Abstract

The historic post-mining objects deserve special attention due to their high cognitive and didactic value. Conducting the revitalization of such facilities is aimed at preserving the mining cultural heritage, and as a result, it will insert attractiveness to the region. The publication attempts to present an approach to the issues of revitalization of post-mining objects and their analysis in Poland, Spain, and UK. In Poland, there is the Revitalization Act, which comprehensively defines stages and ways of conducting revitalization. Spanish legal regulations do not provide for a separate legal act on revitalization, but they are based on mining Law, environmental law, and cultural heritage law. On the other hand, legal regulations in UK do not provide solutions for the revitalization of post-mining areas. However, land leases could incorporate within them, prior to any industrial or mining activities commencement, a requirement for re-stabilization or returning the land to a safe environmental condition on activity completion. Despite the considerable diversity of legal conditions in the described countries, revitalization measures are conducted with positive results, as illustrated by the Gold Mine in Zloty Stok, La Tortilla Mine in Linares, and revitalization of King Edward Mine, an old mining site in Cornwall.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Ores have been mined for centuries, even since the Bronze Age. Hundreds of years of exploration and exploitation works left behind a rich legacy of mining and metallurgical traditions. This legacy primarily includes relics of old open cast and underground workings, spoil banks, slug dumps, ore enrichment waste repositories, elements of hydro-engineering structures—inextricably related with old mining technologies—and even preserved fragments of mining surface infrastructure. Remnants of past mining are mostly development excavations of old mines, especially adits and shaft relics, the latter being preserved in a much worse condition. In all but few cases, historic shaft locations are marked only by small land subsidence areas. Relics of exploratory works have a similar character to remnants of the “multi-shaft” underground mining method, which consists in sinking a number of shallow shafts on a large area and mining minerals from deposits located close to the surface. Remnants of hydro-engineering structures comprise backwaters formed by earth dams built across stream valleys in the vicinity of old mine locations, reservoirs for storing and supplying water to proper locations, and systems of canals and wooden troughs supplying water to sheave wheels built directly in the shafts. A particularly interesting group of relics includes remnants of machines and devices used in water removal and transportation, such as suction pumps and the related power transmission elements (Madziarz 2013; Harfst 2015).

Historic structures of this type are very attractive, and therefore, a significant growth of interest is observed in using them as mining heritage objects in tourism (Conesa et al. 2008; Gligor and Tămaş 2009; Zhang et al. 2011; Marescotti et al. 2018; Baczyńska et al. 2017, 2018). Obviously, such objects must be first adapted to serve particular functions. However, with just a few exceptions, works aimed at cataloging, protecting, preserving, and using such historic objects for economic purposes have been undertaken only recently. Therefore, such actions should be systematically described and defined, as they are performed in a context wider than just reclamation and management of post-mining lands. Their proper definition would also allow a more complex approach to the design, organizational, and financial aspects of their implementation. It should be emphasized that in various cases, the issue of revitalization and the processes of its implementation is understood differently. For comparison purposes, the publication includes a review of formal and legal regulations and applicable procedures governing the revitalization of post-mining objects in Poland, Spain, and UK. The authors also provide examples of post-mining objects revitalized for tourist and recreational purposes in the three countries which will begin to increase interest in the region.

The Notion of Revitalization in the Context of Post-mining Remnants

The heritage concept has evolved from a restricted idea, summed up to the historical and artistic elements or monuments, to a more global idea considering as heritage the landscapes, historical sites, built spaces, biodiversity, groups of several objects, present and past traditions, and the vital knowledge and experiences (ICOMOS 1999). In this way, the mining heritage is formed by the remains of the industrial culture with historical, technological, social, architectural, or scientific values. Remains consisting in buildings and machinery, workshops, mills and factories, mines and places to process and refine, warehouses and stores, sites to produce, transmit and use the energy, means of transportation and all their infrastructure, and places where social activities related with the industry are being developed, as the housing, religious cult, or the education, as the Nizhny Tagil Charter about Industrial Heritage (TICCIH 2003) explained (Cañizares and del Carmen 2011).

Areas in which elements of post-mining infrastructure have already been made available to tourists are highly attractive mostly due to their educational potential. Objects in such areas are treated as museum exhibits. Importantly, industrial heritage represents the history of civilization with particular focus on technical and technological processes. It is also a record of civilization in which industrial history is illustrated, in the material aspect, by buildings and structures related to a given place and landscape, as well as by historical machines and technological processes. Therefore, such sites are valuable assets in the catalogs of tourist products offered by an area. Moreover, they contribute to the economic growth of an area, and as a result improve the region’s economic potential, for example by creating new workplaces in the sector of services, as industrial tourism involves any kind of tourist services (e.g., related to accommodation, gastronomy etc.) (Jędrysiak 2011). Thus, considering the importance and specific nature of opening old mining sites to public, it seems more adequate to view such activities in a context broader than just reclamation and development of post-mining areas. For this reason, it seems justified to use definition of revitalization in Poland, provided in the Government Program for Post-Industrial Areas adopted by the Council of Ministers (Ministerstwo Środowiska 2004), and covering such processes of both reclamation and land development (including the clearing, rebuilding, and modernizing of the existing land cover) which allow for restoring the land to a functional condition. Obviously, the major goal of revitalization is to stimulate social and economic development, largely by increasing the area’s tourism and cultural potential and by providing the degraded objects with social and economic functions (Kołodziej 2005). Moreover, revitalization should be a complex process and include a number of multidirectional, complementary, and mutually reinforcing activities aimed at triggering a positive, qualitative change in the area. However, the Revitalization Act of 9 October 2015 (Ustawa z dnia 9 października 2015r. 2015), revitalization is defined as a complex process of overcoming a crisis condition of degraded areas by integrated activities for the benefit of the local community, area, and economy, concentrated on a particular territory, performed by stakeholders in the revitalization process and based on the municipal revitalization program. Importantly, although the quoted Act does not specify the entity responsible for the revitalization process, preferably an investor, it indicates that if revitalization works are to be performed within a town, municipality, or an area, they are viewed as the municipality’s own task (Parysek 2016).

In Poland, the first phase of revitalization is reclamation. According to Polish law, land affected by the mining of minerals should be reclaimed and developed. Thus, areas affected by metal mining and intended for use in tourism should be first reclaimed and developed. The notion of land reclamation has been defined in Art. 4 of the Polish Act on the Protection of Agricultural and Forest Land (Ustawa z dnia 3 lutego 1995r. 1995) as providing or restoring utility or natural value to degraded or devastated land by means of appropriate land modeling, improvement of physical and chemical properties, adjustment of water conditions, redevelopment of soil, reinforcement of slopes, and reconstruction or construction of necessary roads, while development is understood as agricultural, forest, or other form of usage of reclaimed lands. Importantly, the responsibility for reclamation is placed on the mining operator, while land development is not regulated and remains the within the competence of the future user of the reclaimed land, which is not necessarily the mining operator. In the case of post-mining remnants, one more problem exists: Formal and legal regulations on the reclamation of post-mining land apply first and foremost to the areas of active mineral extraction. They do not apply to areas in which mining activity was stopped long time ago and was not followed immediately by land reclamation and development. These areas are typically private properties, owned either by local municipalities or by State Treasury, which in accordance with the Geological and Mining Law (Ustawa z dnia 9 czerwca 2011r. 2011) and with the Environmental Protection Law (Ustawa z dnia 27 kwietnia 2001r. 2001), are responsible for their reclamation. Additionally, in order to provide these objects with a tourist value, an investor is required: an owner, State Treasury, or a third party (e.g., private individuals or companies).

The post-mining remnants in Spain are not much regulated by the law. Meanwhile, the state is the owner of the underground and all contained in it, the surface of the mining concessions is mainly private property, and the owners can carry out any economic activity in them with the only obligation to maintain the access to the underground works (shafts and addits must be open). The security, which is still a state responsibility, is regulated by the general regulations and basic specifications of mining security. Nevertheless, the Spanish rules include in detail the relationship between the mining and the environment.

The Mining Law (Ley 22/73 1973) from 1973, still current, establishes that the state will carry out studies to fix environment protection conditions that will be imperative during the resources exploitation. This responsibility is passed to the owners and mining companies in 1982, establishing the obligation of the title holder to prepare a restoration plan before to start the exploitation. In this way, to restore must be understood as the necessary actions to reduce the detriment, damage or lessening received by the environment due to the human activities (mining in this case) affecting to the natural and ecological functioning of the system or to the landscape.

The Law 21/2013 (Ley 21 2013) about Environmental evaluation establish the obligation to carry out an environmental evaluation included in the project, as well as in the development and abandon of the mining activities. The current regulation of the mining activity only mentioned the necessity of measures to maintain the security in the abandoned and active mining sites and works. Since the publishing of the Mining Security General Rules Regulation in 1988, it is obligatory: “to present a project including security measures, as well as other aspects, to prevent possible damages in the surface or underground mining works, to apply for the final abandon of the mines to the Mining Authorities.”

So, we can assert in Spain that there is no specific regulation of mining sites revitalization. The way to give them a new value and to promote a new activity for them is practically limited to the consideration of the mining remains as inherited elements. That way, they would remain under the regulation established in the Law 16/85 of Historical Heritage (Ley 16 1985). In this concept, the mining is included in the Industrial heritage: “the group of elements of the industrial exploitation, originated by the economic activities of each society,” and their status and revitalization would regulated by the National Plan for the Industrial Heritage. Despite the lack of orderly legal regulations concerning revitalization in Spain, such activities are conducted, a good example of which is the object described in the publication.

The issues regarding the revitalization of post-mining facilities in the UK have Regional differences. In the country, there are no clear legal requirements and formal guidelines concerning directly revitalization activities. In spite of this, one can find many good examples of conducting revitalization activities on post-mining objects showing relics of mining activity. It can be assumed that these good examples are the result of actions of people who care about maintaining their cultural heritage, which are post-mining objects.

Classification of Revitalization Directions

A number of applications exist for relics of old mining activities, and therefore, they need classification. An approach offered by Kaźmierczak et al. (2017) seems appropriate in this case. This classification includes 6 general directions (agricultural, forest, aquatic, natural, economic, and cultural), which are further divided into 23 particular functions. The essence of the proposed systematic approach lies in the fact that apart from dividing the directions into general and particular, it is possible to combine them in the following form: <general.particular>, <general.particular,particular>, or alternatively <general+general.particular+particular>. This produces a significantly greater number of eventual combinations from number ngen to number ngen × npart and even ngen × npart + ngen × npart.

The areas surrounding post-mining relics may be used in any direction, while the actual relics are most typically revitalized in the cultural direction, with the aim to increase the value related to industrial history. Particular functions within this direction include science and art, and consequently the most important functions will be scientific—related to thematic trails or museums of industry. However, such perspective seems insufficient, and therefore, it is suggested to expand the particular scientific direction by mining/industry relics (Table 1).

Revitalization Procedures in Poland and Spain

Poland

According to the Revitalization Act (Ustawa z dnia 9 października 2015r. 2015), the process of complex revitalization in Poland may be carried out by revitalization stakeholders on the basis of the municipal revitalization program. Revitalization stakeholders include in particular residents, owners and perpetual usufructuaries, entities managing properties, entities and those which operate a business or plan to operate a business and/or community-related activities within the municipality borders, organs of public administration, local authorities, and their organizational units. Of the above, of special importance for the revitalization of post-mining areas are entities which operate a business or plan to operate a business and local authorities. These units will be involved in the revitalization process of post-mining areas depending on the land ownership status. At the same time, the forum of dialog and cooperation between the stakeholders and the municipality’s organs is established in the form of a revitalization Committee that is appointed following a decision by the village mayor, a town mayor, or a city president.

The first stage in outlining a degraded area and a revitalization area is to prepare a diagnosis (Fig. 1), which should be based on objective and verifiable data obtained with the use of scientific methods selected to match the local context (Bazuń 2017). A degraded area is understood as an area in a crisis condition due to concentrated negative social phenomena, in particular of unemployment, poverty, crime, low education level, low social capital, and insufficient level of participation in public and cultural life. The degraded area and the revitalization area are established under a resolution and on the initiative of the municipality council. This resolution is an act of local law. At this stage, the head of a municipality, a town mayor, or a city president is obliged to launch public consultations on the project of the resolution. The revitalization area, on the other hand, is established as either the degraded area or its part. Importantly, according to the discussed Act, post-mining areas may become part of the revitalization area only in the case when possible revitalization activities on this area will help counteract the negative social phenomena. The next stage in the revitalization process is to prepare a Municipal Revitalization Program (MRP), which includes such elements as a detailed diagnosis of the revitalization area, a description of interrelationships between the MRP and the documents on the municipality's strategy, a description of the intended condition of the area after revitalization works, goals of the revitalization, a description of revitalization works, and financial framework for the project. The preparation of MRP starts after the local council adopts a relevant resolution, but the MRP itself is not an act of local law. In addition, if the provisions of the MRP are in opposition to the municipality’s study of conditions and directions of spatial management, the study must be first amended in order to adjust its provisions to the MRP. Simultaneously, changes are made to the local spatial development plan (LSDP). At least once per 3 years, MRP undergoes evaluation for its validity and level of implementation by the village mayor, a town mayor, or a city president. The revitalization process as a whole is obviously carried out with public participation, which is primarily intended to learn about the needs and expectations of the stakeholders (Bazuń 2017). The last stage of the revitalization process consists in implementing the prepared project.

Another possibility is to establish a Special Revitalization Zone (SRZ). Such a zone is established in order to ensure effective implementation of the revitalization works over a period no longer than 10 years (without the possibility of renewal). An SRZ is established following a resolution which is an act of local law.

Spain

The lack of clear legal regulations regarding the revitalization of post-mining facilities in Spain has led to the search for different solutions to regulate these issues. The specific proposal to regulate the mining heritage elements is established in the El Bierzo Charter for the Mining Industrial Heritage Conservation in Spain (Secretaría General Técnica, Ministerio de Cultura 2009). This document includes an intervention in mining sites methodology, following the National Plan:

- 1.

It is considered necessary to undertake an inventory of the Industrial Mining Heritage as a first requisite to be able to plan its protection and promotion. In it, the elements and complexes subject to protection and guardianship must be identified with the necessary scientific rigour, in such a way that the objectivity, coherence, durability, and accessibility of the information collected is guaranteed.

It must include, at least, the following data:

Historic and archaeological study of the complex. Geographic delimitation of the complex

Location of each of the elements that comprise the mining complex, including the real and moveable property, as well as Documentary Heritage from the archives

Legal regimen of the works that make up the mining complex

State of conversation. Pathological analysis

Anthropological/ethnographic study

- 2.

To select the elements of unique relevance and apply the appropriate degree of protection to each case in function of the municipal, autonomous, state, and world legislative regulations.

The criteria of application will be:

The historical authenticity

The representative typology

The absolute and relative antiquity in terms of typology or technique

The state of conservation

The integrity of its cultural identity and typological features

The historic significance

The relation of the property and of the installations with the community in which it is a part

The possibilities of managing the mining complex by the community which owns it, guaranteeing some minimums of sustainability

- 3.

Legal protection of the real estate and personal property that comprise them is imperative for the conservation of mining complexes. This protection will principally be effected through the figures established in the Historic or Cultural Heritage legislation, the Environmental Protections, and the Urban Zoning Restrictions. It is necessary that the Local Administrations contemplate the conservation of Industrial Mining Heritage in their urban planning. For their part, the Public Administrations must protect the most relevant elements of this Heritage through the corresponding declarations of Works of Cultural Interest or other figures of protection.

- 4.

Intervention through tools such as Master Plans, Preliminary Studies, or Viability Studies will permit approaching the actuations upon the Mining Heritage with the adequate guarantees, founded on a solid knowledge of the Work and from a base of strategies that have been properly planned at all levels (technical, manageability, usability, etc.). In the design of the intervention, the combination of activities associated with the enhancement of the particular elements of the complex, as well as the environmental-landscape repercussions of the same, must be considered. The proposals for the use of Cultural Goods must be compatible with the enhancement of its status as Heritage, within the limits that allow us to safeguard the identity, integrity, and authenticity for the sake of a greater social profitability and sustainability for the project. Access to the interior of the mine, motivated by the observation of natural processes-mineralized levels or for the desire to have a life experience, must in all cases be realized after the establishment of some safety minimums, with the limits imposed by the conservation, taking into account the precepts included or incorporated in the legal regulations in effect, and which execution must be responsibility of technicians who are specialists in this area.

- 5.

The dissemination is one of the principles of the work of conservation of Industrial Mining Heritage. The planning of educational and communication programs that facilitate conceptual access to the setting and content of the mining complex is fundamental, adopting the model that the appropriate Administration deems most suitable: mining museums, the museumization of mines, mining parks, cultural parks, heritage parks, etc. To explain Industrial Mining Heritage and sensitize the public about the relevance of its special nature through expositions, publications, conferences, etc. must be viewed as obligatory activities on the part of the public powers, especially when the aesthetic transformation of time and space, characteristic of the contemporary world, pushes social desire in the same direction.

- 6.

The work of conservation and restoration of the elements of the mine must be planned considering its natural geological particularities (continual inundations, collapses, difficulties for environmental controls, etc.). The work of preventative conservation and maintenance will be essential for the effective functioning of the mining installation.

Examples of Revitalizations of Old Mining Sites

Revitalization of the Zloty Stok Gold Mine-Poland

The old infrastructure of the gold mine is located south of Zloty Stok—a town in the north-west part of the Gory Zlote, a range of the Sudety Mountains (Fig. 2). Due to complicated geological conditions in the region, the original sea sediments was subjected to consolidation, and transformed into chalks, shales, and sandstones. Much later, these rocks were subjected to great pressure and temperature and further transformed into the present package of compact, highly folded and fractured gneisses and mica schists with marble pockets, and occasionally also with dark-green amphibolites and serpentinites. A local variscan granitoid intrusion acted on these rocks, and as a result, a polymetallic ore mineralization was formed in the area of Zloty Stok (Lorenc 1991, 1994). It was in such rocks that many generations of miners for hundreds of years developed a complicated and deep network of underground workings. Since prehistory, gold was the only metal searched for in this area and consequently the first well-organized mine was a gold mine. Later discoveries indicated the presence of arsenic, which was mined since the eighteenth century. In polymetallic ores, this element occurs in löllingite (FeAs2) and in arsenopiryte (FeAsS), which can be found in serpentinite and marble. Other ore minerals contain such metals as iron (magnetite Fe3O4, pyrrhotite—Fes i pyrite—FeS2), lead (galena—PbS), zinc (sphalerite—ZnS), and copper (chalcopyrite—CuFeS2). These metals, however, have no industrial importance.

First gold miners are believed to have worked in this area approximately 4000 years ago. The second period of intensive exploration was strictly related to Celtic colonization. The oldest documents related to gold mining in this area date back to the thirteenth century, and the first written record of organized mining activities comes from 1273. In the fifteenth century, the Zloty Stok gold mine was the most productive mine in the region of Silesia. At that time, while mining the deposit under the Haniak, Krzyzowa and Soltysia mountains, miners reached a depth of 100 m—much deeper than the short adits of the period which served to remove water from the workings. Thus, the miners faced an increasing threat of the deeper workings being flooded by underground waters. Therefore, in 1506, the construction of a new main drainage adit started with the aim to remove water from the whole rock mass. The adit was later named “Emanuel.”

With the focus on maximum profit, the shareholders of the mine no longer cared to adequately protect the workings, which started to hinder mining activities in the second half of the sixteenth century. As a result of many cases of technical negligence, in 1565, the “Zloty Osiol” output shaft—72 m deep and located over the Emanuel drainage adit—collapsed. Fifty-nine miners died in this catastrophe, trapped forever in the underground workings. The damage has never been repaired, and the victims of the tragic event have never been found. Only two fragments of human bones were found in the shaft bottom—they probably belonged to workers servicing the shaft (Lorenc et al. 2006).

The Zloty Stok gold mine is also famous for another event, which took place in 1612, when gunpowder was first successfully used in mining. The production of gunpowder was started at the end of the seventeenth century in the nearby Makolin.

At the beginning of the eighteenth century, it was discovered that the local gold-bearing rocks are accompanied by significant amounts of arsenic. Many years of experiments led to the development of industrial method of arsenic recovery, and since 1709, the focus has been on large-scale production of this substance. Since then, for over 100 years, Zloty Stok has been the main supplier of arsenic for the whole world. Before 1723, the value of arsenic produced in Zloty Stok was three times higher than the value of its gold output.

The beginning of the twentieth century was a very important period for the gold mine. In 1910, first steam engines were used to modify the mine drainage system and allow the exploitation of ore levels at a depth of as much as 267 meters. The mine remained in operation both during World War II, and after, it was passed in Polish hands. As a result of political and administrative changes of 1956, and on the pretext that further arsenic production was no longer profitable, the mining and metallurgical activities in Zloty Stok were stopped with an “arbitrary decision” in 1962. This decision, which was definitely not dictated by the technical potential of the mine, is still viewed as controversial, as the mining documentation indicates that gold production, which remained on steady annual level of 20–30 kg since 1946, suddenly dropped to only 7 kg in 1961. The pumps and machines were stopped, all shafts were closed, and underground water quickly filled all workings located below the main drainage adit Emanuel. This was the end of the mine.

When visiting the site, it is worth to remember that during the fifteenth and sixteenth centuries, the mine produced 150 kg of gold a year, which was approximately 8% of gold production in the whole Europe. Being in operation for the period of almost 700 years, the mine produced a total of 16,000 kg of pure gold. This gold was mined in underground workings located on 21 levels, whose total length exceeded 300 km (Lorenc and Szumska 2006; Lorenc and Szumska 2015).

The abandoned mine remained almost completely forgotten for 35 years. In 1991, a group of local residents decided to open some of the workings and adapt them for tourist purposes. After 5 years of intensive work, the “Gertruda” and “Czarna Gorna” adits were cleaned and opened to public (Figs. 3, 4, and 5). The latter communicates with a shaft which leads to the only underground waterfall in Poland (Fig. 6). An official opening of the Underground Tourist Route and the Museum of Mining and Metallurgy in Zloty Stok took place on May 28, 1996. Ten years later, another very important event happened there. After 2 years of intensive mining and engineering works (2004–2006), which involved removing approximately 2500 metric tons of rock waste and several hundred metric tons of rotten wood, it was possible to repair the damage caused by two roof collapses and extend (in 2007) the available tourist route in the “Czarna Dolna” adit. In 2008, the adit was provided with an underground railway route (Lorenc and Szumska 2015).

The Zloty Stok gold mine offers a number of attractions to tourists, primarily the underground route. The part opened for tourist access in organized groups and with a guide covers a 500-m section of the Gertruda adit and a 200-m section of the Czarna Gorna adit, in which tourists may descend the 23-m deep shaft to access an 8-m high underground waterfall. From the waterfall, tourists head to the Czarna Dolna adit and use electric railway cars to travel its 500-m section back to the surface (Figs. 7 and 8). The second part of the route, opened most recently (in 2017), is the “Ochrowa” adit. No guide is also needed to visit the “Ksiazeca” adit—a very interesting, narrow, but with high roof object built at the turn of fifteenth century. An underground water route along the deep part of the Gertruda adit is yet another attraction.

In 2013, a Memorial Chamber was opened in the location of the old pithead waiting building, which holds many precious and unique exhibits documenting the mining and metallurgical heritage of Zloty Stok. The Chamber is divided into several thematic rooms, and the collection of mining picks available in the Mining Room is the biggest one in Europe.

In the same year (2013), 400 m from the mine, another attraction related to the history of mining, was opened for guided tours—the Medieval Technology Park (Figs. 9 and 10). It has replicas of old machines and devices historically used in transportation, moving and lifting of large rocks, as well as in their further crushing and mine drainage, etc. All objects are made to 1:1 scale and in accordance with medieval drawings.

The guests visiting the old mine also have at their disposal a bar, a restaurant in the old forging shop, and a big banquet hall in the old rock breaker building. The old office building now serves as a Mineral Museum and a small hotel. Children also have dedicated attractions, such as gold panning, casting a small “gold” bar or pressing a gold coin.

Since its opening, the Museum of Mining and Metallurgy in Zloty Stok has been enjoying a growing interest, mainly due to investments in new objects and infrastructure at the mining site. In 1996, when the Underground Tourist Route was opened, the place was visited by 10,000 people—4 years later, this number increased to 45,000, and in 2005, it doubled to reach 93,000. After the next 2 years, the mine was visited by 150,000 guests and in 2015 by over 200,000. In 2018, a maximum of 50 people enter the route every 3 min and at the moment of writing this paper, the number of visitors has already exceeded 250,000.

Except having the tourist and museum functions, the old mine is also a site of scientific research in mining, geology, geodesy, and biology. The results of these research projects were presented on many occasions, both in Poland and abroad, in journals, and in conferences and poster sessions.

Revitalization of La Tortilla Mines in Linares-Spain

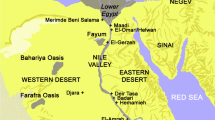

The Linares-La Carolina mining district is in the north of the Province of Jaén, in the region of Andalucía, and extends about 40 km from Despeñaperros (in Sierra Morena) to the south with a width east to west of about 30 km (Fig. 11). The geology and the mineralization of La Tortilla area are very similar to the rest of the district and consist in a pluton of granite developed in the Carboniferous period. The granite was subsequently fractured and faulted, and was later mineralized in the Carboniferous period. The resulting mineral veins or lodes contain predominantly lead minerals. During the Permian, the granite was eroded, and reddish sandstone and conglomerate were deposited on top of the granite. Further faulting took place that displaced both the Permian strata and the underlying granite and mineral lodes. Further sedimentary deposits were laid down in the Miocene, and these are relatively undisturbed. At La Tortilla, there is a thin layer of Permian strata that outcrops on the surface in the vicinity of the smelter, with occasional areas of granite showing through this veneer. South of the Linares-Bailen road, the Permian rocks dip to the south and are overlain by later Miocene sediments (Vernon 2013).

The mining and metallurgical installations of La Tortilla are one of the most prominent elements of the Linares-La Carolina mining district. Located about 2 km west of the town of Linares, close to the main road to Bailén, they were developed along two mineral lodes, the North and the South veins that both trend in a north-north-east direction. The north lode is the shorter with a worked length of about 700 m. The south lode mining workings extend over a horizontal distance of 3000 m.

The mining activity in our area has a 4000-year history, since the Argaric culture came to colonize the district. Later, Romans and Carthaginians fought for the control of the Iberians mines of our district during the Second Punic War. The Roman city of Cástulo is a few kilometres far from Linares, in the south-east, and was once a major Roman lead mining centre. The industrial revolution came with the application of the steam technology brought by British mining companies established in the area since the middle nineteenth century, as well as French, Belgian, and German companies that made our relatively small district into the most important lead producer in 1867. The mining activity stopped in the district in 1991.

In 1863, Thomas Sopwith junior visited several mining areas of Europe, sent by William B. Beaumont, significant mines owner from the northern England, and his father Thomas Sopwith senior. In July, Thomas arrived to Linares and took contact with other English mining owners established in the area that visited with him several mining fields. By early 1864, Thomas Sopwith junior had returned to Linares, and under the advisement of Juan English and Henry Haselden, mine promoters and operators obtained four mining concessions to work in La Tortilla, a mine with a great potential, forming The Spanish Lead Company, Ltd. to work it (Vernon 2013).

Thomas Sopwith junior was appointed as manager and used the initial capital to install the primary pumping and winding machinery and the ore dressing floors. The first steam engine was started in the south vein in April 1865. Two years later, a 60-inch Cornish beam engine was installed on Palmerston Shaft, in the north vein (Fig. 12). In 1869, dressing floors to treat the ore had also been established in the area adjacent to this shaft. In 1874, the mining works in the south vein were extended to the south by the Lord Derby concession, where two main shafts were sunk and two new Cornish pumping engines where installed to drain this area that became very quickly to be the most productive of the mine (Fig. 13).

In 1875 started the construction of La Tortilla lead smelting works, which is one of the most prominent elements of the mining landscape in the district. These smelting works were expanded in 1885 becoming to be the most modern and complete in Europe (Fig. 14). By that year, there were 22 lead crystallizers in the desilvering works, and nine Scotch hearths and seven reverberatory furnaces in the smelting works. In addition, a shot tower (for manufacturing lead shot) and a lead sheet and piping works were constructed on the east side of works, carrying out the full metallurgical process of the lead and manufacturing all the lead products (Revista Minera 1885).

Progressively, the mine was also getting deeper and as a consequence, the water entering the workings increased. The two Cornish pumping engines at San Federico and Santa Annie shafts were not sufficient, and by 1897, it had been decided to replace them with two more efficient Worthington-Simpson pumps. They were installed and working by the end of that year in a new shaft close San Federico called as Bombas shaft or Worthington shaft (Ledoux 1906).

Thomas Sopwith junior died in a tragic hunting accident in 1898, but La Tortilla mine remained operative until 1903, when closed due to the drop of ore reserves and increase of water pumping costs. However, the company continued operating the smelt works until it was taken over by the Societé des Anciens Etablissement Sopwith, in 1907, part of the French owned Societé Minière et Métallurgique de Peñarroya (Vernon 2013).

The smelting works remained active until 1967, being one of the most important metallurgical establishment of the district. In 1922, a Bag-House was built to help the old complex series of zig-zagging flues run from the works that terminate at two chimneys. This building was a great advancement, allowing the lead recovering from the fumes and the clean operations in the fumes evacuation system. At the same time, an ore dressing installation and an aerial ropeway system were built just close the railway line in the north of the foundry to make easy the ore transport from several mines to the smelting works (Ministerio de Fomento 1922).

The principal remains of La Tortilla mine and smelter are a significant part of the group of 125 mining and metallurgical sites included in the Andalusian Historial Heritage List from 2004 to 2006. This generic catalogue was initiative of the Colectivo Proyecto Arrayanes, who was entrusted by the Culture regional ministry to make it. Later, in July 2012, all the mining and metallurgical remains along the veins of La Tortilla were declared as Cultural Good by the Junta of Andalusia, the regional government, as part of the Andalusian Historical Heritage with a specific protection. This declaration includes the following:

Mining elements: shafts, engine houses, chimneys, and other remains

Metallurgy elements: installations of the foundry, warehouses, and shot tower

Other elements as the veins, roads, and railway lines

Our Colectivo had every time the idea to recover and reuse La Tortilla for Cultural and Tourism purposes, and after our intermediation with the owners of Lord Derby area, the Town Council finally obtained the property. By 2007, a design team was made up to plan and prepare a project for the revitalization of the mining installations at Lord Derby concession. It was formed by architects, mining engineers, technicians from the Town Council of Linares, an exhibition specialize company, and our association. The plan consisted of the creation of an Interpretation Centre, reusing the mining buildings of La Tortilla Mines, now of public property, with the aim to show the mining works (Fig. 15).

This was a very ambitious project, divided in several stages:

Construction of a new building to be used as Visitors Centre. The idea was to reproduce an ore crystal surrounded by a granite waste. It would show the relationship between the mining district, the geology, the lead, and the presence of the Cornish technology around the world. It was built throughout 2010 and 2011, but not completed because of the economic crisis. Currently, this building is damaged by the weather and some plundering actions and needs to be restored before the finishing and exhibition reconditioning works (Fig. 16).

Restoration of the engine houses of San Federico, Santa Annie, and Worthington shafts (Fig. 17). Santa Annie shaft building will be allocated to reproduce the Cornish steam technology for pumping and winding installed in the district during the second half of the nineteenth century. The ore dressing process information will be displayed at San Federico shaft pumping engine house and the Worthington shaft engine house will be adapted as Memory House, to show the memory of the mine and the miners, as well as the mining culture in the district. In these buildings of engine and boiler houses in Lord Derby concession, as well as in La Tortilla Smelting Works, we can find evident traces and original examples of a singular and advanced roof covering system unusual in those dates: the corrugated iron sheet curved roofs (Fig. 18). This is a self-carrying structure system that allows structures very light and resistant that can cover several length bays. So, the restoration works must be carried out with special care and respecting the integrity and authenticity of such singular buildings (Fig. 19). The restoration works are currently almost finished after the archaeological works were completed.

Construction of a mine for visitors, between both main shafts, San Federico and Santa Annie. These stage needs the excavation of a tunnel, as the real mining works are not safe, to reproduce a gallery exhibiting the evolution of the underground works and techniques used in our mines along the centuries. The mine is come up as experimentation space throw 24 stops that will surprise the visitors with sensations produced by tremors, fumes, sounds, smells, etc. The exhibition will include models and reproduction of the underground works.

Landscape adaptation of the surface of the mine, including the accessibility and security measures and the environmental and landscape recuperation replanting native vegetation. The restitution of wastes is included in the project too. The site is occupied by a kestrel colony, and several protection measures are already operative to preserve their seasonal presence and preventing any trouble for them due to the visits.

La Tortilla Foundry was acquired in 2009 by the Town Council of Linares, which is offering to the Andalusian Culture Department the possibility to place there an Industrial Archaeology Centre, restoring and using the original warehouses that still have the round roof made of corrugated iron. This project can allow to restore the shot tower and the warehouses, adapting some of them for visits and reproducing the shot manufacturing process.

In this intervention model, the role of the civil society, represented by the Colectivo Proyecto Arrayanes, as in others cases (Landscape Interpretation Centre, signposted paths and roads, security works in abandoned mining sites), is to suggest ideas to protect and recover the mining heritage, to design projects to implement those ideas and to watch that the actions are coherent and preserve the values and the integrity of the inherited remains, in short, acting as intermediary between the heritage, the society, and the authorities.

Revitalization of an Old Mining Site Motivated by Volunteers in Cornwall, UK

Cornwall is a County located in the far south-west of the UK, being a peninsula with many small ports around its rugged coastline (Figs. 20 and 21), geographically positioned to enable easy trade by shipping to Europe and beyond but particularly France and Spain with Trading, recorded by Diodorus Siculus and Pliny some 2000 years ago.

King Edward Mine detailed location (after Edmonds et al. (1975), modified)

Cornwall’s complicated geological land mass comprises mainly of a number of different periods of granite intrusions through a range of altered “country” rocks which the Cornish call “killas.” The mineral-rich lodes (veins) are usually associated to the contact zones between and within the boundary of these structures.

In Cornwall, mining and its associated industries were immense and 150 years ago would have directly or indirectly affect nearly everyone. However, today, there are no underground mines working and few open cast-quarries, working aggregates/stone or China Clay (which is another very important Cornish industry but not covered in this article). Now, they employ few people in comparison, using large or automated machines.

Cornwall’s rich suite of minerals is unsurpassed in number for its size anywhere in the world.

Many metalliferous minerals have been mined but mainly copper and tin, and to a lesser extent alluvial gold. A very recent confirmation using the latest technology has proved the mysterious Bronze Age, and “Nebra sky disk” is made from Cornish Tin & Gold. Although no actual early/ancient extractive location has yet been found, this has been hindered by the fact that the county’s numerous mine sites have been reworked throughout the ages obliterating any previous operations. There is hope that one day, a location can be found and authenticated.

Cornwall’s main mining region was “Redruth and Camborne” located around the Carn Brea Granite mass which yielded mainly copper, tin, and arsenic. Mining in this region has been referred to in estate papers from circa 1400, continuing up to the last mine closing in the 1990s. Copper alone created the wealth that established many stately homes and estates in Cornwall.

The Carn Brea Granite intrusion formed a ”ridge” crating (Fig. 22) two different attitude of folded rock formations to the north, a vertical geological structure meaning that the ore bodies/lodes were vertical. This is the normal characteristic throughout Cornwall where mineral has been located and mined. This differs to that on the southern side of the ridge where the structure is more horizontal and typically dipping 30° to the south.

This shallow dipping structure has given the area its name “The Great Flat Lode” (GFL), although no date has been attributed to this name. The GFL area is approximately 8 km long by 3 km wide and was exploited by many mines, which were owned and operated by different companies. It is in this GFL area that King Edward Mine is located, south of Camborne and near the village of Troon.

The Site that would become King Edward Mine was a section of an old “tin” mine called South Condurrow Mine, established ca. 1860s which in itself a collection of small earlier workings. On this section, it consisted of three engine houses, dressing (processing) floors, count house, blacksmith shop, miners dry, assay office, tin mill, calciners, etc. and mining extensive underground workings, with recorded production outputs of copper and tin from 1860s until early 1900s.

Cornish “engine houses” are iconic buildings seen in numerous locations around the world, and they are a testimonial to the Cornish Miners global Heritage. Whilst many engine houses still remain, the engines that they housed have mostly disappeared. These engines with their houses performed three different essential tasks: winding, stamping, and especially pumping which was critical and being most mine’s major operational costs.

A surveying error by the adjacent mine to the south—Grenville United occurred in 1880s when they were working up-stope “puncturing” the bottom of South Condurrow Mine meaning, disaster for them, as all the water in South Condurrow flooded into Grenville meaning they then had both mines to pump.

South Condurrow did not require its pump/engine house anymore saving a vast amount of money. It is this fact, which encouraged the fledgling Camborne School of Mines (CSM)—who were looking for an opportunity to give their students the best practical experience of operating a hard rock mine.

In 1887/1888, the Camborne School of Mine took a lease on the redundant section of South Condurrow Mine which operationally wise had worked further west by this time. They set about rebuilding the old site and installing the “latest technology” of the day, to give the then best practice training (Figs. 23 and 24). This refurbished CSM Mine was named King Edward Mine ca. 1903 after the Coronation of King Edward VII of England.

The early 1900s saw the rapid development of photography in the UK both for the public enjoyment “postcards” and marketing publicity including training activities. The difficult science and skill of underground photography was also being developed (Figs. 25 and 26). Mr John Charles Burrow, a renown Camborne photographer, and a photographer to Prince Edward, the Prince of Wales, was instrumental in this development along with his two friends William Thomas the King Edward Mine manager, a good amateur photographer, and Herbert Hughes, a coal mine photographer. Between them, they perfected the equipment and techniques of underground photography. They focused on King Edward Mine, where a special photographic dark room was built. Other major mines in the regions also found their attention. These superb photographs are a brilliant legacy for us all to enjoy today.

Camborne School of Mines remained using King Edward Mine as a practical training facility throughout the C20th (Fig. 27) although the underground was lost in the 1920s when Grenville United Mine closed, allowing the water to flood all workings, ending all underground activates in the GFL area. The excellent reputation of the quality of the qualifications from Camborne School of Mines meant that students came from all around the world to train at King Edwards Mine.

By 1987, the Camborne School of Mines use of the King Edward Mine site had drastically reduced and many buildings were redundant or used only for storage. An idea arose from a senior lecturer at CSM in conjunction with some members of the Carn Brea Mining Society (the predominant mining society in the South West of England at that time), an opportunity now presented itself. As mining was all but finished in Cornwall with the last three tin mines struggling to exist. The scrap/salvage companies were stripping all evidence of mining from the landscape including buildings and more importantly the specialist equipment.

It was decided that a major effort was required to save some of this equipment, at least a good working example of each process. These would be stored at King Edward Mine. The principle idea was then to rehabilitate the King Edward Mine “Tin Mill” (dressing floor) to enable preservation and presentation to a fully working Tin Processing Museum (Figs. 28 and 29). This giving the possibility for the future generations to understand and hopefully appreciate a small example of what was once a vast Cornish Industry. The recreation was possible by using the 1900s mill “blueprint” as portrayed in many of the J.C. Burrow/W. Thomas photographs.

In 1987, the only original machinery still in situ on-site was a very rare full sized set of 5-heads Californian Stamps, which were displayed at the 1900 Paris Exposition, as the latest technology of that time, and then shipped and erected at King Edward Mine immediately afterwards. The industrious group of unpaid volunteers formed “The King Edward Mine Preservation Group” (KEMPG). They worked continuously in their quest. Eventually not only achieving the complete mill restoration housing working examples such as a very rare Cornish round frame and a unique Frue Vanner. They also managed to exhibit many other mining-related displays, and tell some stories of the early days of Camborne School of Mines and their impact in the Mining World. From these efforts, KEM became recognized as a worthy working museum. To further ensure the continued survival of the equipment and site, King Edward Mine Ltd. was formed in 2005, and becoming a Charity Trust a few years later.

In 2006, ten areas within Cornwall and West Devon were accredited with World Heritage Site status due to the outstanding Mining Landscapes. With only two “complete” Cornish Tin Mines Sites (WHS) left in the World, i.e., King Edward Mine and Geevor, both now museums and within the WHS, each plays a significant part in telling the Cornish Mining Heritage.

The Camborne School of Mines finally left King Edward Mine in 2009 when the landowner decided to sell the site. However, due to KEM’s significance, Cornwall Council decided to safeguard the site and its private collection by purchasing it (Geevor had already come into the Council’s ownership).

The volunteers at King Edward Mine Museum (all unpaid) have continued to preserve and present its numerous artefacts, which is open to the public for 6 months of each year. The succession of volunteers have accomplished an amazing task over the last 30 years. However, maintaining the many aged buildings, most of which are temporary wooden structure, which are all grade 11* Listed Buildings, signifying their National importance, and all nearly 110 years old, was becoming a task to far. The Council realizing the problem sets about enabling several large grants to be obtained. Totalling nearly £ 5 million GBP, the buildings are now all refurbished securing them and the museum collections. The adaptive re-use of the 1860s assay office into a quality cafe has given the site another step change, appealing to the broader community. With the conversion of other redundant buildings into 9 letting units the maintenance costs should now be sustaining, Collectively raising King Edward Mine’s profile and securing its future for many years to come.

In recognition of the merits to revitalize this unique site of the mining heritage, in 2013, the Institute of Mechanical Engineers distinguished it by the highest prize (Fig. 30). This prestigious engineering award was presented to the King Edward Mine volunteers for their exceptional work in restoring to full working order a 1900 period Tin Processing Mill the only example of its kind. This achievement of listing ranks alongside the Concorde aeroplane.

The vast tracts of land that were associated to the mining activities have mostly disappeared. Where the former sites were associated to conurbations, they have been re-developed under roads and housing or industrial estates. The areas outside of these “towns” can mostly be found within the Ten Area which make up the Cornwall and West Devon World Heritage Site, inscribed 2006 for its Mining Landscape.

The few token representative, now Museum Sites that remain, does enable the rich Cornish Mining Heritage to be explained, educating the young and old alike. These site together also play their important part as a Tourist destinations. Tourism has now become one of Cornwall’s main industries with typically 5 million visitors per annum.

Discussion and Conclusion

Revitalization as a project combining the reclamation and development of post-mining areas is an important process of a comprehensive and multithreaded nature, aimed at economic and social recovery, and as a result, initiation, with high quality, of a positive change in a given area. In particular, it is important to conduct revitalization activities in post-mining areas, which are degraded or devastated as a result of mining activities. Conducting revitalization tasks should be treated with careful care, in particular when a post-mining facility has a very high cultural potential. Facilities on which relics of mining activity have been preserved have high cultural potential, and after proper design and implementation can be a great testimony to the mining cultural heritage.

In European countries, conducting revitalization activities should be based on formal and legal conditions. The presented analysis in Poland, Spain, and UK showed that there are not any specific conditions for the revitalization of post-mining areas. In the Polish legal system, there is the Revitalization Act, which comprehensively defines stages and ways of conducting revitalization. In Spain, rules of law indicate the possibility of using post-mining objects for economic and social purposes; however, it is necessary to ensure full safety of use of such facilities. Here, the basic legal acts regulating these issues are the Mining Law, the Law about Environmental, and the Law of Historical Heritage. However, English legal regulations do not indicate requirements for revitalization. This issue is applied facultatively, and despite this, many examples of adaptation of post-mining areas to new functions of economic and social value are observed.

Despite various legal approaches to revitalization issues, the examples presented in the publication are very good ways of implementing revitalization activities of mining objects, which present relics of industrial activity. The presented examples are a major tourist attraction of high cognitive and didactic value. Moreover, they have a significant impact on the level of local and even regional economy, which also increases interest in the region. It should be emphasized that formal and legal approaches are a kind of guidelines for the implementation of revitalization projects. The effectiveness of their implementation depends mainly on good planning and involvement of the participants in the revitalization process. Therefore, it seems that the basis for the success of revitalization of post-mining areas is the high awareness of the project participants and the society concerning the importance and needs of preserving valuable mining relics.

References

Baczyńska E, Lorenc MW, Kaźmierczak U (2017) Research on the landscape attractiveness of the selected abandoned quarries. Int J Min Reclam Environ 32(6):401–419. https://doi.org/10.1080/17480930.2017.1386756

Baczyńska E, Lorenc MW, Kaźmierczak U (2018) The landscape attractiveness of abandoned quarries. Geoheritage 10:271–285. https://doi.org/10.1007/s12371-017-0231-6

Bazuń D (2017) Rewitalizacja jako obszar współpracy międzysektorowej (Revitalization as a field of cross-sectoral cooperation). Rocznik Lubuski 2(43):111–125 (in Polish)

Cañizares R, del Carmen M (2011) Protección y defensa del patrimonio minero en España. Revista Scripta Nova. Universidad de Barcelona 15(361):1 (in Spanish)

Conesa HM, Schulin R, Nowack B (2008) Mining landscape: a cultural tourist opportunity or an environmental problem? The study case of the Cartagena–La Unión Mining District (SE Spain). Ecol Econ 64:690–700. https://doi.org/10.1016/j.ecolecon.2007.06.023

Edmonds EA, McKeown MC, Williams M (1975) British Regional Geology: South-West England, 4th edn. HMSO, London

Gligor A, Tămaş CG (2009) Roşia Montană Cultural Heritage in the context of a new mining development. Studia Universitatis Babeş-Bolyai, Geologia 54(1):49–54

Harfst J (2015) Utilizing the past: valorizing post-mining potential in Central Europe. Extr Ind Soc 2(2):217–224. https://doi.org/10.1016/j.exis.2015.01.003

ICOMOS (1999) Carta Internacional del Turismo Cultural. México. (in Spanish)

Jędrysiak T (2011) Turystyka kulturowa w obiektach poprzemysłowych – zagadnienia ogólne (Cultural tourism in post-industrial facilities – general issues). Turystka Kulturowa 6:17–35 (in Polish)

Kaźmierczak U, Lorenc MW, Strzałkowski P (2017) The analysis of the existing terminology related to a post-mining land use: a proposal for new classification. Environ Earth Sci 76:693–610. https://doi.org/10.1007/s12665-017-6997-7

Kołodziej J (2005) Rewitalizacja dziedzictwa przemysłowego i jego rola w rozwój turystyki industrialnej. In: Burzyński T, Łabaj M (eds) Dziedzictwo przemysłowe jako atrakcyjny produkt dla turystyki rekreacji. Doświadczenia krajowe i zagraniczne; GWSH, Katowice, pp 309–310 (in Polish)

Ledoux F (1906) Notes sur la mine “Tortilla”. Informe, Linares (in French)

Ley 16 (1985), de 25 de junio, del Patrimonio Histórico Español. Publicado en B.O.E. núm. 155, de 29/06/1985. (in Spanish)

Ley 21 (2013), de 9 de diciembre, de evaluación ambiental. Publicada en B.O.E. 296, de 11 de diciembre de 2013. (in Spanish)

Ley 22/73 (1973), de 21 de julio, de Minas. Publicada en el B.O.E. 176 el 24 de julio de 1973. (in Spanish)

Lorenc MW (1991) Uwagi o genezie intruzji kłodzko-złotostockiej (studium porównawcze na bazie enklaw). Arch Mineral 1(47):79–98 (in Polish)

Lorenc MW (1994) Rola magm zasadowych w ewolucji intruzji granitoidowych (studium porównawcze wybranych masywów hercyńskich) (Role of basic magmas in the granitoid evolution a comparative study of some Hercynian massifs). Geol Sudet 1(28):3–121 (in Polish)

Lorenc MW, Szumska E (2006) The Ancient Gold Mine in Złoty Stok (Lower Silesia, Poland). NAMHO Conference Proceedings: “Mining in the Landscape”, 9-11.VI.2006, Llangollen (UK), pp 62-63.

Lorenc MW, Szumska E (2015) Kopalnia Złota w Złotym Stoku. Przewodnik. Wyd. Usługi Turystyczne „AURUM” Elżbieta Szumska, Złoty Stok, Poland.

Lorenc MW, Kuryszko J, Kaleta J, Szumska E (2006) Micromorphological analysis of human bones from the ancient gold and arsenic mine in Złoty Stok. NAMHO Conference “Mining in the Landscape”, 9-11.VI.2006, Llangollen (UK), Poster.

Madziarz M (2013) Ścieżka turystyczno-dydaktyczna „Śladami dawnego górnictwa Kruszców” jako alternatywa wobec postępującej degradacji historycznych obiektów górniczych na Dolnym Śląsku (Educational & turistic path „On trace of old ore mining” as alternative to progressing degradation of historical minining objects in Lower Silesia). In: Zagożdżon PP, Madziarz M (ed) Dzieje górnictwa-element europejskiego dziedzictwa kultury, 5st edn. Ofic. Wyd. Politechniki Wrocławskiej, Wrocław, Poland; pp 229-244. (in Polish)

Marescotti P, Brancucci G, Sasso J, Solimano M, Marin V, Muzio C, Salmona P (2018) Geoheritage values and environmental issues of derelict mines: examples from the sulfide mines of Gromolo and Petronio Valley (Eastern Liguria, Italy). Minerals 8(6):229. https://doi.org/10.3390/min8060229

Ministerio de Fomento (1922) Ministerio de Fomento referida al año 1922. Madrid 271-273 (in Spanish)

Ministerstwo Środowiska (2004), Program rządowy dla terenów poprzemysłowych przyjęty przez Radę Ministrów 27 kwietnia 2004r., Warszawa. (in Polish)

Parysek JJ (2016) Rewitalizacja jako problem i zadanie własne polskich samorządów lokalnych. Rozwój Regionalnych i Polityka Regionalne 33:17–35 (in Polish)

Revista Minera (1885) Revista Minera, Metalurgia y de Ingeniería. Madrid Núm 36:134 (in Spanish)

Secretaría General Técnica, Ministerio de Cultura (2009) Carta de el Bierzo, para la conservación del patrimonio industrial minero. Madrid, pp 12-27 (in Spanish and English)

TICCIH (2003) The Nizhny Tagil charter for the industrial heritage. Russia (in English)

Ustawa z dnia 27 kwietnia 2001r. (2001) Prawo ochrony środowiska, Dz.U.2001.62.627 (in Polish)

Ustawa z dnia 3 lutego 1995r, (1995). o ochronie gruntów rolnych i leśnych, Dz.U.1995.16.78 (in Polish)

Ustawa z dnia 9 czerwca 2011r. (2011) Prawo geologiczne i górnicze, Dz.U.2011.163. 981 (in Polish)

Ustawa z dnia 9 października 2015r (2015). o rewitalizacji, Dz.U.2015.0.1777 (in Polish)

Vernon RW (2013) Thomas Sopwith Jr. – La Tortilla and his other mining ventures at Linares, Spain, British Mining No. 95, Northern Mine Research Society Nelson: 88

Zhang J, Fu M, Hassani FP, Zeng H, Geng Y, Bai Z (2011) Land use-based landscape planning and restoration in mine closure areas. Environ Manag 47:739–750. https://doi.org/10.1007/s00267-011-9638-z

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Kaźmierczak, U., Strzałkowski, P., Lorenc, M.W. et al. Post-mining Remnants and Revitalization. Geoheritage 11, 2025–2044 (2019). https://doi.org/10.1007/s12371-019-00408-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12371-019-00408-8