Abstract

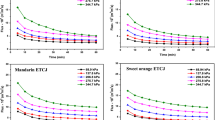

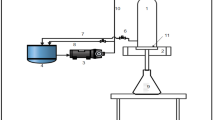

A field demonstration on the ultrafiltration of sugarcane juice for raw sugar production was conducted in a raw sugar mill in Guangxi Province, China. Heated limed sugarcane juice was processed using 0.05 μm ceramic membranes in a pilot plant with a design capacity of 5.5 m3/h. Results indicated that the ceramic membrane modules were satisfactory for sugarcane juice clarification, which yielded 119.13–142.43 L/(m2 h) of average flux under the volumetric concentration factor of 10–12 and produced clarified juice of superior quality with more than 1.2 unit rise in purity, 99.96 % reduction in turbidity, and 10.42 % removal of color. The membrane cleaning period was 10–25 h. Moreover, a high-quality product with high Pol, low color, and low ash content was obtained when the permeate juice was concentrated and crystallized to form raw sugar. However, further studies are necessary to investigate the methods of processing retentate for the recovery of sucrose and handling of wastewater generated during membrane cleaning, as well as the service life of the membrane.

Similar content being viewed by others

References

Farmani, B., M.H. Haddadekhodaparast, J. Hesari, and S. Aharizad. 2008. Determining optimum conditions for sugarcane juice refinement by pilot plant dead-end ceramic micro-filtration. Journal of Agricultural Science and Technology 10: 351–357.

Ghosh, A.M., and M. Balakrishnan. 2003. Pilot demonstration of sugarcane juice ultrafiltration in an Indian sugar factory. Journal of Food Engineering 58: 143–150.

Ghosh, A.M., M. Balakrishnan, M. Dua, and J.J. Bhagat. 2000. Ultrafiltration of sugarcane juice with spiral wound modules: On-site pilot trials. Journal of Membrane Science 174: 205–216.

Hamachi, M., B.B. Gupta, and R. Ben-Aim. 2003. Ultrafiltration: a means for decolorization of cane sugar solution. Separation and Purification Technology 30: 229–239.

Jansen, T.M. 2010. Raw sugar quality from a refiner’s perspective. International Sugar Journal 112: 250–256.

Jegatheesan, V., L. Shu, G. Keir, and D.D. Phong. 2012. Evaluating membrane technology for clarification of sugarcane juice. Reviews in Environmental Science and Bio/Technology 11: 109–124.

Jegatheesan, V., D.D. Phong, L. Shu, and R. Ben-Aim. 2009. Performance of ceramic micro- and ultrafiltration membranes treating limed and partially clarified sugar cane juice. Journal of Membrane Science 327: 69–77.

Kochergin, V., M. Kearney, W. Jacob, L. Velasquez, J. Alvarez, and C. Baez-Smith. 2000. Chromatographic desugarisation of syrups in cane mills. International Sugar Journal 102: 568–578.

Kwok, R.J. 1996. Ultrafiltration/Softening of clarified juice: the door to direct refining and molasses desugarisation in the cane sugar industry. Proceedings of the Annual Congress South African Sugar Technologists’ Association 70: 166–170.

Mcdonald, E.J., and A.L. Turcotte. 1946. Study of Ofner’s method for the determination of invert sugar. Journal of Research of the National Bureau of Standards 37: 429–434.

Priscilla, D.S.G., D.S.G. Paola, T.D.D.B. Sueli, and C.P. Nehemias. 2014. Pretreatment with ceramic membrane microfiltration in the clarification process of sugarcane juice by ultrafiltration. Acta Scientiarum Technology 36: 303–306.

Steindl, R.J. 2001. Membrane filtration technology in the cane sugar industry. Proceedings of International Society of Sugar Cane Technologists 24: 3–10.

Steindl, R.J., and C.D. Doyle. 1999. Applications and benefits of membrane filtration for the Australian sugar industry. Proceedings of the Australian Society of Sugar Cane Technologists 21: 406–411.

Wittwer, S. 1999. Applications for stainless steel crossflow membranes in sugar processing. Symposium on Advanced Technology for Raw Sugar and Cane and Beet Refined Sugar Production, September 9–10.

Funding

This study was funded by Guangxi Science and Technology Development Program (Grant Number: 14122003-6).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Li, W., Ling, GQ., Shi, CR. et al. Pilot Demonstration of Ceramic Membrane Ultrafiltration of Sugarcane Juice for Raw Sugar Production. Sugar Tech 19, 83–88 (2017). https://doi.org/10.1007/s12355-016-0434-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12355-016-0434-1