Abstract

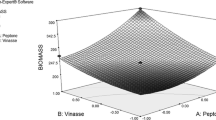

In this study, sugarcane bagasse hydrolysate supplemented with different proportions of sugar-ethanol industrial waste (vinasse) was used to optimize fermentative ethanol production using two Spathaspora passalidarum yeast strains isolated from decaying wood in Amazonian biome. The bagasse samples were pretreated chemically and enzymatically before using a binary factorial experimental design. The factorial design was carried out in two stages; in the first, a 24 factorial design was done to assess the effects of pretreated sugarcane bagasse hydrolysate and vinasse, ammonium sulfate concentration, yeast biomass concentration, and two different strains of yeast, S. passalidarum; in the second stage, a 23 factorial design was done to provide a more detailed analysis of the effects of vinasse supplementation on the fermentation process—this time, by modifying the ratio of sugarcane bagasse hydrolysate and vinasse and, more significantly, the same factor—biomass concentration. The results showed that the most significant factors for increasing bioethanol production in the 24 factorial design proved to be the following: inoculum and hydrolyzed bagasse supplementation with vinasse (the optimal being 75:25), followed by yeast concentration (optimal at 14% w/v cell wet weight) and then the type of strain used (S. passalidarum UFMG-HMD-14.1). The use of only hydrolyzed bagasse without vinasse (23 factorial design) had no significant influence on the results, nor did varying the concentration of nitrogen. This increase in ethanol production, which allows the same amount of ethanol productivity through a reduction in the carbon source, suggests it can lead to an improved final use for vinasse.

Similar content being viewed by others

References

Alencar, B.R.A., A.L.S. Reis, R.F.R. de Souza, M.A. Morais Jr., R.S.C. Menezes, and E.D. Dutra. 2017. Recycling the liquid fraction of alkaline hydrogen peroxide in the pretreatment of corn stover. Bioresource Technology 241: 928–935.

Ballesteros, M., J.M. Oliva, M.J. Negro, P. Manzanares, and I. Ballesteros. 2004. Ethanol from lignocellulosic materials by a simultaneous saccharification and fermentation process (SFS) with Kluyveromyces marxianus CECT 10875. Process Biochemistry 39(12): 1843–1848.

Basso, L.C., H.V. de Amorim, A.J. de Oliveira, and M.L. Lopes. 2008. Yeast selection for fuel ethanol production in Brazil. FEMS Yeast Research 8(7): 1155–1163.

Beato, F.B., B. Bergdahl, C.A. Rosa, J. Forster, and A.K. Gombert. 2016. Physiology of Saccharomyces cerevisiae strains isolated from Brazilian biomes: New insights into biodiversity and industrial applications. FEMS Yeast Research 16(7): 1–14.

Cadete, R.M., M.A. Melo, K.J. Dussán, R.C.L.B. Rodrigues, S.S. Silva, J.E. Zilli, M.J.S. Vital, F.C.O. Gomes, M. Lachance, and C.A. Rosa. 2012. Diversity and physiological characterization of d-xylose-fermenting yeasts isolated from the Brazilian Amazonian forest. PLoS ONE 7(8): 1–11.

Cadete, R.M., R.O. Santos, M.A. Melo, A. Mouro, D.L. Gonçalves, B.U. Stambuk, F.C.O. Gomes, M. Lachance, and C.A. Rosa. 2009. Spathaspora arborariae sp. nov., a d-xylose-fermenting yeast species isolated from rotting wood in Brazil. FEMS Yeast Research 9(8): 1338–1342.

Cassa-Barbosa, L.A., R.E.L. Procópio, I.T.S.R. Matos, and S.A. Filho. 2015. Isolation and characterization of yeasts capable of efficient utilization of hemicellulosic hydrolyzate as the carbon source. Genetics and Molecular Research 14(3): 11605–11612.

de Oliveira, M.C., D.M. da Silva, M.F. Alves, D.M.B. Dias, P.C. Martins, N.P. Bonifácio, and M.A.P. de Souza Júnior. 2013. Effect of including liquid vinasse in the diet of rabbits on growth performance. Revista Brasileira de Zootecnia 42(4): 259–263.

de Souza, R.F.R., E.D. Dutra, F.C.B. Leite, R.M. Cadete, C.A. Rosa, B.U. Stambuk, T.L.M. Stamford, and M.A. de Morais Jr. 2018. Production of ethanol fuel from enzyme-treated sugarcane bagasse hydrolysate using d-xylose-fermenting wild yeast isolated from Brazilian biomes. 3 Biotech 8(7): 312.

Ghose, T.K. 1987. Measurement of cellulase activities. Pure and Applied Chemistry 59(2): 257–268.

Hou, X., and S. Yao. 2012. Improved inhibitor tolerance in xylose-fermenting yeast Spathaspora passalidarum by mutagenesis and protoplast fusion. Applied Microbiology and Biotechnology 93(6): 2591–2601.

Jojima, T., C.A. Omumasaba, M. Inui, and H. Yukawa. 2010. Sugar transporters in efficient utilization of mixed sugar substrates: Current knowledge and outlook. Applied Microbiology and Biotechnology 85(3): 471–480.

Petrini, M.A., J.V. Rocha, J.C. Brown, and R.C. Bispo. 2016. Using an analytic hierarchy process approach to prioritize public policies addressing family farming in Brazil. Land Use Policy 51: 85–94.

Prada, S.M., M. Guekezian, and M.E.V. Suárez-Iha. 1998. Analytical methodology for the determination of sulfate in vinasse. Química Nova 21(3): 249–252.

Qureshi, M.I., A.M. Rasli, and K. Zaman. 2016. Energy crisis, greenhouse gas emissions and sectoral growth reforms: Repairing the fabricated mosaic. Journal of Cleaner Production 112: 3657–3666.

Rabelo, S.C., N.A.A. Fonseca, R.R. Andrade, R. Maciel Filho, and A.C. Costa. 2011. Ethanol production from enzymatic hydrolysis of sugarcane bagasse pretreated with lime and alkaline hydrogen peroxide. Biomass and Bioenergy 35(7): 2600–2607.

Reis, A.L.S., E.D. Dutra, R.S.C. Menezes, and M.A. de Morais Jr. 2016. Second-generation ethanol from sugarcane and sweet sorghum bagasses using the yeast Dekkera bruxellensis. Industrial Crops and Products 92: 255–262.

Salomon, K.R., and E.E.S. Lora. 2009. Estimate of the electric energy generating potential for different sources of biogas in Brazil. Biomass and Bioenergy 33(9): 1101–1107.

Silva, C.F., S.L. Arcuri, C.R. Campos, D.M. Vilela, J.G.L.F. Alves, and R.F. Schwan. 2011. Using the residue of spirit production and bio-ethanol for protein production by yeasts. Waste Management 31(1): 108–114.

Soccol, C.R., L.P.S. Vandenberghe, A.B.P. Medeiros, S.G. Karp, M. Buckeridge, L.P. Ramos, A.P. Pitarelo, V. Ferreira-Leitão, L.M.F. Gottschalk, and M.A. Ferrara. 2010. Bioethanol from lignocelluloses: Status and perspectives in Brazil. Bioresource Technology 101(13): 4820–4825.

Sørensen, B. 2008. A sustainable energy future: Construction of demand and renewable energy supply scenarios. International Journal of Energy Research 32(5): 436–470.

Tanimura, A., T. Nakamura, I. Watanabe, J. Ogawa, and J. Shima. 2012. Isolation of a novel strain of Candida shehatae for ethanol production at elevated temperature. SpringerPlus 1(1): 1–7.

Tauk, S.M. 1982. Culture of Candida in vinasse and molasses: Effect of acid and salt addition on biomass and raw protein production. European Journal of Applied Microbiology and Biotechnology 16(4): 223–227.

Van Soest, P.J. 1963. Use of detergents in the analysis of fibrous feeds. 1. Preparation of fiber residues of low nitrogen content. Journal of the association of Official Agricultural Chemists 46: 825–829.

Wanderley, M.C.A., C. Martín, G.J.M. Rocha, and E.R. Gouveia. 2013. Increase in ethanol production from sugarcane bagasse based on combined pretreatments and fed-batch enzymatic hydrolysis. Bioresource Technology 128: 448–453.

Zhao, H., Q. Wu, S. Hu, H. Xu, and C.N. Rasmussen. 2015. Review of energy storage system for wind power integration support. Applied Energy 137: 545–553.

Acknowledgements

This study was partly supported by The Ministry of Science, Technology, and Innovation (MCTI) through financial subsidy; The Pernambuco State Science and Technology Support Foundation (FACEPE); and the National Counsel of Technological and Scientific Development (CNPq) for Postdoctoral and Graduate scholarship programs. We also thank Professor Everardo Sampaio, from Federal University of Pernambuco, for the suggestions and revision of the manuscript.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Vaz, F.L., de Souza, R.F.R., Dutra, E.D. et al. Valorization of Sugar-Ethanol Industry Waste Vinasse for Increased Second-Generation Ethanol Production Using Spathaspora passalidarum Yeast Strains. Sugar Tech 21, 312–319 (2019). https://doi.org/10.1007/s12355-018-0691-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12355-018-0691-2