Abstract

The objective of this work is to study the influence of nanoclay addition in PP sheet during infrared (IR) heating assisted thermoforming process. The effect of nanoclay on viscoelastic, friction and dimensional characteristics during sheet forming was examined. The result indicated that the nanoclay addition improves the sagging (sagging depth and sagging disintegration) and plugging (plug depth and friction) properties during sheet forming. The plugging properties of nanoclay filled PP sheet resulted in the improved physical characteristics (minimal change in thickness (Δt) and % dimensional elongation) when compared with unfilled PP sheet. The nanoclay filled formed PP sheet resulted in improved tensile and dynamic mechanical properties when compared with unfilled formed PP sheet.

Similar content being viewed by others

References

Ashter SA (2014) The Thermoforming Process. In: Ebnesajjad S (ed) Thermoforming of Single and Multilayer Laminates - Plastic Films Technologies, Testing and Applications. William Andrew imprint of Elsevier, Oxford, pp 13–38

O’Connor CPJ, Martin PJ, Menary G (2012) Viscoelastic material models of polypropylene for thermoforming applications. Int J Mater Form 3:599–602

Choo HL, Martin PJ, Harkin-Jones EMA (2008) Measurement of heat transfer for thermoforming simulations. Int J Mater Form 1:1027–1030

Karamanou M, Warby MK, Whiteman JR (2006) Computational modelling of thermoforming processes in the case of finite viscoelastic materials. Comp Meth App Mech Eng 195:5220–5238

Ahzi, Puissant S (2007) Thermoforming process of amorphous polymeric sheets: modeling and finite element simulations. J App Poly Sci 106:1718–1724

Sala G, Di Landro L, Cassago D (2002) A numerical and experimental approach to optimize sheet stamping technologies: polymers thermoforming. Mater Dsg 23:21–39

Billon N (2008) Constitutive model for HIPS in the thermoforming range. Int J Mater Form 1:679–682

Yamaguchi M, Suzuki K-I (2002) Enhanced strain hardening in elongational viscosity for HDPE/crosslinked HDPE blend. II Processability of thermoforming. J App Polym Sci 86:79–83

Ashton JH, Mertz JAM, Harper JL, Slepian MJ, Mills JL, McGrath DV, Vande Geest JP (2011) Polymeric endoaortic paving: mechanical, thermforming, and degradation properties of polycaprolactone/polyurethane blends for cardiovascular applications. Acta Biomater 7:287–294

Stephenson MJ, Ryan ME (1997) Experimental study of the thermoforming of a blend of styrene-butadiene copolymer with polystyrene. Polym Eng Sci 37:450–459

Bhattacharyya D, Bowis M, Jayaraman K (2003) Thermoforming woodfibre-polypropylene composite sheets. Comp Sci Tech 63:353–365

Hosseini H, Vasilivich BB, Mehrabani-Zeinabad A (2006) Rheological modeling of plug-assist thermoforming. J App Polym Sci 101:4148–4152

Lee JK, Virkler TL, Scott CE (2001) Influence of initial sheet temperature on ABS thermoforming. Polym Eng Sci 41:1830–1844

Walczyk DF, Yoo S (2009) Design and fabrication of a laminated thermoforming tool with enhanced features. J Manf Process 11:8–18

Jagger RG, Okdeh A (1995) Thermoforming of polymethyl methacrylate. J Pros Dent 74:542–545

Hossini H, Berdyshev BV, Mehrabani-Zeinabad A (2006) A solution for warpage in polymeric products by plug-assisted thermoforming. Euro Poly J 42:1836–1843

Torres FG, Bush SF (2000) Sheet extrusion and thermoforming of discrete long glass fibre reinforced polypropylene. Comp Part A: App Sci Man 31:1289–1294

Molnár P, Ogale A, Lahr R, Mitschang P (2007) Influence of drapability by using stitching technology to reduce fabric deformation and shear during thermoforming. Comp Sci Tech 67:3386–3393

Warby MK, Whiteman JR, Jian W-G, Warwick P, Wright T (2003) Finite element simulation of thermoforming processes for polymer sheets. Math Comp Siml 61:209–218

O’Connor CPJ, Menary G, Martin PJ, McConville E (2008) Finite element analysis of the thermoforming of polypropylene. Int J Mater Form 1:779–782

O’Connor CPJ, Martin PJ, Sweeney J, Menary G, Caton-Rose P, Spencer PE (2013) Simulation of the plug-assisted thermoforming of polypropylene using a large strain thermally coupled constitutive model. J Mater Proc Tech 213:1588–1600

Ming-Meng P, Meng-Yan P, Wen-Shyang C, Zainal A, Mohd I (2014) Carbon footprint calculation for thermoformed starch-filled polypropylene biobased materials. J Clean Prod 64:602–608

Kiliaris P, Papaspyrides CD (2010) Polymer/layered silicate (clay) nanocomposites: an overview of flame retardancy. Prog Polym Sci 35:902–958

Xidas PI, Triantafyllidis KS (2010) Effect of the type of alkylammonium ion clay modifier on the structure and thermal/mechanical properties of glassy and rubbery epoxy-clay nanocomposites. E Polym J 46:404–417

Meneghetti P, Qutubuddin S (2006) Synthesis, thermal properties and applications of polymer-clay nanocomposites. Therm Acta 442:74–77

Kim TK, Kim BK, Kim YS, Ya L, Cho SY, Lee YB, Cho JH, Kim HMJ (2008) Properties of reactive hot melt adhesives modified by polyurethane containing PEG segment intercalated in sodium montmorillonite. Int J Mat Form 1:615–618

Abu-Zurayk R, Harkin-Jones L, McNally T, Menary G, Martin P, Armstrong C, McAfee M (2009) Biaxial deformation behavior and mechanical properties of a polypropylene/clay nanocomposite. Comp Sci Tech 69:1644–1652

Abu-Zurayk R, Harkin-Jones E, McNally T, Menary G, Martin P, Armstrong C, McAfee M (2010) Structure–property relationships in biaxially deformed polypropylene nanocomposites. Comp Sci Tech 70:1353–1359

Sun T, Chen F, Dong X, Zhou Y, Wang D, Han CC (2009) Shear-induced orientation in the crystallization of an isotactic polypropylene nanocomposite. Polym 50:2465–2471

Tabatabaei SH, Abdellah A (2011) Structure-oreintation-properties relationships for polypropylene nanoclay composite films. J Plas Film Sheet 27:87–115

Kashyap MJ, Ghosh AK (2013) Processing, rheology and characterization of polypropylene nanocomposites and their blown films. J Plas Film Sheet 29:228–248

Mirzadeh A, Kokabi M (2007) The effect of composition and draw-down ratio on morphology and oxygen permeability of polypropylene nanocomposite blown films. E Polym J 43:3757–3765

Feng-Hua S, Yan J-H, Huang H-X (2011) Structure and melt rheology of long-chain branching polypropylene/clay nanocomposites. J App Poly Sci 119:1230–1238

Hambir S, Bulakh N, Jog JP (2002) Polypropoylene/clay nanocomposites: effect of compatibilizer on thermal, crystallization and dynamic mechanical behaviour. Polym Eng Sci 42:1800–1807

Hong CK, Kim M-J, Oh SH, Lee Y-S, Nah C (2008) Effects of polypropylene-g-(maleic anhydride/styrene) compatibiizer on mechanical and rheological properties of polypropylene/clay nanocomposites. J Ind Eng Chem 14:236–242

Drozdov AD, Høg Lejre A-L, Christiansen J dC (2009) Viscoelasticity, viscoplasticity and creep failure of polypropylene/clay nanocomposites. Comp Sci Tech 69:2596–2603

Morales RA, Candal MV, Santana OO, Gordillo A, Salazar R (2014) Effect of the thermoforming process variables on the sheet friction coefficient. Mater Dsgn 53:1097–1103

Throne J (2011) Thermoforming. In: Kutz M (ed) Applied Plastics Engineering Handbook: Processing and Materials. William Andre imprint of Elsevier, Oxford, pp 333–358

Finney Charles R, Gnanamoorthy PR (2010) Rolling contact fatigue behavior of polyamide clay reinforced nanocomposite - effect of load and speed. Wear 269:565–571

Bhuyan S, Sundararajan S, Lu Y, Larock RC (2010) A study of the physical and tribological properties of biobased polymer–clay. Wear 268:797–802

Jawahar P, Gnanamoorthy R, Balasubramanian M (2006) Tribological behavior of clay-thermoset polyester nanocomposites. Wear 261:835–840

Dayma N, Satapathy BK, Patnaik A (2013) Structural correlations to sliding wear performance of PA-6/PP-g-MA/nanoclay ternary nanocomposites. Wear 271:827–836

Morales RA, Candal MV (2006) Diseño y fabricación de un molde de termoformado utilizando herramientas CAD/CAE. Revista de la Facultad de Ingeniería de la UCV 21:83–100

Chen S-C, Huang S-T, Lin M-C, Chein R-D (2008) Study on the thermoforming of PC films used for in-mold decoration. Int Comm Heat Mass Trns 35:967–973

Patil N, Invigorito C, Gahleitner M, Rastogi S (2013) Influence of a particulate nucleating agent on the quiescent and flow-induced crystallization of isotactic polypropylene. Polym 54:5883–5891

Mollova A, Androsch R, Mileva D, Gahleitner M, Funari SS (2013) Crystallization of isotactic polypropylene containing beta-phase nucleating agent at rapid cooling. E Polym J 49:1057–1065

Fermino DM, Parra DF, Oliani WL, Lugao AB, Diaz FRV (2013) HMSPP nanocomposite and Brazilian bentonite properties after gamma radiation exposure. Rad Phy Chem 84:176–184

Cauvin L, Kondo D, Brieu M, Bhatnagar N (2010) Mechanical properties of polypropylene layered silicate nanocomposites: characterization and micro–macro modelling. Poly Test 29:245–250

Lai SM, Chen WC, Zhu XS (2009) Melt mixed compatibilized polypropylene/clay nanocomposites: part 1 – the effect of compatibilizers on optical transmittance and mechanical properties. Comp: Part A App Sci Man 40:754–765

Mohan TP, Ramesh Kumar M, Velmurugan R (2006) Mechanical and barrier properties of epoxy polymer filled with nanolayered silicate clay particles. J Mater Sci 41:2929–2937

Bureau MN, Ton-That M-T, Perrin-Sarazin F (2006) Essential work of fracture and failure mechanisms of polypropylene-clay nanocomposites. Eng Frac Mech 73:2360–2374

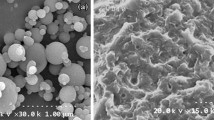

Mohan TP, Kanny K (2010) Using image analysis for structural and mechanical characterization of nanoclay reinforced polypropylene composites. Engg 2:802–812

Lu HB, Nutt S (2003) Restricted relaxation in polymer nanocomposites near the glass transition. Macromol 36:4010

Acknowledgments

The authors acknowledge the support by the National Research Foundation (NRF) of South Africa [Grant No: 71599, Postdoctoral Fellowship]; and Postgraduate Research Assistance from Durban University of Technology, South Africa.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mohan, T.P., Kanny, K. Infrared heating assisted thermoforming of polypropylene clay nanocomposites. Int J Mater Form 8, 401–413 (2015). https://doi.org/10.1007/s12289-014-1183-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12289-014-1183-x