Abstract

The paper studies a three-level supply chain having one supplier, one vendor and multiple buyers under multi-shipment consignment stock policy which is applied by the supplier when he delivers semi-finished products to the vendor. The vendor who produces fully finished products applies the same policy when he delivers to buyers. The integrated system cost which consists of production cost, shipment cost and stock-holding cost is minimized subject to no-shortage in any part of the chain. Optimal decisions are obtained for a numerical example. It is found that the consignment stock policy performs better than the usual shipment policy when the stocking component of holding cost of the item is less in the downstream. The effectiveness of the consignment stock policy under different situations is also investigated.

Similar content being viewed by others

References

Adida E, Ratisoontorn N (2011) Consignment contracts with retail competition. Eur J Oper Res 215:136–148

Bazan E, Jaber MY, Zanoni S, Zavanella LE (2014) Vendor managed inventory (VMI) with consignment stock (CS) agreement for a two-level supply chain with an imperfect production process with/without restoration interruptions. Int J Prod Econ 157:289–301

Ben-Daya M, Al-Nassar A (2008) An integrated inventory production system in a three-layer supply chain. Prod Plan Control 19(2):97–104

Ben-Daya M, As’ad R, Seliaman M (2013) An integrated production inventory model with raw material replenishment considerations in a three layer supply chain. Int J Prod Econ 143(1):53–61

Blackstone WT (1971) The definition of civil disobedience. J Soc Phil 2(1):5–8

Braglia M, Castellano D, Frosolini M (2014) Safety stock management in single vendor single buyer problem under VMI with consignment stock agreement. Int J Prod Econ 154:16–31

Braglia M, Zavanella L (2003) Modelling an industrial strategy for inventory management in supply chains: the ‘Consignment Stock’ case. Int J Prod Res 41:3793–3808

Bylka S (2013) Non-cooperative consignment stock strategies for management in supply chain. Int J Prod Econ 143:424–433

Cárdenas-Barrón LE (2007) Optimizing inventory decisions in a multi-stage multi-customer supply chain: a note. Transp Res E 43(5):647–654

Cárdenas-Barrón LE, Treviño-Garza G, Wee HM (2012a) A simple and better algorithm to solve the vendor managed inventory control system of multi-product multi-constraint economic order quantity model. Expert Syst Appl 39(3):3888–3895

Cárdenas-Barrón LE, Teng JT, Treviño-Garza G, Wee HM, Lou KR (2012b) An improved algorithm and solution on an integrated production-inventory model in a three-layer supply chain. Int J Prod Econ 136(2):384–388

Cárdenas-Barrón LE, Wee HM, Blos MF (2011) Solving the vendor–buyer integrated inventory system with arithmetic–geometric inequality. Math Comput Model 53(5–6):991–997

Chan CK, Kingsman BG (2007) Coordination in a single-vendor multi-buyer supply chain by synchronizing delivery and production cycles. Transp Res E 43:90–111

Chen JM, Lin IC, Cheng HL (2010) Channel coordination under consignment and vendor-managed inventory in a distribution system. Transp Res E 46:831–843

Darwish MA, Odah OM (2010) Vendor managed inventory model for single-vendor multi-retailer supply chains. Eur J Oper Res 204:473–484

Ding D, Chen J (2008) Coordinating a three level supply chain with flexible return policies. Omega 36(5):865–876

Fenton RD, Sanborn BA (1987) Consignment purchasing: from industry to health care. Hosp Mater Manag Q 8(4):1–7

Giri BC, Bardhan S (2015) A vendorbuyer JELS model with stock-dependent demand and consigned inventory under buyer’s space constraint. Oper Res Int J 15(1):79–93

Goyal SK (1995) An optimal method for a deterministic joint replenishment inventory policy in discrete time. J Oper Res Soc 46(11):1404–1404

Goyal SK, Nebebe F (2000) Determination of economic productionshipment policy for a single-vendor single-buyer system. Eur J Oper Res 121(1):175–178

Gümüş M, Jawkes EM, Bookbinder JH (2008) Impact of consignment inventory and vendor-managed inventory for a two-party supply chain. Int J Prod Econ 113:502–517

Hu W, Li Y, Govindan K (2014) The impact of consumer returns policies on consignment contracts with inventory control. Eur J Oper Res 233:398–407

Huang Y, Huang GQ, Newman ST (2011) Coordinating pricing and inventory decisions in a multi-level supply chain: a game-theoretic approach. Transp Res E 47:115–129

Hung JS, Fun YP, Li CC (1995) Inventory management in the consignment system. Prod Inventory Manag J 36(4):1–6

Jaber MY, Bonney M, Guiffrida AL (2010) Coordinating a three-level supply chain with learning-based continuous improvement. Int J Prod Econ 127(1):27–38

Jaber MY, Goyal SK (2008) Coordinating a three-level supply chain with multiple suppliers, a vendor and multiple buyers. Int J Prod Econ 116(1):95–103

Jaber MY, Osman IH, Guiffrida AL (2006) Coordinating a three-level supply chain with price discounts, price dependent demand, and profit sharing. Int J Integr Supply Manag 2(1):28–48

Khouja M (2003) Optimizing inventory decisions in a multi-stage multi-customer supply chain. Transp Res E 39:193–208

Lee JH, Moon IK (2006) Coordinated inventory models with compensation policy in a three level supply chain. LNCS 3982:600–609

Leng M, Parlar M (2009) Allocation of cost savings in a three-level supply chain with demand information sharing: a cooperative-game approach. Oper Res 57(1):200–213

Li S, Zhu Z, Huang L (2009) Supply chain coordination and decision making under consignment contract with revenue sharing. Int J Prod Econ 120:88–99

Munson CL, Rosenblatt MJ (2001) Coordinating a three-level supply chain with quantity discounts. IIE Trans 33(5):371–384

Omar M, Sarker R, Othman WAM (2013) A just-in-time three-level integrated manufacturing system for linearly time-varying demand process. Appl Math Model 37:1275–1281

Park S, Lee TE, Sung CS (2010) A three-level supply chain network design model with risk-pooling and lead times. Transp Res E 46(5):563–581

Rau H, Wu MY, Wee HM (2003) Integrated inventory model for deteriorating items under a multi-echelon supply chain environment. Int J Prod Econ 86:155–168

Ru J, Wang Y (2010) Consignment contracting: who should control inventory in the supply chain? Eur J Oper Res 201:760–769

Scarf HE, Giford DM, Shelly MW (1963) Multistage inventory models and techniques. Stanford University Press, Stanford

Seifert RW, Zequeira RI, Liao S (2012) A three-echelon supply chain with price-only contracts and sub-supply chain coordination. Int J Prod Econ 138:345–353

Surini V (2011) Inventory management in supply chains: the three-level case in traditional and consignment policies. Thesis work, Faculty of Engineering, University of Brescia, Italy

Teng JT, Cárdenas-Barrón LE, Lou KR (2011) The economic lot size of the integrated vendor–buyer inventory system derived without derivatives: a simple derivation. Appl Math Comput 217(12):5972–5977

Valentini G, Zavanella L (2003) The consignment stock of inventories: industrial case and performance analysis. Int J Prod Econ 81–82:215–224

Veinott A (1965) Computing \((s, S)\) inventory policies. Manag Sci 11:525–552

Wagner HM, Whitin TM (1958) Dynamic version of the economic lot size model. Manag Sci 5:89

Wang Y, Jiang L, Shen ZJ (2004) Channel performance under consignment contract with revenue sharing. Manag Sci 50(1):34–47

Wang KJ, Lin YS, Yu JCP (2011) Optimizing inventory policy for products with time-sensitive deteriorating rates in a multi-echelon supply chain. Int J Prod Econ 130:66–76

Wang SP, Lee W, Chang CY (2012) Modeling the consignment inventory for a deteriorating item while the buyer has warehouse capacity constraint. Int J Prod Econ 138:284–292

Zanoni S, Jaber MY (2015) A two-level supply chain with consignment stock agreement and stock-dependent demand. Int J Prod Res 53:3561–3572

Zanoni S, Jaber MY, Zavanella LE (2012) Vendor managed inventory (VMI) with consignment considering learning and forgetting effects. Int J Prod Econ 140:721–730

Zavanella L, Zanoni S (2009) A one-vendor multi-buyer integrated production inventory model: the ‘Consignment Stock’ case. Int J Prod Econ 118:225–232

Zhang D, Matta RD, Lowe TJ (2010) Channel coordination in a consignment contract. Eur J Oper Res 207(2):897–905

Zhang CT, Liu LP (2013) Research on coordination mechanism in three-level green supply chain under non-cooperative game. Appl Math Model 37:3369–3379

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

We declare that we have no conflict of interest for submitting this work.

Appendices

Appendix 1

To find the supplier’s holding area, we use the method adopted by Huang (2004):

However, the bold area in our model is different from that of Huang’s (2004) model because of synchronizing delivery policy. We have

Appendix 2

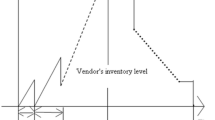

For the consignment stock policy, the shipment size is \(q_{s}\) and the length between two consecutive shipments is \(\frac{q_{s}}{P_{1}}\). Let \(X_{i}\) be the inventory level at the vendor’s warehouse at the time of ith shipment, \(i=1,2,3,\ldots .\). Then we have

The holding area includes \((k-1)\) trapeziums and one triangle. The sum of \((k-1)\) trapeziums is given by

and the area of the triangle is \(\frac{X_{k}^{2}}{2P_{2}}\).

Rights and permissions

About this article

Cite this article

Giri, B.C., Chakraborty, A. & Maiti, T. Effectiveness of consignment stock policy in a three-level supply chain. Oper Res Int J 17, 39–66 (2017). https://doi.org/10.1007/s12351-015-0215-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12351-015-0215-8