Abstract

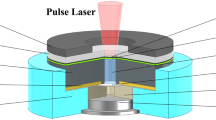

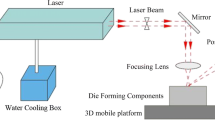

Laser shock hydroforming is a novel microforming method that adopts laser energy as the driving force and liquid as the medium to transmit pressure. The method combines the advantages of laser shock forming and micro hydroforming. Previous research has demonstrated that this method can deform thin sheets into complex shapes at high strain rates. We know that the formability of materials is improved at high strain rates, but experimental analysis on this method alone cannot examine the deformation process. Therefore, this study first conducted free- and die-forming experiments of laser shock hydroforming to characterise the features of the deformation process and understand the factors that may contribute formability enhancement. Experimental results were discussed to uncover the formability of thin sheets under different conditions, including the laser energy and the effect of the die. Then, a numerical model was established considering fluid–solid interaction. The deformation process, sheet velocity, contact stress and strain rate were investigated through numerical means, and these indicators explain the mechanism of formability improvement in this method. Furthermore, the numerical results indicate a positive phenomenon—pressure equalisation—which might be due to the reflection of pressure off the rigid side wall of the liquid chamber.

Similar content being viewed by others

References

Choudhary V, Iniewski K (2017) MEMS: fundamental technology and applications. https://doi.org/10.1201/b14970

Fu MW, Chan WL (2013) A review on the state-of-the-art microforming technologies. Int J Adv Manuf Technol 67(9-12):2411–2437. https://doi.org/10.1007/s00170-012-4661-7

Gao H, Cheng GJ (2011) 3D microscale laser dynamic forming: Multiscale modeling and experimental validation. J Appl Phys 109(10):103511. https://doi.org/10.1063/1.3590144

Mahabunphachai S, Cora ÖN, Koç M (2010) Effect of manufacturing processes on formability and surface topography of proton exchange membrane fuel cell metallic bipolar plates. J Power Sources 195(16):5269–5277. https://doi.org/10.1016/j.jpowsour.2010.03.018

Hung JC, Lin CC (2012) Fabrication of micro-flow channels for metallic bipolar plates by a high-pressure hydroforming apparatus. J Power Sources 206:179–184. https://doi.org/10.1016/j.jpowsour.2012.01.112

Xu ZT, Peng LF, Fu MW, Lai XM (2015) Size effect affected formability of sheet metals in micro/meso scale plastic deformation: experiment and modeling. Int J Plast 68:34–54. https://doi.org/10.1016/j.ijplas.2014.11.002

Diehl A, Engel U, Geiger M (2010) Influence of microstructure on the mechanical properties and the forming behaviour of very thin metal foils. Int J Adv Manuf Technol 47(1-4):53–61. https://doi.org/10.1007/s00170-008-1851-4

Vollertsen F, Hu Z, Wielage H, Blaurock L (2010) Fracture limits of metal foils in micro forming. In Proc 36th Int MATADOR Conf. https://doi.org/10.1007/978-1-84996-432-6_11

Furushima T, Tsunezaki H, Manabe KI, Alexsandrov S (2014) Ductile fracture and free surface roughening behaviors of pure copper foils for micro/meso-scale forming. Int J Mach Tools Manuf 76:34–48. https://doi.org/10.1016/j.ijmachtools.2013.10.001

Zhuang W, Wang S, Cao J, Lin J, Hartl C (2010) Modelling of localised thinning features in the hydroforming of micro-tubes using the crystal-plasticity FE method. Int J Adv Manuf Technol 47(9-12):859–865. https://doi.org/10.1007/s00170-009-2134-4

Hmida RB, Thibaud S, Gilbin A, Richard F (2013) Influence of the initial grain size in single point incremental forming process for thin sheets metal and microparts: experimental investigations. Mater Des 45:155–165. https://doi.org/10.1016/j.matdes.2012.08.077

Balanethiram VS, Daehn GS (1994) Hyperplasticity: increased forming limits at high workpiece velocity. Scr Metall Mater 30(4):515–520. https://doi.org/10.1016/0956-716X(94)90613-0

Cheng J, Green DE, Golovashchenko SF (2017) Formability enhancement of DP600 steel sheets in electro-hydraulic die forming. J Mater Process Technol 244:178–189. https://doi.org/10.1016/j.jmatprotec.2017.01.027

Zheng C, Zhang X, Liu Z, Ji Z, Yu X, Song L (2018) Investigation on initial grain size and laser power density effects in laser shock bulging of copper foil. Int J Adv Manuf Technol 96(1-4):1483–1496. https://doi.org/10.1007/s00170-018-1722-6

Gao H, Cheng GJ (2010) Laser-induced high-strain-rate superplastic 3-D microforming of metallic thin films. J Microelectromechanical Syst 19:273–281. https://doi.org/10.1109/JMEMS.2010.2040947

Gau JT, Chen PH, Gu H, Lee RS (2013) The coupling influence of size effects and strain rates on the formability of austenitic stainless steel 304 foil. J Mater Process Technol 213:376–382. https://doi.org/10.1016/J.JMATPROTEC.2012.10.004

Kim JS, Huh H (2011) Evaluation of the Material Properties of an OFHC Copper Film at High Strain Rates Using a Micro-Testing Machine. Exp Mech 51:845–855. https://doi.org/10.1007/s11340-010-9395-6

Hasebe T, Imaida Y (2007) On micro forming by hydro spark forming method. Mater Sci Forum 566:167–172. https://doi.org/10.4028/www.scientific.net/msf.566.167

Je G, Malka D, Kim H, Hong S, Shin B (2017) A study on micro hydroforming using shock wave of 355 nm UV-pulsed laser. Appl Surf Sci 417:244–249. https://doi.org/10.1016/j.apsusc.2017.02.146

Liu H, Liu F, Ma Y, Jiang C, Wang X (2018) Investigation of a novel laser shock liquid flexible microforming process applied to embossing three-dimensional large area microarrays on metallic foils. Int J Adv Manuf Technol 99:419–435. https://doi.org/10.1007/s00170-018-2453-4

Sun K, Liu H, Ma Y, Shen Z, Liu F, Wang X (2019) Laser shock hydraulic forming for micro-bowl with miniature concave. Int J Adv Manuf Technol 105:441–455. https://doi.org/10.1007/s00170-019-04239-3

Livermore Software Technology Corporation (2016) LS-DYNA Keyword user’s manual, R9.0. LivermoreSoftware Technology Corporation (Vol. I)

Johnson GR, Cook WH (1983) A constitutive model and data for metals subjected to large strains, high strain rates and high temperatures. Proc 7th Int Symp Ballist 21(1):541–547

Varas D, Zaera R, López-Puente J (2009) Numerical modelling of the hydrodynamic ram phenomenon. Int J Impact Eng 36:363–374. https://doi.org/10.1016/j.ijimpeng.2008.07.020

Dirikolu MH, Akdemir E (2004) Computer aided modelling of flexible forming process. J Mater Process Technol 148:376–381. https://doi.org/10.1016/j.jmatprotec.2004.02.049

Fabbro R, Fournier J, Ballard P, Devaux D, Virmont J (1990) Physical study of laser-produced plasma in confined geometry. J Appl Phys 68:775–784. https://doi.org/10.1063/1.346783

Zheng C, Sun S, Ji Z, Wang W, Liu J (2010) Numerical simulation and experimentation of micro scale laser bulge forming. Int J Mach Tools Manuf 50:1048–1056. https://doi.org/10.1016/j.ijmachtools.2010.08.012

Peyre P, Fabbro R (1995) Laser shock processing: a review of the physics and applications. Opt Quantum Electron 27:1213–1229. https://doi.org/10.1007/BF00326477

Zhang W, Yao YL, Noyan IC (2004) Microscale Laser Shock Peening of Thin Films, Part 1: Experiment, Modeling and Simulation. J Manuf Sci Eng 126:18–24. https://doi.org/10.1115/1.1645878

Hassannejadasl A, Green DE, Golovashchenko SF, Samei J, Maris C (2014) Numerical modelling of electrohydraulic free-forming and die-forming of DP590 steel. J Manuf Process 16:391–404. https://doi.org/10.1016/j.jmapro.2014.04.004

Regazzoni G, Johnson JN, Follansbee PS (1986) Theoretical Study of the Dynamic Tensile Test. J Appl Mech 53:519–528. https://doi.org/10.1115/1.3171805

Hu X, Daehn GS (1996) Effect of velocity on flow localization in tension. Acta Mater 44:1021–1033. https://doi.org/10.1016/1359-6454(95)00228-6

Golovashchenko SF, Gillard AJ, Mamutov AV (2013) Formability of dual phase steels in electrohydraulic forming. J Mater Process Technol 213:1191–1212. https://doi.org/10.1016/j.jmatprotec.2013.01.026

Wu PD, Embury JD, Lloyd DJ, Huang Y, Neale KW (2009) Effects of superimposed hydrostatic pressure on sheet metal formability. Int J Plast 25:1711–1725. https://doi.org/10.1016/j.ijplas.2008.10.002

Acknowledgements

This work is supported by the National Natural Science Foundation of China (Grant No.52075226) and the 2018 Innovation Practice Fund of Jiangsu University Industrial Centre (Grant No.ZXJG2018007).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

He, Y., Gong, J., Liu, H. et al. Investigation on formability improvement in laser shock hydroforming. Int J Mater Form 14, 855–869 (2021). https://doi.org/10.1007/s12289-020-01599-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12289-020-01599-0