Remarks on Acoustic Separation Associated Phenomena

Acoustic separation and associated phenomena were discussed in the above sections in detail. The summary of the effect of these phenomena and interrelations can be presented in Table 2. It is worth noting that the threshold values for cavitation and free radical release are case sensitive as stated before and depend on the characteristics of the sample, vessel/chamber dimensions, transducer shape, frequency and acoustic intensity, etc.

Ultrasound Transducers

Configurations, shapes, and operating specifications of ultrasound transducers play important roles in the separation performance as well as the occurrence of the phenomena explained above. This section elaborates on various shapes and configurations of transducers employed for separation process.

Rectangular & Circular Plate Transducers

Rectangular and circular plates are the most common types of ultrasonic transducers employed in various investigations. Dionne et al. investigated the difference between the effect of a square and a circular plate transducer to separate oil droplets from a water-in-oil emulsion [40]. A one-inch round PZT-8 transducer and a 1″ × 1″ PZT-8 square transducer both operating at 2 MHz and 20 W applied power were used in an acoustic chamber with a cross section of 1″ × 2″ to investigate the effect of the transducer shape. The square transducer was found to be more efficient than the round transducer, which was explained by the better coverage of the flow channel with stronger acoustic forces when using the square transducer. The strong acoustic forces were only observed along the centerline of the acoustic field for the circular transducer. Although not discussed in their work, we envisage this might be attributed to the vibration mode shapes of the transducer which play an important role in the acoustic radiation characteristics of the transducer. This can be controlled through introducing some geometrical variations in the form of stepped-thickness variations [11, 13, 14, 16, 41,42,43,44,45].

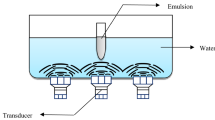

To evaluate the effect of ultrasound on the destabilization and creaming process of milk, two types of transducers were investigated, one was a rectangular plate transducer working at 400 kHz and the other was a 1.6-MHz nebulizer (circular plate) [46]. Two setups were also considered, one with a single transducer (either 400 kHz or 1.6 MHz) placed at the bottom of the tank/chamber with a reflector at the top and the other with two 400-kHz transducers facing each other on both sides of the chamber (Fig. 7). There was a gap of 1 cm between the transducers and the vessel containing the milk in the chamber. The chamber was filled with water at 35 °C, the same temperature of the sample, in order to minimize the changes of temperature in the sample due to sonication. The time of sonication for each case was 5 min and the measurements were taken 10 min after turning off the transducers. For both types of transducers, improved creaming was observed through clustering of fat particles which can be controlled by manipulating the sonication conditions.

a Single transducer (either rectangular plate at 400 kHz or circular plate at 1.6 MHz) placed at the bottom of the tank with a reflector at the top b two 400 kHz rectangular plate transducers facing each other [46]

In another study, the use of ultrasound was investigated for extracting canola oil from canola cake. A submersible 16 × 16 × 3.2 cm3 ultrasonic plate transducer was used at 0.4, 1, and 2 MHz in a 200-ml vessel tub placed inside a reactor of 40 × 21 × 20 cm3 size [38]. The temperature was kept constant with a cooling jacket. The samples were sonicated for 10, 20, and 30 min at different temperatures (60, 70, and 80 °C). The concentration of the canola cake in the sonicated samples varied from 10 to 30%. The net ultrasonic extractability reported at 2 MHz was three times higher than that at 1 MHz. The highest extractability rate was 48.8% at 2 MHz sonicated for 30 min, which was only 5% higher than the extractability in samples with similar conditions sonicated for 20 min. The effect of the temperature on the extractability of the cake was reported to be independent of the frequency. Higher extractability rates were seen in samples treated at higher temperatures (70 and 80 °C) in comparison with samples treated at the same frequency and time.

Cylindrical Transducers

Another type of ultrasonic transducers which has not been sufficiently investigated for particle separation is cylindrical transducers. The hollow geometry of a cylinder makes it suitable for particles separation in a flowing fluid medium. Further, the curved geometry of the cylinder allows for a focused stronger acoustic field inside the transducer. However, limited literature has investigated the use of ultrasound cylindrical transducers for particles separation. In an investigation, which was not for food industry, a cylindrical transducer (PZT-4, outer diameter 19 mm, inner diameter 16 mm and length of 28 mm) was used to separate microparticles in a continuous flow system [20]. Two suspensions were considered in the study, a water-based and a biological suspension-viscous fluid which resembled human blood. When the transducer was operating at 202 kHz, it presented a flow instability and the suspension mixed instead of getting separated. However, at 345 kHz, successful separation was achieved. This verifies that identifying the suitable frequency and acoustic pressure level is important to be able to achieve acoustic separation. The processing time required to separate the suspensions was lower for the water-based than for the biological based fluid. The extraction of microparticles was achieved through a custom designed collector with channels in-line with the nodal circles where particles gathered. Even though the distribution of both biological and water suspension particles in the acoustic pressure field was the same, the velocity of particle convergence to the nodal circles was different.

Other Transducer Types (Horn & Ultrasonic Bath Transducers)

There were other types of transducers which have been employed and investigated for various purposes. Several applications for the use of ultrasonic horn transducers have been investigated and compared with other shapes of transducers in terms of efficiency, cavitation threshold changes, temperature changes during sonication, among others. As an example, the effect of acoustic cavitation created with a sonotrode and discharged plasma on water purification was investigated by Komarov et al. [47]. The sonotrode was placed in the middle of a cylindrical vessel with continuous flow and operated at low ultrasonic frequencies between 19 and 21 kHz with an acoustic power up to 300 W. The sonotrode worked under strong cavitation conditions, so in addition to the plasma discharge, the water in the cavitation region was purified. The temperature was kept at 20 ± 2 °C during the experiments, and the flow rate was fixed at either 2, 4, 6, or 8 L/min. In order to evaluate the impact of the flow inside the vessel, experiments in non-circulating conditions were run by keeping the liquid at the same level as with continuous flow and sonicated for 12 min in all the experiments. The ultrasound power applied to the samples was measured calorimetrically. The purification efficiency increased with the use of ultrasound in a combined treatment. It was also shown that the direction of flow inside a vessel under cavitation conditions was determined by the acoustic streaming.

Another type of transducer is ultrasonic bath. Although the use of ultrasonic baths for cleaning proposes is widely known in the industry, new applications for laboratory samples have been considered. For instance, the extraction of oil form tobacco seeds using two chemical solvents was compared with and without ultrasound [48]. Samples of 100 ml at different solvents’ concentration were sonicated in an ultrasonic bath of 30 × 15 × 20 cm3 at 40 kHz for 2.5, 5, 20, 40, and 60 min. The experiments were reproduced at 3 different temperatures of 25, 40 °C and boiling temperature. The extraction of the oil from the solid residue was performed through a vacuum filtration process. A higher extraction rate was achieved in the samples with particle size below 0.4 mm. The optimal sonication time changed according to the particle size distribution of the sample, increasing with bigger particles. The use of ultrasound for extraction of oil reported 1.5 to 2 times the efficiency of extraction than in samples treated without ultrasound processing. The time for oil extraction when using ultrasound decreased from 90 to 20 min.

Transducer Configurations

The configuration of the transducers has a direct effect on the sound intensity in the fluid even if the transducers are working at the same frequency or power. Juliano et al. investigated four configurations for stainless steel plate transducers: a single vertical transducer with a reflector, a single horizontal transducer, double vertical parallel and double vertical perpendicular transducers with reflectors (Fig. 8) [49]. Each of those configurations were operated at 0.4, 1 and 2 MHz and 8.5 ± 0.6 kJ/kg in a 5L milk emulsion containing stained fat globules at 35 °C and sonicated for 4 min. For the cases of single transducers, the vertical configuration has proven more effective in improving separation at 0.4 MHz followed by 1 MHz. The vertical 2 MHz configuration proved unsuccessful in separation which might be attributed to the increased acoustic streaming at higher frequencies. The same applies to double vertical configurations at 2 MHz.

Experimental set-ups for various configurations: a a single vertical transducer with a reflector; b a single horizontal transducer; c double vertical parallel and d double vertical perpendicular transducers with reflectors [49]

The double vertical perpendicular configuration and the single vertical configuration at 0.4 MHz performed similarly in terms of separation followed by the double vertical parallel configuration at 0.4 MHz. Although the specific energy in the chamber was higher in case of double vertical transducers, this did not improve the separation efficiency compared to the single vertical transducer at 0.4 MHz. This might be due to the fact that the two transducers were not synchronized leading to turbulence generation rather than acoustic standing field. However, the double vertical perpendicular configuration had a quicker separation.

The single horizontal transducer configuration performed better in terms of separation at 2 MHz compared to 0.4 and 1 MHz. The horizontal configuration with vertical radiation generated conspicuous acoustic streaming and strong turbulence which was more prominent at 0.4 and 1 MHz than at 2 MHz. Hence, contrary to vertical configurations, it achieved a better separation at 2 MHz than at 0.4 and 1 MHz. To explain this, it is required to discuss the acoustic standing wave formation. In the vertical configurations, there is a reflector parallel to the transducer, however, for the single horizontal case, there exists no reflector and the waves move towards the surface and liquid-air interface and are scattered. Hence, reflected waves after the disturbance at the interface are at a lower intensity forming a less pronounced acoustic standing field. At higher frequencies, i.e., 2 MHz, with a shorter wavelength, this disturbance is minor at the surface leading to stronger acoustic forces and standing field forcing fat particles to gather at anti-nodes. Further, the acoustic streaming helps move the particles across the nodes towards the top.

Juliano et al. conducted comparison between ultrasonic plate and horn transducers for separation and recovery of palm using two set-ups as in Fig. 9 [50]. For low-frequency ultrasound processing, two separate flowing fluid vessels were used, one with a focused sonotrode (306 kJ/kg) and the other with a long radial sonotrode (161 kJ/kg), both transducers run at 20 kHz. On the other hand, for the high-frequency ultrasound processing, a set of three transducers was used in a rectangular vessel, two 400-kHz plate transducers (28 kJ/kg) in a vertical configuration and one 1.6 MHz nebulizer (6 kJ/kg) in the middle of the vessel. For this setup, a test tube with the sample was placed above the nebulizer with the vessel full of liquid. While the samples were sonicated at low and high frequencies, a third set of samples was sonicated first at low frequency and then at high frequency to evaluate the effect of the two configurations. The sonication time was 5 min for all the experiments. The results showed that high-frequency ultrasound was useful to separate oil from non-oil solids in the samples which were in the range of submicron and micron. Low-frequency ultrasound can increase or decrease the oil recovery depending on the transducer being used and the feed type. Although the use of high frequency ultrasound increased the total oil recovery by 5 to 12.6%, the total recovery of oil in the samples treated with both low and high frequency ultrasound was not significantly different to the control sample which was due to the low frequency ultrasound effects. In case of using both low and high frequencies, re-emulsification of the oil occurred which reduced total recoverable oil. The underflow sludge has lower oil content and higher non-oil solids forming a more stable emulsion under low frequency ultrasound. The release of surface-active materials (pectins and hemicelluloses) from the non-oil solids increases under ultrasound-induced shear effects at 20 kHz which stabilizes the emulsion such that the oil does not coalesce within the anti-nodal planes for separation. Overall, it was concluded that oil recovery depends on ultrasound treatment applied, type of transducer used and the feed stream.

Experimental set-ups employed by [50]: a low frequency ultrasound processing at 20 kHz in a flow-through chamber with two transducers, once with a focused sonotrode (bottom) and the other a long radial sonotrode (top); b high frequency ultrasound processing with a set of three transducers, two 400 kHz plate transducers in a vertical configuration and one 1.6 MHz nebulizer in the middle of the vessel below the test tube

Remarks on Ultrasound Transducer Shapes and Configurations

Various ultrasound transducer shapes and configurations were discussed in the previous sections. In order to sum up more conveniently, Table 3 is presented as below.

Discussion

From the above sections, particles separation has various applications in different areas including but not limited to food industry, biomedical sector, etc. Consequently, numerous techniques have been developed and employed meeting the requirements for each application. Each separation technique employed for food industry was discussed briefly indicating pros and cons. As a result of disadvantages and the need for newer and more efficient techniques, ultrasonic separation was considered and investigated as a potential alternative to other available techniques. An important component of ultrasonic separation is inherent in the transducers and their performance. Accordingly, common types of ultrasonic transducers, related phenomena such as cavitation and influential parameters such as frequency and temperature were discussed. Geometry of the transducer, vibration mode shapes and the corresponding frequencies play important roles in the acoustic radiation characteristics of the transducer and affect the ultrasonic separation. While different geometries were discussed, it was observed that the literature lacks investigations on cylindrical transducers for separation purposes. They have two features which may make them superior over other types of transducers. The hollow structure allows for dynamic flows so that as the fluid medium and floating particles are flowing along the length of the cylindrical transducer, they can be exposed to ultrasound to be separated. Further, the cylindrical geometry and the curved surface allow for stronger and focused acoustic fields inside the transducer. Despite having all these features, they have not been investigated for separation purposes. In some other investigations for levitation of water droplets in air, cylindrical transducers were employed. As mentioned above, the selection of the frequency for the vibration of the piezoelectric transducers is an important factor to generate the standing wave inside the transducer with pressure nodes. In order to synchronize the resonance frequency of the cavity inside the cylindrical shell and the shell itself, two methods were proposed for levitating aerosols at pressure nodes, a physical change of the transducer or a change in the resonance frequency of the cavity within the transducer [51]. The first method is structurally tuning where the structure of the cylinder was modified with an opening along the length to tune the resonance frequency of the piezoelectric transducer to match that of the cavity in order to have specific number of nodal circles inside the transducer. The second method is cavity tuning which aims to change the resonance frequency of the cavity inside the transducer to match the transducer resonance frequency. The cavity inside the cylinder is filled either with an elliptical or circular rod. These rods placed coaxially within the cylindrical transducer allow for certain number of nodal circles or points depending on their position and dimensions. For collection purposes, a tube was placed at the end of the cavity around the localized pressure nodes to collect water droplets. Although not very relevant to particles separation or food industry, the designs incorporated in the transducer may be of interest for designing transducers for particle separation through applying the same mechanism.

A physical change of the transducer has an impact on the acoustic power achieved within the transducer. For example, the use of stepped-thickness variations in a piezoelectric cylindrical transducer to generate amplified acoustic field in localized areas was studied by the authors [13, 14, 16]. While these may not be the only options, they are some examples on how it might be possible to design cylindrical transducers to generate strong acoustic fields and/or certain number of pressure nodes inside the transducer to be able to achieve the required particle separation for the intended application.

Concluding Remarks

This paper may shed light to some of the future investigations in order to direct them towards (1) application of cylindrical ultrasound transducers and (2) design and development of cylindrical ultrasound transducers suitable for various particle separation applications in food industry or any other field depending on the specific requirements. This may in turn result in identification of the associated phenomena and effective operational parameters for various applications using cylindrical transducers in the food industry. Consequently, the development of better transducers with more efficient separation and less detrimental effects is aspired.

Change history

03 March 2023

Missing Open Access funding information has been added in the Funding Note.

References

Rosenthal A, Pyle DL, Niranjan K (1996) Aqueous and enzymatic processes for edible oil extraction. Enzyme Microb Technol 19(6):402–420. https://doi.org/10.1016/S0141-0229(96)80004-F

Leong T, Juliano P, Johansson L, Mawson R, McArthur S, Manasseh R (2015) Continuous flow ultrasonic skimming of whole milk in a liter-scale vessel. Ind Eng Chem Res 54(50):12671–12681. https://doi.org/10.1021/acs.iecr.5b03142

Li P, Mao Z, Peng Z, Zhou L, Chen Y, Huang PH, Truica CI, Drabick JJ, El-Deiry WS, Dao M, Suresh S, Huang TJ (2015) Acoustic separation of circulating tumor cells. Proc Natl Acad Sci USA 112(16):4970–4975. https://doi.org/10.1073/pnas.1504484112

Martinez-Padilla LP, Franke L, Xu XQ, Juliano P (2018) Improved extraction of avocado oil by application of sono-physical processes. Ultrason Sonochem 40(Pt A):720–726. https://doi.org/10.1016/j.ultsonch.2017.08.008

Caplan Z, Melilli C, Barbano DM (2013) Gravity separation of fat, somatic cells, and bacteria in raw and pasteurized milks. J Dairy Sci 96(4):2011–2019. https://doi.org/10.3168/jds.2012-6006

Negin C, Ali S, Xie Q (2017) Most common surfactants employed in chemical enhanced oil recovery. Petroleum 3(2):197–211. https://doi.org/10.1016/j.petlm.2016.11.007

Lambert S, Leconte N, Blot M, Rousseau F, Robert B, Camier B, Gassi J-Y, Cauty C, Lopez C, Gésan-Guiziou G (2016) The lipid content and microstructure of industrial whole buttermilk and butter serum affect the efficiency of skimming. Food Res Int 83:121–130. https://doi.org/10.1016/j.foodres.2016.03.002

Jo MC, Guldiken R (2012) Active density-based separation using standing surface acoustic waves. Sens Actuators A 187:22–28. https://doi.org/10.1016/j.sna.2012.08.020

Leong T, Johansson L, Mawson R, McArthur SL, Manasseh R, Juliano P (2016) Ultrasonically enhanced fractionation of milk fat in a litre-scale prototype vessel. Ultrason Sonochem 28:118–129. https://doi.org/10.1016/j.ultsonch.2015.06.023

Garcia-Perez JV, Carcel JA, de la Fuente-Blanco S, Riera-Franco de Sarabia E (2006) Ultrasonic drying of foodstuff in a fluidized bed: Parametric study. Ultrasonics 44(Suppl 1):e539–e543. https://doi.org/10.1016/j.ultras.2006.06.059

Al-Jumaily AM, Meshkinzar A (2017) On the development of focused ultrasound liquid atomizers. Adv Acoust Vib 2017:1–10. https://doi.org/10.1155/2017/7861726

Meshkinzar A, Al-Jumaily AM (2019) Vibration of circumferentially stepped-thickness piezoelectric cylindrical shells. Vibroeng Proced 24:1–5. https://doi.org/10.21595/vp.2019.20737

Meshkinzar A, Al-Jumaily AM (2021) Vibration and acoustic radiation characteristics of cylindrical piezoelectric transducers with circumferential steps. J Sound Vib 511:116346. https://doi.org/10.1016/j.jsv.2021.116346

Al-Jumaily AM, Meshkinzar A, Harris PD, Huang L (2020) Acoustic radiation characteristics of piezoelectric shells with internal and external axial stepped-thickness configurations. Sens Actuators Phys 302:111819. https://doi.org/10.1016/j.sna.2019.111819

Ahmed A, Meshkinzar A (2020) Stepped cylindrical piezoelectric transducer. US Patent App. 16/765,624

Meshkinzar A, Al-Jumaily AM, Harris PD (2018) Acoustic amplification utilizing stepped-thickness piezoelectric circular cylindrical shells. J Sound Vib 437:110–118. https://doi.org/10.1016/j.jsv.2018.08.033

Meshkinzar A, Al-Jumaily AM (2018) Acoustic radiation of axially stepped-thickness piezoelectric cylindrical shells. Proceedings of the ASME 2018 International Mechanical Engineering Congress and Exposition IMECE2018. https://doi.org/10.1115/IMECE2018-86306

Meshkinzar A (2018) Vibration Characteristics of stepped thickness circular cylindrical piezoelectric shells for ultrasound amplifications. Auckland University of Technology, New Zealand (Doctoral Thesis)

Meshkinzar A, Al-Jumaily AM (2020) Acoustically enhanced evaporation of a polydisperse stream of micro water droplets. J Aerosol Sci 139:105466. https://doi.org/10.1016/j.jaerosci.2019.105466

Ostasevicius V, Jurenas V, Golinka I, Gaidys R, Aleksa A (2018) Separation of microparticles from suspension utilizing ultrasonic standing waves in a piezoelectric cylinder actuator. Actuators 7(2):14. https://doi.org/10.3390/act7020014

Ma Y, Barbano DM (2000) Gravity separation of raw bovine milk: fat globule size distribution and fat content of milk fractions. J Dairy Sci 83(8):1719–1727

Drewniak MA, Lyon AW, Fenton TR (2013) Evaluation of fat separation and removal methods to prepare low-fat breast milk for fat-intolerant neonates with chylothorax. Nutr Clin Pract 28(5):599–602. https://doi.org/10.1177/0884533613497763

Jukkola A, Hokkanen S, Kämäräinen T, Partanen R, Heino A, Rojas OJ (2019) Changes in milk fat globules and membrane lipids under the shear fields of microfiltration and centrifugation. J Membr Sci 573:218–225. https://doi.org/10.1016/j.memsci.2018.12.007

Sørensen I, Jensen S, Ottosen N, Neve T, Wiking L (2016) Chemical quality of raw milk retentate processed by ultra-filtration or reverse osmosis at the dairy farm. Int J Dairy Technol 69(1):31–37

Jukkola A, Partanen R, Rojas OJ, Heino A (2018) Effect of heat treatment and pH on the efficiency of micro-diafiltration for the separation of native fat globules from cream in butter production. J Membr Sci 548:99–107

Brouillet F, Bullón J, Cárdenas A, Sánchez J, Marti-Mestres G, Briceño MI (2003) Modification of the droplet size and distribution of parenteral emulsions by tangential microfiltration. J Membr Sci 221(1–2):199–206

Hirasaki GJ, Miller CA, Puerto M (2008) Recent advances in surfactant EOR. SPE Annual Technical Conference and Exhibition. Society of Petroleum Engineers

Shi J, Huang H, Stratton Z, Huang Y, Huang TJ (2009) Continuous particle separation in a microfluidic channel via standing surface acoustic waves (SSAW). Lab Chip 9(23):3354–3359. https://doi.org/10.1039/b915113c

Trippa G, Ventikos Y, Taggart DP, Coussios CC (2011) CFD modeling of an ultrasonic separator for the removal of lipid particles from pericardial suction blood. IEEE Trans Biomed Eng 58(2):282–290. https://doi.org/10.1109/TBME.2010.2061845

Sarabia ERFD, Gallego-Juarez JA, Rodriguez G, Elvira-Segura L, Gonzalez-Gomez II (2000) Application of high-power ultrasound to enhance fluid/solid particle separation processes. Ultrasonics 38:642–646

Gupta S, Feke DL, Manas-Zloczower I (1995) Fractionation of mixed particulate solids according to compressibility using ultrasonic standing wave fields. Chem Eng Sci 50(20):3275–3284

Johansson L, Singh T, Leong T, Mawson R, McArthur S, Manasseh R, Juliano P (2016) Cavitation and non-cavitation regime for large-scale ultrasonic standing wave particle separation systems–In situ gentle cavitation threshold determination and free radical related oxidation. Ultrason Sonochem 28:346–356. https://doi.org/10.1016/j.ultsonch.2015.08.003

Mawson R, Rout M, Ripoll G, Swiergon P, Singh T, Knoerzer K, Juliano P (2014) Production of particulates from transducer erosion: implications on food safety. Ultrason Sonochem 21(6):2122–2130

Juliano P, Torkamani AE, Leong T, Kolb V, Watkins P, Ajlouni S, Singh TK (2014) Lipid oxidation volatiles absent in milk after selected ultrasound processing. Ultrason Sonochem 21(6):2165–2175. https://doi.org/10.1016/j.ultsonch.2014.03.001

Mizushima Y, Nagami Y, Nakamura Y, Saito T (2013) Interaction between acoustic cavitation bubbles and dispersed particles in a kHz-order-ultrasound-irradiated water. Chem Eng Sci 93:395–400. https://doi.org/10.1016/j.ces.2013.02.028

Liu Z, Juliano P, Williams RP, Niere J, Augustin MA (2014) Ultrasound effects on the assembly of casein micelles in reconstituted skim milk. J Dairy Res 81(2):146–155. https://doi.org/10.1017/S0022029913000721

Leong T, Juliano P, Johansson L, Mawson R, McArthur SL, Manasseh R (2014) Temperature effects on the ultrasonic separation of fat from natural whole milk. Ultrason Sonochem 21(6):2092–2098. https://doi.org/10.1016/j.ultsonch.2014.02.003

Gaber MAFM, Trujillo FJ, Mansour MP, Taylor C, Juliano P (2019) Megasonic-assisted aqueous extraction of canola oil from canola cake. J Food Eng 252:60–68. https://doi.org/10.1016/j.jfoodeng.2019.02.017

Luo X, Cao J, Yan H, Gong H, Yin H, He L (2018) Study on separation characteristics of water in oil (W/O) emulsion under ultrasonic standing wave field. Chemical Engineering and Processing - Process Intensification 123:214–220. https://doi.org/10.1016/j.cep.2017.11.014

Dionne J, McCarthy B, Ross-Johnsrud B, Masi L, Lipkens B (2013) Large volume flow rate acoustophoretic phase separator for oil water emulsion splitting. Acoust Soc Am 141(3):1664. https://doi.org/10.1121/1.4977030

Darvizeh A, Meshkinzar A, Alitavoli M, Rajabiehfard R (2017) Low velocity impact of empty and foam filled circumferentially grooved thick-walled circular tubes. Thin-Walled Struct 110:97–105. https://doi.org/10.1016/j.tws.2016.09.002

Darvizeh A, Darvizeh M, Ansari R, Meshkinzar A (2014) Analytical and experimental investigations into the controlled energy absorption characteristics of thick-walled tubes with circumferential grooves. J Mech Sci Technol 28(10):4199–4212. https://doi.org/10.1007/s12206-014-0933-5

Darvizeh A, Darvizeh M, Ansari R, Meshkinzar A (2013) Effect of low density, low strength polyurethane foam on the energy absorption characteristics of circumferentially grooved thick-walled circular tubes. Thin-Walled Structures 71:81–90. https://doi.org/10.1016/j.tws.2013.04.014

Gallego-Juárez JA, Rodrı́guez-Corral G, Riera-Franco de Sarabia E, Vázquez-Martı́nez F, Campos-Pozuelo C, Acosta-Aparicio VM (2002) Recent developments in vibrating-plate macrosonic transducers. Ultrasonics 40(1–8):889–893. https://doi.org/10.1016/s0041-624x(02)00220-2

Gallego-Juárez JA, Rodríguez-Corral G, Sarabia ER-FD, Vázquez-Martínez F, Acosta-Aparicio VM, Campos-Pozuelo C (2001) Development of industrial models of high-power stepped-plate sonic and ultrasonic transducers for use in fluids. Ultrasonics Symposium. IEEE

Juliano P, Kutter A, Cheng LJ, Swiergon P, Mawson R, Augustin MA (2011) Enhanced creaming of milk fat globules in milk emulsions by the application of ultrasound and detection by means of optical methods. Ultrason Sonochem 18(5):963–973. https://doi.org/10.1016/j.ultsonch.2011.03.003

Komarov S, Yamamoto T, Fang Y, Hariu D (2020) Combined effect of acoustic cavitation and pulsed discharge plasma on wastewater treatment efficiency in a circulating reactor: A case study of Rhodamine B. Ultrason Sonochem 68:105236. https://doi.org/10.1016/j.ultsonch.2020.105236

Stanisavljevic IT, Lazic ML, Veljkovic VB (2007) Ultrasonic extraction of oil from tobacco (Nicotiana tabacum L.) seeds. Ultrason Sonochem 14(5):646–652. https://doi.org/10.1016/j.ultsonch.2006.10.003

Juliano P, Temmel S, Rout M, Swiergon P, Mawson R, Knoerzer K (2013) Creaming enhancement in a liter scale ultrasonic reactor at selected transducer configurations and frequencies. Ultrason Sonochem 20(1):52–62. https://doi.org/10.1016/j.ultsonch.2012.07.018

Juliano P, Swiergon P, Mawson R, Knoerzer K, Augustin MA (2013) Application of ultrasound for oil separation and recovery of palm oil. J Am Oil Chem Soc 90(4):579–588. https://doi.org/10.1007/s11746-012-2191-y

Kaduchak G, Sinha DN (2001) Low-power acoustic harvesting of aerosols. 2001 IEEE Ultrasonics Symposium. IEEE, Atlanta, GA, USA. https://doi.org/10.1109/ULTSYM.2001.991803

Funding

Open Access funding enabled and organized by CAUL and its Member Institutions. This work is supported by SRIF Grant No R11797.01 Auckland University of Technology.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing Interests

The authors declare is no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Al-Jumaily, A.M., Meshkinzar, A. & Torres, L.M.P. On the Development of Emulsion Destabilization Technologies for Dairy Industry. Food Eng Rev 15, 215–229 (2023). https://doi.org/10.1007/s12393-023-09336-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12393-023-09336-4