Abstract

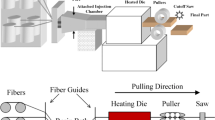

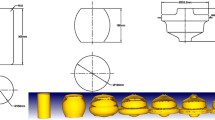

This paper in particular deals with the integrated modeling of a pultruded NACA0018 blade profile being a part of EU funded DeepWind project. The manufacturing aspects of the pultrusion process are associated with the preliminary subsequent service loading scenario. A 3D thermo-chemical analysis of the pultrusion process is sequentially coupled with a 2D quasi-static mechanical analysis in which the process induced residual stresses and distortions are predicted using the generalized plane stain elements in a commercial finite element software ABAQUS. The temperature- and cure-dependent resin modulus is implemented by employing the cure hardening instantaneous linear elastic (CHILE) model in the process simulation. The subsequent bent-in place simulation of the pultruded blade profile is performed taking the residual stresses into account. The integrated numerical simulation tool predicts the internal stress levels of the profile at the end of the bending analysis. It is found that the process induced residual stresses have the potential to influence the internal stresses arise in the structural analysis.

Similar content being viewed by others

References

Wisnom MR, Gigliotti M, Ersoy N, Campbell M, Potter KD (2006) Mechanisms generating residual stresses and distortion during manufacture of polymermatrix composite structures. Compos Part A 37:522–529

Ersoy N, Garstka T, Potter K, Wisnom M R, Porter D, Stringer G (2010) Modelling of the spring-in phenomenon in curved parts made of a thermosetting composite. Compos Part A 41:410–418

Nielsen MW, Schmidt JW, Hattel JH, Andersen TL, Markussen CM (2013) In situ measurement using FBGs of process-induced strains during curing of thick glass/epoxy laminate plate: experimental results and numerical modelling. Wind Energy 16(8):1241–1257

Sutherland HJ, Berg DE, Ashwill TD (January 2012) A Retrospective of VAWT Technology. Sandia Report, SAND2012-0304

Paulsen US, Vita L, Madsen HA, Hattel JH, Ritchie E, Leban KM et al. (2012) 1st DeepWind 5 MW Baseline design. Energy Procedia 24:27–35

Paulsen US, Madsen HA, Hattel JH, Baran I, Nielsen PH (2013) Design optimization of a 5 MW floating offshore vertical-axis wind turbine. Energy Procedia 35:22–32

Gorthala R, Roux JA, Vaughan JG (1994) Resin flow, cure and heat transfer analysis for pultrusion process. J Compos Mater 28:486–506

Ding Z, Li S, Yang H, Lee L J, Engelen H, Puckett PM (2000) Numerical and experimental analysis of resin flow and cure in resin injection pultrusion (RIP). Poly Compos 21(5):762–778

Palikhel DR, Roux JA, Jeswani AL (2013) Die-attached versus die-detached resin injection chamber for pultrusion. Appl Compos Mater 20(1):55–72

Batch GL, Mocosko CW (1993) Heat transfer, cure in pultrusion: model and experimental verification. AIChE J 39:1228–1241

Joshi SC, Lam YC (2001) Three-dimensionalfinite-element/nodal-control-volume simulation of the pultrusion process with temperature-dependent material properties including resin shrinkage. Compos Sci Technol 61:1539–1547

Liu XL, Crouch IG, Lam YC (2000) Simulation of heat transfer and cure in pultrusion with a general-purpose finite element package. Compos Sci Technol 60:857–864

Suratno BR, Ye L, Mai YW (1998) Simulation of temperature and curing profiles in pultruded composite rods. Compos Sci Technol 58:191–197

Chachad YR, Roux JA, Vaughan JG, Arafat E (1995) Three-dimensional characterization of pultruded fiberglass-epoxy composite materials. J Reinf Plast Comp 14:495–512

Carlone P, Palazzo GS, Pasquino R (2006) Pultrusion manufacturing process development by computational modelling and methods. Math Comput Model 44:701–709

Li S, Xu L, Ding Z, Lee LJ, Engelen H (2003) Experimental and theoretical analysis of pulling force in pultrusion and resin injection pultrusion (RIP) - Part II: modeling and simulation. J Compos Mater 37:195–216

Moschiar S M, Reboredo M M, Larrondo H, Vazquez A (1996) Pultrusion of epoxy matrix composites: pulling force model and thermal stress analysis. Poly Compos 17(6):850–858

Carlone P, Baran I, Hattel JH, Palazzo GS (2013) Computational Approaches for Modeling the Multiphysics in Pultrusion Process. Advances in Mechanical Engineering, vol. 2013, Article ID 301875 14 pages. doi:10.1155/2013/301875

Baran I, Tutum CC, Hattel JH (2013) The effect of thermal contact resistance on the thermosetting pultrusion process. Compos Part B: Eng 45:995–1000

Baran I, Tutum CC, Hattel JH (2013) Thermo-chemical modelling strategies for the pultrusion process. App Compos Mat 20(6):1247–1263

Baran I, Tutum CC, Hattel JH (2013) Reliability estimation of the pultrusion process using the first-order reliability method (FORM). App Compos Mat 20:639–653

Baran I, Tutum CC, Hattel JH (2013) Optimization of the thermosetting pultrusion process by using hybrid and mixed integer genetic algorithms. App Compos Mat 20:449–463

Tutum CC, Baran I, Hattel JH (2013) Utilizing multiple objectives for the optimization of the pultrusion process. Key Eng Mat 554-557:2165–2174

Baran I, Tutum CC, Nielsen MW, Hattel JH, Process induced residual stresses and distortions in pultrusion (2013). Compos Part B Eng 51:148–161

Baran I, Tutum CC, Hattel JH (2013) The internal stress evaluation of the pultruded blades for a Darrieus wind turbine. Key Eng Mat 554-557:2127–2137

ABAQUS (2011) 6.11 Reference Guide. Dassault Systems

Johnston A (1997) An Integrated Model of the Development of Process-Induced Deformation in Autoclave Processing of Composites Structures, Ph.D. thesis. The University of British Columbia, Vancouver

Khoun L, Centea T, Hubert P (2010) Characterization methodology of thermoset resins for the processing of composite materials -case study: CYCOM 890RTM epoxy resin. J Compos Mater 44:1397415

Bogetti TA, Gillespie JW (1992) Process-induced stress and deformation in thick-section thermoset composite laminates. J Compos Mater 26(5):626–660

Star TF (2000) Pultrusion for engineers. CRC Press

Huang ZM (2001) Simulation of the mechanical properties of fibrous composites by the bridging micromechanics model. Compos Part A 32: 143172

Acknowledgments

This work is a part of DeepWind project which has been granted by the European Commission (EC) under the FP7 program platform Future Emerging Technology.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Baran, I., Hattel, J.H., Tutum, C.C. et al. Pultrusion of a vertical axis wind turbine blade part-II: combining the manufacturing process simulation with a subsequent loading scenario. Int J Mater Form 8, 367–378 (2015). https://doi.org/10.1007/s12289-014-1178-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12289-014-1178-7