Abstract

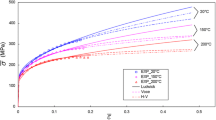

This paper presents a new phenomenological model for describing the main features of the viscoplastic behavior of superplastic sheet metals, namely, strain hardening, softening, and damage. The proposed model is based on a variable strain rate sensitivity index (m-value) measured from uniaxial tensile tests at different strain rates under constant temperature. In this study, the uniaxial tensile tests were carried out at three strain rates (i.e., 10−3, 10−2, and 10−1 s−1) on a superplastic grade AA5083 aluminum sheet alloy. In addition, the volume fractions of cavities at different plastic strain levels were assessed using X-ray microtomography. The performance of the model was investigated by comparing its predictions with the experimental data. In addition, the model was validated with two sets of reference data for AA5083 aluminum alloy and AZ31 magnesium alloy. In particular, it was observed that the new model could predict the flow behavior of these metals more successfully compared with two reference models; nevertheless, it requires minimal experimentation and calculation efforts.

Similar content being viewed by others

References

Pérez I, Aranguren I, González B, Eguia I (2009) Electromagnetic forming: a new coupling method. Int J Mater Form 2(1):637

Endou J, Murata C (2015) New forming technologies using screw type servo press. In: Tekkaya AE et al (eds) 60 excellent inventions in metal forming. Springer Berlin, Berlin, pp 127–133

Barnes A (2007) Superplastic forming 40 years and still growing. J Mater Eng Perform 16(4):440–454

Ridley N (2011) Metals for superplastic forming. In: Giuliano G (ed) Superplastic forming of advanced metallic materials: methods and applications, 1st edn. Woodhead Publishing, Cambridge, pp 3–33

Krajewski PE, Schroth JG (2007) Overview of quick plastic forming technology. In: Zhang KF (ed) Materials science forum. Trans Tech Publ Ltd, Zurich, pp 3–12

Luckey S, Friedman P, Weinmann K (2007) Correlation of finite element analysis to superplastic forming experiments. J Mater Process Technol 194(1):30–37

Filice L, Gagliardi F, Lazzaro S, Rocco C (2010) FE simulation and experimental considerations on Ti alloy superplastic forming for aerospace applications. Int J Mater Form 3(1):41–46

Bonet J, Gil A, Wood RD, Said R, Curtis RV (2006) Simulating superplastic forming. Comput Methods Appl Mech Eng 195(48):6580–6603

Franchitti S, Giuliano G, Palumbo G, Sorgente D, Tricarico L (2008) On the optimisation of superplastic free forming test of an AZ31 magnesium alloy sheet. Int J Mater Form 1(S1):1067–1070

Sorgente D, Tricarico L (2014) Characterization of a superplastic aluminium alloy ALNOVI-U through free inflation tests and inverse analysis. Int J Mater Form 7(2):179–187

Deshmukh PV (2003) Study of superplastic forming process using finite element analysis. Dissertation, University of Kentucky

Norton FH (1929) The creep of steel at high temperatures. McGraw-Hill Book Company, New York

Hoff N (1954) Approximate analysis of structures in the presence of moderately large creep deformations. Q Appl Math 12(1):49–55

Sellars CM, McTegart W (1966) On the mechanism of hot deformation. Acta Metall 14(9):1136–1138

Bird J, Mukherjee A, Dorn J (1969) In: Brandon DG, Rosen A (eds) Quantitative Relation between Properties and Microstructure. Israel University Press, Jerusalem, pp 255–342

Sherby OD, Burke PM (1968) Mechanical behavior of crystalline solids at elevated temperature. Prog Mater Sci 13:323–390

Lin J, Yang J (1999) GA-based multiple objective optimisation for determining viscoplastic constitutive equations for superplastic alloys. Int J Plast 15(11):1181–1196

Hamilton C, Zbib H, Johnson C, Richter S (1991) Dynamic grain coarsening and its effect on flow localization in superplastic deformation, In: The second international SAMPE symposium, Chipa, Japan, pp. 272–279

Khraisheh M, Zbib H, Hamilton C, Bayoumi A (1997) Constitutive modeling of superplastic deformation. Part I: theory and experiments. Int J Plast 13(1–2):143–164

Abu-Farha F (2007) Integrated approach to the superplastic forming of magnesium alloys. Dissertation, University of Kentucky

Hart E (1967) Theory of the tensile test. Acta Metall 15(2):351–355

Hedworth J, Stowell M (1971) The measurement of strain-rate sensitivity in superplastic alloys. J Mater Sci 6(8):1061–1069

Majidi O, Jahazi M, Bombardier N, Samuel E (2017) Variation of strain rate sensitivity index of a superplastic aluminum alloy in different testing methods. AIP Conf Proc 1896(1): 020022

Comley PN (2008) ASTM E2448-a unified test for determining SPF properties. J Mater Eng Perform 17(2):183–186

Martin C, Josserond C, Blandin J, Salvo L, Cloetens P, Boller E (2000) X-ray microtomography study of cavity coalescence during superplastic deformation of an Al–mg alloy. Mater Sci Technol 16(11–12):1299–1301

Friedman P, Ghosh A (1996) Microstructural evolution and superplastic deformation behavior of fine grain 5083Al. Metall Mater Trans A 27(12):3827–3839

Nazzal MA, Khraisheh MK, Darras BM (2004) Finite element modeling and optimization of superplastic forming using variable strain rate approach. J Mater Eng Perform 13(6):691–699

Jarrar FS, Abu-Farha F, Hector L, Khraisheh M (2009) Simulation of high-temperature AA5083 bulge forming with a hardening/softening material model. J Mater Eng Perform 18(7):863

Albakri M, Khraisheh M (2011) Optimization of superplastic forming; effects of interfacial friction on variable strain rate forming paths. In: Seliger G et al (eds) Advances in sustainable manufacturing: proceedings of the 8th global conference on sustainable manufacturing. Springer Berlin, Berlin, pp 121–126

Jarrar F, Jafar R, Tulupova O, Enikeev F, Al-Huniti N (2016) Constitutive Modeling for the Simulation of the Superplastic Forming of AA5083. In: Materials Science Forum. Trans Tech Publ, pp. 512–517

Abu-Farha F, Khraisheh MK (2007) Mechanical characteristics of superplastic deformation of AZ31 magnesium alloy. J Mater Eng Perform 16(2):192–199

Acknowledgments

The tensile tests were carried out at the National Research Council Canada Aluminum Technology Center NRC-ATC. The authors would like to thank Dr. Ehab Samuel from NRC-ATC for his invaluable support. Financial support from the Natural Sciences and Engineering Research Council of Canada (NSERC), Innovation en Énergie Électrique (INOVÉE), and Aluminium Association of Canada (AAC) are acknowledged by all the authors.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Majidi, O., Jahazi, M. & Bombardier, N. A viscoplastic model based on a variable strain rate sensitivity index for superplastic sheet metals. Int J Mater Form 12, 693–702 (2019). https://doi.org/10.1007/s12289-018-1443-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12289-018-1443-2